$40

Komatsu SK714-5, SK815-5 Skid-Steer Loader Shop Manual - PDF DOWNLOAD

Komatsu SK714-5, SK815-5 Skid-Steer Loader Shop Manual

FILE DETAILS:

Komatsu SK714-5, SK815-5 Skid-Steer Loader Shop Manual

File Format : PDF

Language : English

Bookmarked : Yes

Searchable : Yes

Printable : Yes

Product Code : WEBM003400

Total Pages : 250

DESCRIPTION:

Komatsu SK714-5, SK815-5 Skid-Steer Loader Shop Manual

FOREWORD:

GENERAL:

This shop manual has been prepared as an aid to improve the quality of repairs by giving the serviceman an accurate understanding of the product and by showing him the correct way to perform repairs and make judgements. Make sure you understand the contents of this manual and use it to full effect at every opportunity. This shop manual mainly contains the necessary technical information for operations performed in a service workshop. For ease of understanding, the manual is divided into the following chapters: these chapters are further divided into the each main group of components.

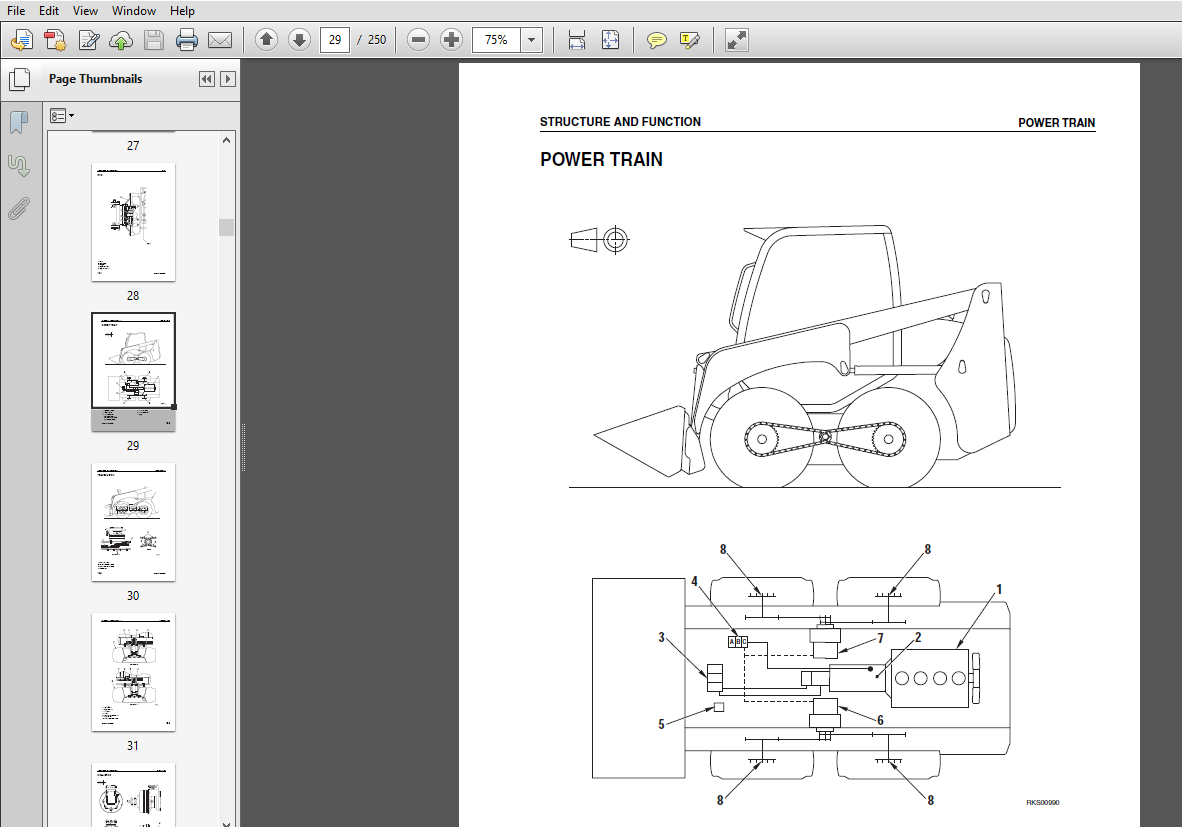

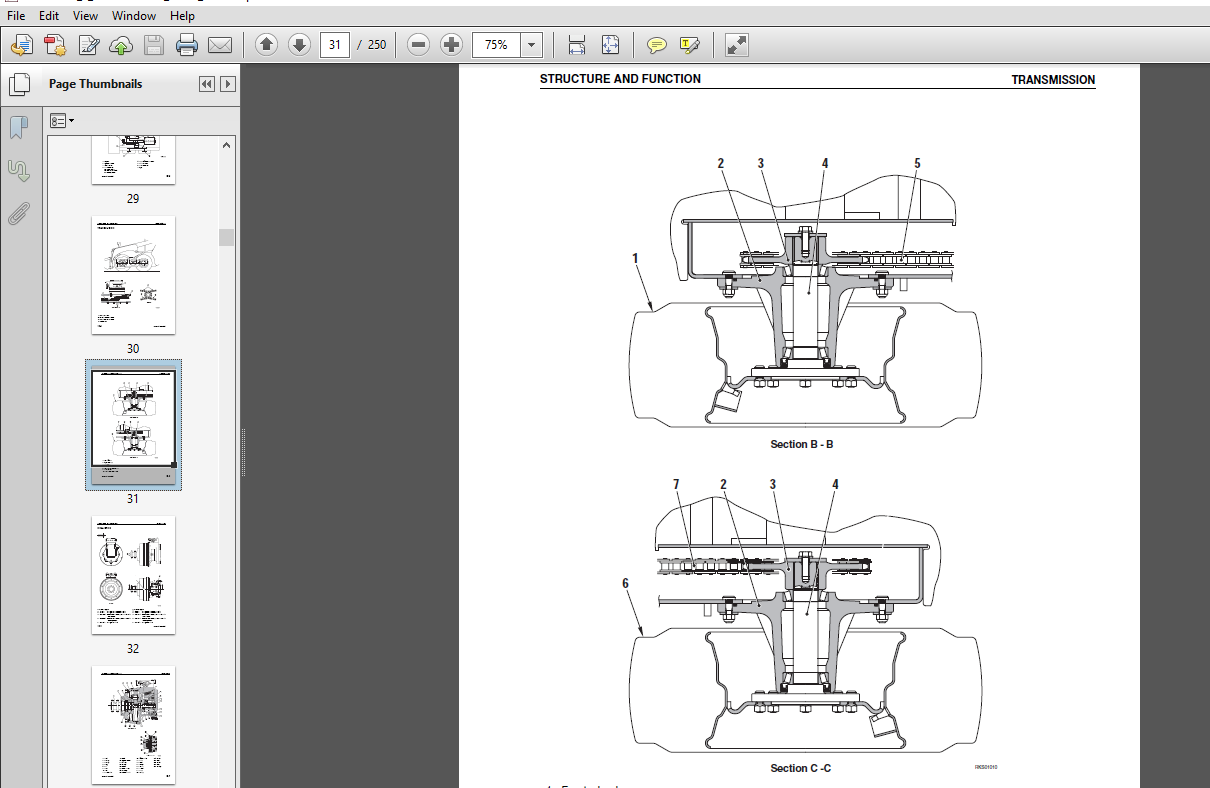

STRUCTURE AND FUNCTION:

This section explains the structure and function of each component. It serves not only to give an understanding of the structure, but also serves as reference material for troubleshooting.

TESTING AND ADJUSTING:

This section explains checks to be made before and after performing repairs , as well as adjustments to be made at completion of the checks and repairs. Troubleshooting charts correlating “problems” to “Causes” are also included in this section.

DISASSEMBLY AND ASSEMBLY:

This section explains the order to be followed when removing, installing, disassembling or assembling eachr component, as well as precautions to be taken for these operations.

MAINTENANCE STANDARD:

This section gives the judgement standards when inspecting disassembled parts.

TABLE OF CONTENTS:

Komatsu SK714-5, SK815-5 Skid-Steer Loader Shop Manual

COVER....................................................................... 1 CONTENTS.................................................................... 2 LIST OF REVISED PAGES....................................................... 3 SAFETY...................................................................... 5 FOREWORD.................................................................... 7 HOWTO READ THE SHOP MANUAL.................................................. 8 HOISTING INSTRUCTIONS....................................................... 9 STANDARD TIGHTENING TORQUE.................................................. 10 COATI NG MATERI ALS......................................................... 12 ELECTRIC.................................................................... 13 WEIGHT TABLE................................................................ 14 TABLE OF OIL AND COOLANT QUANTITIES......................................... 15 CONVERSION TABLE............................................................ 17 10. STRUCTURE AND FUNCTION.................................................. 27 P. T. O................................................................. 28 POWER TRAIN............................................................. 29 TRANSMISSION............................................................ 30 FINAL DRIVE............................................................. 32 HYDRAULIC CIRCUIT SK714- 5 (STANDARD)................................... 39 HYDRAULIC CIRCUIT SK714- 5 (ROAD HOMOLOGATION).......................... 40 HYDRAULIC CIRCUIT SK815- 5 (STANDARD)................................... 41 HYDRAULIC CIRCUIT SK815- 5 (ROAD HOMOLOGATION).......................... 42 HYDRAULIC PUMP.......................................................... 43 CONTROL VALVE (3-SPOOL)................................................. 62 CONTROL VALVE (4-SPOOL)................................................. 65 CLSS.................................................................... 69 SOLENOID VALVE.......................................................... 77 ACCUMULATOR............................................................. 79 PATTERN CHANGE VALVE (OPTIONAL)......................................... 80 R.H. PPC VALVE (STANDARD)............................................... 84 R.H. PPC VALVE (PATTERN CHANGE) (OPTIONAL).............................. 88 L.H. PPC VALVE (STANDARD)............................................... 92 L.H. PPC VALVE - PATTERN CHANGE (OPTIONAL).............................. 96 CYLINDERS...............................................................100 ELECTRICAL DIAGRAM (ENGINE LINE)........................................101 ELECTRICAL DIAGRAM (FRAME LINE STANDARD)................................105 ELECTRICAL DIAGRAM (FRAME LINE OPTIONAL)................................109 ELECTRICAL DIAGRAM (CABIN LINE STANDARD)................................113 ELECTRICAL DIAGRAM (CABIN LINE OPTIONAL)................................119 ELECTRICAL DIAGRAM (TOP- CABIN LIGHT LINE STANDARD).....................127 ELECTRICAL DIAGRAM (TOP- CABIN LIGHT LINE OMOLOGATION)..................129 ELECTRICAL DIAGRAM (TOP- CABIN LIGHT LINE OPTIONAL).....................131 20. TESTING AND ADJUSTMENTS.................................................135 NORMAL OR STANDARD TECHNICAL DATA.......................................136 SPECIAL TOOLS...........................................................148 CHECKING THE ENGINE SPEED...............................................149 ADJUSTMENT OF VALVE CLEARANCE...........................................150 MEASUREMENT OF THE COMPRESSION PRESSURE.................................151 CONTROL AND ADJUSTMENT OF THE FAN BELT TENSION..........................152 CONTROL AND ADJUSTMENT OF THE INJECTION TIMING..........................153 CHECKING ENGINE OIL PRESSURE............................................155 ADJUSTING THE STROKE OF THE ACCELERATOR CABLES..........................156 ADJUSTMENT OF THE PPC VALVE CLEARANCES..................................157 ADJUSTING THE POSITION OF THE SERVO-CONTROL ENGAGEMENT SAFETY SENSOR....158 TESTING AND ADJUSTMENT OF GEARING CHAIN TENSION.........................159 CONTROL AND REGULATION OF THE PRESSURES IN THE HYDRAULIC CIRCUITS.......160 TESTING THE HYDRAULIC PUMP..............................................161 VALVE CALIBRATION.......................................................162 CHECKING THE TRAVEL DEVIATION...........................................164 CONTROL VALVE...........................................................166 CONTROL AND REGULATION OF THE SERVO-CONTROL POWER SUPPLY................167 ELIMINATION OF RESIDUAL PRESSURES - PRESSURISATION OF THE TANK..........169 BLEEDING AIR FROM THE HYDRAULIC CIRCUITS................................170 30. REMOVAL AND INSTALLATION................................................175 HOWTO READ THE MANUAL...................................................177 PRECAUTIONS TO BE TAKEN WHILE WORKING...................................178 TILTING THE CAB.........................................................179 LOWERING THE CAB........................................................181 BATTERY.................................................................182 STARTING MOTOR..........................................................183 ALTERNATOR..............................................................184 MUFFLER.................................................................185 NOZZLE HOLDER...........................................................186 INJECTION PUMP..........................................................187 CYLINDER HEAD...........................................................190 COOLANT LIQUID PUMP.....................................................192 RADIATOR GROUP..........................................................193 FUEL TANK...............................................................195 CAB.....................................................................196 ENGINE-PUMP GROUP.......................................................199 COMPLETE HYDRAULIC PUMP.................................................202 HYDRAULIC PUMP..........................................................204 GEAR PUMP...............................................................205 ENGINE-PUMP COUPLING....................................................206 CONTROL VALVE...........................................................207 PPC VALVES..............................................................208 HUB WHEEL...............................................................209 FINAL DRIVE.............................................................213 RAISING CYLINDER........................................................215 BUCKET CYLINDER.........................................................216 WORK EQUIPMENT CYLINDERS................................................218 WORKING EQUIPMENT.......................................................224 WORKING EQUIPMENT SUPPORT FRAME.........................................226 40. STANDARD MAINTENANCE....................................................229 P. T. O.................................................................230 TRANSMISSION............................................................231 FINAL DRIVE.............................................................232 HYDRAULIC PUMP..........................................................233 CONTROL VALVE...........................................................236 R.H. PPC VALVE..........................................................242 L.H. PPC VALVE..........................................................243 PATTERN CHANGE VALVE (OPTIONAL).........................................245 CYLINDERS...............................................................246 WORKING EQUIPMENT.......................................................248

IMAGES PREVIEW OF THE MANUAL: