$46

Komatsu WA1200-3 Wheel Loader Shop Manual SEBM018231 – PDF DOWNLOAD

Komatsu WA1200-3 Wheel Loader Shop Manual SEBM018231 – PDF DOWNLOAD

FILE DETAILS:

Komatsu WA1200-3 Wheel Loader Shop Manual SEBM018231 – PDF DOWNLOAD

Language : English

Pages : 2502

Downloadable : Yes

File Type : PDF

Size: 137 MB

TABLE OF CONTENTS:

Komatsu WA1200-3 Wheel Loader Shop Manual SEBM018231 – PDF DOWNLOAD

COVER 1

CONTENTS 2

LIST OF REVISED PAGE 3

00 FOREWORD 17

SAFETY NOTICE 17

HOW TO READ THE SHOP MANUAL 26

EXPLANATION OF TERMS FOR MAINTENANCE STANDARD 28

HOW TO READ ELECTRIC WIRE CODE 30

PRECAUTIONS WHEN CARRYING OUT OPERATION 33

METHOD OF DISASSEMBLING AND CONNECTING PUSH-PULL TYPE COUPLER 36

STANDARD TIGHTENING TORQUE TABLE 39

CONVERSION TABLE 43

01 GENERAL 49

GENERAL ASSEMBLY DRAWING 50

SPECIFICATIONS 51

WEIGHT TABLE 54

LIST OF LUBRICANT AND WATER 56

10 STRUCTURE AND FUNCTION 59

OUTLINE 60

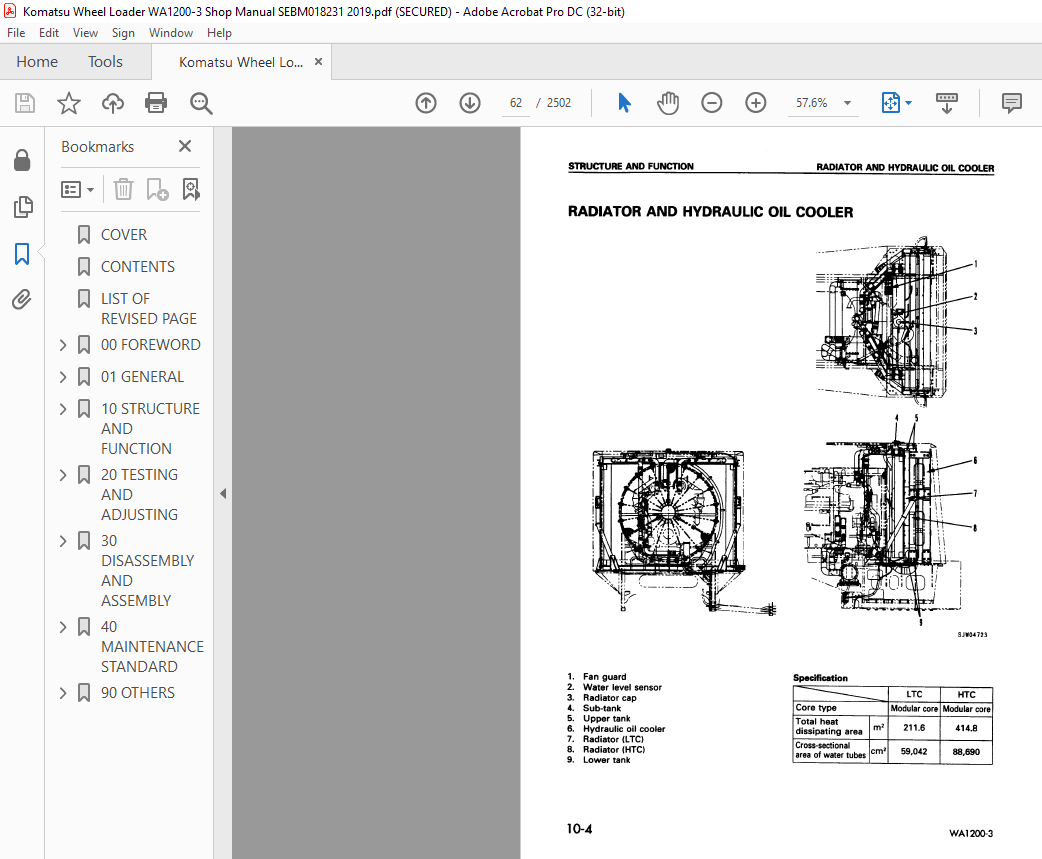

TADIATOR AND HYDRAULIC OIL COOLER 62

DAMPER 63

TORQUE CONVERTER AND TRANSMISSION PIPING 64

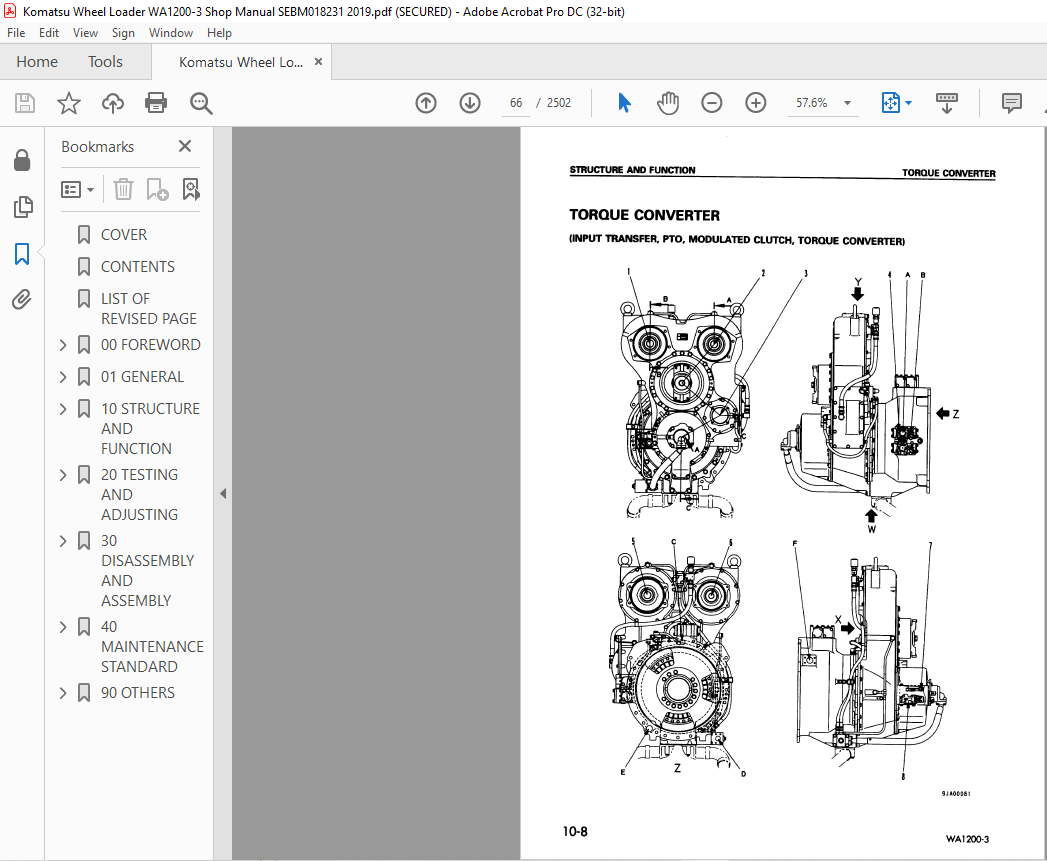

TORQUE CONVERTER 66

MAIN RELIEF VALVE AND TORQUE CONVERTER RELIEF VALVE 74

TORQUE CONVERTER REGULATOR VALVE 78

ECMV 80

TRANSMISSION 86

TRANSMISSION CONTROL VALVE 96

LUBRICATING OIL RELIEF VALVE 107

TRANSFER 108

TORQUE CONVERTER OIL COOLER 110

CENTER SUPPORT 111

AXLE 112

FINAL DRIVE 117

AXLE MOUNT 120

CENTER HINGE PIN 122

JACK-UP POINT 123

ARRANGEMENT OF STEERING EQUIPMENT 125

AJSS (ADVANCED JOYSTICK STEERING SYSTEM) 126

STEERING PUMP 127

SWITCH PUMP 130

SERVO VALVE 133

STEERING DEMAND VALVE 137

ROTARY VALVE 148

EPC VALVE 151

DIVERTER VALVE 152

ARRANGEMENT OF BRAKE EQUIPMENT 156

BRAKE VALVE 158

HARGE VALVE 163

ACCUMULATOR (FOR BRAKE) 167

SLACK ADJUSTER 168

BRAKE 171

PARKING BRAKE 172

PARKING BRAKE OIL CIRCUIT CHECK VALVE ASSEMBLY 174

ARRANGEMENT OF HYDRAULIC EQUIPMENT 178

WORK EQUIPMENT LEVER LINKAGE 180

HYDRAULIC TANK 181

WORK EQUIPMENT PUMP NO 1 184

WORK EQUIPMENT PUMP NO 2 197

WORK EQUIPMENT PUMP NEUTRAL CUT VALVE (NC VALVE) 214

PPC VALVE (PROPORTIONAL PRESSURE VALVE) 216

PPC RELIEF VALVE 220

ACCUMULATOR(FOR PPC VALVE) 221

MAIN CONTROL VALVE 222

WORK EQUIPMENT LINKAGE 236

OPERATION OF PROXIMITY SWITCH 238

AIR CONDITIONER 240

MACHINE MONITOR SYSTEM 243

MAIN MONITOR 247

CGC MONITOR 251

MULTI MONITOR 292

ALL-RANGE ELECTRONIC CONTROL AUTOMATIC TRANSMISSION (ATM) SYSTEM 328

MODULATED CLUTCH (MOD/C) CONTROL SYSTEM 343

WORK EQUIPMENT AND JOYSTICK STEERING CONTROL SYSTEM 347

WORK EQUIPMENT AND JOYSTICK STEERING CONTROLLER 357

ENGINE STARTING CIRCUIT 358

ENGINE STOPPING CIRCUIT 364

ETHER INJECTION CIRCUIT 366

ELECTRIC PARKING BRAKE CONTROL 368

PARKING BRAKE SOLENOID VALVE 378

EMERGENCY PARKING BRAKE RESET SOLENOID VALVE 379

KICK-DOWN SWITCH AND AUTO SHIFT/MANUAL SHIFT SELECTOR SWITCH 380

BATTERY DISCONNECTOR SWITCH 382

EMERGENCY ENGINE STOP SWITCH (FOR RIO TINTO) 384

HYDRAULIC OIL LEVEL CAUTION DISPLAY (FOR RIO TINTO) 387

20 TESTING AND ADJUSTING 391

STANDARD VALUE TABLE 391

STANDARD VALUE TABLE FOR ENGINE 392

STANDARD VALUE TABLE FOR CHASSIS 393

STANDARD VALUE TABLE FOR ELECTRICAL PARTS 399

TESTING AND ADJUSTING 421

ITEMS TO BE PREPARED LIST OF DEVICES FOR TROUBLESHOOTING 424

SAFETY PRECAUTIONS BEFORE STARTING WORK 428

ITEMS RELATED TO ENGINE MEASURING ENGINE SPEED 431

MEASURING EXHAUST GAS COLOR 435

MEASURING BLOW-BY PRESSURE 436

MEASURING ENGINE OIL PRESSURE 438

MEASURING EXHAUST TEMPERATURE 440

MEASURING BOOSTP RESSURE 442

PERFORMANCE CHECK OF RADIATOR 444

MEASURING WIND VELOCITY THROUGH RADIATOR AND OIL COOLER 445

TESTING AND ADJUSTING FAN BELT TENSION 447

TESTING AND ADJUSTING BELT TENSION OF AIR CONDITIONER COMPRESSOR 447

ADJUSTING ROTATION SENSOR 448

POWER TRAIN TESTING AND ADJUSTING TORQUE CONVERTER AND TRANSMISSION OIL PRESSURE 450

TRACTION CONTROL FUNCTION CHECK PROCEDURE 458

PERFORMANCE CHECK OF TORQUE CONVERTER OIL COOLER 459

MEASURING FAN SPEED FOR ADDITIONAL COOLER 460

FLUSHING PROCEDURE FOR HYDRAULIC CIRCUIT OF TORQUE CONVERTER AND TRANSMISSION 461

HOW TO MOVE MACHINE WHEN TRANSMISSION VALVE IS BROKEN 462

HOW TO MEASURE CLEARANCE (PLAY) IN CENTER HINGE BEARING 466

MEASUREMENT PROCEDURE FOR WEAR OF REAR AXLE SUPPORT 468

STEERING SYSTEM TESTING AND ADJUSTING STEERING OIL PRESSURE 469

TESTING AND ADJUSTING EMERGENCY STEERING OIL PRESSURE 471

BLEEDING AIR FROM STEERING CIRCUIT 473

ADJUSTING STEERING STOPPER BOLT 475

ADJUSTING STEERING FOLLOW-UP LINKAGE 476

TESTING STEERING EPC VALVE 481

TESTING AND ADJUSTING STEERING SURGE CUT VALVE OIL PRESSURE 483

TESTING AND ADJUSTING STEERING MAIN RELIEF VALVE OIL PRESSURE 485

MEASURING ROTARY VALVE OUTPUT PRESSURE 489

BRAKE SYSTEM TESTING DROP OF WHEEL BRAKE OIL PRESSURE 491

TESTING WHEEL BRAKE FUNCTION 492

CHECKING SLACK ADJUSTER 493

MEASURING WEAR OF WHEEL BRAKE DISC 495

TESTING AND ADJUSTING CHARGE CUT-IN AND CUT-OUT PRESSURE OF ACCUMULATOR 496

TESTING BRAKE ACCUMULATOR FOR LEAKAGE 500

TESTING EMERGENCY PARKING BRAKE VALVE FOR OIL LEAKAGE 502

TESTING BRAKE VALVE FOR OIL LEAKAGE 504

TESTING BRAKE COOLING OIL PRESSURE 508

PERFORMANCE CHECK OF BRAKE OIL COOLER 510

TESTING PARKING BRAKE PERFORMANCE 511

TESTING WEAR OF PARKING BRAKE DISC 512

HOW TO RESET PARKING BRAKE MANUALLY 513

MEASURING PARKING BRAKE OIL PRESSURE 514

HYDRAULIC EQUIPMENT TESTING AND ADJUSTING WORK EQUIPMENT OIL PRESSURE 515

MEASUREMENT PROCEDURE OF WORK EQUIPMENT OIL PRESSURE WITH OIL PRESSURE GAUGE 519

TESTING AND ADJUSTING PPC OIL PRESSURE 521

ADJUSTING PPC VALVE LINKAGE 526

MEASURING POINTS OF HYDRAULIC PUMP OIL PRESSURE 528

HYDRAULIC PUMP PIPING LINE 530

TESTING AND ADJUSTING PV CONTROL RELIEF VALVE OIL PRESSURE 532

TESTING AND ADJUSTING DIFFERENTIAL PRESSURE VALVE CONTROL OIL PRESSURE 533

TESTING WORK EQUIPMENT PUMP ES VALVE OUTPUT PRESSURE 536

TESTING AND ADJUSTING WORK EQUIPMENT PUMP CO VALVE (CUT-OFF) OIL PRESSURE 538

TESTING WORK EQUIPMENT CONTROL VALVE OPERATION BY WORK EQUIPMENT SPEED (WORK EQUIPMENT SPEED IS LOW) 546

PERFORMANCE CHECK OF HYDRAULIC OIL COOLER (CHECK BY TEMPERATUREDIFFERENCE) 554

PERFORMANCE CHECK OF HYDRAULIC OIL COOLER (CHECK BY MEASURING OIL PRESSURE) 555

BLEEDING AIR FROM EACH PART 559

RELEASING RESIDUAL PRESSURE FROM HYDRAULIC CIRCUIT 566

TESTING OF ACCUMULATOR NITROGEN GAS PRESSURE AND PROCEDURE FOR CHARGING ACCUMULATOR WITH NITROGEN GAS 567

WORK EQUIPMENT SYSTEM CHECKING AND ADJUSTING WORK EQUIPMENT CONTROL LEVER LINKAGE 579

ELECTRICAL EQUIPMENT TESTING AND ADJUSTING BUCKET PROXIMITY SWITCH 583

TESTING AND ADJUSTING LIFT ARM POTENTIOMETER 584

ADJUSTING LIFT ARM HORIZONTAL DETECTION SWITCH 585

PROCEDURE FOR SETTING INITIAL VALUE FOR REMOTE LIFT ARM POSITIONER (METHOD OF INPUTTING BASE POINT) 586

CHECKING PROXIMITY SWITCH ACTUATION PILOT LAMP 589

INITIAL LEARNING METHOD OF TRANSMISSION CONTROLLER 590

ADJUSTING MAIN MONITOR (SPEEDOMETER MODULE) 591

ADJUSTING STEERING LEVER ANGLE AND FRAME ANGLE SENSORS 592

CHECKING AND ADJUSTING INSTALLED POSITIONS OF POTENTIOMETERS 594

PROCEDURE FOR CHECKING DIODE 598

CHECKING GREASING CONDITION OF CENTER HINGE PIN PORTION 599

METHOD OF ADJUSTING AUTO-GREASE INJECTOR DISCHARGE AMOUNT 600

METHOD OF SETTING AUTO-GREASE TIMER 601

VHMS CONTROLLER BASIC PRECAUTIONS 603

TESTING AND MAINTAINING VHMS CONTROLLER 609

VHMS CONTROLLER INITIAL SETTING PROCEDURE 610

PRECAUTIONS FOR REPLACING VHMS CONTROLLER 628

MEASUREMENT PROCEDURE BY DOWNLOADING DATA IN VHMS CONTROLLER 636

MEASUREMENT PROCEDURE BY CGC MONITOR 643

MEASUREMENT PROCEDURE BY MULTI MONITOR 645

SPECIAL FUNCTIONS OF MACHINE CONTROL MONITOR (MULTI MONITOR) 647

OUTLINE OF MEASUREMENT PROCEDURE FOR PM CLINIC 702

PREPARATION FOR MEASUREMENT FOR PM CLINIC 704

Pm clinic check sheet 706

TROUBLESHOOTING 711

POINTS TO REMEMBER WHEN TROUBLESHOOTING 712

SEQUENCE OF EVENTS IN TROUBLESHOOTING 713

CHECKS BEFORE TROUBLESHOOTING 714

TROUBLESHOOTING PROCEDURE FOR WORK EQUIPMENT HYDRAULIC SYSTEM AND STEERING SYSTEM 726

HANDLING OF ELECTRIC EQUIPMENT AND HYDRAULIC COMPONENT 736

CONNECTOR TYPES AND MOUNTING LOCATIONS 745

CONNECTOR ARRANGEMENT DIAGRAM 752

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS 762

T-BRANCH BOX AND T-BRANCH ADAPTER TABLE 798

EXPLANATION OF FUNCTIONS OF ELECTRIC CONTROL MECHANISM 801

METHOD OF DISPLAYING ACTION CODE AND FAILURE CODE 807

FAILURE CODES LIST 820

METHOD OF USING JUDGEMENT TABLE 827

METHOD OF USING TROUBLESHOOTING CHARTS 828

METHOD OF USING MATRIX TROUBLESHOOTING TABLES 830

TROUBLESHOOTING OF ENGINE CONTROLLER SYSTEM (G MODE) 833

DISPLAY METHOD OF CUMMINS ENGINE CONTROLLERFAILURE CODES AND CONTENTS OF DISPLAY 834

FAILURE CODES AND ACTIONS TABLE 835

TROUBLESHOOTING OF TRANSMISSION CONTROLLER SYSTEM (T MODE) 843

JUDGEMENT TABLE FOR TRANSMISSION CONTROL SYSTEM RELATED PARTS 846

OPERATIONS OF CONTROLLER AGAINST ABNORMALITY AND CONDITIONS OF MACHINE CAUSED BY ABNORMALITY 848

ELECTRICAL CIRCUIT DIAGRAM FOR TRANSMISSION CONTROLLER SYSTEM 858

T-1 Failure code [10] (Short circuit, disconnection, short circuit with power source in backup lamp relay) is displayed 860

T-2 Error code [11] (Disconnection in modulated clutch outlet rotation signal sensor system) is displayed 861

T-3 Error code [12] (Short circuit, disconnection, or short circuit with power source in F solenoid system) is displayed 862

T-4 Error code [13] (Short circuit, disconnection, or short circuit with power source in R solenoid system) is displayed 863

T-5 Error code [14] (Short circuit, disconnection, or short circuit with power source in 1st solenoid system) is displayed 864

T-6 Error code [15] (Short circuit, disconnection, or short circuit with power source in 2nd solenoid system) is displayed 865

T-7 Error code [16] (Short circuit, disconnection, or short circuit with power source in 3rd solenoid system) is displayed 866

T-8 Error code [18] (Short circuit, disconnection, or short circuit with power source in R clutch drain valve solenoid system) is displayed 867

T-9 Error code [20] (Short circuit or disconnection in joystick FNR switch system) is displayed 868

T-10 Error code [21] (Short circuit or disconnection in joystick shift-up/shift-down switch system) is displayed 869

T-11 Error code [22] (Disconnection in travel speed sensor system) is displayed 870

T-12 Error code [23] (Short circuit or disconnection in engine speed sensor system) is displayed 871

T-13 Failure code [24] (Short circuit, disconnection in EEP ROM) is displayed 872

T-14 Error code [25] (Short circuit in transmission oil temperature sensor system) is displayed 873

T-15 Error code [26] (Short circuit in F ECMV fill switch system) is displayed 874

T-16 Error code [27] (Short circuit in R ECMV fill switch system) is displayed 874

T-17 Error code [28] (Short circuit in 1st ECMV fill switch system) is displayed 875

T-18 Error code [29] (Short circuit in 2nd ECMV fill switch system) is displayed 875

T-19 Error code [30] (Short circuit in 3rd ECMV fill switch system) is displayed 876

T-20 Error code [32] (Disconnection in F or R ECMV fill switch system) is displayed 877

T-21 Error code [33] (Disconnection in 1st, 2nd, or 3rd ECMV fill switch system) is displayed 878

T-22 Error code [34] (Disconnection or 3rd short circuit with power source in F bypass solenoid system) is displayed 879

T-23 Error code [35] (Short circuit in F bypass solenoid system) is displayed 880

T-24 Error code [36] (Disconnection or short circuit with power source in R bypass solenoid system) is displayed 881

T-25 Error code [37] (Short circuit in R bypass solenoid system) is displayed 882

T-26 Error code [38] (Disconnection or short circuit with power source in 1st bypass solenoid system) is displayed 883

T-27 Error code [39] (Short circuit in 1st bypass solenoid system) is displayed 884

T-28 Auto/Manual selector switch system 885

T-29 Kickdown switch system 885

T-30 Transmission cut-off switch signal system 886

T-31 Steering lock switch signal system 887

T-32 Neutralizer relay signal system 888

T-33 Buzzer signal system 889

T-34 Network system 890

T-35 Transmission controller power supply system 891

T-36 Short circuit in travel speed sensor system 892

T-37 Short circuit in modulated clutch outlet rotation sensor system 893

T-38 Disconnection in transmission oil temperature sensor system 894

T-39 F1 (Forward 1st gear) signal system 895

T-40 Abnormality in auto shift indicator lamp 896

TROUBLESHOOTING OF MODULATED CLUTCH CONTROLLER SYSTEM (MC MODE) 899

JUDGEMENT TABLE FOR MODULATED CLUTCH CONTROL SYSTEM RELATED PARTS 900

OPERATIONS OF CONTROLLER AGAINST ABNORMALITY AND CONDITIONS OF MACHINE CAUSED BY ABNORMALITY 902

ELECTRIC CIRCUIT DIAGRAM OF MODULATED CLUTCH CONTROL SYSTEM 908

MC-1 Error code [70] (Disconnection in boom RAISE/LOWER or bucket TILT/DUMP pressure switch system) is displayed 910

MC-2 Error code [72] (Abnormality in accelerator pedal sensor system) is displayed 912

MC-3 Error code [73] (Short circuit in F/R ECMV fill switch system) is displayed 913

MC-4 Error code [74] (Disconnection in 1st, 2nd, or 3rd ECMV fill switch system) is displayed 914

MC-5 Error code [75] (Short circuit with chassis ground in 1st, 2nd, or 3rd ECMV fill switch system) is displayed 915

MC-6 Error code [76] (Short circuit in RPM-SET IDLE-UP/RESUME IDLE-DOWN switch system) is displayed 916

MC-7 Error code [77] (Short circuit or disconnection in drive force control dial system) is displayed 917

MC-8 Error code [78] (Short circuit or disconnection in travel speed control dial system) is displayed 918

MC-9 Error code [80] (Short circuit or disconnection in wheel rotation sensor system) is displayed 919

MC-10 Error code [81] (Short circuit, disconnection, or short circuit with power source in modulated clutch outlet rotation sensor system) is displayed 920

MC-11 Error code [82] (Short circuit, disconnection, or short circuit with power source in engine speed sensor system) is displayed 921

MC-12 Error code [83] (Short circuit or disconnection in travel speed sensor system) is displayed 922

MC-13 Error code [84] (Short circuit, disconnection, or short circuit with power source in neutral cut solenoid system) is displayed 924

MC-14 Error code [85] (Short circuit, disconnection, or short circuit with power source in modulated clutch ECMV solenoid system) is displayed 925

MC-15 Short circuit in boom RAISE/LOWER or bucket TILT/DUMP pressure switch system 926

MC-16 Disconnection in F ECMV fill switch system 927

MC-17 Disconnection in R ECMV fill switch system 927

MC-18 Disconnection in RPM-SET IDLE-UP/RESUME IDLE-DOWN switch system 928

MC-19 Abnormality in electronic governor voltage command system 929

MC-20 Abnormality in transmission cut-off signal system 930

MC-21 Abnormality in modulated clutch ECMV fill switch system 931

MC-22 Abnormality in right brake pedal switch system 932

MC-23 Abnormality in travel speed control ON/OFF switch system 933

MC-24 Abnormality in RPM-SET ON/OFF switch system 934

MC-25 Abnormality in engine rotation output signal system 935

MC-26 Abnormality in power supply system of modulated clutch control system 936

MC-27 Abnormality in network system 937

MC-28 Abnormality in F1 (Forward 1st gear) input signal system 937

TROUBLESHOOTING OF WORK EQUIPMENT CONTROLLER (JOYSTICK STEERING CONTROL) SYSTEM (J MODE) 939

JUDGEMENT TABLE FOR WORK EQUIPMENT CONTROL SYSTEM RELATED PARTS 940

OPERATIONS OF CONTROLLER AGAINST ABNORMALITY AND CONDITIONS OF MACHINE CAUSED BY ABNORMALITY 942

ELECTRICAL CIRCUIT DIAGRAM FOR JOYSTICK STEERING SYSTEM 946

J-1 Error code [55] (Abnormality in travel speed sensor system) is displayed 947

J-2 Error code [56] (Disconnection or short circuit with chassis ground in caution buzzer relay system) is displayed 948

J-3 Error code [57] (Disconnection or short circuit with chassis ground in steering lever angle sensor system) is displayed 949

J-4 Error code [58] (Deviation of steering lever angle sensor and frame angle sensor potentiometer signals 950

J-5 Error code [59] (Disconnection or short circuit with chassis ground in frame angle sensor system) is displayed 951

J-6 Error code [61] (Disconnection or short circuit with chassis ground in steering lever lock pressure switch system) is displayed 952

J-7 Error code [62] (Disconnection or short circuit with chassis ground in steering neutral interlock relay system) is displayed 953

J-8 Error code [63] (Disconnection, short circuit with chassis ground, or short circuit with power source in steering main pressure control EPC solenoid system) is displayed 954

J-9 Short circuit with chassis ground in travel speed sensor system 955

J-10 Steering speeds in both directions are different 956

J-11 Abnormality in console switch (adjustment of steering lever angle sensor and frame angle sensor is impossible) 957

J-12 Abnormality in power source and voltage 958

TROUBLESHOOTING OF WORK EQUIPMENT CONTROLLER (REMOTE BOOM POSITIONER CONTROL) SYSTEM (W MODE) 959

JUDGEMENT TABLE FOR WORK EQUIPMENT CONTROLLER (REMOTE BOOM POSITIONER CONTROLLER SYSTEM) RELATED PARTS 960

ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE 962

ELECTRICAL CIRCUIT DIAGRAM FOR WORK EQUIPMENT CONTROLLER SYSTEM 964

W-1 Failure code [43] (Short circuit, disconnection in damping solenoid) is displayed 966

W-2 Failure code [44] (Short circuit in power source at hot end of damping solenoid) is displayed 967

W-3 Failure code [45] (Short circuit in power source at return end of damping solenoid) is displayed 967

W-4 Failure code [49] (Short circuit, disconnection in boom lever kick-out relay system) is displayed 968

W-5 Failure code [51] (Disconnection in boom RAISE, LOWER detection pressure switch) is displayed 969

W-6 Failure code [52] (Short circuit, disconnection in boom angle potentiometer system) is displayed 970

W-7 Sensor cannot be adjusted 971

W-8 Abnormality in engine speed signal system 971

W-9 Remote positioner RAISE, LOWER LEDs do not light up 972

W-10 Remote positioner RAISE stop lamp (CGC monitor) does not flash (for 2 5 seconds) 973

W-11 Remote positioner LOWER stop lamp (CGC monitor) does not flash (for 2 5 seconds) 973

W-12 Buzzer for switch operation does not sound 974

W-13 Shock when stopping boom (abnormality in boom lever detent switch) 975

W-14 Short circuit in boom RAISE, LOWER pressure detection switch 976

TROUBLESHOOTING OF MAIN MONITOR SYSTEM (M MODE) 977

TROUBLE DATA DISPLAY 979

ELECTRICAL CIRCUIT DIAGRAM OF MAIN MONITOR SYSTEM 980

M-1 Main monitor does not work 982

M-2 When starting switch is turned ON (within 3 seconds) and engine is started (PRE-LUBE) immediately, all lamps stay lighted up 983

M-3 Speedometer display does not work properly 984

M-4 Abnormality in shift indicator 985

a) Displays N even when directional lever is at F 985

b) Displays N even when directional lever is at R 985

c) Does not display N even when FNR (Forward-reverse) switch is set in N 986

d) Does not display F even when FNR (Forward-reverse) switch is set in F 986

e) Does not display R even when FNR (Forward-reverse) switch is set in R 986

M-5 Turn signal display does not light up 988

a) L H turn signal display does not light up 988

b) R H turn signal display does not light up 988

M-6 Abnormality in parking display 989

a) Parking lamp display does not light up 989

b) Parking lamp display stays lighted up 989

M-7 Night lighting does not light up 990

M-8 Abnormality in front working lamp 991

a) Neither monitor display nor front working lamp light up 991

b) Working lamp lights up but monitor display does not light up 991

c) Monitor display lights up but front working lamp does not light up 991

M-9 Abnormality in rear working lamp 993

a) Neither monitor display nor rear working lamp light up 993

b) Rear working lamp lights up but monitor display does not light up 993

c) Monitor display lights up but working lamp does not light up 993

M-10 Abnormality in transmission cut-off 995

a) When monitor switch (transmission cut-off switch) is pressed, cut-off function is not switched and display does not change 995

b) When monitor switch (transmission cut-off switch) is OFF, monitor display goes out but cut-off function is actuated when pedal is depressed 995

c) When monitor display is turned off (transmission cut-off switch turned OFF), cut-off function is always actuated 995

d) Cut-off function is always actuated regardless of monitor display (transmission cut-off switch ON or OFF) 995

e) Monitor display lights up (transmission cut-off switch turned ON), but cut-off function is not actuated 996

M-11 Abnormality in emergency steering normal display Emergency steering normal display does not light up 997

M-12 Abnormality in emergency steering actuation display 998

a) Emergency steering actuation display does not light up 998

b) Emergency steering actuation display stays lighted up 998

M-13 Abnormality in parking brake dragging warning 999

a) When parking brake is applied, buzzer sounds (intermittently) and CAUTION lamp flashes even when directional lever is at N 999

b) When parking brake is applied, buzzer does not sound and CAUTION lamp does not light up even when directional lever is at position other than N 999

M-14 Abnormality in parking brake dragging warning (When joystick steering mode) 1001

a) When parking brake is applied, buzzer sounds (intermittently) and CAUTION lamp flashes even when directional lever is at N 1001

b) When parking brake is applied, buzzer does not sound and CAUTION lamp does not light up even when directional lever is at position other than N 1001

M-15 When parking brake dragging warning is given, buzzer and CAUTION lamp are actuated continuously, or they are not actuated 1003

a) Actuated continuously 1003

b) Not actuated 1003

M-16 Abnormality in buzzer 1004

a) Buzzer does not sound when starting switch is at ON (for 3 seconds) (during self-check) 1004

b) Buzzer always sounds 1004

M-17 Condition of monitor switches is not stored in memory 1006

M-18 Service meter does not advance or advances while engine is stopped 1007

a) Service meter does not advance 1007

b) Service meter advances while engine is stopped 1007

M-19 Buzzer is not made to sound by transmission controller 1008

M-20 Abnormality in auto-greasing system 1009

a) Forced greasing cannot be carried out 1009

b) Monitor display flashes rapidly (2 times/sec) 1009

c) Monitor display flashes slowly (1 time/sec) 1009

M-21 Failure code is not sent to main monitor (abnormality in network) 1011

TROUBLESHOOTING OF VHMS CONTROLLER SYSTEM (V MODE) 1013

OPERATIONS OF VHMS CONTROLLER AGAINST ABNORMALITY AND CONDITIONS OF MACHINE CAUSED BY ABNORMALITY 1016

LIST OF ALARM ITEMS DISPLAYED ON CGC MONITOR 1032

ELECTRICAL CIRCUIT DIAGRAM FOR VHMS SYSTEM 1034

V-1 [E901] (Engine oil level below LOW level) is displayed 1036

V-2 [E902] (Engine oil pressure below specified pressure) is displayed 1036

V-4 [E904] (Engine coolant temperature above specified temperature) is displayed 1036

V-5 [E905] [Fuel level below specified level (before engine starts)] is displayed 1037

V-6 [E906] [Fuel level below specified level (While engine is running)] is displayed 1039

V-7 [E907] (Torque converter oil temperature above 120°C) is displayed 1041

V-8 [E908] (Torque converter oil temperature above 130°C) is displayed 1042

V-9 [E911] (Hydraulic oil temperature above 105°C) is displayed 1043

V-10 [E912] (Low front or rear brake oil pressure) is displayed 1044

V-11 [E913] (Low front brake oil pressure) is displayed 1046

V-12 [E915] (Low rear brake oil pressure) is displayed 1048

V-13 [916] (Disconnection or short circuit with chassis ground in battery fluid level sensor “1”) is displayed 1050

V-14 [917] (Disconnection or short circuit with chassis ground in battery fluid level sensor “2”) is displayed 1051

V-15 [918] (Disconnection or short circuit with chassis ground in battery fluid level sensor “3”) is displayed 1052

V-16 [E925] [Brake fluid level below specified level (before engine starts)] is displayed 1053

V-17 [E926] [Brake fluid level below specified level (While engine is running)] is displayed 1054

V-18 [E927] [Coolant level below LOW level (before engine starts] is displayed 1055

V-19 [E928] [Coolant level below LOW level (While engine is running)] is displayed 1056

V-20 [E931] (Clogging of transmission oil filter) is displayed 1057

V-21 [E932] [Clogging of air cleaner (1)] is displayed 1059

V-22 [E933] [Clogging of air cleaner (2)] is displayed 1061

V-23 [E934] [Clogging of air cleaner (3)] is displayed 1062

V-24 [E935] [Clogging of air cleaner (4)] is displayed 1063

V-25 [E937] (Abnormal charge by alternator) is displayed 1064

V-101 [E811] (Abnormality in NSW power source system) is displayed in history 1065

V-102 [E812] (Short circuit with chassis ground in 24-V circuit of sensor power supply) 1066

V-103 [E813] (Short circuit with chassis ground in 12-V circuit of sensor power supply) 1068

V-104 [E814] (Short circuit with chassis ground in 5-V circuit of sensor power supply) 1069

V-105 [E818] (Wrong connection of connector) is displayed in history 1070

V-107 [E824] (Communication with CGC and engine controller is impossible) is displayed in history 1071

V-108 [E825] (Abnormality in S-NET communication between VHMS – transmission controller) is displayed in history 1072

V-109 [E826] (Abnormality in S-NET communication between VHMS – modulated clutch controller) is displayed in history 1074

V-110 [E827] (Abnormality in S-NET communication between VHMS – work equipment controller) is displayed in history 1076

V-111 [E828] (Abnormality in S-NET communication between VHMS – main monitor) is displayed in history 1078

V-113 [E841] (Short circuit with power source in buzzer output system) is displayed in history 1081

V-114 [E843] (Short circuit with power source in check lamp system) is displayed in history 1082

V-115 [E844] (Short circuit with power source in flash synchronizing signal system) is displayed in history 1083

V-116 [E861] (Disconnection or short circuit with chassis ground in boom bottom pressure sensor system) is displayed in history 1084

V-117 [E862] (Disconnection or short circuit with chassis ground in boom head pressure sensor system) is displayed in history 1086

V-118 [E863] (Disconnection or short circuit with chassis ground in rear brake oil pressure sensor system) is displayed in history 1088

V-119 [E864] (Disconnection or short circuit with chassis ground in work equipment relief pressure sensor system) is displayed in history 1090

V-120 [E865] (Disconnection or short circuit with chassis ground in front brake oil pressure sensor system) is displayed in history 1092

V-121 [E866] (Disconnection or short circuit with chassis ground in transmission main relief pressure sensor system) is displayed in history 1094

V-122 [E867] (Disconnection or short circuit with chassis ground in steering relief pressure sensor system) is displayed in history 1096

V-123 [E868] (Disconnection or short circuit with chassis ground in torque converter outlet oil pressure sensor system) is displayed in history 1098

V-124 [E871] (Disconnection or short circuit with chassis ground in transmission modulation pressure sensor system) is displayed in history 1100

V-125 [E872] (Disconnection or short circuit with chassis ground in transmission lubricating oil pressure sensor system) is displayed in history 1102

V-126 [E874] (Short circuit with chassis ground in torque converter oil temperature sensor system) is displayed in history 1104

V-127 [E875] (Short circuit with chassis ground and with power source in hydraulic oil temperature sensor system) is displayed in history 1105

V-128 [E877] (Short circuit with chassis ground in ambient temperature sensor system) is displayed in history 1106

V-129 [E878] (Disconnection or short circuit with chassis ground in PPC relief pressure sensor system) is displayed in history 1108

V-130 [E884] (Disconnection or short circuit with chassis ground in torque converter inlet oil pressure sensor system) is displayed in history 1110

V-201 Disconnection or short circuit with power source in 24-V system of sensor power supply 1112

V-202 Disconnection or short circuit with power source in 12-V system of sensor power supply 1114

V-203 Disconnection or short circuit with power source in 5-V system of sensor power supply 1115

V-204 Disconnection or short circuit with chassis ground in buzzer output system 1116

V-205 Disconnection or short circuit with chassis ground in check lamp system 1117

V-206 Disconnection or short circuit with chassis ground in flash synchronizing signal system 1118

V-207 Short circuit with power source in boom bottom pressure sensor system 1119

V-208 Short circuit with power source in boom head pressure sensor system 1120

V-209 Short circuit with power source in rear brake oil pressure sensor system 1121

V-210 Short circuit with power source in front brake oil pressure sensor system 1122

V-211 Short circuit with power source in work equipment relief pressure sensor system 1123

V-212 Short circuit with power source in transmission relief pressure sensor system 1124

V-213 Short circuit with power source in steering relief pressure sensor system 1125

V-214 Short circuit with power source in torque converter outlet oil pressure sensor system 1126

V-215 Short circuit with power source in transmission modulation pressure sensor system 1127

V-216 Disconnection or short circuit with power source in torque converter oil temperature sensor 1128

V-217 Disconnection in hydraulic oil temperature sensor system 1129

V-218 Disconnection in ambient temperature sensor system 1130

V-219 Short circuit with power source in PPC relief sensor system 1131

V-220 Short circuit with chassis ground in fuel level sensor system 1132

V-221 Short circuit with power source in battery fluid level sensor “1” 1133

V-222 Short circuit with power source in battery fluid level sensor “2” 1134

V-223 Short circuit with power source in battery fluid level sensor “3” 1135

V-224 Short circuit with chassis ground or power source in brake fluid level sensor 1136

V-225 Short circuit with power source in coolant level sensor 1137

V-226 Short circuit with chassis ground or power source in transmission oil filter clogging sensor 1138

V-227 Short circuit with power source in air cleaner clogging (1) relay system 1139

V-228 Short circuit with power source in air cleaner clogging (2) relay system 1140

V-229 Short circuit with power source in air cleaner clogging (3) relay system 1140

V-230 Short circuit with power source in air cleaner clogging (4) relay system 1141

V-231 Abnormal charge by alternator 1142

TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H MODE) 1143

BEFORE CARRYING OUT TROUBLESHOOTING OF WORK EQUIPMENT HYDRAULIC SYSTEM (HOW TO USE MULTI-MONITOR) 1144

GENERAL TROUBLESHOOTING OF WORK EQUIPMENT HYDRAULIC SYSTEM 1154

WORK EQUIPMENT HYDRAULIC SYSTEM GROUP 1156

BEFORE CARRYING OUT TROUBLESHOOTING OF STEERING HYDRAULIC SYSTEM (HOW TO USE MULTI-MONITOR) 1217

CONFIRMATION ON SPECIFICATION VALUES RELATED TO STEERING (CONFIRMATION OF LOW PERFORMANCE) 1229

GENERAL TROUBLESHOOTING OF STEERING HYDRAULIC SYSTEM 1230

STEERING HYDRAULIC SYSTEM GROUP 1231

GENERAL TROUBLESHOOTING OF BRAKE HYDRAULIC SYSTEM 1271

BRAKE HYDRAULIC SYSTEM GROUP 1272

IMPORTANT TROUBLESHOOTING ITEMS 1324

H-1 Torque converter overheat 1324

H-2 Performance or response of steering is degraded 1326

H-3 Joystick lever is heavy 1328

H-4 Steering is unstable or jolts 1330

H-5 Wheel brake does not work or its performance is low 1332

H-6 Lift arm speed is low or lift arm rising force is insufficient 1334

H-7 Large shocks are made when lift arm stops 1338

H-8 Hydraulic oil overheat 1339

COMMON TROUBLESHOOTING ITEMS 1342

H-1 Machine does not move 1342

H-2 Machine lacks power or speed (every speed range) 1343

H-3 Excessive time lag when starting machine or shifting gear 1344

H-4 Torque converter oil temperature is high 1345

H-4 Torque converter oil temperature is high 1346

H-6 Turning, response of steering is poor 1347

H-7 Joystick lever is heavy 1348

H-8 Steering wheel shakes or jerks 1349

H-9 Turning radius is different between left and right at maximum steering 1350

H-10 Wheel brakes do not work or braking effect is poor 1350

H-11 Wheel brakes are not released or brakes drag 1351

H-12 Boom does not rise 1352

H-13 Boom moves slowly or does not have sufficient lifting power 1353

H-14 When raising boom, becomes slow at certain height 1354

H-15 Boom cylinder cannot hold down bucket 1354

H-16 Boom has large amount of hydraulic drift 1354

H-17 Boom fluctuates while working 1355

H-18 Boom drops momentarily when lever is operated from HOLD to RAISE 1355

H-19 Bucket does not tilt 1356

H-20 Bucket is moves slowly or has insufficient tilt back power 1357

H-21 Bucket movement becomes slow during tilt back 1358

H-22 Bucket cylinder cannot hold down bucket 1358

H-23 Bucket has large amount of hydraulic drift 1358

H-24 Bucket fluctuates while traveling under load (work equipment valve HOLD) 1359

H-25 Bucket dumps momentarily when lever is operated from HOLD to TILT 1359

H-26 Boom and bucket levers do not move smoothly 1360

TROUBLESHOOTING BY FAILUE CODE (DISPLAY OF CODE) 1361

FAILURE CODES LIST 1364

BEFORE CARRYING OUT TROUBLESHOOTING FOR ELECTRICAL SYSTEM1 1373

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE 1376

Failure code [15B0NX] Transmission oil filter clogging 1378

Failure code [2G41MB] Front and rear brake pressure reduction (When engine is started) 1380

Failure code [2G42ZG] Front brake pressure reduction (While engine is running) 1382

Failure code [2G43ZG] Rear brake pressure reduction (While engine is running) 1384

Failure code [AA1ANX] Air cleaner clogging [1] 1386

Failure code [AA1BNX] Air cleaner clogging [2] 1388

Failure code [AA1CNX] Air cleaner clogging [3] 1390

Failure code [AA1DNX] Air cleaner clogging [4] 1392

Failure code [AB00MA] Defective alternator charge 1394

Failure code [B@BCZK] Coolant level reduction (Before engine is started) 1396

Failure code [b@BCZK] Coolant level reduction (While engine is running) 1398

Failure code [B@BFZK] Fuel level reduction (Before engine is started) 1400

Failure code [b@BFZK] Fuel level reduction (While engine is running) 1402

Failure code [B@C5ZK] Brake oil level reduction (Before engine is started) 1404

Failure code [b@C5ZK] Brake oil level reduction (While engine is running) 1405

Failure code [B@CENS] High torque converter oil temperature (above 120°C) 1406

Failure code [b@CENS] Abnormally high torque converter oil temperature (above 130°C) 1407

Failure code [B@GAZK] Battery electrolyte level reduction [1] 1408

Failure code [B@GBZK] Battery electrolyte level reduction [2] 1409

Failure code [B@GCZK] Battery electrolyte level reduction [3] 1410

Failure code [B@HANS] Abnormally high hydraulic oil temperature (overheat) 1411

Failure code [D100KZ] Caution buzzer system abnormality 1412

Failure code [D160KZ] Backup lamp system abnormality 1413

Failure code [D191KZ] Steering neutral interlock relay system abnormality 1414

Failure code [D5ZPKB] Check lamp system abnormality (Hot short) 1415

Failure code [D5ZQKB] Blink synchronizing signal power supply abnormality (Hot short) 1416

Failure code [DAF0KR] Monitor panel (Main monitor) S-net communication error 1417

Failure code [DAQ0KT] Transmission controller abnormality 1419

Failure code [DAQSKR] Transmission controller S-net communication abnormality 1420

Failure code [DB9SKR] Work equipment controller S-net communication error 1422

Failure code [DBB0KK] VHMS power supply abnormality 1424

Failure code [DBB0KQ] VHMS selector connector wrong connection 1426

Failure code [DBB3KK] VHMS backup power supply abnormality 1428

Failure code [DBB5KP] VHMS sensor power supply (5 V) abnormality 1430

Failure code [DBB6KP] VHMS sensor power supply (24 V) abnormality 1431

Failure code [DBB7KP] VHMS sensor power supply (12 V) abnormality 1433

Failure code [DBBQKR] CAN communication error (VHMS controller – multi-monitor) 1434

Failure code [DBBRKR] CAN communication error (J1939) 1435

Failure code [DBCSKR] S-net communication error (MOD/C controller) 1436

Failure code [DBD0KT] Modulated clutch system abnormality 1438

Failure code [DDA7LD] RPM set ON/OFF switch system abnormality 1440

Failure code [DDD7KX] Vehicle speed control dial system abnormality 1442

Failure code [DDD8KX] Drive force control dial system abnormality 1444

Failure code [DDF2KZ] Joystick F, N, R selector switch system abnormality 1446

Failure code [DDF3KZ] Joystick shift up/down switch system abnormality 1448

Failure code [DDNGL4] Boom PPC pressure switch system abnormality 1450

Failure code [DDNJL4] Work equipment PPC pressure switch system abnormality 1452

Failure code [DDQ2L6] Steering lock pressure switch system abnormality 1454

Failure code [DDT8KA] 1st, 2nd or 3rd fill signal system abnormality 1456

Failure code [dDT8KA] Gear speed fill signal abnormality (Disconnection) 1458

Failure code [DDT8KB] Gear speed fill signal abnormality (Ground fault) 1459

Failure code [DDTDKA] F or R fill signal system abnormality (Disconnection) 1460

Failure code [DDTDKB] F or R fill signal system abnormality (Hot short) 1462

Failure code [DDTKKB] 1st fill signal system abnormality 1463

Failure code [DDTLKB] 2nd fill signal system abnormality 1464

Failure code [DDTMKB] 3rd fill signal system abnormality 1465

Failure code [DDTNKB] R fill signal system abnormality 1466

Failure code [DDTQKB] F fill signal system abnormality 1467

Failure code [DGE5KX] Ambient temperature sensor system abnormality 1468

Failure code [DGF1KB] Transmission oil temperature sensor system abnormality 1469

Failure code [DGT1KX] Torque converter oil temperature sensor system abnormality 1470

Failure code [DGT2KX] Hydraulic oil temperature sensor system abnormality 1471

Failure code [DH20KX] Torque converter outlet oil pressure sensor system abnormality 1472

Failure code [DH24KX] Work equipment relief oil pressure sensor system abnormality 1474

Failure code [DHPCKX] Boom bottom pressure sensor system abnormality 1476

Failure code [DHPDKX] Boom head pressure sensor system abnormality 1478

Failure code [DHT3KX] Transmission main pressure sensor system abnormality 1480

Failure code [DHT4KX] Main PPC oil pressure sensor system abnormality 1482

Failure code [DHT5KX] Torque converter inlet oil pressure sensor system abnormality 1484

Failure code [DHT8KX] Steering oil pressure sensor system abnormality 1486

Failure code [DHT9KX] Transmission modulated pressure sensor system abnormality 1488

Failure code [DHTAKX] Transmission lubricating oil pressure sensor system abnormality 1490

Failure code [DHU2KX] Front brake oil pressure sensor system abnormality 1492

Failure code [DHU3KX] Rear brake oil pressure sensor system abnormality 1494

Failure code [DK10L5] Accelerator pedal signal system abnormality 1496

Failure code [DK5FKX] Steering lever angle sensor system abnormality 1498

Failure code [DKA0KX] Boom angle sensor system abnormality 1500

Failure code [DKD0KX] Frame angle sensor system abnormality 1502

Failure code [DKD0KZ] Steering frame angle and lever angle sensors are shifted 1504

Failure code [DLE2KZ] Engine speed sensor system abnormality 1506

Failure code [dLE2KZ] Engine speed sensor system abnormality 1508

Failure code [DLF6L8] Wheel rotation signal system abnormality 1510

Failure code [DLFAKA] Modulated clutch speed sensor system abnormality 1511

Failure code [DLT2KZ] Modulated clutch output speed sensor system abnormality 1512

Failure code [DLT3KZ] Travel speed sensor system abnormality 1514

Failure code [DLt3KZ] Travel speed sensor system abnormality 1516

Failure code [dLT3KZ] Travel speed sensor system abnormality 1518

Failure code [DV00KB] Buzzer output system abnormality (Hot short) 1520

Failure code [DW23KB] F bypass valve system abnormality (Hot short) 1521

Failure code [DW23KZ] F bypass valve system abnormality(Disconnection or hot short) 1522

Failure code [DW24KB] R bypass valve system abnormality (Hot short) 1523

Failure code [DW24KZ] R bypass valve system abnormality (Disconnection or hot short) 1524

Failure code [DW25KB] 1st bypass valve system abnormality (Hot short) 1525

Failure code [DW25KZ] 1st bypass valve system abnormality (Disconnection or hot short) 1526

Failure code [DW72KZ] Boom kick-out solenoid system abnormality 1527

Failure code [DWJ2KZ] R drain valve system abnormality 1528

Failure code [DWNAKZ] Modulation NC solenoid system abnormality 1529

Failure code [DXF0KZ] Steering basic pressure EPC solenoid system abnormality 1531

Failure code [DXH4KZ] Transmission 1st solenoid system abnormality 1532

Failure code [DXH5KZ] Transmission 2nd solenoid system abnormality 1534

Failure code [DXH6KZ] Transmission 3rd solenoid system abnormality 1536

Failure code [DXH7KZ] Transmission R solenoid system abnormality 1538

Failure code [DXH8KZ] Transmission F solenoid system abnormality 1540

Failure code [DXHNKB] Damping solenoid system abnormality (Short circuit) 1542

Failure code [DXHNKY] Damping solenoid system abnormality (Short circuit to power line) 1543

Failure code [DXHNKZ] Damping solenoid system abnormality (Disconnection or short circuit) 1544

Failure code [DXHPKZ] Modulation ECMV solenoid system abnormality 1545

TROUBLESHOOTING OF ELECTRICAL SYSTEM (Without failure code) (E-MODE) 1547

BEFORE CARRYING OUT TROUBLESHOOTING FOR ELECTRICAL SYSTEM 1550

INFORMATION IN TROUBLESHOOTING TABLE 1554

TRANSMISSION CONTROLLER SYSTEM 1556

E-1 Auto/Manual selector switch system abnormality 1556

E-2 Kick-down switch system abnormality 1557

E-3 Transmission cut-off signal system abnormality 1558

E-4 Steering lock switch signal system abnormality 1559

E-5 Neutralizer relay signal abnormality 1560

E-6 Buzzer signal system abnormality 1561

E-7 Network system abnormality 1562

E-8 Transmission controller power supply system abnormality 1564

E-9 Ground fault or short circuit in travel speed sensor system 1565

E-10 Ground fault or short circuit in modulated clutch output speed sensor system 1566

E-11 Disconnection in transmission oil temperature sensor 1567

E-12 F1 (Forward 1st) signal system abnormality 1568

E-13 Auto shift indicator lamp system abnormality 1569

MODULATED CLUTCH CONTROLLER SYSTEM 1571

E-14 Ground fault or short circuit in boom raise/lower or bucket tilt/dump pressure switch system 1571

E-15 Disconnection in F ECMV fill switch system 1572

E-16 Disconnection in R ECMV fill switch system 1573

E-17 Disconnection in RPM set switch 1574

E-18 Electronic governor voltage command system abnormality 1575

E-19 Transmission cut-off signal system abnormality 1576

E-20 Modulated clutch ECMV fill switch system abnormality 1577

E-21 Right brake pedal switch system abnormality 1578

E-22 Travel speed control ON/OFF switch system abnormality 1579

E-23 RPM set ON/OFF switch system abnormality 1580

E-24 Engine speed output signal system abnormality 1581

E-25 Modulated clutch controller power supply abnormality 1582

E-26 Network system abnormality 1583

E-27 F1 (Forward 1st) input signal system abnormality 1583

WORK EQUIPMENT AND JOYSTICK STEERING CONTROLLER SYSTEM (JOYSTICK STEERING CONTROL SYSTEM) 1584

E-28 Ground fault or short circuit in travel speed sensor system 1584

E-29 Right and left steering speeds are different 1586

E-30 Console switch abnormality (Steering lever angle sensor or frame angle sensor cannot be adjusted) 1587

E-31 Power supply voltage abnormality 1588

WORK EQUIPMENT AND JOYSTICK STEERING CONTROLLER SYSTEM (REMOTE BOOM POSITIONER CONTROL SYSTEM) 1589

E-32 Remote positioner sensor cannot be adjusted 1589

E-33 Engine speed signal system abnormality 1590

E-34 Remote positioner “Raise”/”Lower” LED does not light 1591

E-35 Remote positioner “Raise” stop lamp (multi-monitor screen) does not blink (for 2 5 sec) 1592

E-36 Remote positioner “Lower” stop lamp (multi-monitor screen) does not blink (for 2 5 sec) 1592

E-37 Switch operation buzzer does not sound 1593

E-38 Boom stop shocks are made (Boom detent switch abnormality) 1594

E-39 Short circuit in boom “Raise”/”Lower” sensor pressure switch 1596

VHMS CONTROLLER SYSTEM 1598

E-40 Disconnection or hot short in sensor power supply 24 V system 1598

E-41 Disconnection or hot short in sensor power supply 12V system 1600

E-42 Disconnection or hot short in sensor power supply 5 V system 1601

E-43 Disconnection or ground fault in buzzer output system 1602

E-44 Disconnection or ground fault in check lamp system 1603

E-45 Disconnection or ground fault in blink synchronizing signal system 1604

E-46 Hot short in boom bottom pressure sensor system 1605

E-47 Hot short in boom head pressure sensor system 1606

E-48 Hot short in rear brake oil pressure sensor system 1607

E-49 Hot short in front brake oil pressure sensor system 1608

E-50 Hot short in work equipment relief oil pressure sensor system 1609

E-51 Hot short in transmission main relief oil pressure sensor system 1610

E-52 Hot short in steering relief oil pressure sensor system 1611

E-53 Hot short in torque converter outlet oil pressure sensor system 1612

E-54 Hot short in transmission modulated oil pressure sensor system 1613

E-55 Disconnection or hot short in torque converter oil temperature sensor system 1614

E-56 Disconnection in hydraulic oil temperature sensor system 1615

E-57 Disconnection in ambient temperature sensor system 1616

E-58 Hot short in main PPC oil pressure sensor system 1617

E-59 Ground fault in fuel level sensor 1618

E-60 Hot short in battery electrolyte level sensor [1] system 1619

E-61 Hot short in battery electrolyte level sensor [2] system 1620

E-62 Hot short in battery electrolyte level sensor [3] system 1621

E-63 Ground fault or hot short in brake oil level sensor system 1622

E-64 Hot short in coolant level sensor system 1623

E-65 Ground fault or hot short in transmission oil filter sensor system 1624

E-66 Hot short in dust indicator relay [1] system 1625

E-67 Hot short in dust indicator relay [2] system 1626

E-68 Hot short in dust indicator relay [3] system 1627

E-69 Hot short in dust indicator relay [4] system 1628

E-70 Ground fault in alternator charge system 1629

MAIN MONITOR SYSTEM 1630

E-71 Main monitor does not operate 1630

E-72 All main monitor items keep lighting when engine is started (PRE-LUBE) just (within 3 sec) after starting switch is turned ON 1632

E-73 Speedometer does not indicate normally 1636

E-74 Gear shift indicator abnormality 1637

E-75 Winker display does not light 1640

E-76 Parking display abnormality 1641

E-77 Night lamp does not light 1642

E-78 Front working lamp abnormality 1644

E-79 Rear working lamp abnormality 1646

E-80 Transmission cut-off function abnormality 1648

E-81 Emergency steering normal display abnormality 1651

E-82 Emergency steering operation display abnormality 1652

E-83 Parking brake dragging alarm abnormality 1653

E-84 Parking brake dragging alarm abnormality (Joystick steering mode) 1654

E-85 When parking brake dragging alarm is turned ON, buzzer and caution lamp operate continuously or do not operate at all 1656

E-86 Caution buzzer abnormality 1657

E-87 Monitor switch state is not saved 1659

E-88 Service meter does not advance or it advances while engine is stopped 1660

E-89 Transmission controller does not sound buzzer 1662

E-90 Auto grease system abnormality 1663

E-91 Failure code is not transferred to main monitor (Network abnormality) 1665

30 DISASSEMBLY AND ASSEMBLY 1667

How to read this manual 1669

Coating materials list 1671

Special tool list 1674

Sketches of special tools 1679

Procedure for flushing work equipment and steering hydraulic circuit 1725

Procedure for flushing brake hydraulic circuit 1730

Bleeding air from piston pump 1735

Bleeding air from work equipment circuit and steering circuit 1736

Bleeding air from brake circuit 1738

Removal and installation of DT connector pin 1740

Removal and installation of HD connector pin 1742

Repair procedure of HD connector pin harness 1743

Removal and installation of engine assembly 1744

Removal and installation of damper assembly 1772

Disassembly and assembly of damper assembly 1778

Removal and installation of radiator and hydraulic oil cooler assembly 1786

Procedure for disassembly and assembly of MESABI oil cooler assembly 1798

Disassembly and assembly of MESABI oil cooler assembly 1801

Removal and installation of fuel cooler assembly 1809

Removal and installation of torque converter and transmission oil cooler assembly 1814

Removal and installation of bumper and fuel tank assembly 1817

Removal and installation of hood assembly 1820

Removal and installation of bulkhead assembly 1822

Disassembly and assembly of ECMV 1826

Removal and installation of torque converter and transmission assembly 1833

Disconnection and connection of transmission assembly and torque converter assembly 1871

Disconnection and connection of torque converter assembly and PTO • transfer assembly 1880

Disassembly and assembly of torque converter assembly 1883

Disassembly and assembly of modulated clutch assembly 1894

Disassembly and assembly of PTO and transfer assembly 1898

Disconnection and connection of transmission assembly and transfer • parking brake assembly 1912

Disassembly and assembly of transmission assembly 1920

Disassembly and assembly of transfer assembly 1944

Disassembly and assembly of parking brake assembly 1952

Removal and installation of parking brake assembly (from machine body) 1955

Disassembly and assembly of drive shaft assembly 1959

Removal and installation of front axle assembly 1968

Removal and installation of front final drive assembly 1972

Removal and installation of rear axle assembly 1976

Disconnection and connection of differential assembly 1992

Disassembly and assembly of differential assembly 1994

Removal and installation of rear final drive assembly 2004

Disassembly and assembly of final drive and brake assembly 2008

Removal and installation of center support assembly 2020

Disassembly and assembly of center support assembly 2022

Removal and installation of steering demand valve assembly 2026

Removal and installation of steering cylinder assembly 2029

Removal and installation of steering pump, control pump and PPC pump assembly 2035

Removal and installation of switching pump assembly 2042

Removal and installation of emergency diverter valve assembly 2045

Removal and installation of emergency steering pump assembly 2050

Removal and installation of brake accumulator charge valve assembly 2054

Removal and installation of brake oil cooler assembly 2056

Removal and installation of brake oil tank assembly 2059

Removal and installation of transmission, brake cooling and brake pump assembly 2062

Disconnecting procedure for front frame and rear frame 2066

Removal and installation of center hinge pin 2067

Removal and installation of work equipment control valve assembly 2084

Removal and installation of work equipment pump assembly (Right side) 2102

Removal and installation of work equipment pump assembly (Left side) 2106

Removal and installation of hydraulic tank and filter case assembly 2110

Removal and installation of bucket cylinder assembly 2116

Removal and installation of lift cylinder assembly 2130

Disassembly and assembly of hydraulic cylinder assembly 2148

Removal and installation of work equipment assembly 2152

Run-in procedure for bucket pin 2233

Run-in procedure for lift arm pin 2235

Removal and installation of air conditioner unit assembly 2238

Removal and installation of operator’s cab and floor assembly 2240

Removal and installation of operator’s cab assembly 2243

Disassembly and assembly of operator’s seat assembly 2244

Removal and installation of controller assemblies 2277

SERVICE KIT PARTS LIST 2279

40 MAINTENANCE STANDARD 2343

ENGINE MOUNT 2344

TRANSMISSION MOUNT 2346

RADIATOR AND OIL COOLER 2348

DAMPER 2350

TORQUE CONVERTER, TRANSMISSION, BRAKE COOLING AND BRAKE PUMP 2351

INPUT TRANSFER PTO 2354

MODULATED CLUTCH 2356

TORQUE CONVERTER 2357

TRANSMISSION 2358

TRANSFER 2362

MAINRELIEF, TORQUE CONVERTER RELIEF VALVE 2364

TORQUE CONVERTER REGULATOR VALVE 2366

BY-PASS FILL VALVE 2367

BY-PASS FILL VALVE AND BY-PASS DRAIN VALVE 2368

ECMV 2369

LUBRICATIONG OIL RELIEF VALVE 2371

DRIVE SHAFT 2372

CENTER SUPPORT 2373

DIFFERENTIAL 2374

FINAL DRIVE 2378

AXLE MOUNT 2382

CENTER HINGE PIN 2384

STEERING PUMP 2388

SWITCH PUMP 2389

STEERING DEMAND VALVE 2390

DIVERTER VALVE 2392

STEERING CYLINDER MOUNT 2393

EMERGENCY STEERING PUMP 2396

BRAKE VALVE 2397

SLACK ADJUSTER 2399

BRAKE 2400

PARDING BRAKE 2402

WORK EQUIPMENT PUMP NO 1 2404

WORK EQUIPMENT PUMP NO 2 2405

PPC VALVE 2406

PPC RELIEF VALVE 2408

PUMP CONTROL RELIEF VALVE 2409

MAIN CONTROL VALVE 2410

HYDRAULIC CYLINDER 2412

BUCKET POSITIONER AND REMOTE POSITIONER 2415

BUCKET LINKAGE 2416

90 OTHERS 2421

TRANSMISSION HYDRAULIC CIRCUIT DIAGRAM 2422

BRAKE CIRCUIT DIAGRAM 2424

WORK EUIPMENT HYDRAULIC CIRCUIT DIAGRAM (1/2) Serial No : 50001 – 50084 2427

WORK EUIPMENT HYDRAULIC CIRCUIT DIAGRAM (2/2) Serial No : 50001 – 50084 2429

WORK EUIPMENT HYDRAULIC CIRCUIT DIAGRAM (1/2) Serial No : 50085 and up 2431

WORK EUIPMENT HYDRAULIC CIRCUIT DIAGRAM (2/2) Serial No : 50085 and up 2433

ELECTRICAL CIRCUIT DIAGRAM (1/7) Serial No : 50001 – 50038 (Standard specification machine) 2435

ELECTRICAL CIRCUIT DIAGRAM (1/7) Serial No : 50001 – 50038 (Trainer seat specification machine) 2437

ELECTRICAL CIRCUIT DIAGRAM (2/7) Serial No : 50001 – 50038 2439

ELECTRICAL CIRCUIT DIAGRAM (3/7) Serial No : 50001 – 50038 2441

ELECTRICAL CIRCUIT DIAGRAM (4/7) Serial No : 50001 – 50038 2443

ELECTRICAL CIRCUIT DIAGRAM (5/7) Serial No : 50001 – 50038 2445

ELECTRICAL CIRCUIT DIAGRAM (6/7) Serial No : 50001 – 50038 2447

ELECTRICAL CIRCUIT DIAGRAM (7/7) Serial No : 50001 – 50038 2449

ELECTRICAL CIRCUIT DIAGRAM (1/7) Serial No : 50039 – 50074 2451

ELECTRICAL CIRCUIT DIAGRAM (2/7) Serial No : 50039 – 50074 2453

ELECTRICAL CIRCUIT DIAGRAM (3/7) Serial No : 50039 – 50074 2455

ELECTRICAL CIRCUIT DIAGRAM (4/7) Serial No : 50039 – 50074 2457

ELECTRICAL CIRCUIT DIAGRAM (5/7) Serial No : 50039 – 50074 2459

ELECTRICAL CIRCUIT DIAGRAM (6/7) Serial No : 50039 – 50074 2461

ELECTRICAL CIRCUIT DIAGRAM (7/7) Serial No : 50039 – 50074 2463

ELECTRICAL CIRCUIT DIAGRAM (1/8) Serial No : 50075 – 50084, 50086, 50087 2465

ELECTRICAL CIRCUIT DIAGRAM (2/8) Serial No : 50075 – 50084, 50086, 50087 2467

ELECTRICAL CIRCUIT DIAGRAM (3/8) Serial No : 50075 – 50084, 50086, 50087 2469

ELECTRICAL CIRCUIT DIAGRAM (4/8) Serial No : 50075 – 50084, 50086, 50087 2471

ELECTRICAL CIRCUIT DIAGRAM (5/8) Serial No : 50075 – 50084, 50086, 50087 2473

ELECTRICAL CIRCUIT DIAGRAM (6/8) Serial No : 50075 – 50084, 50086, 50087 2475

ELECTRICAL CIRCUIT DIAGRAM (7/8) Serial No : 50075 – 50084, 50086, 50087 2477

ELECTRICAL CIRCUIT DIAGRAM (8/8) Serial No : 50075 – 50084, 50086, 50087 2479

ELECTRICAL CIRCUIT DIAGRAM (1/11) Serial No : 50085, 50088 and up 2481

ELECTRICAL CIRCUIT DIAGRAM (2/11) Serial No : 50085, 50088 and up 2483

ELECTRICAL CIRCUIT DIAGRAM (3/11) Serial No : 50085, 50088 and up 2485

ELECTRICAL CIRCUIT DIAGRAM (4/11) Serial No : 50085, 50088 and up 2487

ELECTRICAL CIRCUIT DIAGRAM (5/11) Serial No : 50085, 50088 and up 2489

ELECTRICAL CIRCUIT DIAGRAM (6/11) Serial No : 50085, 50088 and up 2491

ELECTRICAL CIRCUIT DIAGRAM (7/11) Serial No : 50085, 50088 and up 2493

ELECTRICAL CIRCUIT DIAGRAM (8/11) Serial No : 50085, 50088 and up 2495

ELECTRICAL CIRCUIT DIAGRAM (9/11) Serial No : 50085, 50088 and up 2497

ELECTRICAL CIRCUIT DIAGRAM (10/11) Serial No : 50085, 50088 and up 2499

ELECTRICAL CIRCUIT DIAGRAM (11/11) Serial No : 50085, 50088 and up 2501

DESCRIPTION:

Komatsu WA1200-3 Wheel Loader Shop Manual SEBM018231 – PDF DOWNLOAD

MACHINE MODEL SERIAL NO.

WA1200-3 50001 and up

How to read the shop manual

1. Composition of shop manual

This shop manual contains the necessary technical information for services performed in a workshop.

For ease of understanding, the manual is divided into the following sections.

00. FOREWORD

This section explains the safety and basic information.

01. GENERAL

This section explains the specifications of the machine.

10. STRUCTURE AND FUNCTION

This section explains the structure and function of each component. It serves not only to give an

understanding of the structure, but also serves as reference material for troubleshooting.

In addition, this section may contain hydraulic circuit diagrams, electric circuit diagrams, and maintenance

standards.

20. TESTING AND ADJUSTING

This section explains checks to be made before and after performing repairs, as well as adjustments

to be made at completion of the checks and repairs.

Troubleshooting charts correlating “Problems” with “Causes” are also included in this section.

30. DISASSEMBLY AND ASSEMBLY

This section explains the procedures for removing, installing, disassembling and assembling each

component, as well as precautions for them.

40. MAINTENANCE STANDARD

This section gives the judgment standards for inspection of disassembled parts.

The contents of this section may be described in “STRUCTURE AND FUNCTION”.

90. OTHERS

This section mainly gives hydraulic circuit diagrams and electric circuit diagrams.

In addition, this section may give the specifications of attachments and options together.

VIDEO PREVIEW OF THE MANUAL:

IMAGES PREVIEW OF THE MANUAL: