$41

Komatsu WA320-5 Wheel Loader Shop Manual SEBM034610 – PDF DOWNLOAD

Komatsu WA320-5 Wheel Loader Shop Manual SEBM034610 – PDF DOWNLOAD

FILE DETAILS:

Komatsu WA320-5 Wheel Loader Shop Manual SEBM034610 – PDF DOWNLOAD

Language : English

Pages : 870

Downloadable : Yes

File Type : PDF

Size: 86.9 MB

DESCRIPTION:

Komatsu WA320-5 Wheel Loader Shop Manual SEBM034610 – PDF DOWNLOAD

Machine model Serial number

WA320-5 60001 and up

GENERAL PRECAUTIONS:

Mistakes in operation are extremely dangerous. Read the Operation and Maintenance Manual carefully BEFORE operating the machine.1. Before carrying out any greasing or repairs, read all the precautions given on the decals which are fixed to the machine.2. When carrying out any operation, always wear safety shoes and helmet. Do not wear loose work clothes, or clothes with buttons missing.• Always wear safety glasses when hitting parts with a hammer.• Always wear safety glasses when grinding parts with a grinder, etc.3. If welding repairs are needed, always have a trained, experienced welder carry out the work. When carrying out welding work, always wear welding gloves, apron, hand shield, cap and other clothes suited for welding work.4. When carrying out any operation with two or more workers, always agree on the operating procedure before starting. Always inform your fellow workers before starting any step of the operation. Before starting work, hang UNDER REPAIR signs on the controls in the operator’s compartment.5. Keep all tools in good condition and learn the correct way to use them.6. Decide a place in the repair workshop to keep tools and removed parts. Always keep the tools and parts in their correct places. Always keep the work area clean and make sure that there is no dirt or oil on the floor. Smoke only in the areas provided for smoking. Never smoke while working.

PREPARATIONS FOR WORK:

- 7. Before adding oil or making any repairs, park the machine on hard, level ground, and block the wheels or tracks to prevent the machine from moving.

- 8. Before starting work, lower blade, ripper, bucket or any other work equipment to the ground. If this is not possible, insert the safety pin or use blocks to prevent the work equipment from falling. In addition, be sure to lock all the control levers and hang warning signs on them.

- 9. When disassembling or assembling, support the machine with blocks, jacks or stands before starting work.

- 10.Remove all mud and oil from the steps or other places used to get on and off the machine. Always use the handrails, ladders or steps when getting on or off the machine. Never jump on or off the machine. If it is impossible to use the handrails, ladders or steps, use a stand to provide safe footing.

FOREWORD

GENERAL

This shop manual has been prepared as an aid to improve the quality of repairs by giving the serviceman an

accurate understanding of the product and by showing him the correct way to perform repairs and make judgements.

Make sure you understand the contents of this manual and use it to full effect at every opportunity.

This shop manual mainly contains the necessary technical information for operations performed in a service

workshop. For ease of understanding, the manual is divided into the following chapters; these chapters are further

divided into the each main group of components.

STRUCTURE AND FUNCTION

This section explains the structure and function of each component. It serves not only to give an understanding

of the structure, but also serves as reference material for troubleshooting.

In addition, this section may contain hydraulic circuit diagrams, electric circuit diagrams, and maintenance

standards.

TESTING AND ADJUSTING

This section explains checks to be made before and after performing repairs, as well as adjustments to

be made at completion of the checks and repairs.

Troubleshooting charts correlating “Problems” with “Causes” are also included in this section.

DISASSEMBLY AND ASSEMBLY

This section explains the procedures for removing, installing, disassembling and assembling each component,

as well as precautions for them.

MAINTENANCE STANDARD

This section gives the judgment standards for inspection of disassembled parts.

The contents of this section may be described in STRUCTURE AND FUNCTION.

OTHERS

This section mainly gives hydraulic circuit diagrams and electric circuit diagrams.

In addition, this section may give the specifications of attachments and options together.

TABLE OF CONTENTS:

Komatsu WA320-5 Wheel Loader Shop Manual SEBM034610 – PDF DOWNLOAD

COVER 1

CONTENTS 2

LIST OF REVISED PAGES 3

01 GENERAL 27

GENERAL ASSEMBLY DRAWINGS 28

SPECIFICATIONS 29

WEIGHT TABLE 33

LIST OF LUBRICANT AND COOLANT 35

10 STRUCTURE,FUNCTION AND MAINTENANCE STANDARD 37

ENGINE MOUNT AND TRANSFER MOUNT 38

DAMPER 39

COOLING SYSTEM 40

POWER TRAIN 43

POWER TRAIN SYSTEM DIAGRAM 44

DRIVE SHAFT (PROPELLER SHAFT) 46

HST HYDRAULIC PIPING DIAGRAM 47

HST PUMP 48

HIGH-PRESSURE RELIEF VALVE 50

LOW-PRESSURE RELIEF VALVE 52

HST CHARGE PUMP 53

SPEED-RELATED VALVE (DA VALVE) 54

HIGH-PRESSURE CUT-OFF VALVE 55

HST MOTOR 56

EP SERVO VALVE 59

HA SERVO VALVE 60

FORWARD-REVERSE SHUTTLE VALVE 61

TRANSFER 62

CLUTCH SOLENOID VALVE 73

AXLE 74

DIFFERENTIAL 76

LIMITED-SLIP DIFFERENTIAL 84

FINAL DRIVE 88

AXLE MOUNTING AND CENTER HINGE PIN 90

STEERING PIPING 99

STEERING COLUMN 100

PRIORITY VALVE 101

ORBIT-ROLL VALVE 104

CUSHION VALVE 112

STEERING CYLINDER 113

EMERGENCY STEERING PIPING 115

EMERGENCY STEERING VALVE 116

BRAKE PIPING 119

BRAKE VALVE 120

INCHING VALVE 124

CHARGE VALVE 126

ACCUMULATOR (FOR BRAKE) 130

SLACK ADJUSTER 132

BRAKE 134

PARKING BRAKE CONTROL 136

PARKING BRAKE 137

HYDRAULIC PIPING 138

WORK EQUIPMENT LEVEL LINKAGE 140

HYDRAULIC TANK 142

4-GEAR PUMP UNIT 144

ACCUMULATOR (FOR PPC CIRCUIT) 146

LOCK VALVE 147

E C S S VALVE 148

ACCUMULATOR (FOR E C S S ) 150

HYDRAULIC PIPING OF COOLING SYSTEM 151

COOLING FAN MOTOR 152

WORK EQUIPMENT CONTROL VALVE 155

WORK EQUIPMENT PPC VALVE 176

ATTACHMENT PPC VALVE 188

WORK EQUIPMENT LINKAGE 192

BUCKET 194

BUCKET POSITIONER AND BOOM KICK-OUT 196

WORK EQUIPMENT CYLINDER 202

AIR CONDITIONER 203

MACHINE MONITORING SYSTEM 204

MACHINE MONITOR 214

LIST OF ITEMS DISPLAYED ON MONITOR 215

ELECTRICAL SYSTEM (HST CONTROLLER SYSTEM) 241

HST CONTROLLER 245

KOMTRAX SYSTEM 246

ENGINE START CIRCUIT 248

ENGINE STOP CIRCUIT 250

PREHEATING CIRCUIT (AUTOMATIC PREHEATING SYSTEM) 251

PARKING BRAKE CIRCUIT 252

ELECTRONICALLY CONTROLLED SUSPENSION SYSTEM 255

SENSORS 256

20 TESTING AND ADJUSTING 265

STANDARD VALUE TABLE FOR ENGINE 266

STANDARD VALUE TABLE FOR CHASSIS 267

TESTING AND ADJUSTING 271

TOOLS FOR TESTING, ADJUSTING,AND TROUBLESHOOTING 272

MEASURING ENGINE SPEED 274

MEASURING EXHAUST GAS COLOR 275

ADJUSTING VALVE CLEARANCE 277

MEASURING COMPRESSION PRESSURE 278

MEASURING BLOW-BY PRESSURE 279

TESTING AND ADJUSTING FUEL INJECTION TIMING 280

MEASURING ENGINE OIL PRESSURE 281

MEASURING, TESTING OPERATION FORCE OF ACCELERATOR PEDAL 282

ADJUSTING ENGINE STOP SOLENOID 284

ADJUSTING ENGINE SPEED SENSOR 285

TESTING AND ADJUSTING AIR CONDITIONER COMPRESSOR BELT TENSION 285

MEASURING DIRECTIONAL LEVER 286

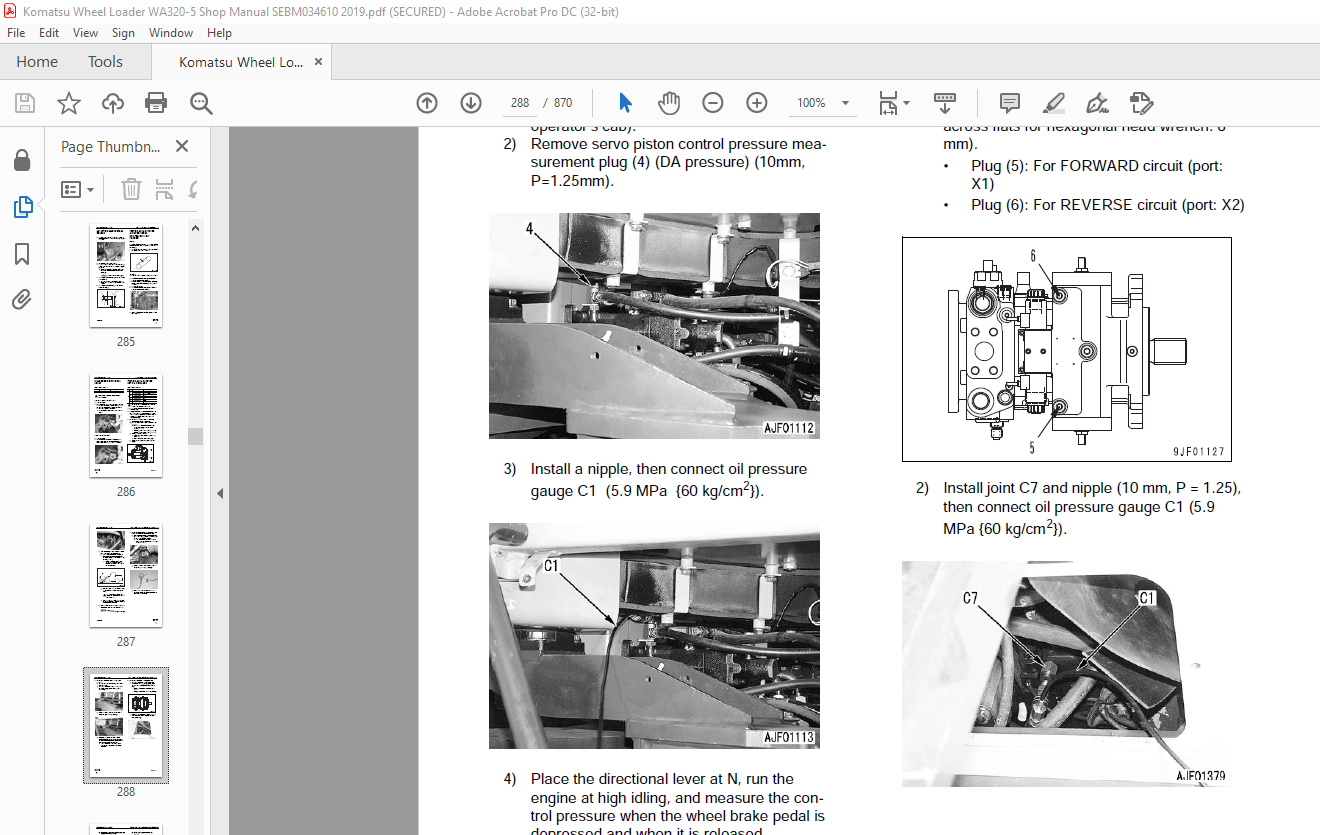

TESTING AND ADJUSTING HST OIL PRESSURE 286

MEASURING CLUTCH CONTROL PRESSURE 291

TESTING AND ADJUSTING STEERING WHEEL 292

TESTING AND ADJUSTING STEERING OIL PRESSURE 293

BLEEDING AIR FROM STEERING CIRCUIT 294

TESTING HYDRAULIC FAN 295

MEASURING BRAKE PEDAL 296

TESTING AND ADJUSTING BRAKE PEDAL LINKAGE 297

MEASURING BRAKE PERFORMANCE 298

TESTING AND ADJUSTING ACCUMULATOR CHARGE PRESSURE 299

MEASURING BRAKE OIL PRESSURE 300

MEASURING WEAR OF BRAKE DISC 302

BLEEDING AIR FROM BRAKE CIRCUIT 303

MEASURING PARKING BRAKE PERFORMANCE 304

TESTING AND ADJUSTING PARKING BRAKE LINKAGE 305

MEASURING AND ADJUSTING WORK EQUIPMENT CONTROL LEVER 306

TESTING AND ADJUSTING WORK EQUIPMENT HYDRAULIC PRESSURE 307

TESTING AND ADJUSTING WORK EQUIPMENT PPC OIL PRESSURE 308

BLEEDING AIR 310

RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT 311

TESTING AND ADJUSTING BUCKET POSITIONER 311

TESTING AND ADJUSTING OF BOOM KICK-OUT 313

CHECKING PROXIMITY SWITCH ACTUATION DISPLAY LAMP 314

PROCEDURE FOR CHECKING DIODE 315

METHOD OF CONNECTING T-ADAPTER FOR HST CONTROLLER 316

STARTING KOMTRAX TERMINAL OPERATIONS 317

INDICATOR LAMPS OF KOMTRAX TERMINAL 321

SPECIAL FUNCTIONS OF MACHINE MONITOR 325

FLOW OF MODES AND FUNCTIONS 326

FAILURE CODE TABLE 334

PM CLINIC INSPECTION CHART 344

TROUBLESHOOTING 347

POINTS TO REMEMBER WHEN TROUBLESHOOTING 348

SEQUENCE OF EVENTS IN TROUBLESHOOTING 349

PRECAUTIONS WHEN CARRYING OUT MAINTENANCE 350

CHECKS BEFORE TROUBLESHOOTING 358

CATEGORIES,PROCEDURE,AND METHOD OF USING TROUBLESHOOTING CHARTS 359

PHENOMENA CONSIDERED TO BE FAILURES AND TROUBLESHOOTING NO 360

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS 363

T-ADAPTER TABLE 386

CONNECTOR TYPES AND MOUNTING LOCATIONS 389

CONNECTOR LAYOUT DRAWING 396

TROUBLESHOOTING OF HST CONTROLLER SYSTEM (HST MODE) 401

BEFORE TROUBLESHOOTING CODE DISPLAY 402

BEFORE TROUBLESHOOTING ELECTRICAL SYSTEM 404

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE 405

FAILURE CODE [989F00] (HST MOTOR PROTECTION CAUTION(00)) 407

FAILURE CODE [DHH1KX] (HST OIL PRESSURE SENSOR INPUT SIGNAL OUTSIDE RANGE(KX)) 408

FAILURE CODE [DLE2LC] (ENGINE REVOLUTION SENSOR REVOLUTION SPEED SIGNAL MISMATCH (LC)) 410

FAILURE CODE [DW26KZ] (MOTOR 2 SOLENOID SYSTEM DISCONTINUITY OR SHORT-CIRCUITING(KZ)) 412

FAILURE CODE [DX19KZ] (MOTOR 1 SOLENOID SYSTEM DISCONTINUITY OR SHORT-CIRCUITING (KZ)) 414

FAILURE CODE [DX20KZ] (CLUTCH SOLENOID SYSTEM DISCONTINUITY OR SHORT-CIRCUITING (KZ)) 416

TROUBLESHOOTING CODE [HST-1](DEFECTIVE HST CONTROLLER POWER SOURCE (HST CONTROLLER DOES NOT FUNCTION)) 418

TROUBLESHOOTING CODE [HST-2] (TRAVEL SPEED DOES NOT SHIFTED) 420

TROUBLESHOOTING CODE [HST-3] HST OUTPUT CONTROL(TRACTION CONTROL) CANNOT BE CONTROLLED 424

TROUBLESHOOTING CODE [HSR-4] (TRAVEL SPEED LIMIT CANNOT BE CHANGED WHEN GEAR SPEED SELECTOR SWITCH IS IN “1ST” POSITION) 426

TROUBLESHOOTING CODE [HST-5] (TRAVEL SPEED IS NOT INCREASED) 428

TROUBLESHOOTING OF TRAVEL DAMPER SYSTEM(ECSS MODE) 429

RELATED ELECTRICAL CIRCUIT DIAGRAM 430

ECSS-1 MALFUNCTION OF TRAVEL DAMPER 431

TROUBLESHOOTING OF MONITOR SYSTEM(MON MODE) 437

BEFORE TROUBLESHOOTING CODE DISPLAY 440

BEFORE TROUBLESHOOTING ELECTRICAL SYSTEM 442

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE 443

FAILURE CODE [15B0NX] (HST OIL FILTER CLOGGED (NX)) 445

FAILURE CODE [2G42ZG] (DECREASED BRAKE OIL PRESSURE(ZG)) 446

FAILURE CODE [989FOO] (HST MOTOR PROTECTION CAUTION (OO)) 447

FAILURE CODE [989FN1] (HST OVERRUNNING (N1)) 448

FAILURE CODE [AA1ANX] (CLOGGING OF AIR CLEANER (NX)) 450

FAILURE CODE [ABOOL6] (DEFECTIVE BATTERY CHARGING CIRCUIT(L6)) 452

FAILURE CODE [ABOOMA] (DEFECTIVE BATTERY CHARGING CIRCUIT (MA)) 453

FAILURE CODE [B@BAZG] (DEGREASED ENGINE OIL PRESSURE(ZG)) 454

FAILURE CODE [B@BAZK] LOWERING OF ENGINE OIL LEVEL(ZK) 455

FAILURE CODE [B@BCNS] (ENGINE WATER TEMPERATURE OVERHEATING(NS)) 456

FAILURE CODE [B@BCZK] (ALARM INDICATING LOW COOLANT LEVEL(ZK)) 457

FAILURE CODE [B@C7NS] (AXLE OIL TEMPERATURE OVERHEATING(NS)) 458

FAILURE CODE [B@CRNS] (HST OIL TEMPERATURE OVERHEATING(NS)) 459

FAILURE CODE [D5ZHL6] (STARTING SWITCH “C”(IGN”C”)INPUT FAILURE(L6)) 460

FAILURE CODE [DAFOKT] (CONTROLLER INSIDE FAILURE(KT)) 462

FAILURE CODE [DAJOKR] (HST CONTROLLER COMMUNICATION FAILURE(KR)) 464

FAILURE CODE [DD15LD] (MONITOR PANEL MODE SELECTOR SWITCH 1[■](PANEL SWITCH 1)INPUT ERROR(LD)) 466

FAILURE CODE [DD16LD] (MONITOR PANEL MODE SELECTOR SWITCH 1[◇](PANEL SWITCH 2)INPUT ERROR (LD) 467

FAILURE CODE [DD17LD] (MONITOR PANEL MODE SELECTOR SWITCH 2[<](PANEL SWITCH 3)INPUT ERROR (LD) 468

FAILURE CODE [DD18LD] (MONITOR PANEL MODE SELECTOR SWITCH 2[>](PANEL SWITCH 4)INPUT ERROR (LD) 469

FAILURE CODE [DDK3KB] (MULTIPLE DIRECTIONAL LEVER FR SIGNAL INPUT (KB)) 470

FAILURE CODE [DDS5L6] (DECREASED STEERING OIL PRESSURE(L6)) 472

FAILURE CODE [DGE2KX] (ENGINE WATER TEMPERATURE (HIGH TEMPERATURE) SENSOR SYSTEM FAILURE(KX)) 473

FAILURE CODE [DGE3L6] (ENGINE WATER TEMPERATURE (LOW TEMPERATURE)SENSOR SYSTEM FAILURE(L6)) 474

FAILURE CODE [DGH1LX] (HST OIL TEMPERATURE SENSOR SYSTEM FAILURE(KX)) 475

FAILURE CODE [DGR4KA] (AXLE OIL TEMPERATURE SENSOR SYSTEM DISCONTINUITY(KA)) 476

FAILURE CODE [DGR4KX] (AXLE OIL TEMPERATURE SENSOR SYSTEM FAILURE(KX)) 477

FAILURE CODE [DHE4L6] (ENGINE OIL PRESSURE SENSOR SYSTEM DISCONTINUITY(L6)) 478

TROUBLESHOOTING CODE [MON-1] (THE PARKING BRAKE INDICATOR LAMP DOES NOT LIGHT ON) 480

TROUBLESHOOTING CODE [MON-2] (THE BRAKE OIL PRESSURE CAUTION LAMP DOES NOT LIGHT ON) 484

TROUBLESHOOTING CODE [MON-3] (THE ENGINE WATER TEMPERATURE CAUTION LAMP DOES NOT LIGHT ON,OR AFTER THE ENGINE STARTS,THE ENGINE WATER TEMPERATURE GAUGE DOES NOT RISE ) 485

TROUBLESHOOTING CODE [MON-4] (THE HST OIL TEMPERATURE CAUTION LAMP DOES NOT LIGHT ON,OR AFTER THE ENGINE STARTS,THE HST OIL TEMPERATURE GAUGE DOES NOT RISE ) 486

TROUBLESHOOTING CODE [MON-5] (THE FUEL LEVEL GAUGE DOES NOT RISE OR DECREASE ) 487

TROUBLESHOOTING CODE [MON-6] (THE RADIATOR COOLANT LEVEL CAUTION LAMP DOES NOT LIGHT ON) 488

TROUBLESHOOTING CODE [MON-7] (THE STEERING OIL PRESSURE CAUTION LAMP DOES NOT LIGHT ON) 489

TROUBLESHOOTING CODE [MON-6] (THE EMERGENCY STEERING OIL PRESSURE INDICATOR LAMP DOES NOT LIGHT ON) 490

TROUBLESHOOTING CODE [MON-9] (INPUT FAILURE IN MONITOR PANEL MODE SELECTOR SWITCH 1[■](PANEL SWITCH 1)) 491

TROUBLESHOOTING CODE [MON-10] (INPUT FAILURE IN MONITOR PANEL MODE SELECTOR SWITCH 1[◇](PANEL SWITCH 2)) 492

TROUBLESHOOTING CODE [MON-11] (INPUT FAILURE IN MONITOR PANEL MODE SELECTOR SWITCH 2[<](PANEL SWITCH 3)) 493

TROUBLESHOOTING CODE [MON-12] (INPUT FAILURE IN MONITOR PANEL MODE SELECTOR SWITCH 2[>](PANEL SWITCH 4)) 494

TROUBLESHOOTING CODE [MON-13] (THE ALARM BUZZER DOES NOT SOUND OR STOP) 496

TROUBLESHOOTING CODE [MON-14] ENGINE OIL LEVEL CAUTION LAMP DOES NOT LIGHT UP 498

TROUBLESHOOTING CODE [MON-15] (AIR CLEANER CLOGGING INDICATOR LAMP DOES NOT LIGHT UP) 500

TROUBLESHOOTING CODE [MON-16] THE WIPER DOES NOT FUNCTION 502

TROUBLESHOOTING CODE [MON-17] (THE LAMPS DO NOT WORK PROPERLY) 502

TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE) 503

BEFORE TROUBLESHOOTING ELECTRICAL SYSTEM 504

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE 505

TROUBLESHOOTING CODE [E-1](THE ENGINE DOES NOT START) 508

TROUBLESHOOTING CODE [E-2](THE ENGINE DOES NOT STOP) 514

TROUBLESHOOTING CODE [E-3](PREHEATING IS IMPOSSIBLE OR CONSTANT) 516

TROUBLESHOOTING CODE [E-4](THE PARKING BRAKE (MECHANICAL TYPE) DOES NOT FUNCTION) 520

TROUBLESHOOTING CODE [E-5](DEFECTIVE BOOM KICK-OUT FUNCTION AND CANCELLATION) 526

TROUBLESHOOTING CODE [E-6](DEFECTIVE BUCKET POSITIONER FUNCTION AND CANCELLATION) 530

TROUBLESHOOTING CODE [E-7](DEFECTIVE LIFT ARM FLOATING HOLDING FUNCTION AND CANCELLATION) 533

TROUBLESHOOTING CODE [E-8](TRAVEL DIRECTION IS NOT CHANGED NORMALLY) 534

TROUBLESHOOTING CODE [E-9](THE WIPER DOES NOT FUNCTION) 540

TROUBLESHOOTING CODE [E-10](THE WINDOW WASHER DOES NOT FUNCTION) 546

TROUBLESHOOTING CODE [E-11](LAMPS DO NOT WORK PROPERLY) 550

TROUBLESHOOTING CODE [E-12](THE HORN DOES NOT SOUND) 562

TROUBLESHOOTING CODE [E-13](DEFECTIVE THE AIR CONDITIONER) 564

TROUBLESHOOTING OF HYDRAULIC, MECHANICAL SYSTEM(H MODE) 577

METHOD OF USING TROUBLESHOOTING CHART 578

FAILURE CODE AND CAUSE TABLE 580

H-1 THE MACHINE DOES NOT START 582

H-2 THE TRAVEL SPEED IS SLOW 583

H-3 THE THRUSTING FORCE IS WEAK 584

H-4 ENGINE STALLS WHEN TRAVELING OR ENGINE SPEED DROPS EXCESSIVELY 585

H-5 THE GEAR IS NOT SHIFTED 586

H-6 THE STEERING WHEEL DOES NOT TURN 587

H-7 THE STEERING WHEEL IS HEAVY 588

H-8 STEERING WHEEL SHAKES OR JERKS 589

H-10 THE BRAKE DOES NOT WORK OR NOES NOT WORK WELL 590

H-11 THE BRAKE IS NOT RELEASED OR IS DRAGGED 591

H-12 THE LIFT ARM DOES NOT RISE OR LOWER 592

H-13 THE LIFT ARM MOVES SLOWLY OR THE LIFT ARM RISING FORCE IS INSUFFICIENT 593

H-14 WHEN RISING,THE LIFT ARM COMES TO MOVE SLOWLY AT SPECIFIC HEIGHT 594

H-15 THE LIFT ARM CYLINDER CANNOT HOLD DOWN THE BUCKET(THE BUCKET RISES IN THE AIR) 594

H-16 HYDRAULIC DRIFTS OF THE LIFT ARM OCCUR OFTEN 594

H-17 THE LIFT ARM WOBBLES DURING OPERATION 594

H-18 WHEN THE CONTROL LEVEL IS SWITCHED FROM “HOLD” TO “RAISE”, THE LIFT ARM FALLS TEMPORARILY 595

H-19 THE BUCKET DOES NOT TILT BACK 596

H-20 THE BUCKET MOVES SLOWLY OR THE TILTING-BACK FORCE IS INSUFFICIENT 597

H-21 THE BUCKET COMES TO OPERATE SLOWLY IN HE MIDST OF TILTING BACK 598

H-22 THE BUCKET CYLINDER CANNOT HOLD DOWN THE BUCKET 598

H-23 HYDRAULIC DRIFTS OF THE BUCKET OCCUR OFTEN 598

H-24 THE BUCKET WOBBLES DURING TRAVEL WITH CARGO (THE WORK EQUIPMENT VALVE IS SET TO “HOLD”) 599

H-25 WHEN THE CONTROL LEVEL IS SWITCHED FROM “HOLD”TO “TILT”,THE BUCKET FALLS TEMPORARILY 599

H-26 THE CONTROL LEVELS OF THE LIFT ARM AND BUCKET DO NOT MOVE SMOOTHLY AND HEAVY 599

H-27 THE TRAVEL DAMPER DOES NOT OPERATE AND MACHINE PITCHES AND BOUNCES 600

TROUBLESHOOTING OF ENGINE (S MODE) 601

METHOD OF USING TROUBLESHOOTING CHARTS 602

S-1 STARTING PERFORMANCE IS POOR(STARTING ALWAYS TAKES TIME) 606

S-2 ENGINE DOES NOT START 608

(1)ENGINE DOES NOT TURN 608

(2)ENGINE TURNS BUT NO EXHAUST SMOKE COMES OUT(FUEL IS NOT BEING INJECTED) 609

(3)EXHAUST SMOKE COMES OUT BUT ENGINE DOES NOT START(FUEL IS BEING INJECTED) 610

S-3 ENGINE DOES NOT PICK UP SMOOTHLY(FOLLOW-UP IS POOR) 611

S-4 ENGINE STOPS DURING OPERATIONS 612

S-5 ENGINE DOES NOT ROTATE SMOOTHLY(HUNTING) 613

S-6 ENGINE LACKS OUTPUT(OR LACKS POWER) 614

S-7 EXHAUST SMOKE IS BLACK(INCOMPLETE COMBUSTION) 615

S-8 OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST SMOKE IS BLUE) 616

S-9 OIL BECOMES CONTAMINATED QUICKLY 617

S-10 FUEL CONSUMPTION IS EXCESSIVE 618

S-11 OIL IS IN COOLING WATER,OR WATER SPURTS BACK,OR WATER LEVEL GOES DOWN 619

S-12 OIL PRESSURE CAUTION LAMP LIGHTS UP(DROP IN OIL PRESSURE) 620

S-13 OIL LEVEL RISES(WATER, FUEL IN OIL) 621

S-14 WATER TEMPERATURE BECOMES TOO HIGH(OVERHEATING) 622

S-15 ABNORMAL NOISE IS MADE 623

S-16 VIBRATION IS EXCESSIVE 624

30 DISASSEMBLY AND ASSEMBLY 625

HOW TO READ THIS MANUAL 626

PRECAUTIONS WHEN CARRYING OUT OPERATION 628

SPECIAL TOOL LIST 630

SKETCH OF SPECIAL TOOLS 633

REMOVAL,INSTALLATION OF FUEL INJECTION PUMP ASSEMBLY 640

REMOVAL,INSTALLATION OF NOZZLE HOLDER ASSEMBLY 644

REMOVAL,INSTALLATION OF CYLINDER HEAD ASSEMBLY 646

REMOVAL,INSTALLATION OF ENGINE ASSEMBLY 654

REMOVAL,INSTALLATION OF RADIATOR ASSEMBLY 661

REMOVAL,INSTALLATION OF AIR AFTERCOOLER 662

REMOVAL,INSTALLATION OF HYDRAULIC OIL COOLER ASSEMBLY 664

REMOVAL,INSTALLATION OF COOLING FAN AND FAN MOTOR ASSEMBLY 666

REMOVAL,INSTALLATION OF FUEL TANK ASSEMBLY 668

REMOVAL,INSTALLATION OF TRANSFER 670

DISASSEMBLY,ASSEMBLY OF TRANSFER ASSEMBLY 672

REMOVAL,INSTALLATION OF PARKING BRAKE ASSEMBLY 692

DISASSEMBLY,ASSEMBLY OF PARKING BRAKE ASSEMBLY 694

REMOVAL,INSTALLATION OF FRONT AXLE ASSEMBLY 699

REMOVAL,INSTALLATION OF REAR AXLE ASSEMBLY 701

DISASSEMBLY,ASSEMBLY OF AXLE HOUSING ASSEMBLY 704

DISASSEMBLY,ASSEMBLY OF DIFFERENTIAL ASSEMBLY 717

REMOVAL,INSTALLATION OF HST PUMP AND 4-GEAR PUMP ASSEMBLY 741

REMOVAL,INSTALLATION OF HST MOTOR 1 ASSEMBLY 744

REMOVAL,INSTALLATION OF HST MOTOR 2 ASSEMBLY 746

REMOVAL,INSTALLATION OF WORK EQUIPMENT CONTROL VALVE ASSEMBLY 748

REMOVAL,INSTALLATION OF TRAVEL DAMPER VALVE ASSEMBLY(IF EQUIPPED) 750

REMOVAL,INSTALLATION OF HYDRAULIC TANK ASSEMBLY 752

REMOVAL,INSTALLATION OF WORK EQUIPMENT ASSEMBLY 754

DISASSEMBLY AND ASSEMBLY OF HST PUMP ASSEMBLY 761

DISASSEMBLY AND ASSEMBLY OF HST MOTOR ASSEMBLY 788

DISASSEMBLY,ASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY 804

REMOVAL,INSTALLATION OF OPERATOR’S CAB ASSEMBLY 811

REMOVAL,INSTALLATION OF OPERATOR’S CAB GLASS(STUCK GLASS) 817

REMOVAL,INSTALLATION OF CENTER HINGE PIN 825

REMOVAL,INSTALLATION OF COUNTERWEIGHT 838

REMOVAL,INSTALLATION OF AIR CONDITIONER UNIT ASSEMBLY 840

REMOVAL,INSTALLATION OF AIR CONDITIONER COMPRESSOR ASSEMBLY 843

REMOVAL,INSTALLATION OF MONITOR PANEL 844

REMOVAL,INSTALLATION OF HST CONTROLLER ASSEMBLY 848

90 OTHERS 849

HYDRAULIC CIRCUIT DIAGRAM 851

ELECTRICAL CIRCUIT DIAGRAM 1/4(1/4) 853

ELECTRICAL CIRCUIT DIAGRAM 1/4(2/4) 855

ELECTRICAL CIRCUIT DIAGRAM 1/4(3/4) 857

ELECTRICAL CIRCUIT DIAGRAM 1/4(4/4) 859

ELECTRICAL CIRCUIT DIAGRAM 2/4 861

ELECTRICAL CIRCUIT DIAGRAM 3/4 863

ELECTRICAL CIRCUIT DIAGRAM 4/4 865

ELECTRICAL CIRCUIT DIAGRAM (A1 SIZE) 867

CONNECTORS TABLE AND ARRANGEMENT DRAWING (A1 SIZE) 869

IMAGES PREVIEW OF THE MANUAL: