$45

Komatsu WA1200-6 Wheel Loader Shop Manual SEN06774-02 – PDF DOWNLOAD

Komatsu WA1200-6 Wheel Loader Shop Manual SEN06774-02 – PDF DOWNLOAD

FILE DETAILS:

Komatsu WA1200-6 Wheel Loader Shop Manual SEN06774-02 – PDF DOWNLOAD

Language : English

Pages : 2180

Downloadable : Yes

File Type : PDF

Size: 134 MB

DESCRIPTION:

Komatsu WA1200-6 Wheel Loader Shop Manual SEN06774-02 – PDF DOWNLOAD

SERIAL NUMBERS 70001 and up

How to read the shop manual 0-21

1. Composition of shop manual

This shop manual contains the necessary technical information for services performed in a workshop. For

ease of understanding, the manual is divided into the following sections.

00. Index and foreword

This section contains the index, foreword, safety and basic information. If any revision is made, the LIST

OF REVISED PAGES will be added.

01. Specification

This section explains the specifications of the machine.

10. Structure and function

This section explains the structure and function of each component. It serves not only to give an understanding

for the structure of each component, but also serves as reference material for troubleshooting.

20. Standard value table

This section explains the standard values for new machine and judgement criteria for testing, adjusting,

and troubleshooting. This standard value table is used to check the standard values in testing and adjusting

and to judge parts in troubleshooting.

30. Testing and adjusting

This section explains measuring tools and measuring methods for testing and adjusting, as well as the

adjusting method of each part. The standard values and judgment criteria for “Testing and adjusting” are

explained in “Standard value table”.

40. Troubleshooting

This section explains how to find out failed parts and how to repair them. The troubleshooting is divided

by failure modes. The “S mode” of the troubleshooting related to the engine may be also explained in the

Chassis volume and Engine volume. In this case, see the Chassis volume.

50. Disassembly and assembly

This section explains the special tools and procedures for removing, installing, disassembling, and assembling

each component, as well as precautions for them. In addition, tightening torque, and quantity and

weight of coating material, oil, grease, and coolant necessary for the work are also explained.

60. Maintenance standard

This section gives maintenance standard values of each component. The maintenance standard sub-section

explains the criteria and remedies for disassembly and service.

80. Appendix

This section explains the structure, function, testing, adjusting, and troubleshooting for the equipment not

classifiable in other sections.

90. Diagrams and drawings (chassis volume) /Repair and replacement of parts (engine volume)

q Chassis volume

This section gives hydraulic circuit diagrams and electrical circuit diagrams.

q Engine volume

This section explains the method of remanufacturing and repairing engine and replacing parts.

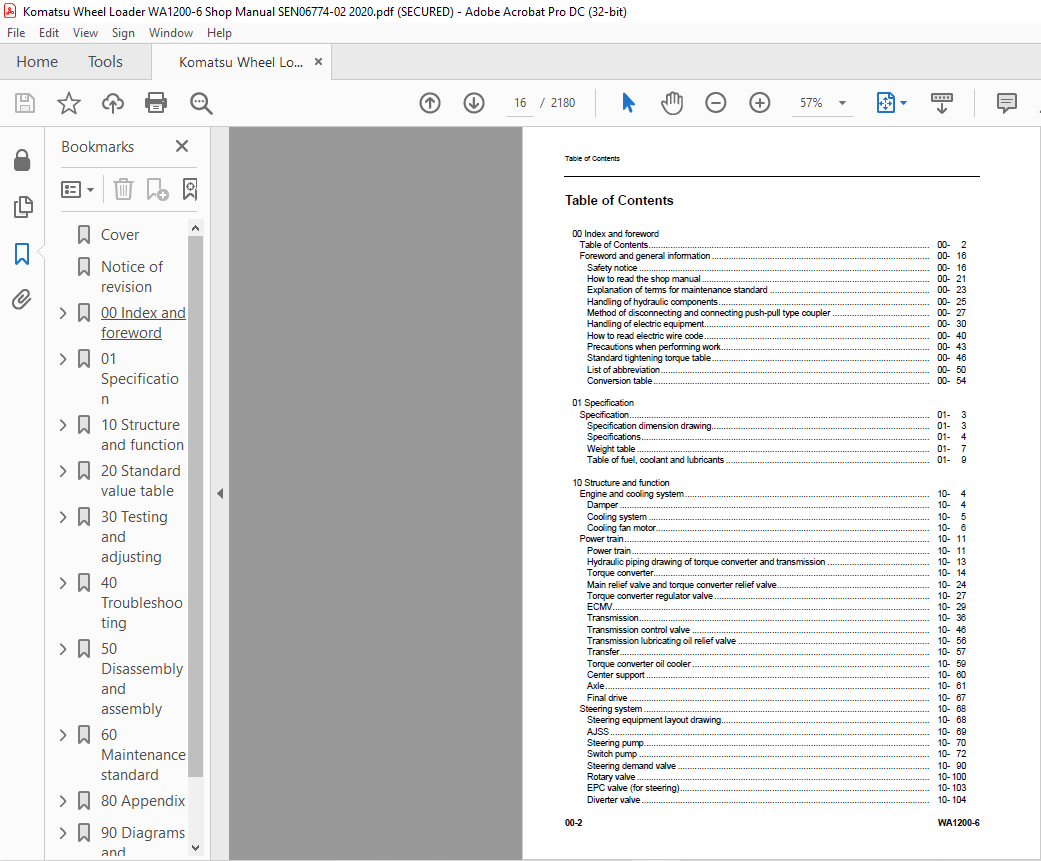

TABLE OF CONTENTS:

Komatsu WA1200-6 Wheel Loader Shop Manual SEN06774-02 – PDF DOWNLOAD

Cover 1

Notice of revision 3

00 Index and foreword 15

Table of Contents 16

Foreword and general information 30

Safety notice 30

How to read the shop manual 35

Explanation of terms for maintenance standard 37

Handling of hydraulic components 39

Method of disconnecting and connecting push-pull type coupler 41

Handling of electric equipment 44

How to read electric wire code 54

Precautions when performing work 57

Standard tightening torque table 60

List of abbreviation 64

Conversion table 68

01 Specification 73

Contents 74

Specification 75

Specification dimension drawing 75

Specifications 76

Weight table 79

Table of fuel, coolant and lubricants 81

10 Structure and function 83

Contents 84

Engine and cooling system 86

Damper 86

Cooling system 87

Cooling fan motor 88

Power train 93

Power train 93

Hydraulic piping drawing of torque converter and transmission 95

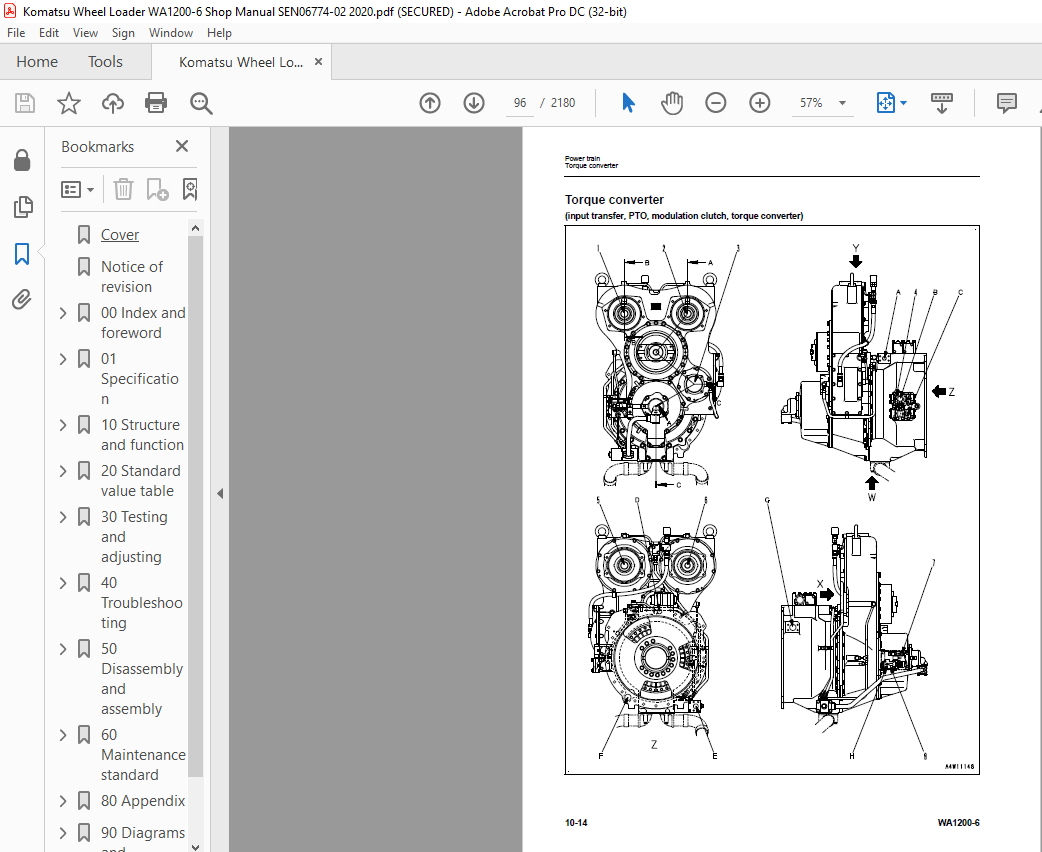

Torque converter 96

Main relief valve and torque converter relief valve 106

Torque converter regulator valve 109

ECMV 111

Transmission 118

Transmission control valve 128

Transmission lubricating oil relief valve 138

Transfer 139

Torque converter oil cooler 141

Center support 142

Axle 143

Final drive 149

Steering system 150

Steering equipment layout drawing 150

AJSS 151

Steering pump 152

Switch pump 154

Steering demand valve 172

Rotary valve 182

EPC valve (for steering) 185

Diverter valve 186

Emergency steering relief valve 189

Steering lock valve 190

Brake system 191

Brake equipment layout drawing 191

Brake valve 192

Charge valve 198

Accumulator (for brake) 202

Slack adjuster 203

Brake 205

Parking brake 206

Parking brake solenoid valve 207

Emergency parking brake release valve 208

Check valve of parking brake circuit 209

Undercarriage and frame 212

Axle mount 212

Center hinge pin 214

Jack-up point 215

Hydraulic system 216

Hydraulic piping layout drawing 216

Work equipment control lever linkage 218

Hydraulic tank 219

Work equipment pump No 1 223

Work equipment pump No 2 236

EPC valve (for work equipment) 260

Neutral cutoff solenoid valve (NC valve) 262

Relief valve 264

Accumulator (for EPC valve) 265

Work equipment control valve 266

Work equipment 280

Work equipment linkage 280

Electrical system 282

Machine monitor system 282

Multi-function monitor 310

Work equipment and AJSS control system 364

Work equipment control lever 400

Transmission control system 403

Engine starting circuit 429

Engine stopping circuit 431

Electric parking brake control 435

Sensor 445

20 Standard value table 467

Contents 468

Standard value table 469

Standard value table for engine 469

Standard value table for chassis 470

30 Testing and adjusting 475

Contents 476

Tool for testing, adjusting and troubleshooting 478

Tools for testing, adjusting, and troubleshooting 478

Safety precautions to follow before starting work 483

Engine and cooling system 487

Testing engine speed 487

Testing exhaust gas color 489

Testing blow-by pressure 490

Measuring engine oil pressure 491

Measuring exhaust gas temperature 492

Testing intake air pressure (boost pressure) 493

Testing radiator performance 494

Measuring wind speed across radiator and oil cooler 495

Testing and adjusting fan belt tension 496

Testing and adjusting air conditioner compressor belt tension 497

Power train 498

Adjusting speed sensor 498

Testing and adjusting torque converter and transmission oil pressure 500

Traction control function checking procedure 503

Testing torque converter oil cooler performance 504

Testing additional cooler fan speed 505

Flushing procedure for torque converter and transmission circuit 506

Retrieval of disabled machine due to transmission valve failure 507

How to measure play of center hinge bearing 510

Measuring wear of rear axle support 512

Steering system 513

Testing and adjusting steering oil pressure 513

Testing and adjusting emergency steering oil pressure 514

Bleeding air from steering circuit 516

Testing and adjusting steering stopper bolt 518

Adjusting steering follow-up linkage 519

Testing steering EPC valve 524

Testing and adjusting steering surge cut valve oil pressure 526

Testing and adjusting steering main relief valve oil pressure 528

Testing rotary valve output pressure 530

Brake system 532

Testing brake performance 532

Testing lowering of wheel brake oil pressure 533

Testing of slack adjuster 534

Measuring wear of wheel brake disc 535

Testing and adjusting accumulator charge pressure 536

Testing brake accumulator oil pressure leakage 538

Testing emergency parking brake valve oil leakage amount 540

Testing brake valve oil leakage amount 543

Testing brake cooling oil pressure 548

Testing brake oil cooler performance 550

Testing parking brake performance 550

Testing wear of parking brake disc 551

Method of releasing parking brake manually 552

Testing parking brake oil pressure 553

Testing of accumulator nitrogen gas pressure and procedure for charging accumulator with nitrogen gas 554

Hydraulic system 564

Testing and adjusting work equipment oil pressure by using multi monitor 564

Testing and adjusting work equipment oil pressure by using oil pressure gauge 566

Testing and adjusting work equipment PPC oil pressure 567

Measuring point of hydraulic pump oil pressure 569

Testing and adjusting PV control relief valve oil pressure 573

Testing and adjusting differential valve output oil pressure 575

Testing work pump ES valve output pressure 577

Testing and adjusting work pump CO (cut-off) valve oil pressure 579

Testing and adjusting work equipment pump TVC valve oil pressure 583

Operation test of work equipment valve by work equipment speed (speed of work equipment is low) 585

Testing hydraulic oil cooler performance 592

Bleeding air from hydraulic circuit 595

Releasing remaining pressure in hydraulic circuit 599

Work equipment 601

Checking center hinge pin lubrication 601

Adjustment method of auto grease injector delivery 603

Setting method of auto grease timer 604

Electrical system 606

Testing and adjusting bucket proximity switch 606

Adjusting lift arm potentiometer 607

Initial setting procedure for remote boom positioner (origin input method) 609

Checking proximity switch operation pilot lamp 610

Adjusting AJSS lever angle sensor and frame angle sensor 611

Testing and adjusting potentiometer mounting position 612

Procedure for testing diodes 615

Basic precautions for KOMTRAX Plus controller 616

Inspection and maintenance of KOMTRAX Plus controller 625

Initial setting procedure for KOMTRAX Plus controller 626

Precautions for replacing KOMTRAX Plus controller 643

Measurement procedure by downloading data in KOMTRAX Plus controller 651

Measurement procedure by multi monitor 655

Special functions of multi monitor 657

Pm Clinic 720

Outline of measurement procedure for Pm Clinic 720

Preparation for measurement for Pm Clinic 721

Pm clinic service 722

40 Troubleshooting 727

Contents 728

General information on troubleshooting 734

Symptom and troubleshooting numbers 734

Sequence of events in troubleshooting 735

Check before troubleshooting 736

Classification and procedures of troubleshooting 747

Breakage of hydraulic cylinder 750

Failure codes table 753

Symptom and troubleshooting numbers 769

Information in troubleshooting table 770

Troubleshooting method for open circuit in wiring harness of pressure sensor system 772

Layout drawing of connector pins 774

Connector list and layout 810

T- branch box and T- branch adapter table 830

Table of fuse locations 833

Troubleshooting by failure code 842

Failure code [1500L0] Double Engagement of Transmission Clutches 842

Failure code [1540N1] T/M overrun 843

Failure code [15B0NX] T/M Oil Filter Clogged 844

Failure code [15SAL1] ECMV (F) Fill Switch Short Circuit 846

Failure code [15SALH] ECMV (F) Fill Switch circuit Disconnect 848

Failure code [15SBL1] ECMV (R) Fill Switch Short Circuit 850

Failure code [15SBLH] ECMV (R) Fill Switch circuit Disconnect 852

Failure code [15SEL1] ECMV (1) Fill Switch Short Circuit 854

Failure code [15SELH] ECMV (1) Fill Switch circuit Disconnect 856

Failure code [15SFL1] ECMV (2) Fill Switch Short Circuit 858

Failure code [15SFLH] ECMV (2) Fill Switch circuit Disconnect 860

Failure code [15SGL1] ECMV (3) Fill Switch Short Circuit 862

Failure code [15SGLH] ECMV (3) Fill Switch circuit Disconnect 864

Failure code [2F00MA] Parking brake circuit failure 867

Failure code [2G42ZG] Accumulator Oil Press F Low 870

Failure code [2G43ZG] Accumulator Oil Press R Low 872

Failure code [44K0L4] Bucket cylinder position detector SW failure 874

Failure code [7REAKA] ACC Signal Malfunction 875

Failure code [989P00] Direction protection warning 876

Failure code [989Q00] Work equipment protection 876

Failure code [989R00] Tire slip 877

Failure code [989S00] Parking Brake Dragging 878

Failure code [989T00] Stationary steering (Brake: OFF, Load: OFF) 880

Failure code [989U00] Stationary steering (Brake: OFF, Load: ON) 881

Failure code [989V00] Stationary steering (Brake: ON, Load: OFF) 882

Failure code [989W00] Stationary steering (Brake: ON, Load: ON) 883

Failure code [AA1ANX] Air Cleaner 1 Clogging 884

Failure code [AA1BNX] Air Cleaner 2 Clogging 886

Failure code [AA1CNX] Air Cleaner 3 Clogging 888

Failure code [AA1DNX] Air Cleaner 4 Clogging 890

Failure code [AB00L6] Discharge of alternator R terminal 892

Failure code [AB00MA] Discharge of alternator R terminal 894

Failure code [AB00MB] Discharge of alternator R terminal 896

Failure code [B@BCZK] Drop in Engine Coolant Level 898

Failure code [b@C5ZK] Low brake fluid level (before engine start) 900

Failure code [B@C5ZK] Low brake fluid level (while engine is running) 901

Failure code [B@C6NS] High brake oil temp 902

Failure code [b@CENS] High torque converter oil temp 903

Failure code [B@CENS] Very high torque converter oil temp 904

Failure code [B@GAZK] Low battery 1 fluid level 906

Failure code [B@GBZK] Low battery 2 fluid level 908

Failure code [B@GCZK] Low battery 3 fluid level 910

Failure code [B@HANS] High hydraulic oil temp 912

Failure code [B@HAZK] Low hydraulic oil level 913

Failure code [D191KA] Neutral Output Relay Disconnection 914

Failure code [D191KB] Neutral Output Relay hot short 916

Failure code [D19MKA] SW pump PNC solenoid Relay (Disconnect/Short Circuit) 918

Failure code [D19MKY] SW pump PNC solenoid Relay hot short 920

Failure code [D19MMA] SW pump PNC solenoid circuit 1 Failure 922

Failure code [D19MMB] SW pump PNC solenoid circuit 2 Failure 924

Failure code [D5ZHKA] Starting Switch C signal circuit (Disconnect/Short Circuit) 926

Failure code [D5ZHKB] Starting Switch C signal circuit Hot short 928

Failure code [D5ZHKZ] Starting Switch C signal circuit failure 930

Failure code [D5ZHL6] Ignition C terminal Circuit Failure 932

Failure code [DAF5KP] Monitor Panel 5 V source sys Error 934

Failure code [DAFRKR] Communication Lost Monitor Panel Controller 936

Failure code [DAQ0KK] Drop in Transmission Controller Main Power Source 938

Failure code [DAQ0KT] Nonvolatile Memory (EEPROM) Abnormal 940

Failure code [DAQ2KK] Drop in Transmission Controller Solenoid Power Source 942

Failure code [DAQRKR] Communication Lost T/M Controller 944

Failure code [DAQRMA] Defective Option Selection Data in Transmission 946

Failure code [DB2RKR] Communication Lost Engine Controller 948

Failure code [DB90KK] Drop in Work Controller Main Power Source 950

Failure code [DB90KT] Nonvolatile Memory (EEPROM) Abnormal 952

Failure code [DB92KK] Solenoid Voltage Failure (Work controller) 954

Failure code [DB95KX] 5 V source sys Error (Work controller) 956

Failure code [DB9RKR] Communication Lost Boom Bucket & Joy stick Controller 958

Failure code [DB9RMA] Defective Option Selection Data in Boom Bucket Controller 960

Failure code [DB9RMC] Communication Lost (Work Controller) 962

Failure code [DBB0KK] VHMS source voltage Error 964

Failure code [DBB0KQ] VHMS Connector Mismatch 966

Failure code [DBB3KK] Abnormality in VBAT voltage (VHMS VBAT<10V) 968

Failure code [DBB5KP] VHMS 5 V source sys Error 970

Failure code [DBB6KP] VHMS 24 V source sys Error 972

Failure code [DBB7KP] VHMS 12 V source sys Error 974

Failure code [DBBQMC] Communication Lost (VHMS CAN0) 976

Failure code [DBBRKR] Communication Lost VHMS Controller 978

Failure code [DBBRMC] Communication Lost (VHMS CAN1) 980

Failure code [DD10KX] Verification Mode SW Failure 982

Failure code [DD1ALD] Remote positioner upper side set sw failure 984

Failure code [DD1BLD] Remote positioner lower side set sw failure 986

Failure code [DDA7L4] Throttle Lock Input signal Short Circuit 988

Failure code [DDA8KB] Throttle Lock (set/accelerator) switch Short Circuit 990

Failure code [DDA9KB] Throttle Lock (set/decelerator) switch Short Circuit 992

Failure code [DDB6L4] Neutral Signal Malfunction 994

Failure code [DDD7KA] Speed control dial circuit (Low Voltage) 996

Failure code [DDD7KB] Speed control dial circuit (High Voltage) 998

Failure code [DDDBKA] Traction control dial circuit (Low Voltage) 1000

Failure code [DDDBKB] Traction control dial circuit (High Voltage) 1002

Failure code [DDE5MA] Emergency steering signal Failure 1004

Failure code [DDK4KA] AJSS F/N/R Input Signal Disconnection 1006

Failure code [DDK4KB] AJSS F/N/R Input Signal Short Circuit 1008

Failure code [DDK5L4] Joystick Shift up/down SW circuit (Disconnect/Short Circuit) 1010

Failure code [DDP5KA] Steering lock detector pressure switch signal circuit Disconnect 1012

Failure code [DDT4LD] T/M Cut Off set switch signal short circuit 1014

Failure code [DDW9LD] Kickdown Switch Short Circuit 1016

Failure code [DGE5KX] Ambient air temp Sensor Failure 1018

Failure code [DGF1KA] Transmission Oil Temperature sensor signal Disconnect 1020

Failure code [DGF1KB] Abnormality in Transmission Oil Temperature sensor Short Circuit 1022

Failure code [DGF1KX] Transmission Oil Temperature sensor Failure (For Check) 1024

Failure code [DGH2KX] Hydraulic oil temp sensor circuit failure 1026

Failure code [DGR2KA] Brake oil temp sensor circuit Disconnection 1028

Failure code [DGR2KX] Brake oil temp sensor circuit failure 1030

Failure code [DGT1KX] T/C oil temp sensor circuit failure 1032

Failure code [DH20KX] Torque converter pressure sensor circuit 1034

Failure code [DH21KA] Loader pump oil press sensor (Disconnect/Short Circuit) 1036

Failure code [DH21KB] Loader pump oil press sensor hot short 1038

Failure code [DHPCKA] Boom bottom press (Disconnect/Short Circuit) 1040

Failure code [DHPCKX] Boom bottom press sensor circuit failure 1042

Failure code [DHPCKY] Boom bottom press hot short 1044

Failure code [DHPDKX] Boom head press sensor circuit failure 1046

Failure code [DHT1KX] T/M Cut Off pressure sensor signal Disconnect 1048

Failure code [DHT2L6] T/M oil filter sensor circuit failure 1050

Failure code [DHT3KX] Transmission main pressure sensor circuit 1052

Failure code [DHT4KX] Main PPC oil pressure sensor circuit 1054

Failure code [DHT5KX] Torque converter intake pressure sensor circuit 1056

Failure code [DHT8KX] Steering Oil Press Sensor Failure 1058

Failure code [DHTAKX] Transmission lubrication pressure sensor circuit 1060

Failure code [DHTBKA] Modulation clutch pressure sensor circuit Disconnect 1062

Failure code [DHTBKB] Modulation clutch pressure sensor signal short circuit 1064

Failure code [DHU2KA] F Brake Oil press Sensor Disconnect 1066

Failure code [DHU2KB] F Brake Oil press Sensor Hot short 1068

Failure code [DHU2KX] F Brake Oil press Sensor Failure 1070

Failure code [DHU3KA] R Brake Oil press Sensor Disconnect 1072

Failure code [DHU3KB] R Brake Oil press Sensor Hot short 1074

Failure code [DHU3KX] R Brake Oil press Sensor Failure 1076

Failure code [DJF1KA] Fuel level sensor circuit Disconnection 1078

Failure code [DK30KA] Steering lever angle sensor (Disconnect/Short Circuit) 1079

Failure code [DK30KY] Steering lever angle sensor circuit hot short 1080

Failure code [DK59KA] Boom lever potentiometer (main) (Disconnect/Short Circuit) 1082

Failure code [DK59KY] Boom lever potentiometer (main) hot short 1084

Failure code [DK59L8] Boom lever potentiometer (main & sub) failure 1085

Failure code [DK5AKA] Boom lever potentiometer (sub) (Disconnect/Short Circuit) 1088

Failure code [DK5AKY] Boom lever potentiometer (sub) hot short 1090

Failure code [DK5BKA] Bucket lever potentiometer (main) (Disconnect/Short Circuit) 1092

Failure code [DK5BKY] Bucket lever potentiometer (main) hot short 1094

Failure code [DK5BL8] Bucket lever potentiometer (main & sub) failure 1095

Failure code [DK5CKA] Bucket lever potentiometer (sub) (Disconnect/Short Circuit) 1098

Failure code [DK5CKY] Bucket lever potentiometer (sub) hot short 1099

Failure code [DKA0KA] Boom angle sensor (Disconnect/Short Circuit) 1100

Failure code [DKA0KX] Boom angle sensor circuit failure 1102

Failure code [DKA0KY] Boom angle sensor circuit hot short 1104

Failure code [DKA0L0] Boom angle sensor failure 1106

Failure code [DKD0KA] Frame angle sensor (Disconnect/Short Circuit) 1108

Failure code [DKD0KY] Frame angle sensor circuit hot short 1109

Failure code [DKD0KZ] Frame and steering angle sensor failure 1110

Failure code [DKH0KA] Angle sensor circuit (FR) Disconnect 1111

Failure code [DKH0KB] Angle sensor circuit (FR) Hot short 1112

Failure code [DKH1KA] Angle sensor circuit (LR) Disconnect 1114

Failure code [DKH1KB] Angle sensor circuit (LR) Hot short 1116

Failure code [DLE2KA] Engine Speed Sensor Disconnection 1118

Failure code [DLE2LC] Engine Speed Sensor Short Circuit 1120

Failure code [DLF6LC] Tire speed sensor circuit 1122

Failure code [DLFAKA] Mod/c Output Speed Sensor Disconnect 1124

Failure code [DLFALC] Mod/c Output Speed Sensor Short Circuit 1126

Failure code [DLT4KB] Output Shaft Speed Sensor (1) Short Circuit 1128

Failure code [DLT4KX] Output Shaft Speed Sensor (1) Disconnection 1130

Failure code [DT20KB] Transmission cut off indicator Output short circuit 1132

Failure code [DT21KB] Speed Control indicator Output short circuit 1133

Failure code [DUM8KB] VHMS Operation lamp Short Circuit 1134

Failure code [DV00KY] Buzzer circuit hotshort (for usually) 1136

Failure code [DV01KY] Buzzer circuit hotshort (for special) 1138

Failure code [DW23KA] T/M E-POCV (F bypass) Solenoid Disconnection 1140

Failure code [DW23KB] T/M E-POCV (F bypass) Solenoid Short Circuit 1141

Failure code [DW23KY] T/M E-POCV (F bypass) Solenoid circuit Hot short 1142

Failure code [DW24KA] T/M E-POCV (R bypass) Solenoid Disconnection 1143

Failure code [DW24KB] T/M E-POCV (R bypass) Solenoid Short Circuit 1144

Failure code [DW24KY] T/M E-POCV (R bypass) Solenoid circuit Hot short 1145

Failure code [DW25KA] T/M E-POCV (1st bypass) Solenoid Disconnection 1146

Failure code [DW25KB] T/M E-POCV (1st bypass) Solenoid Short Circuit 1147

Failure code [DW25KY] T/M E-POCV (1st bypass) Solenoid circuit Hot short 1148

Failure code [DW4PKA] Boom EPC solenoid (raise1) disconnection 1149

Failure code [DW4PKB] Boom Raise EPC solenoid (1) ground fault 1150

Failure code [DW4PKY] Boom Raise EPC solenoid (1) hot short 1151

Failure code [DW4QKA] Boom Lower EPC solenoid (1) disconnection 1152

Failure code [DW4QKB] Boom EPC solenoid (take down1) short circuit 1153

Failure code [DW4QKY] Boom EPC solenoid (take down1) hot short 1154

Failure code [DW4RKA] Bucket tilt EPC solenoid (1) disconnection 1155

Failure code [DW4RKB] Bucket tilt EPC solenoid (1) ground fault 1156

Failure code [DW4RKY] Bucket tilt EPC solenoid (1) hot short 1157

Failure code [DW4SKA] Bucket dump1 EPC solenoid disconnection 1158

Failure code [DW4SKB] Bucket dump EPC solenoid (1) short circuit 1159

Failure code [DW4SKY] Bucket dump EPC solenoid (1) hot short 1160

Failure code [DW5PKA] Boom EPC solenoid (raise2) disconnection 1161

Failure code [DW5PKB] Boom Raise EPC solenoid (2) ground fault 1162

Failure code [DW5PKY] Boom Raise EPC solenoid (2) hot short 1163

Failure code [DW5QKA] Boom EPC solenoid (take down2) disconnection 1164

Failure code [DW5QKB] Boom Lower EPC solenoid (2) ground fault 1165

Failure code [DW5QKY] Boom Lower EPC solenoid (2) hot short 1166

Failure code [DW5RKA] Bucket tilt2 EPC solenoid disconnection 1167

Failure code [DW5RKB] Bucket tilt EPC solenoid ground fault 1168

Failure code [DW5RKY] Bucket tilt2 EPC solenoid hot short 1169

Failure code [DW5SKA] Bucket dump2 EPC solenoid disconnection 1170

Failure code [DW5SKB] Bucket dump2 EPC solenoid short circuit 1171

Failure code [DW5SKY] Bucket dump2 EPC solenoid hot short 1172

Failure code [DWJ2KA] T/M E-POCV (R drain) Solenoid Disconnection 1173

Failure code [DWJ2KB] T/M E-POCV (R drain) Solenoid Short Circuit 1174

Failure code [DWJ2KY] T/M E-POCV (R drain) Solenoid circuit Hot short 1175

Failure code [DWM1KA] Work equipment neutral lock solenoid disconnection 1176

Failure code [DWM1KB] Work equipment neutral lock solenoid short circuit 1177

Failure code [DWM1KY] Work equipment neutral lock solenoid hot short 1178

Failure code [DWN6KA] Magnet detent solenoid (Boom raise) disconnection 1179

Failure code [DWN6KB] Magnet detent solenoid (Boom raise) short circuit 1180

Failure code [DWN6KY] Magnet detent solenoid (Boom raise) hot short 1181

Failure code [DWN7KA] Magnet detent solenoid (Boom float) disconnection 1182

Failure code [DWN7KB] Magnet detent solenoid (Boom float) short circuit 1183

Failure code [DWN7KY] Magnet detent solenoid (Boom float) hot short 1184

Failure code [DWN8KA] Magnet detent solenoid (Bucket tilt) disconnection 1185

Failure code [DWN8KB] Magnet detent solenoid (Boom tilt) short circuit 1186

Failure code [DWN8KY] Magnet detent solenoid (Boom tilt) hot short 1187

Failure code [DWNAKA] NC solenoid disconnection 1188

Failure code [DWNAKB] NC solenoid short circuit 1189

Failure code [DWNAKY] NC solenoid hot short 1190

Failure code [DXA1KA] Loader pump solenoid Relay (Disconnect/Short Circuit) 1192

Failure code [DXA1KY] Loader pump solenoid Relay hot short 1194

Failure code [DXA1MA] Loader pump solenoid Relay (Disconnect/Short Circuit) 1196

Failure code [DXF0KA] AJSS EPC solenoid disconnection 1198

Failure code [DXF0KB] AJSS EPC solenoid short circuit 1200

Failure code [DXH4KA] T/M E-POCV (1st) Solenoid Disconnection 1202

Failure code [DXH4KB] T/M E-POCV (1st) Solenoid Short Circuit 1204

Failure code [DXH4KY] T/M E-POCV (1st) Solenoid circuit Hot short 1206

Failure code [DXH5KA] T/M E-POCV (2nd) Solenoid Disconnection 1208

Failure code [DXH5KB] T/M E-POCV (2nd) Solenoid Short Circuit 1210

Failure code [DXH5KY] T/M E-POCV (2nd) Solenoid circuit Hot short 1212

Failure code [DXH6KA] T/M E-POCV (3rd) Solenoid Disconnection 1214

Failure code [DXH6KB] T/M E-POCV (3rd) Solenoid Short Circuit 1216

Failure code [DXH6KY] T/M E-POCV (3rd) Solenoid circuit Hot short 1218

Failure code [DXH7KA] T/M E-POCV (R) Solenoid Disconnection 1220

Failure code [DXH7KB] T/M E-POCV (R) Solenoid Short Circuit 1222

Failure code [DXH7KY] T/M E-POCV (R) Solenoid circuit Hot short 1224

Failure code [DXH8KA] T/M E-POCV (F) Solenoid Disconnection 1226

Failure code [DXH8KB] T/M E-POCV (F) Solenoid Short Circuit 1228

Failure code [DXH8KY] T/M E-POCV (F) Solenoid circuit Hot short 1230

Failure code [DXHPKA] T/M E-POCV (MOD/C) Solenoid Disconnection 1231

Failure code [DXHPKB] T/M E-POCV (MOD/C) Solenoid Short Circuit 1232

Failure code [DXHPKY] T/M E-POCV (MOD/C) Solenoid Short Circuit to 24 V 1233

Failure code [DXHPMA] T/M E-POCV (MOD/C) Solenoid Malfunction 1234

Troubleshooting of electrical system (E-mode) 1236

E-1 Remote positioner “RAISE” or “LOWER” LED does not light up 1236

E-2 Open circuit or ground fault in check lamp system 1237

E-3 Machine monitor does not operate 1238

E-4 Turn signal lamp does not light up 1240

E-5 Defective parking lamp 1242

E-6 Defective front working lamp 1244

E-7 Defective rear working lamp 1246

E-8 Headlamp does not light up 1248

E-9 Service meter does not work, or service meter works while engine is stopped 1250

E-10 Monitor panel controller does not sound buzzer 1252

E-11 Defective auto-greasing system 1254

Troubleshooting of hydraulic and mechanical system (H-mode) 1256

Before performing troubleshooting of work equipment hydraulic system (how to use the multi monitor) 1256

Work equipment hydraulic system, general 1266

Work equipment oil pressure group 1268

Before performing troubleshooting of steering oil pressure system (how to use the multi monitor) 1333

Checking steering related standard values 1346

Steering oil pressure system, general 1347

Steering oil pressure group 1348

Brake oil pressure system, general 1388

Brake oil pressure group 1390

Information contained in troubleshooting table (H mode) 1444

H-1 Torque converter oil temperature rises too high (overheats) 1445

H-2 Turning or response of steering is poor 1448

H-3 AJSS lever is hard to operate 1451

H-4 Steering shakes or jolts 1453

H-5 Wheel brake does not work at all or is weak 1455

H-6 Lift arm speed is low or lift arm rising force is insufficient 1457

H-7 Shock is large when lift arm stops 1460

H-8 Hydraulic oil temperature rises too high (overheating) 1461

50 Disassembly and assembly 1463

CONTENTS 1464

General information on disassembly and assembly 1466

How to read Disassembly and Assembly 1466

Coating materials list 1468

Special tool list 1471

Sketches of special tools 1485

Flushing procedure 1523

Flushing procedure for brake circuit 1523

Flushing procedure for work equipment and steering circuit 1530

Air bleeding procedure 1537

Bleeding air from brake circuit 1537

Bleeding air from piston motor of brake and torque converter 1538

Bleeding air from piston pump 1540

Bleeding air from work equipment circuit and steering circuit 1541

Engine and cooling system 1544

Removal and installation of radiator and hydraulic oil coolerassembly 1544

Removal and installation of engine assembly 1554

Removal and installation of air-cooled torque converter and transmission,and brake oil cooler assembly 1562

Removal and installation of water-cooled torque converter andtransmission oil cooler assembly 1565

Removal and installation of damper assembly 1567

Disassembly and assembly of damper 1570

Removal and installation of bumper and fuel tank assembly 1579

Removal and installation of hood assembly 1582

Disassembly and assembly procedures for MESABI oil cooler 1584

Disassembly and assembly of MESABI oil cooler 1587

Power train 1597

Removal and installation of torque converter and transmissionassembly 1597

Disconnection and connection of transmission assembly and torqueconverter assembly 1609

Disconnection and connection of torque converter assembly, PTOand transfer assembly 1617

Disassembly and assembly of torque converter 1624

Disassembly and assembly of modulation clutch 1635

Disassembly and assembly of PTO and transfer 1639

Disconnection and connection of transmission assembly,transfer, and parking brake assembly 1652

Disassembly and assembly of transmission assembly 1662

Disassembly and assembly of transfer 1685

Disassembly and assembly of parking brake 1692

Removal and installation of parking brake assembly (installed onthe machine) 1696

Removal and installation of transmission, brake cooling deviceand brake pump assembly 1700

Removal and installation of steering pump, control pump and PPCpump assembly 1702

Disassembly and assembly of drive shaft 1704

Removal and installation of front axle assembly 1706

Removal and installation of front final drive assembly 1709

Removal and installation of rear axle assembly 1713

Removal and installation of rear final drive assembly 1727

Removal and installation of differential assembly 1731

Disassembly and assembly of differential 1734

Disassembly and assembly of final drive and brake 1748

Removal and installation of center support assembly 1763

Disassembly and assembly of center support 1765

Steering system 1770

Removal and installation of steering demand valve assembly 1770

Removal and installation of steering cylinder assembly 1772

Removal and installation of emergency diverter valve assembly 1777

Removal and installation of emergency steering pump assembly 1780

Brake system 1782

Removal and installation of brake accumulator charge valveassembly 1782

Removal and installation of brake oil tank assembly 1783

Undercarriage and frame 1785

Procedure for disconnecting front frame and rear frame 1785

Removal and installation of center hinge pin 1787

Hydraulic system 1806

Removal and installation of hydraulic tank, filter case assembly 1806

Removal and installation of No 1 work equipment pump assembly 1809

Removal and installation of No 2 work equipment pump assembly 1812

Removal and installation of switch pump assembly 1814

Removal and installation of work equipment control valveassembly 1816

Work equipment 1833

Removal and installation of bucket cylinder assembly 1833

Removal and installation of lift cylinder assembly 1845

Disassembly and assembly of work equipment cylinder 1860

Removal and installation of work equipment assembly 1867

Procedure for running in bucket pin 1933

Procedure for running in lift arm pin 1936

Cab 1939

Removal and installation of bulkhead assembly 1939

Removal and installation of operator’s cab and floor assembly 1941

Removal and installation of operator’s cab assembly 1947

Removal and installation of air conditioner unit assembly 1950

Disassembly and assembly of operator seat 1952

Removal and installation of AJSS lever switch assembly 1978

Electrical system 1985

Removal and installation of DT connector pin 1985

Removal and installation of HD connector pin 1987

Repairing HD connector pin harness 1989

Removal and installation of controller assembly 1991

60 Maintenance standard 1993

Contents 1994

Engine and cooling system 1995

Engine mount 1995

Cooling system 1996

Cooling fan motor 1997

Damper 1999

Power train 2000

Transmission mount 2000

Torque converter 2002

Main relief valve, torque converter relief valve 2006

Torque converter regulator valve 2008

ECMV 2009

Transmission 2010

Transmission control valve 2012

Lubrication relief valve 2015

Transfer 2016

Drive shaft 2018

Center support 2020

Differential 2022

Final drive 2026

Steering system 2028

Steering pump 2028

Switch pump 2029

Steering demand valve 2031

Diverter valve 2033

Steering cylinder mount 2034

Steering cylinder 2035

Emergency steering pump 2037

Brake system 2038

Brake valve 2038

Slack adjuster 2040

Brake 2041

Parking brake 2042

Undercarriage and frame 2044

Axle mount 2044

Center hinge pin 2046

Hydraulic system 2049

No 1 work equipment pump 2049

No 2 work equipment pump 2052

PPC relief valve 2055

Pump control relief valve 2056

Work equipment control valve 2057

Work equipment 2059

Work equipment linkage 2059

Bucket positioner, remote positioner 2064

Work equipment cylinder 2065

Electrical system 2067

Work equipment control lever 2067

80 Appendix 2069

Contents 2070

Air conditioner 2071

Precautions for refrigerant 2071

Configuration and function of refrigeration cycle 2072

Outline of refrigeration cycle 2073

Control system 2075

Air conditioner components 2080

Compressor 2087

Electric fan and condenser 2088

Receiver drier 2090

Service tools 2091

Troubleshooting procedures 2098

Interview and confirmation of failure symptom 2099

Basic checks 2100

Troubleshooting 2101

Checking of refrigeration cycle 2107

Troubleshooting for unusual noise 2115

Electrical system 2116

Parts replacement 2118

Periodic inspection and maintenance 2121

Testing and adjusting compressor belt tension 2125

90 Diagrams and drawings 2127

Contents 2128

Hydraulic circuit diagram 2129

Circuit symbols used in hydraulic circuit diagrams 2129

Transmission hydraulic circuit diagram 2132

Brake hydraulic circuit diagram 2134

Work equipment hydraulic circuit diagram 2137

Electrical circuit diagram 2141

Circuit symbols used in electrical circuit diagrams 2141

Electrical circuit diagram 2145

INDEX 2171

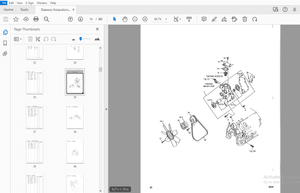

IMAGES PREVIEW OF THE MANUAL: