$42

Komatsu SAA4D94LE-3 Engine Shop Manual VENBM07100 – PDF DOWNLOAD

Komatsu SAA4D94LE-3 Engine Shop Manual VENBM07100 – PDF DOWNLOAD

FILE DETAILS:

Komatsu SAA4D94LE-3 Engine Shop Manual VENBM07100 – PDF DOWNLOAD

Language : English

Pages : 1206

Downloadable : Yes

File Type : PDF

Size: 113 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu SAA4D94LE-3 Engine Shop Manual VENBM07100 – PDF DOWNLOAD

- The Komatsu SAA4D94LE-3 Engine Shop Manual VENBM07100 is a comprehensive guide that provides detailed information on the maintenance, repair, and overhaul of the SAA4D94LE-3 engine. This engine is used in a variety of Komatsu equipment, including excavators, bulldozers, and other construction machinery.

- The manual is organized into several sections, each covering a different aspect of the engine. The first section provides an overview of the engine, including its specifications and performance data. This section also includes a table of contents, a list of illustrations, and a list of symbols and abbreviations used throughout the manual.

- The second section of the manual covers engine inspection and measurement procedures. This section provides step-by-step instructions for checking and measuring various components of the engine, including the cylinder block, crankshaft, and connecting rods. The manual includes detailed illustrations to help the reader understand the procedures.

- The third section covers engine disassembly and assembly procedures. This section provides instructions for removing and installing various components of the engine, including the cylinder head, pistons, and crankshaft. The manual also includes torque specifications for each component.

- The fourth section covers engine testing and adjusting procedures. This section provides instructions for testing and adjusting various components of the engine, including the fuel injection system, the turbocharger, and the valve clearance. The manual includes detailed illustrations to help the reader understand the procedures.

- The fifth section covers engine maintenance procedures, including routine maintenance and inspections. This section provides instructions for maintaining the engine to ensure its continued performance and longevity.

- The sixth section covers engine troubleshooting and diagnosis procedures. This section provides instructions for diagnosing and troubleshooting various engine problems, including starting problems, low power output, and excessive smoke. The manual includes a troubleshooting chart and detailed illustrations to help the reader diagnose and fix the problem.

- Overall, the Komatsu SAA4D94LE-3 Engine Shop Manual VENBM07100 is an essential tool for anyone working on or maintaining this engine. The manual is available in print or digital formats, making it a convenient and accessible resource for mechanics and technicians. It is designed to be user-friendly and easy to understand, with clear instructions and detailed illustrations. With this manual, you can ensure that your Komatsu equipment is operating at its best and avoid costly repairs and downtime.

TABLE OF CONTENTS:

Komatsu SAA4D94LE-3 Engine Shop Manual VENBM07100 – PDF DOWNLOAD

VENBM07100 SHOP MANUAL ENGINE…………………………………………………………………………………………………………………… 1

Table of Contents……………………………………………………………………………………………………………………………… 3

Introduction………………………………………………………………………………………………………………………………….. 5

Safety……………………………………………………………………………………………………………………………………….. 7

Safety Statements………………………………………………………………………………………………………………………….. 9

Safety Precautions…………………………………………………………………………………………………………………………. 10

General Service Information…………………………………………………………………………………………………………………….. 23

Component Identification……………………………………………………………………………………………………………………. 25

Location of Labels…………………………………………………………………………………………………………………………. 26

Location of labels/nameplates on direct injection model engines……………………………………………………………………………… 26

Engine Nameplate (Typical)………………………………………………………………………………………………………………. 26

Emission Control Regulations………………………………………………………………………………………………………………… 26

EPA/ARB Regulations – USA Only…………………………………………………………………………………………………………… 26

Emission Control Labels…………………………………………………………………………………………………………………….. 26

EPA/ARB labels (Typical)………………………………………………………………………………………………………………… 26

EPA……………………………………………………………………………………………………………………………….. 26

EPA and ARB………………………………………………………………………………………………………………………… 26

The 97/68/EC Directive Certified Labels…………………………………………………………………………………………………… 27

ENGINE FAMILY……………………………………………………………………………………………………………………………… 27

Function of Major Engine Components………………………………………………………………………………………………………….. 28

Function of Cooling System Components………………………………………………………………………………………………………… 29

Main Electronic Control Components and Features……………………………………………………………………………………………….. 30

Installation Position of Sensors…………………………………………………………………………………………………………….. 32

Crank rotation sensor…………………………………………………………………………………………………………………… 33

Cam speed sensor……………………………………………………………………………………………………………………….. 33

New air temperature sensor………………………………………………………………………………………………………………. 34

EGR gas temperature sensor………………………………………………………………………………………………………………. 34

Intake air temperature sensor……………………………………………………………………………………………………………. 34

Fuel temperature sensor (equipped on supply pump)………………………………………………………………………………………….. 35

Engine coolant temperature sensor………………………………………………………………………………………………………… 35

Exhaust temperature sensor………………………………………………………………………………………………………………. 36

Diesel Particulate Filter (DPF) inlet/inside temperature sensor……………………………………………………………………………… 36

SCR temperature sensor………………………………………………………………………………………………………………….. 36

Rail pressure sensor……………………………………………………………………………………………………………………. 36

EGR pressure sensor…………………………………………………………………………………………………………………….. 37

Diesel Particulate Filter (DPF) exhaust differential pressure sensor…………………………………………………………………………. 38

NOx sensor…………………………………………………………………………………………………………………………….. 39

Intake air throttles……………………………………………………………………………………………………………………. 41

Acceleration sensor (YANMAR standard)…………………………………………………………………………………………………….. 42

Diesel Fuel……………………………………………………………………………………………………………………………….. 43

Diesel Fuel Specifications………………………………………………………………………………………………………………. 43

Additional technical fuel requirements………………………………………………………………………………………………… 43

Precautions and concerns regarding the use of diesel fuel……………………………………………………………………………….. 43

Biodiesel fuels…………………………………………………………………………………………………………………….. 43

Kit component for B20 (4TNV94FHT)…………………………………………………………………………………………………….. 46

Filling The Fuel Tank…………………………………………………………………………………………………………………… 47

Priming the Fuel System…………………………………………………………………………………………………………………. 48

Engine Oil………………………………………………………………………………………………………………………………… 49

Engine Oil Specifications……………………………………………………………………………………………………………….. 49

Service categories………………………………………………………………………………………………………………….. 49

Definitions………………………………………………………………………………………………………………………… 49

Additional technical engine oil requirements:………………………………………………………………………………………….. 49

Engine Oil Viscosity……………………………………………………………………………………………………………………. 49

Checking Engine Oil…………………………………………………………………………………………………………………….. 50

Adding Engine Oil………………………………………………………………………………………………………………………. 50

Engine Oil Capacity (Typical)……………………………………………………………………………………………………………. 50

Engine Coolant…………………………………………………………………………………………………………………………….. 51

Engine Coolant Specifications……………………………………………………………………………………………………………. 51

Alternative engine coolant…………………………………………………………………………………………………………… 51

Filling Radiator with Engine Coolant……………………………………………………………………………………………………… 52

Daily Check of the Cooling System………………………………………………………………………………………………………… 52

Engine Coolant Capacity (Typical)………………………………………………………………………………………………………… 52

Aqueous urea………………………………………………………………………………………………………………………………. 53

Aqueous Urea Solution Standard…………………………………………………………………………………………………………… 53

Property and Characteristics of Aqueous Urea………………………………………………………………………………………………. 53

Prohibition……………………………………………………………………………………………………………………………. 53

Precaution…………………………………………………………………………………………………………………………….. 54

Storing the Aqueous Urea………………………………………………………………………………………………………………… 54

Refilling Aqueous Urea………………………………………………………………………………………………………………….. 54

Specifications…………………………………………………………………………………………………………………………….. 55

Description of Model Number……………………………………………………………………………………………………………… 55

Engine General Specifications……………………………………………………………………………………………………………. 55

Principal Engine Specifications……………………………………………………………………………………………………………… 56

4TNV94FHT (EPA Final Tier 4)…………………………………………………………………………………………………………….. 56

Engine Service Standards……………………………………………………………………………………………………………………. 57

Tightening Torques for Standard Bolts and Nuts………………………………………………………………………………………………… 58

Abbreviations and Symbols…………………………………………………………………………………………………………………… 60

Abbreviations………………………………………………………………………………………………………………………….. 60

Symbols……………………………………………………………………………………………………………………………….. 60

Unit Conversions…………………………………………………………………………………………………………………………… 61

Unit prefixes………………………………………………………………………………………………………………………….. 61

Units of length………………………………………………………………………………………………………………………… 61

Units of volume………………………………………………………………………………………………………………………… 61

Units of mass………………………………………………………………………………………………………………………….. 61

Units of force…………………………………………………………………………………………………………………………. 61

Units of torque………………………………………………………………………………………………………………………… 61

Units of pressure………………………………………………………………………………………………………………………. 61

Units of power…………………………………………………………………………………………………………………………. 61

Units of temperature……………………………………………………………………………………………………………………. 61

Periodic Maintenance…………………………………………………………………………………………………………………………… 63

Before You Begin Servicing………………………………………………………………………………………………………………….. 65

Introduction………………………………………………………………………………………………………………………………. 66

The Importance of Periodic Maintenance……………………………………………………………………………………………………. 66

Performing Periodic Maintenance………………………………………………………………………………………………………….. 66

YANMAR Replacement Parts………………………………………………………………………………………………………………… 66

Required EPA/ARB Maintenance – USA Only…………………………………………………………………………………………………… 66

EPA/ARB Installation Requirements – USA Only………………………………………………………………………………………………. 66

Periodic Maintenance Schedule……………………………………………………………………………………………………………….. 67

Periodic Maintenance Procedures……………………………………………………………………………………………………………… 69

After Initial 50 Hours of Operation………………………………………………………………………………………………………. 69

Check and adjust cooling fan V-belt…………………………………………………………………………………………………… 69

Every 50 Hours of Operation……………………………………………………………………………………………………………… 70

Drain water separator……………………………………………………………………………………………………………….. 70

Check battery………………………………………………………………………………………………………………………. 72

Every 250 Hours of Operation…………………………………………………………………………………………………………….. 73

Drain fuel tank…………………………………………………………………………………………………………………….. 73

Check and clean radiator fins………………………………………………………………………………………………………… 74

Check and adjust cooling fan V-belt…………………………………………………………………………………………………… 74

Clean air cleaner element……………………………………………………………………………………………………………. 74

Every 500 Hours of Operation…………………………………………………………………………………………………………….. 75

Replace air cleaner element………………………………………………………………………………………………………….. 75

Replace fuel filter…………………………………………………………………………………………………………………. 76

Replace water separator element………………………………………………………………………………………………………. 77

Replace engine oil and engine oil filter………………………………………………………………………………………………. 78

Every 1000 Hours of Operation……………………………………………………………………………………………………………. 80

Check and adjust intake/exhaust valve clearance………………………………………………………………………………………… 80

Every 1500 Hours of Operation……………………………………………………………………………………………………………. 81

Inspect crankcase breather system…………………………………………………………………………………………………….. 81

Every 2000 Hours of Operation……………………………………………………………………………………………………………. 82

Check and replace fuel hoses, engine coolant hoses and engine lubricating oil hoses………………………………………………………… 82

Lap the intake and exhaust valves…………………………………………………………………………………………………….. 82

Replace engine coolant………………………………………………………………………………………………………………. 82

Every 3000 Hours of Operation……………………………………………………………………………………………………………. 84

Inspect ECU and related sensors and actuators………………………………………………………………………………………….. 84

Inspect turbocharger (blower cleaning if necessary)…………………………………………………………………………………….. 84

Cleaning the EGR cooler (water side/exhaust passage)……………………………………………………………………………………. 84

Inspect DPF DOC…………………………………………………………………………………………………………………….. 84

Inspect and test intake throttle valve………………………………………………………………………………………………… 85

Inspect SCR catalyst and related sensors and actuators………………………………………………………………………………….. 85

Check and replace SM (Supply Module) main filter……………………………………………………………………………………….. 85

Check and clean injector…………………………………………………………………………………………………………….. 85

Every 6000 Hours of Operation……………………………………………………………………………………………………………. 85

Check and clean of DPF soot filter……………………………………………………………………………………………………. 85

Engine……………………………………………………………………………………………………………………………………….. 87

Before You Begin Servicing………………………………………………………………………………………………………………….. 89

Introduction………………………………………………………………………………………………………………………………. 90

Cylinder Head Specifications………………………………………………………………………………………………………………… 90

Adjustment Specifications……………………………………………………………………………………………………………….. 90

Cylinder Head………………………………………………………………………………………………………………………….. 90

Intake/Exhaust Valve and Guide…………………………………………………………………………………………………………… 90

Push Rod………………………………………………………………………………………………………………………………. 91

Rocker Arm and Shaft……………………………………………………………………………………………………………………. 91

Valve Spring…………………………………………………………………………………………………………………………… 91

Valve Bridge…………………………………………………………………………………………………………………………… 91

Camshaft and Timing Gear Train Specifications…………………………………………………………………………………………………. 92

Camshaft………………………………………………………………………………………………………………………………. 92

Idler Gear Shaft and Bushing…………………………………………………………………………………………………………….. 92

Timing Gear Backlash……………………………………………………………………………………………………………………. 92

Crankshaft and Piston Specifications…………………………………………………………………………………………………………. 93

Crankshaft…………………………………………………………………………………………………………………………….. 93

Thrust Bearing…………………………………………………………………………………………………………………………. 93

Piston………………………………………………………………………………………………………………………………… 93

Piston Ring……………………………………………………………………………………………………………………………. 94

Connecting Rod…………………………………………………………………………………………………………………………. 94

Connecting rod small end…………………………………………………………………………………………………………….. 94

Connecting rod big end………………………………………………………………………………………………………………. 94

Tappet………………………………………………………………………………………………………………………………… 95

Cylinder Block Specifications……………………………………………………………………………………………………………….. 95

Cylinder Block…………………………………………………………………………………………………………………………. 95

Special Torque Chart……………………………………………………………………………………………………………………….. 96

Torque for Bolts and Nuts……………………………………………………………………………………………………………….. 96

Special Service Tools………………………………………………………………………………………………………………………. 97

Measuring Instruments………………………………………………………………………………………………………………………. 100

Cylinder Head……………………………………………………………………………………………………………………………… 102

Cylinder Head Components………………………………………………………………………………………………………………… 102

Disassembly of Cylinder Head…………………………………………………………………………………………………………….. 103

Removal of rocker arm assembly……………………………………………………………………………………………………….. 111

Disassembly of rocker arm assembly……………………………………………………………………………………………………. 111

Removal of cylinder head…………………………………………………………………………………………………………….. 112

Removal of intake and exhaust valves………………………………………………………………………………………………….. 112

Removal of valve guides……………………………………………………………………………………………………………… 113

Cleaning of Cylinder Head Components……………………………………………………………………………………………………… 113

Inspection of Cylinder Head Components……………………………………………………………………………………………………. 113

Inspection of push rods……………………………………………………………………………………………………………… 113

Inspection of rocker arm assembly…………………………………………………………………………………………………….. 114

Inspection of valve guides…………………………………………………………………………………………………………… 114

Inspection of cylinder head………………………………………………………………………………………………………….. 114

Inspection of intake and exhaust valves……………………………………………………………………………………………….. 115

Inspection of valve springs………………………………………………………………………………………………………….. 117

Inspection of valve bridges………………………………………………………………………………………………………….. 117

Reassembly of Cylinder Head……………………………………………………………………………………………………………… 117

Reassembly of valve guides…………………………………………………………………………………………………………… 118

Reassembly of intake and exhaust valves……………………………………………………………………………………………….. 118

Reassembly of cylinder head………………………………………………………………………………………………………….. 119

Reassembly of rocker arm assembly…………………………………………………………………………………………………….. 120

Reassembly of surrounding parts of cylinder heads………………………………………………………………………………………. 121

Measuring and Adjusting Valve Clearance………………………………………………………………………………………………………. 124

4-cylinder engines……………………………………………………………………………………………………………………… 124

4-Valve Cylinder Heads………………………………………………………………………………………………………………….. 125

Crankshaft and Camshaft Components…………………………………………………………………………………………………………… 127

Disassembly of Engine…………………………………………………………………………………………………………………… 128

Disassembly of Camshaft and Timing Components……………………………………………………………………………………………… 129

Removal of timing gear case cover…………………………………………………………………………………………………….. 129

Checking timing gear backlash………………………………………………………………………………………………………… 129

Measuring idler gear-to-crankshaft gear backlash……………………………………………………………………………………….. 129

Measuring idler gear-to-camshaft gear backlash…………………………………………………………………………………………. 130

Removal of timing gears……………………………………………………………………………………………………………… 130

Removal of oil pan………………………………………………………………………………………………………………….. 130

Removal of camshaft…………………………………………………………………………………………………………………. 131

Removal of gear case………………………………………………………………………………………………………………… 132

Disassembly of Crankshaft and Piston Components……………………………………………………………………………………………. 132

Removal of pistons………………………………………………………………………………………………………………….. 132

Removal of crankshaft……………………………………………………………………………………………………………….. 134

Inspection of Crankshaft and Camshaft Components…………………………………………………………………………………………… 135

Replacement of crankshaft oil seals…………………………………………………………………………………………………… 136

Measure crankshaft bearing oil clearance………………………………………………………………………………………………. 136

Inspection of cylinder block…………………………………………………………………………………………………………. 136

Inspection of pistons, piston rings and wrist pin………………………………………………………………………………………. 136

Inspection of connecting rod…………………………………………………………………………………………………………. 138

Inspection of tappets……………………………………………………………………………………………………………….. 139

Inspection of crankshaft…………………………………………………………………………………………………………….. 139

Inspection of camshaft………………………………………………………………………………………………………………. 140

Inspection of camshaft bushing and bores………………………………………………………………………………………………. 141

Inspection of idler gear and shaft……………………………………………………………………………………………………. 141

Honing and Boring………………………………………………………………………………………………………………………. 141

Reassembly of Crankshaft and Piston Components…………………………………………………………………………………………….. 142

Reassembly of pistons……………………………………………………………………………………………………………….. 143

Installation of crankshaft…………………………………………………………………………………………………………… 145

Installation of pistons……………………………………………………………………………………………………………… 146

Reassembly of Camshaft and Timing Components………………………………………………………………………………………………. 148

Installation of gear case……………………………………………………………………………………………………………. 148

Installation of camshaft…………………………………………………………………………………………………………….. 148

Installation of timing gears…………………………………………………………………………………………………………. 149

Installation of gear case cover………………………………………………………………………………………………………. 149

Installation of oil pan……………………………………………………………………………………………………………… 150

Final Reassembly of Engine………………………………………………………………………………………………………………. 150

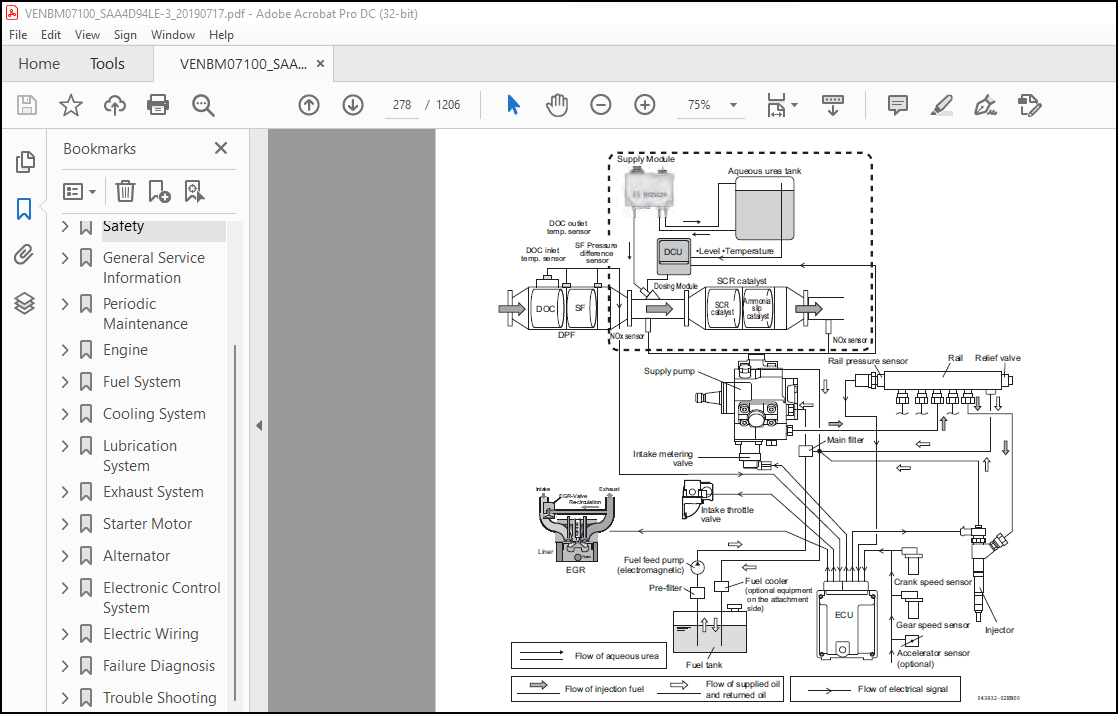

Fuel System…………………………………………………………………………………………………………………………………… 151

Before You Begin Servicing………………………………………………………………………………………………………………….. 153

System Structure…………………………………………………………………………………………………………………………… 154

Supply pump……………………………………………………………………………………………………………………………. 154

Rail………………………………………………………………………………………………………………………………….. 154

Injector………………………………………………………………………………………………………………………………. 154

Crank speed sensor and cam speed sensor…………………………………………………………………………………………………… 155

ECU…………………………………………………………………………………………………………………………………… 155

Fuel System Specifications………………………………………………………………………………………………………………….. 156

Torque Chart for Major Bolts and Nuts…………………………………………………………………………………………………….. 156

General Torque Chart (Lubrication Oil not Applied)…………………………………………………………………………………………. 157

Fuel System Diagram………………………………………………………………………………………………………………………… 158

Fuel System Components……………………………………………………………………………………………………………………… 159

Common Rail……………………………………………………………………………………………………………………………. 160

Pressure limiter replacement procedures……………………………………………………………………………………………….. 160

Pressure sensor replacement procedures………………………………………………………………………………………………… 162

Common rail replacement procedures……………………………………………………………………………………………………. 164

Injector………………………………………………………………………………………………………………………………. 166

Injector replacement procedures………………………………………………………………………………………………………. 166

Supply Pump……………………………………………………………………………………………………………………………. 169

SCV replacement procedures…………………………………………………………………………………………………………… 169

Hollow screw replacement procedures…………………………………………………………………………………………………… 172

Fuel temperature sensor replacement procedures…………………………………………………………………………………………. 174

Supply pump replacement procedures……………………………………………………………………………………………………. 176

Cooling System………………………………………………………………………………………………………………………………… 181

Before You Begin Servicing………………………………………………………………………………………………………………….. 183

Cooling System Diagram……………………………………………………………………………………………………………………… 184

Engine Coolant Pump Components………………………………………………………………………………………………………………. 185

Engine Coolant System Check…………………………………………………………………………………………………………………. 186

Engine Coolant Pump………………………………………………………………………………………………………………………… 186

Removal of Engine Coolant Pump…………………………………………………………………………………………………………… 186

Disassembly of Engine Coolant Pump……………………………………………………………………………………………………….. 187

Cleaning and Inspection…………………………………………………………………………………………………………………. 188

Engine coolant temperature sensor…………………………………………………………………………………………………….. 188

Thermostat…………………………………………………………………………………………………………………………. 188

Radiator cap……………………………………………………………………………………………………………………….. 188

Reassembly of Engine Coolant Pump………………………………………………………………………………………………………… 189

Installation of Engine Coolant Pump………………………………………………………………………………………………………. 189

Lubrication System…………………………………………………………………………………………………………………………….. 191

Before You Begin Servicing………………………………………………………………………………………………………………….. 193

Introduction………………………………………………………………………………………………………………………………. 193

Oil Pump Service Information………………………………………………………………………………………………………………… 194

Engine oil pressure…………………………………………………………………………………………………………………….. 194

Outer rotor outside clearance……………………………………………………………………………………………………………. 194

Outer rotor side clearance………………………………………………………………………………………………………………. 194

Outer rotor to inner rotor tip clearance………………………………………………………………………………………………….. 194

Rotor shaft clearance…………………………………………………………………………………………………………………… 194

Lubrication System Diagram………………………………………………………………………………………………………………….. 195

Checking Engine Oil Pressure………………………………………………………………………………………………………………… 196

Trochoid Oil Pump………………………………………………………………………………………………………………………….. 196

Oil Pump Components…………………………………………………………………………………………………………………….. 196

Disassembly of Oil Pump…………………………………………………………………………………………………………………. 197

Cleaning and Inspection…………………………………………………………………………………………………………………. 197

Check outer rotor outside clearance…………………………………………………………………………………………………… 197

Outer rotor to inner rotor tip clearance………………………………………………………………………………………………. 198

Check outer rotor side clearance……………………………………………………………………………………………………… 198

Check rotor shaft clearance………………………………………………………………………………………………………….. 198

Reassembly of Oil Pump………………………………………………………………………………………………………………….. 198

Exhaust System………………………………………………………………………………………………………………………………… 201

EGR System………………………………………………………………………………………………………………………………… 203

EGR System Configuration………………………………………………………………………………………………………………… 203

EGR valve………………………………………………………………………………………………………………………….. 204

EGR lead valve……………………………………………………………………………………………………………………… 204

EGR cooler…………………………………………………………………………………………………………………………. 204

Disassembly of EGR System……………………………………………………………………………………………………………….. 204

EGR cooler…………………………………………………………………………………………………………………………. 205

EGR valve/Lead valve………………………………………………………………………………………………………………… 205

Cleaning the EGR Cooler (Water Side/Exhaust Passage Blower)…………………………………………………………………………………. 206

Cleaning the EGR Pipe and Other Connecting Elbows………………………………………………………………………………………….. 206

Check, Clean, and Test EGR Valve…………………………………………………………………………………………………………. 206

EGR active control………………………………………………………………………………………………………………….. 207

Cleaning the EGR valves……………………………………………………………………………………………………………… 208

Exit the EGR active control………………………………………………………………………………………………………….. 209

Precautions for cleaning…………………………………………………………………………………………………………….. 209

Cleaning the EGR Lead Valves…………………………………………………………………………………………………………….. 209

Precautions for installation…………………………………………………………………………………………………………. 209

Assembling around the EGR Valve………………………………………………………………………………………………………….. 209

Intake Throttle………………………………………………………………………………………………………………………… 210

Precautions for handling the intake throttle…………………………………………………………………………………………… 210

Turbocharger………………………………………………………………………………………………………………………………. 211

Before You Begin Servicing………………………………………………………………………………………………………………. 211

Introduction…………………………………………………………………………………………………………………………… 211

Specifications…………………………………………………………………………………………………………………………. 211

Turbocharger service information……………………………………………………………………………………………………… 211

Structure of turbocharger……………………………………………………………………………………………………………. 213

Role of waste gate………………………………………………………………………………………………………………….. 214

Periodic Inspection…………………………………………………………………………………………………………………….. 215

Visual inspection…………………………………………………………………………………………………………………… 215

Inspection of rotor rotation…………………………………………………………………………………………………………. 215

Checking the rotor play……………………………………………………………………………………………………………… 215

Checking the waste gate valve………………………………………………………………………………………………………… 216

Removal and Installation of turbocharger………………………………………………………………………………………………….. 217

Removal of turbocharger……………………………………………………………………………………………………………… 217

Installation of turbocharger…………………………………………………………………………………………………………. 217

Cleaning Procedure……………………………………………………………………………………………………………………… 218

Excessive exhaust smoke……………………………………………………………………………………………………………… 219

Sudden oil decrease…………………………………………………………………………………………………………………. 220

Decrease in output………………………………………………………………………………………………………………….. 220

Poor (slow) response (starting) of turbocharger………………………………………………………………………………………… 220

Abnormal sound or vibration………………………………………………………………………………………………………….. 220

Diesel Particulate Filter (DPF)……………………………………………………………………………………………………………… 221

Outline of Diesel Particulate Filter (DPF)………………………………………………………………………………………………… 221

Overview of Diesel Particulate Filter (DPF) Regeneration Control…………………………………………………………………………….. 222

Self-Regeneration………………………………………………………………………………………………………………………. 222

Assisted Regeneration…………………………………………………………………………………………………………………… 222

Reset Regeneration……………………………………………………………………………………………………………………… 222

Stationary Regeneration…………………………………………………………………………………………………………………. 222

Operation Procedures of Stationary Regeneration……………………………………………………………………………………………. 223

Precautions for Stationary Regeneration…………………………………………………………………………………………………… 223

Recovery Regeneration (Optional)…………………………………………………………………………………………………………. 223

Precautions for Recovery Regeneration…………………………………………………………………………………………………….. 223

Urea SCR System……………………………………………………………………………………………………………………………. 224

Description……………………………………………………………………………………………………………………………. 224

System Structure……………………………………………………………………………………………………………………….. 224

Description of SCR……………………………………………………………………………………………………………………… 225

Device of Urea SCR System……………………………………………………………………………………………………………….. 226

SCR……………………………………………………………………………………………………………………………….. 226

SM (Supply Module)………………………………………………………………………………………………………………….. 227

DM (Dosing Module)………………………………………………………………………………………………………………….. 227

DCU (Dosing Control Unit)……………………………………………………………………………………………………………. 228

Aqueous urea hose…………………………………………………………………………………………………………………… 230

Maintenance service for After Treatment Device………………………………………………………………………………………………… 231

Service Period…………………………………………………………………………………………………………………………. 231

Replacing and Cleaning………………………………………………………………………………………………………………….. 232

Replacing the DPF or SCR…………………………………………………………………………………………………………….. 232

Cleaning the SF…………………………………………………………………………………………………………………….. 237

Replacing the ATD unit………………………………………………………………………………………………………………. 238

Urea SCR System Maintenance…………………………………………………………………………………………………………………. 239

Checking and Replacing the SM (Supply Module) Main Filter…………………………………………………………………………………… 239

Replacing the main filter……………………………………………………………………………………………………………. 239

Caution on replacing the filter cover…………………………………………………………………………………………………. 241

Replacing procedure of the Supply Module………………………………………………………………………………………………. 241

Inspection of the DM (Dosing Module) and Replacing the Sealing Plate…………………………………………………………………………. 242

Replacing procedure for DM sealing plate………………………………………………………………………………………………. 242

Starter Motor…………………………………………………………………………………………………………………………………. 245

Before You Begin Servicing………………………………………………………………………………………………………………….. 247

Introduction………………………………………………………………………………………………………………………………. 247

Starter Motor Information…………………………………………………………………………………………………………………… 248

Starter Motor Specifications………………………………………………………………………………………………………………… 248

Starter Motor Troubleshooting……………………………………………………………………………………………………………….. 249

Starter Motor Components……………………………………………………………………………………………………………………. 250

Starter Motor……………………………………………………………………………………………………………………………… 251

Removal of Starter Motor………………………………………………………………………………………………………………… 251

Disassembly of Starter Motor…………………………………………………………………………………………………………….. 251

Cleaning and Inspection…………………………………………………………………………………………………………………. 253

Armature…………………………………………………………………………………………………………………………… 253

Field coil…………………………………………………………………………………………………………………………. 255

Magnetic switch…………………………………………………………………………………………………………………….. 255

Pinion clutch assembly………………………………………………………………………………………………………………. 256

Reassembly of Starter Motor……………………………………………………………………………………………………………… 257

Check Pinion Projection Length…………………………………………………………………………………………………………… 258

No-Load Test…………………………………………………………………………………………………………………………… 259

Installation of Starter Motor……………………………………………………………………………………………………………. 260

Alternator……………………………………………………………………………………………………………………………………. 261

Before You Begin Servicing………………………………………………………………………………………………………………….. 263

Introduction………………………………………………………………………………………………………………………………. 263

Alternator Specifications…………………………………………………………………………………………………………………… 264

Alternator Troubleshooting………………………………………………………………………………………………………………….. 265

Alternator Components………………………………………………………………………………………………………………………. 266

Alternator Wiring Diagram…………………………………………………………………………………………………………………… 267

Alternator Standard Output………………………………………………………………………………………………………………….. 268

Alternator………………………………………………………………………………………………………………………………… 269

Removal of Alternator…………………………………………………………………………………………………………………… 269

Disassembly of Alternator……………………………………………………………………………………………………………….. 269

Reassembly of Alternator………………………………………………………………………………………………………………… 271

Installation of Alternator………………………………………………………………………………………………………………. 273

Electronic Control System………………………………………………………………………………………………………………………. 275

Before You Begin Servicing………………………………………………………………………………………………………………….. 277

Introduction………………………………………………………………………………………………………………………………. 277

Electronic Control System…………………………………………………………………………………………………………………… 278

Troubleshooting of Electronic Control System………………………………………………………………………………………………….. 279

Fault detection capability………………………………………………………………………………………………………………. 279

SMARTASSIST-DIRECT (SA-D)……………………………………………………………………………………………………………….. 280

About SA-D use……………………………………………………………………………………………………………………… 281

Replacement of Components…………………………………………………………………………………………………………………… 282

Processing the DPF regeneration after the parts replacement…………………………………………………………………………………. 282

Processing after the ECU replacement (when it is impossible to inherit from the old ECU)……………………………………………………….. 283

Required processing at the CR-related parts replacement…………………………………………………………………………………….. 284

Electronic Control Harness Connections……………………………………………………………………………………………………….. 286

Electric Wiring……………………………………………………………………………………………………………………………….. 299

Electric Wiring Precautions…………………………………………………………………………………………………………………. 301

Electrical Wire Resistance………………………………………………………………………………………………………………….. 302

Battery Cable Resistance……………………………………………………………………………………………………………………. 303

Electrical Wire Sizes – Voltage Drop…………………………………………………………………………………………………………. 304

Conversion of AWG to European Standards………………………………………………………………………………………………………. 305

Failure Diagnosis……………………………………………………………………………………………………………………………… 307

Special Service Tools………………………………………………………………………………………………………………………. 309

Troubleshooting by Measuring Compression Pressure……………………………………………………………………………………………… 310

Compression pressure inspection procedures………………………………………………………………………………………………… 310

Injector reassembly procedures…………………………………………………………………………………………………………… 311

Engine speed and compression pressure (use for reference)…………………………………………………………………………………… 312

Measured Value and Troubleshooting…………………………………………………………………………………………………………… 313

Quick Reference Table for Troubleshooting…………………………………………………………………………………………………….. 314

Failure Diagnostic List…………………………………………………………………………………………………………………. 315

Trouble Shooting………………………………………………………………………………………………………………………………. 319

CONTENTS………………………………………………………………………………………………………………………………….. 321

GENERAL DESCRIPTION OF ENGINE ELECTRONIC CONTROL SYSTEM………………………………………………………………………………………… 333

System Configuration of Engine Electronic Control System……………………………………………………………………………………. 333

Engine ECU and DCU After-run Time………………………………………………………………………………………………………… 337

Output Limit by Inducement at SCR System Error…………………………………………………………………………………………….. 338

Output Limit by Inducement when Aqueous Urea Tank Level is Low………………………………………………………………………………. 340

SCR System Limited Operation…………………………………………………………………………………………………………….. 341

DTC (DIAGNOSTIC TROUBLE CODES) GENERAL DESCRIPTION…………………………………………………………………………………………….. 343

DTC Code List………………………………………………………………………………………………………………………….. 343

Engine ECU judgment item…………………………………………………………………………………………………………….. 343

DCU judgment item…………………………………………………………………………………………………………………… 347

Description……………………………………………………………………………………………………………………………. 351

Engine ECU Judgment Item………………………………………………………………………………………………………………… 352

Sensor related……………………………………………………………………………………………………………………… 352

Crankshaft speed sensor………………………………………………………………………………………………………….. 352

P0336: Crankshaft signal error………………………………………………………………………………………………… 352

P0337: No signal from crankshaft………………………………………………………………………………………………. 354

Camshaft speed sensor……………………………………………………………………………………………………………. 356

P0341: Camshaft signal error………………………………………………………………………………………………….. 356

P0342: No signal from camshaft………………………………………………………………………………………………… 358

Crankshaft speed sensor/camshaft speed sensor………………………………………………………………………………………. 360

P0008: Crankshaft/camshaft speed sensor non-input (simultaneous)………………………………………………………………….. 360

Accelerator sensor 1…………………………………………………………………………………………………………….. 362

P0123: Accelerator sensor 1 error (voltage high)………………………………………………………………………………… 362

P0122: Accelerator sensor 1 error (voltage low)…………………………………………………………………………………. 364

Accelerator sensor 3…………………………………………………………………………………………………………….. 366

P0228: Accelerator sensor 3 error (voltage high)………………………………………………………………………………… 366

P0227: Accelerator sensor 3 error (voltage low)…………………………………………………………………………………. 368

P1126: Accelerator sensor 3 error (foot pedal in open position)…………………………………………………………………… 370

P1125: Accelerator sensor 3 error (foot pedal in closed position)…………………………………………………………………. 372

Intake throttle position sensor…………………………………………………………………………………………………… 374

P02E9: Intake throttle position sensor error (voltage high)………………………………………………………………………. 374

P02E8: Intake throttle position sensor error (voltage low)……………………………………………………………………….. 376

EGR low pressure side pressure sensor……………………………………………………………………………………………… 378

P0238: EGR low pressure side pressure sensor error (voltage high)…………………………………………………………………. 378

P0237: EGR low pressure side pressure sensor error (voltage low)………………………………………………………………….. 380

P0236: EGR low pressure side pressure sensor error (abnormal learning value)……………………………………………………….. 382

P1673: EGR low pressure side pressure sensor error (detected value error)………………………………………………………….. 384

EGR high pressure side pressure sensor…………………………………………………………………………………………….. 386

P0473: EGR high pressure side pressure sensor error (voltage high)………………………………………………………………… 386

P0472: EGR high pressure side pressure sensor error (voltage low)…………………………………………………………………. 388

P0471: EGR high pressure side pressure sensor error (abnormal learning value)………………………………………………………. 390

P1679: EGR high pressure side pressure sensor error (detected value error)…………………………………………………………. 392

Engine coolant temperature sensor…………………………………………………………………………………………………. 394

P0118: Engine coolant temperature sensor error (voltage high)…………………………………………………………………….. 394

P0117: Engine coolant temperature sensor error (voltage low)……………………………………………………………………… 396

P0217: Engine coolant temperature high (overheat)……………………………………………………………………………….. 398

P1674: Engine coolant temperature sensor error (detected value error)……………………………………………………………… 400

Ambient air temperature sensor……………………………………………………………………………………………………. 402

P0113: Ambient air temperature sensor error (voltage high)……………………………………………………………………….. 402

P0112: Ambient air temperature sensor error (voltage low)………………………………………………………………………… 404

P1678: Ambient air temperature sensor error (detected value error)………………………………………………………………… 406

Fuel temperature sensor………………………………………………………………………………………………………….. 408

P0183: Fuel temperature sensor error (voltage high)……………………………………………………………………………… 408

P0182: Fuel temperature sensor error (voltage low)………………………………………………………………………………. 410

P0168: Fuel temperature high………………………………………………………………………………………………….. 412

Rail pressure sensor…………………………………………………………………………………………………………….. 414

P0193: Rail pressure sensor error (voltage high)………………………………………………………………………………… 414

P0192: Rail pressure sensor error (voltage low)…………………………………………………………………………………. 416

DPF differential pressure sensor………………………………………………………………………………………………….. 418

P2455: DPF differential pressure sensor error (voltage high)……………………………………………………………………… 418

P2454: DPF differential pressure sensor error (voltage low)………………………………………………………………………. 420

P2453: DPF differential pressure sensor error (abnormal learning value)……………………………………………………………. 422

P2452: DPF differential pressure sensor abnormal rise in differential pressure……………………………………………………… 424

DPF substrate/DPF differential pressure sensor……………………………………………………………………………………… 425

P226D: DPF substrate/DPF differential pressure sensor error (DPF substrate removal/DPF differential pressure sensor detected value error)…. 425

DPF high pressure side pressure sensor…………………………………………………………………………………………….. 427

P1455: DPF high pressure side pressure sensor error (detected value error)…………………………………………………………. 427

P1454: DPF high pressure side pressure sensor error (voltage low)…………………………………………………………………. 429

DPF inlet temperature sensor……………………………………………………………………………………………………… 433

P1428: DPF inlet temperature sensor error (voltage high)…………………………………………………………………………. 433

P1427: DPF inlet temperature sensor error (voltage low)………………………………………………………………………….. 435

P167E: DPF inlet temperature sensor error (detected value error)………………………………………………………………….. 437

P1436: DPF inlet temperature sensor abnormal temperature (abnormally high)…………………………………………………………. 439

DPF intermediate temperature sensor……………………………………………………………………………………………….. 440

P1434: DPF intermediate temperature sensor error (voltage high)…………………………………………………………………… 440

P1435: DPF intermediate temperature sensor error (voltage low)……………………………………………………………………. 442

P167A: DPF intermediate temperature sensor error (detected value error)……………………………………………………………. 444

P0420: DPF intermediate temperature sensor abnormal temperature (abnormally low)……………………………………………………. 446

P1426: DPF intermediate temperature sensor abnormal rise in temperature (post-injection malfunction)………………………………….. 447

Atmospheric pressure sensor………………………………………………………………………………………………………. 448

P2229: Atmospheric pressure sensor error (voltage high)………………………………………………………………………….. 448

P2228: Atmospheric pressure sensor error (voltage low)…………………………………………………………………………… 449

P1231: Atmospheric pressure sensor error (characteristic error)…………………………………………………………………… 450

EGR gas temperature sensor……………………………………………………………………………………………………….. 451

P041D: EGR gas temperature sensor error (voltage high)…………………………………………………………………………… 451

P041C: EGR gas temperature sensor error (voltage low)……………………………………………………………………………. 453

P1675: EGR gas temperature sensor error (detected value error)……………………………………………………………………. 455

Intake manifold temperature sensor………………………………………………………………………………………………… 457

P040D: Intake manifold temperature sensor error (voltage high)……………………………………………………………………. 457

P040C: Intake manifold temperature sensor error (voltage low)…………………………………………………………………….. 459

P1676: Intake manifold temperature sensor error (detected value error)…………………………………………………………….. 461

Exhaust manifold temperature sensor……………………………………………………………………………………………….. 463

P0546: Exhaust manifold temperature sensor error (voltage high)…………………………………………………………………… 463

P0545: Exhaust manifold temperature sensor error (voltage low)……………………………………………………………………. 465

P1677: Exhaust manifold temperature sensor error (detected value error)……………………………………………………………. 467

Contact output related………………………………………………………………………………………………………………. 469

Main relay……………………………………………………………………………………………………………………… 469

P068A: Power off without main relay self-holding………………………………………………………………………………… 469

Starting aid relay………………………………………………………………………………………………………………. 470

P0543: Starting aid relay disconnection/VB short circuit…………………………………………………………………………. 470

P0541: Starting aid relay GND short circuit…………………………………………………………………………………….. 472

CRS (common rail system) related……………………………………………………………………………………………………… 474

Injector-specific……………………………………………………………………………………………………………….. 474

P0201: Injector (No. 1 cylinder) disconnection (injector-specific)………………………………………………………………… 474

P0202: Injector (No. 2 cylinder) disconnection (injector-specific)………………………………………………………………… 476

P0203: Injector (No. 3 cylinder) disconnection (injector-specific)………………………………………………………………… 478

P0204: Injector (No. 4 cylinder) disconnection (injector-specific)………………………………………………………………… 480

All injectors…………………………………………………………………………………………………………………… 482

P2148: Injector bank 1 + B short circuit……………………………………………………………………………………….. 482

P2147: Injector bank 1 GND short circuit……………………………………………………………………………………….. 484

P2146: Injector bank 1 disconnection…………………………………………………………………………………………… 486

P2151: Injector bank 2 + B short circuit……………………………………………………………………………………….. 488

P2150: Injector bank 2 GND short circuit……………………………………………………………………………………….. 490

P2149: Injector bank 2 disconnection…………………………………………………………………………………………… 492

Injector drive circuit…………………………………………………………………………………………………………… 494

P0611: Low charge error………………………………………………………………………………………………………. 494

P0200: Overcharge error………………………………………………………………………………………………………. 495

SCV (MPROP)…………………………………………………………………………………………………………………….. 496

P0629: SCV (MPROP) H/L side VB short circuit……………………………………………………………………………………. 496

P0627: SCV (MPROP) H side GND short circuit/disconnection………………………………………………………………………… 498

P2635: Drive circuit error (SCV sticking)………………………………………………………………………………………. 500

High pressure pump………………………………………………………………………………………………………………. 502

P1235: Pump protection failure………………………………………………………………………………………………… 502

P1236: Pump replacement failure……………………………………………………………………………………………….. 504

P1237: Pump learning not performed alarm……………………………………………………………………………………….. 506

Rail pressure error……………………………………………………………………………………………………………… 507

P0088: Rail pressure too high…………………………………………………………………………………………………. 507

P0094: Rail pressure deviation error (low rail pressure)…………………………………………………………………………. 508

Actuator…………………………………………………………………………………………………………………………… 509

Intake throttle drive circuit…………………………………………………………………………………………………….. 509

P0660: Intake throttle drive circuit disconnection………………………………………………………………………………. 509

P1658: Intake throttle drive circuit VB/GND short circuit………………………………………………………………………… 510

P1655: Intake throttle drive circuit deviation error…………………………………………………………………………….. 511

P1656: Intake throttle drive circuit drive duty error……………………………………………………………………………. 513

EGR……………………………………………………………………………………………………………………………. 515

P0403: Disconnection in EGR motor coils………………………………………………………………………………………… 515

P1405: EGR short circuit in motor coils………………………………………………………………………………………… 516

P0488: EGR position sensor error………………………………………………………………………………………………. 517

P1409: EGR feedback error…………………………………………………………………………………………………….. 518

P148A: EGR valve sticking error……………………………………………………………………………………………….. 519

P049D: EGR initialization error……………………………………………………………………………………………….. 520

U0401: EGR ECM data error…………………………………………………………………………………………………….. 521

U1401: EGR target value out of range…………………………………………………………………………………………… 522

P0404: EGR overvoltage error………………………………………………………………………………………………….. 523

P1404: EGR low voltage error………………………………………………………………………………………………….. 524

P1410: EGR high temperature thermistor error……………………………………………………………………………………. 525

P1411: EGR low temperature thermistor error…………………………………………………………………………………….. 526

Communication related……………………………………………………………………………………………………………….. 527

CAN……………………………………………………………………………………………………………………………. 527

U0292: TSC1 (SA1) reception timeout……………………………………………………………………………………………. 527

U1301: TSC1 (SA2) reception timeout……………………………………………………………………………………………. 528

U1292: Y_ECR1 reception timeout……………………………………………………………………………………………….. 529

U1293: Y_EC reception timeout…………………………………………………………………………………………………. 530

U0168: VI reception timeout…………………………………………………………………………………………………… 531

U3002: VI received data error…………………………………………………………………………………………………. 532

U1303: Y_DPFIF reception timeout………………………………………………………………………………………………. 533

U1302: EBC1 reception timeout…………………………………………………………………………………………………. 534

U010B: CAN reception timeout from the EGR valve…………………………………………………………………………………. 535

U0167: Immobilizer error (CAN communication)……………………………………………………………………………………. 536

U0426: Immobilizer error (system)……………………………………………………………………………………………… 537

U1501: CAN reception timeout from DCU………………………………………………………………………………………….. 538

U1503: DCU system error (FS action instruction 1 from DCU)……………………………………………………………………….. 540

U1504: DCU system error (FS action instruction 2 from DCU)……………………………………………………………………….. 541

U1505: DCU system error (FS action instruction 3 from DCU)……………………………………………………………………….. 542

U1506: DCU system error (FS action instruction 4 from DCU)……………………………………………………………………….. 543

U1507: DCU system error (FS action instruction 5 from DCU)……………………………………………………………………….. 544

U1508: DCU system error (FS action instruction 6 from DCU)……………………………………………………………………….. 545

U1509: DCU system error (FS action instruction 7 from DCU)……………………………………………………………………….. 546

U1510: DCU system error (FS action instruction 8 from DCU)……………………………………………………………………….. 547

P1672: Data verification error between ECU and DCU (engine model unmatched)………………………………………………………… 548

P264F: Data verification error between ECU and DCU (serial No. unmatched)………………………………………………………….. 549

U1502: Data verification error between ECU and DCU (verification timeout)………………………………………………………….. 550

ECU related………………………………………………………………………………………………………………………… 552

EEPROM…………………………………………………………………………………………………………………………. 552

P1601: EEPROM error………………………………………………………………………………………………………….. 552

ECU internal error………………………………………………………………………………………………………………. 553

P0652: Sensor 5 V circuit 1 error (voltage low)…………………………………………………………………………………. 553

P0653: Sensor 5 V circuit 1 error (voltage high)………………………………………………………………………………… 555

P0698: Sensor 5 V circuit 2 error (voltage low)…………………………………………………………………………………. 557

P0699: Sensor 5 V circuit 2 error (voltage high)………………………………………………………………………………… 559

P0607: CPU monitoring IC error………………………………………………………………………………………………… 561

P0606: CPU error…………………………………………………………………………………………………………….. 562

P1602: Flash ROM error (checksum error)………………………………………………………………………………………… 563

Contact input related……………………………………………………………………………………………………………….. 564

Air cleaner switch………………………………………………………………………………………………………………. 564

P1101: Air cleaner clogged alarm………………………………………………………………………………………………. 564

Water separator switch…………………………………………………………………………………………………………… 566

P1151: Water separator alarm………………………………………………………………………………………………….. 566

Charge switch…………………………………………………………………………………………………………………… 568

P1562: Charge switch disconnection…………………………………………………………………………………………….. 568

P1568: Charge alarm………………………………………………………………………………………………………….. 570

Oil pressure switch……………………………………………………………………………………………………………… 572

P1192: Oil pressure switch disconnection……………………………………………………………………………………….. 572

P1198: Low oil pressure alarm…………………………………………………………………………………………………. 574

After treatment control……………………………………………………………………………………………………………… 576

DPF……………………………………………………………………………………………………………………………. 576

P2463: Excessive PM accumulation (method C)…………………………………………………………………………………….. 576

P1463: Excessive PM accumulation (method P)…………………………………………………………………………………….. 577

P2458: Regeneration failure (stationary regeneration failure)…………………………………………………………………….. 578

P1445: Regeneration failure (recovery regeneration failure)………………………………………………………………………. 579

P2459: Regeneration failure (stationary regeneration not performed)……………………………………………………………….. 580

DPF OP interface………………………………………………………………………………………………………………… 581

P242F: Ash cleaning request 1…………………………………………………………………………………………………. 581

P1420: Ash cleaning request 2…………………………………………………………………………………………………. 582

P1421: Stationary regeneration standby…………………………………………………………………………………………. 583

P1424: Backup mode…………………………………………………………………………………………………………… 584

P1446: Recovery regeneration is inhibited………………………………………………………………………………………. 585

Others…………………………………………………………………………………………………………………………….. 586

Overspeed………………………………………………………………………………………………………………………. 586

P0219: Overspeed…………………………………………………………………………………………………………….. 586

QR data………………………………………………………………………………………………………………………… 587

P1631: QR data not written……………………………………………………………………………………………………. 587

P1632: QR data error…………………………………………………………………………………………………………. 588

P1630: QR data correction input error………………………………………………………………………………………….. 589

DCU Judgment Item………………………………………………………………………………………………………………………. 590

Sensor related……………………………………………………………………………………………………………………… 590

SCR upstream NOx sensor………………………………………………………………………………………………………….. 590

P1545: SCR upstream NOx value rise error……………………………………………………………………………………….. 590

P2209: SCR upstream NOx sensor incomplete heating error………………………………………………………………………….. 592

P2203: SCR upstream NOx sensor internal circuit short circuit…………………………………………………………………….. 593

P151C: SCR upstream NOx sensor internal circuit disconnection…………………………………………………………………….. 594

P1525: SCR upstream NOx sensor detected value error (upper limit error)……………………………………………………………. 595

P1526: SCR upstream NOx sensor detected value error (lower limit error)……………………………………………………………. 597

SCR downstream NOx sensor………………………………………………………………………………………………………… 599

P1546: SCR downstream NOx value rise error……………………………………………………………………………………… 599

P2222: SCR downstream NOx sensor incomplete heating error………………………………………………………………………… 600

P2216: SCR downstream NOx sensor internal circuit short circuit…………………………………………………………………… 601

P151D: SCR downstream NOx sensor internal circuit disconnection…………………………………………………………………… 602

P1524: SCR downstream NOx sensor detected value error……………………………………………………………………………. 603

SCR catalyst upstream temperature sensor…………………………………………………………………………………………… 605

P0428: SCR catalyst upstream temperature sensor error (voltage high)………………………………………………………………. 605

P0427: SCR catalyst upstream temperature sensor error (voltage low)……………………………………………………………….. 607

P0426: SCR catalyst upstream temperature sensor temperature rise error…………………………………………………………….. 609

P153B: SCR catalyst upstream temperature sensor detected value error (upper limit error)…………………………………………….. 611

P1541: SCR catalyst upstream temperature sensor detected value error (lower limit error)…………………………………………….. 612

P1542: SCR catalyst upstream temperature sensor detected value error (at cold start check)…………………………………………… 613

Supply module pump pressure sensor………………………………………………………………………………………………… 614

P204D: Supply module pump pressure sensor error (voltage high)……………………………………………………………………. 614

P204C: Supply module pump pressure sensor error (voltage low)…………………………………………………………………….. 616

P153C: Supply module pump pressure sensor detected value error (upper limit error)………………………………………………….. 618

P153D: Supply module pump pressure sensor detected value error (lower limit error)………………………………………………….. 620

P1516: Sensor supply voltage error…………………………………………………………………………………………….. 622

Aqueous urea quality sensor/aqueous urea tank temperature sensor (A1DEFI)……………………………………………………………… 624

P1559: Aqueous urea quality sensor/aqueous urea tank temperature sensor (A1DEFI) controller temperature rise error……………………… 624

P206D: Aqueous urea quality sensor (A1DEFI) internal circuit disconnection…………………………………………………………. 626

P206C: Aqueous urea quality sensor (A1DEFI) internal circuit short circuit…………………………………………………………. 627

P154F: Aqueous urea quality sensor (A1DEFI) controller internal failure……………………………………………………………. 628

P1551: Aqueous urea tank temperature sensor (A1DEFI) internal circuit disconnection…………………………………………………. 629

P1552: Aqueous urea tank temperature sensor (A1DEFI) internal circuit short circuit…………………………………………………. 630

P1550: Aqueous urea tank temperature sensor (A1DEFI) controller internal failure……………………………………………………. 631

Aqueous urea tank temperature sensor/aqueous urea tank level sensor (AT1T1I)…………………………………………………………… 632

P1557: Aqueous urea tank temperature sensor/aqueous urea tank level sensor (AT1T1I) controller temperature rise error…………………… 632

P203D: Aqueous urea tank level sensor (AT1T1I) internal circuit disconnection………………………………………………………. 634

P203C: Aqueous urea tank level sensor (AT1T1I) internal circuit short circuit………………………………………………………. 635

P155A: Aqueous urea tank level sensor (AT1T1I) controller internal failure…………………………………………………………. 636

P205D: Aqueous urea tank temperature sensor (AT1T1I) internal circuit disconnection…………………………………………………. 637

P205C: Aqueous urea tank temperature sensor (AT1T1I) internal circuit short circuit…………………………………………………. 638

P1556: Aqueous urea tank temperature sensor (AT1T1I) controller internal failure……………………………………………………. 639

P155B: Aqueous urea tank level sensor detected value error……………………………………………………………………….. 640

P205B: Aqueous urea tank temperature rise error…………………………………………………………………………………. 641

P1539: Aqueous urea tank temperature sensor detected value error (upper limit error)………………………………………………… 642

P153A: Aqueous urea tank temperature sensor detected value error (lower limit error)………………………………………………… 643

P154B: Aqueous urea tank temperature rise error…………………………………………………………………………………. 644

DCU internal temperature sensor…………………………………………………………………………………………………… 645

P1504: DCU internal temperature rise error……………………………………………………………………………………… 645

Contact output related………………………………………………………………………………………………………………. 647

Hose heater relay……………………………………………………………………………………………………………….. 647

P21C4: Hose heater relay L side VB short circuit………………………………………………………………………………… 647

P21C3: Hose heater relay L side GND short circuit……………………………………………………………………………….. 649

P21C2: Hose heater relay disconnection…………………………………………………………………………………………. 651

P1509: Hose heater relay power stage temperature rise error………………………………………………………………………. 653

Actuator…………………………………………………………………………………………………………………………… 655

Dosing module…………………………………………………………………………………………………………………… 655

P2049: Dosing module H side VB short circuit/disconnection……………………………………………………………………….. 655

P2047: Dosing module H side GND short circuit…………………………………………………………………………………… 657

P151B: Dosing module L side VB short circuit……………………………………………………………………………………. 659

P2048: Dosing module L side GND short circuit…………………………………………………………………………………… 661

P1505: Dosing module power stage temperature rise error………………………………………………………………………….. 663

P208E: Dosing module valve sticking……………………………………………………………………………………………. 665

Supply module…………………………………………………………………………………………………………………… 667

P208D: Supply module (pump motor) PWM signal wire VB short circuit………………………………………………………………… 667

P208C: Supply module (pump motor) PWM signal wire GND short circuit……………………………………………………………….. 669

P208A: Supply module (pump motor) PWM signal wire disconnection…………………………………………………………………… 671

P150D: Supply module (pump motor) power stage temperature rise error………………………………………………………………. 673

P151F: Supply module (pump motor) pump motor drive error 1……………………………………………………………………….. 675

P208B: Supply module (pump motor) pump motor drive error 2……………………………………………………………………….. 677

P20AD: Not starting to measure temperature of supply module (pump motor)…………………………………………………………… 679

P152F: Supply module temperature information PWM cycle error……………………………………………………………………… 681

P152E: Supply module temperature information PWM signal error…………………………………………………………………….. 683

P1530: Supply module (supply module temperature sensor) fault value for temperature information duty value received…………………….. 685

P1531: Supply module (supply module temperature sensor) invalid value for temperature information duty value received…………………… 687

P152B: Supply module (supply module temperature sensor) detected value error……………………………………………………….. 689

P1544: Supply module (supply module temperature sensor) detected value error (at cold start check)……………………………………. 690

P20A3: Supply module (reverting valve) L side VB short circuit……………………………………………………………………. 691

P20A2: Supply module (reverting valve) L side GND short circuit…………………………………………………………………… 693

P20A0: Supply module (reverting valve) disconnection…………………………………………………………………………….. 695

P150E: Supply module (reverting valve) power stage temperature rise error………………………………………………………….. 697

P26E9: Supply module (supply module heater) H side VB short circuit……………………………………………………………….. 699

P26E8: Supply module (supply module heater) H side GND short circuit………………………………………………………………. 701

P20C8: Supply module (supply module heater) L side VB short circuit……………………………………………………………….. 703

P20C5: Supply module (supply module heater) disconnection………………………………………………………………………… 705

P150B: Supply module (supply module heater) power stage temperature rise error……………………………………………………… 707

P20B6: Supply module (supply module heater) detected value error………………………………………………………………….. 709

P152C: Supply module (supply module heater temperature sensor) fault value for temperature information duty value received………………. 711

P152D: Supply module (supply module heater temperature sensor) invalid value for temperature information duty value received…………….. 713

P152A: Supply module (supply module heater temperature sensor) detected value error…………………………………………………. 715

P1543: Supply module (supply module heater temperature sensor) detected value error (at cold start check)……………………………… 716

P2671: Supply module (reverting valve) H side VB short circuit……………………………………………………………………. 717

P2670: Supply module (reverting valve) H side GND short circuit…………………………………………………………………… 719

Hose heater relay/tank heating valve………………………………………………………………………………………………. 721

P2686: Hose heater relay/tank heating valve H side VB short circuit……………………………………………………………….. 721

P2685: Hose heater relay/tank heating valve H side GND short circuit………………………………………………………………. 723

Aqueous urea hose heater (back flow, pressure, suction)……………………………………………………………………………… 725

P1510: Aqueous urea hose heater (back flow, pressure, suction) H side VB short circuit/L side VB short circuit…………………………. 725

Aqueous urea hose heater (back flow)………………………………………………………………………………………………. 727

P20BC: Aqueous urea hose heater (back flow) L side VB short circuit……………………………………………………………….. 727

P20B9: Aqueous urea hose heater (back flow) disconnection………………………………………………………………………… 729

P1507: Aqueous urea hose heater (back flow) power stage temperature rise error……………………………………………………… 731

Aqueous urea hose heater (pressure)……………………………………………………………………………………………….. 733

P20C0: Aqueous urea hose heater (pressure) L side VB short circuit………………………………………………………………… 733

P20BD: Aqueous urea hose heater (pressure) disconnection…………………………………………………………………………. 735

P1508: Aqueous urea hose heater (pressure) power stage temperature rise error………………………………………………………. 737

Aqueous urea hose heater (suction)………………………………………………………………………………………………… 739

P20C4: Aqueous urea hose heater (suction) L side VB short circuit…………………………………………………………………. 739

P20C1: Aqueous urea hose heater (suction) disconnection………………………………………………………………………….. 741

P150A: Aqueous urea hose heater (suction) power stage temperature rise error……………………………………………………….. 743

Tank heating valve………………………………………………………………………………………………………………. 745

P202C: Tank heating valve L side VB short circuit……………………………………………………………………………….. 745

P202B: Tank heating valve L side GND short circuit………………………………………………………………………………. 747

P202A: Tank heating valve disconnection………………………………………………………………………………………… 749

P150C: Tank heating valve power stage temperature rise error……………………………………………………………………… 751

Communication related……………………………………………………………………………………………………………….. 753

CAN (engine side)……………………………………………………………………………………………………………….. 753

U029D: CAN reception timeout from SCR upstream NOx sensor………………………………………………………………………… 753

U029E: CAN reception timeout from SCR downstream NOx sensor………………………………………………………………………. 755

U1607: CAN reception timeout from ECU………………………………………………………………………………………….. 757

P1555: ECU system error (invalid ambient air temperature value is received)………………………………………………………… 759

P155C: ECU system error (FS action instruction 1 from ECU)……………………………………………………………………….. 760

CAN (driven machine side)………………………………………………………………………………………………………… 762

U1610: A1DEFI reception timeout……………………………………………………………………………………………….. 762

U1611: AT1T1I reception timeout……………………………………………………………………………………………….. 764

Battery related…………………………………………………………………………………………………………………….. 766

DCU supply voltage………………………………………………………………………………………………………………. 766

P1512: DCU supply voltage error (voltage high 1)………………………………………………………………………………… 766

P1514: DCU supply voltage error (voltage high 2)………………………………………………………………………………… 768

P1511: DCU supply voltage error (voltage low 1)…………………………………………………………………………………. 770

P1513: DCU supply voltage error (voltage low 2)…………………………………………………………………………………. 772

Main relay……………………………………………………………………………………………………………………… 774

P20EA: Main relay opens early…………………………………………………………………………………………………. 774

DCU internal related………………………………………………………………………………………………………………… 776

P1600: EEPROM memory deletion error……………………………………………………………………………………………….. 776

P160E: EEPROM memory reading error………………………………………………………………………………………………… 777

P160F: EEPROM memory writing error………………………………………………………………………………………………… 778

P1500: SPI communication error 1………………………………………………………………………………………………….. 779

P1501: SPI communication error 2………………………………………………………………………………………………….. 780

P21CC: Supply 1 overvoltage error…………………………………………………………………………………………………. 781

P21CB: Supply 1 low voltage error…………………………………………………………………………………………………. 782

P1502: AD converter error 1………………………………………………………………………………………………………. 783

P1503: AD converter error 2………………………………………………………………………………………………………. 784

DCU internal temperature sensor…………………………………………………………………………………………………… 785

P1517: DCU internal temperature sensor error (voltage high)………………………………………………………………………. 785

P1519: DCU internal temperature sensor error (voltage low)……………………………………………………………………….. 786

Main relay……………………………………………………………………………………………………………………… 787

P20EB: Main relay sticking……………………………………………………………………………………………………. 787

Contact input related……………………………………………………………………………………………………………….. 788

Key switch……………………………………………………………………………………………………………………… 788

P1561: Key switch disconnection……………………………………………………………………………………………….. 788

SCR control related…………………………………………………………………………………………………………………. 790

Aqueous urea hose (back flow side)………………………………………………………………………………………………… 790

P1533: Aqueous urea hose (back flow side) pressure rise error…………………………………………………………………….. 790

Aqueous urea hose (pressure side)…………………………………………………………………………………………………. 791

P1534: Aqueous urea hose (pressure side) pressure rise error……………………………………………………………………… 791

Supply module…………………………………………………………………………………………………………………… 792

P20E9: Supply module (pump motor) pressure rise error 1………………………………………………………………………….. 792

P1536: Supply module (pump motor) pressure rise error 2………………………………………………………………………….. 793

P1532: Supply module (pump motor) pressure reduction failure……………………………………………………………………… 794

P1535: Supply module (reverting valve) failure………………………………………………………………………………….. 795

P150F: Supply module (pump motor) pressure stability error……………………………………………………………………….. 796

P1537: Supply module pressure drop error……………………………………………………………………………………….. 797

P1538: Supply module aqueous urea pressure rise failure………………………………………………………………………….. 798

P204F: Supply module aqueous urea suck-back failure……………………………………………………………………………… 799

SCR system……………………………………………………………………………………………………………………… 800

P1520: Inefficient NOx cleaning……………………………………………………………………………………………….. 800

P1506: SCR system forced termination…………………………………………………………………………………………… 802

P1553: SCR system error (Inducement 1)…………………………………………………………………………………………. 804

P1554: SCR system error (Inducement 2)…………………………………………………………………………………………. 805

Aqueous urea related………………………………………………………………………………………………………………… 806

Aqueous urea tank level………………………………………………………………………………………………………….. 806

P1549: Low aqueous urea tank level (Inducement 1)……………………………………………………………………………….. 806

P154A: Low aqueous urea tank level (Inducement 2)……………………………………………………………………………….. 808

Aqueous urea quality sensor………………………………………………………………………………………………………. 810

P154E: Aqueous urea quality sensor concentration error (small deviation)…………………………………………………………… 810

P154D: Aqueous urea quality sensor concentration error (large deviation)…………………………………………………………… 812

P1558: Aqueous urea quality sensor contamination error in aqueous urea tank………………………………………………………… 814

METHOD AND PROCEDURE OF FAILURE DIAGNOSIS…………………………………………………………………………………………………….. 817

Description……………………………………………………………………………………………………………………………. 817

Engine ECU Judgment Item………………………………………………………………………………………………………………… 818

ECU pin layout drawing………………………………………………………………………………………………………………. 818

ECU engine side (wire-harness side)……………………………………………………………………………………………….. 818

Driven machine side (wire-harness side)……………………………………………………………………………………………. 818

Analog input related………………………………………………………………………………………………………………… 821

Accelerator sensor………………………………………………………………………………………………………………. 821

Rail pressure sensor…………………………………………………………………………………………………………….. 825

DPF inlet temperature sensor……………………………………………………………………………………………………… 828

DPF intermediate temperature sensor……………………………………………………………………………………………….. 832

Engine coolant temperature sensor…………………………………………………………………………………………………. 836

Engine coolant temperature sensor 2……………………………………………………………………………………………….. 840

Ambient air temperature sensor……………………………………………………………………………………………………. 845

Ambient air temperature sensor 2………………………………………………………………………………………………….. 849

Fuel temperature sensor………………………………………………………………………………………………………….. 854

Intake throttle position sensor…………………………………………………………………………………………………… 858

EGR pressure sensor 1……………………………………………………………………………………………………………. 861

EGR pressure sensor 2……………………………………………………………………………………………………………. 864

EGR pressure sensor 3……………………………………………………………………………………………………………. 865

DPF differential pressure sensor 1………………………………………………………………………………………………… 870

DPF differential pressure sensor 2………………………………………………………………………………………………… 873

ECU sensor 5 V circuit 1…………………………………………………………………………………………………………. 874

ECU sensor 5 V circuit 2…………………………………………………………………………………………………………. 876

Engine overspeed………………………………………………………………………………………………………………… 878

Pulse sensor related………………………………………………………………………………………………………………… 879

Crankshaft speed sensor………………………………………………………………………………………………………….. 879

Camshaft speed sensor……………………………………………………………………………………………………………. 882

Crankshaft speed sensor/camshaft speed sensor………………………………………………………………………………………. 885

EGR gas temperature sensor……………………………………………………………………………………………………….. 887

EGR gas temperature sensor 2……………………………………………………………………………………………………… 891

Intake manifold temperature sensor………………………………………………………………………………………………… 896

Intake manifold temperature sensor 2………………………………………………………………………………………………. 900

Exhaust manifold temperature sensor……………………………………………………………………………………………….. 905

Exhaust manifold temperature sensor 2……………………………………………………………………………………………… 909

Contact output related………………………………………………………………………………………………………………. 914

Starting aid relay………………………………………………………………………………………………………………. 914

Contact input related……………………………………………………………………………………………………………….. 918

Contact input related 1………………………………………………………………………………………………………….. 918

Contact input related 2………………………………………………………………………………………………………….. 921

After treatment related……………………………………………………………………………………………………………… 924

DPF……………………………………………………………………………………………………………………………. 924

Excessive PM accumulation…………………………………………………………………………………………………….. 924

Regeneration failure 1…………………………………………………………………………………………………………… 927

Regeneration failure 2…………………………………………………………………………………………………………… 929

DPF OP interface………………………………………………………………………………………………………………… 932

Ash cleaning request…………………………………………………………………………………………………………. 932

Stationary regeneration standby……………………………………………………………………………………………….. 933

Recovery regeneration is inhibited…………………………………………………………………………………………….. 934

Backup mode…………………………………………………………………………………………………………………. 935

Actuator, etc………………………………………………………………………………………………………………………. 936

Injector……………………………………………………………………………………………………………………….. 936

Disconnection of the injector…………………………………………………………………………………………………. 936

Short circuit of the injector…………………………………………………………………………………………………. 939

SCV drive circuit……………………………………………………………………………………………………………….. 942

SCV……………………………………………………………………………………………………………………………. 945

Intake throttle…………………………………………………………………………………………………………………. 947

ECU internal and communication related………………………………………………………………………………………………… 953

ECU internal related…………………………………………………………………………………………………………….. 953

QR data………………………………………………………………………………………………………………………… 955

Pump learning not performed alarm…………………………………………………………………………………………………. 957

Intake throttle drive circuit…………………………………………………………………………………………………….. 959

Communication related……………………………………………………………………………………………………………….. 962

CAN (engine side)……………………………………………………………………………………………………………….. 962

CAN (engine side)……………………………………………………………………………………………………………….. 965

CAN (driven machine side)………………………………………………………………………………………………………… 968

EGR valve………………………………………………………………………………………………………………………. 971

EGR valve………………………………………………………………………………………………………………………. 975

DCU system error………………………………………………………………………………………………………………… 976

Data verification between ECU and DCU……………………………………………………………………………………………… 977

DCU Judgment Item………………………………………………………………………………………………………………………. 979

DCU pin layout drawing………………………………………………………………………………………………………………. 979

DCU engine side (wire-harness side)……………………………………………………………………………………………….. 979

DCU body side (wire-harness side)…………………………………………………………………………………………………. 979

Sensor related……………………………………………………………………………………………………………………… 981

SCR upstream NOx sensor 1………………………………………………………………………………………………………… 981

SCR upstream NOx sensor 2………………………………………………………………………………………………………… 985

SCR upstream NOx sensor 3………………………………………………………………………………………………………… 987

SCR downstream NOx sensor 1………………………………………………………………………………………………………. 991

SCR downstream NOx sensor 2………………………………………………………………………………………………………. 995

SCR downstream NOx sensor 3………………………………………………………………………………………………………. 997

SCR catalyst upstream temperature sensor 1………………………………………………………………………………………….1001

SCR catalyst upstream temperature sensor 2………………………………………………………………………………………….1005

SCR catalyst upstream temperature sensor 3………………………………………………………………………………………….1009

SCR catalyst upstream temperature sensor 4………………………………………………………………………………………….1013

Supply module pump pressure sensor…………………………………………………………………………………………………1017

Aqueous urea quality sensor/aqueous urea tank temperature sensor (A1DEFI)………………………………………………………………1020

Aqueous urea quality sensor (A1DEFI)……………………………………………………………………………………………….1022

Aqueous urea tank temperature sensor (A1DEFI)……………………………………………………………………………………….1023

Aqueous urea tank temperature sensor/aqueous urea tank level sensor (AT1T1I)……………………………………………………………1024

Aqueous urea tank level sensor (AT1T1I)…………………………………………………………………………………………….1026

Aqueous urea tank temperature sensor (AT1T1I)……………………………………………………………………………………….1027

Aqueous urea tank level sensor…………………………………………………………………………………………………….1028