$45

Komatsu WA320-7 Wheel Loader Shop Manual SEN06202-06 – PDF DOWNLOAD

Komatsu WA320-7 Wheel Loader Shop Manual SEN06202-06 – PDF DOWNLOAD

FILE DETAILS:

Komatsu WA320-7 Wheel Loader Shop Manual SEN06202-06 – PDF DOWNLOAD

Language : English

Pages : 2078

Downloadable : Yes

File Type : PDF

Size: 60 MB

DESCRIPTION:

Komatsu WA320-7 Wheel Loader Shop Manual SEN06202-06 – PDF DOWNLOAD

SERIAL NUMBERS 80001 and up

Foreword, safety and general information

Important safety notice

• Appropriate servicing and repair are extremely important to ensure safe operation of the machine. The

shop manual describes the effective and safe servicing and repair methods recommended by Komatsu.

Some of these methods require the use of the special tools designed by Komatsu for the specific purpose.

• The symbol markkis used for such matters that require special cautions during the work. The work

indicated by the caution mark should be performed according to the instructions with special attention to

the cautions. Should hazardous situation occur or be anticipated during such work, be sure to keep safe

first and take every necessary measure.

Safety points

• Good arrangement

• Correct work clothes

• Observance of work standard

• Practice of making and checking signals

• Prohibition of operation and handling by

unlicensed workers

• Safety check before starting work

• Wearing protective goggles (for cleaning or

grinding work)

• Wearing shielding goggles and protectors (for

welding work)

• Good physical condition and preparation

• Precautions against work which you are not used to or you are used to too much

General precautions:

• Before performing any greasing or repairs, read all the safety labels stuck to the machine. For the locations of the safety labels and detailed explanation of precautions, see the operation and maintenance manual.• Locate a place in the repair workshop to keep the tools and removed parts. Always keep the tools and parts in their correct places. Always keep the work area clean and make sure that there is no dirt, water or oil on the floor. Smoke only in the areas provided for smoking. Never smoke while working.• When performing any work, always wear the safety shoes and helmet. Do not wear loose work cloths, or clothes with buttons missing. 1. Always wear the protective eyeglasses when hitting parts with a hammer.Always wear the protective eyeglasses when grinding parts with a grinder, etc.• When performing any work with 2 or more workers, always agree on the working procedure before starting. While working, always keep conversations of the work between your fellow workers and your self on any step of the work. During the work, hang the warning tag of “UNDER WORKING” in the operator’s compartment.• Only qualified workers must perform the work and operation which require license or qualification.• Keep the tools in good condition. And learn the correct way to use the tools, and use the proper ones among them. Before starting the work, thoroughly check the tools, lift truck, service vehicle, etc.• If welding repairs is required, always have a trained and experienced welder with good knowledge of welding perform the work. When performing welding work, always wear welding gloves, apron, shielding goggles, cap, etc.• Before starting work, warm up your body thoroughly to start work under good condition.• Avoid continuing work for long hours and take rests with proper intervals to keep your body in good condition. Take a rest in a specified safe place.

How to read the shop manual :

• Some attachments and optional parts described in this shop manual may not be arranged for certain

areas. Contact your Komatsu distributor if one or some of them are required.

• Materials and specifications are subject to change without notice.

• The shop manuals are available for “Machine part” and “Engine part”. For the engine, see the shop

manual for the same model of the engine as the one which is mounted on the machine.

Composition of shop manual

• This shop manual describes the technical information required for the services performed in a workshop.

The shop manual is divided into the following chapters for the convenience of use.

00. Index and foreword

• This section includes the index, foreword, safety and basic information.

01. Specification

• This section explains the specifications of the machine.

10. Structure and function

• This section explains the structure and function of the machine. The section of “Structure and function”

serves not only to give an understanding for the structure of each component, but also serves as

reference material for troubleshooting.

20. Standard value table

• The standard values for a new machine and trouble shooting are indicated. This standard value table is

used for testing and adjusting, and determining a failure at troubleshooting.

30. Testing and adjusting

• This section describes the measuring tools and how to measure, and how to adjust various parts. As for

the standard value and failure criterion, see the standard value table.

40. Troubleshooting

• This section describes the troubleshooting in a suspected area when a failure occurs and the remedy for

the failure. Troubleshooting is described by each failure mode.

50. Disassembly and assembly

• This section explains the procedures for removing, installing, disassembling, and assembling each part or

component and the special tools for the works as well as precautions for doing them safely. In addition,

tightening torque, and quantity and weight of coating material, oil, grease, and coolant required for the

works are also explained.

60. Maintenance standard

• This section describes the maintenance standard values for each component. This section gives the

criterion values for each component and required remedy at disassembly or maintenance.

80. Appendix

• The structure and function, testing and adjusting, and troubleshooting for all of the other components or

equipment which can not be separately classified are explained together in the appendix.

90. Diagrams and drawings

• This section gives hydraulic circuit diagrams and electrical circuit diagrams.

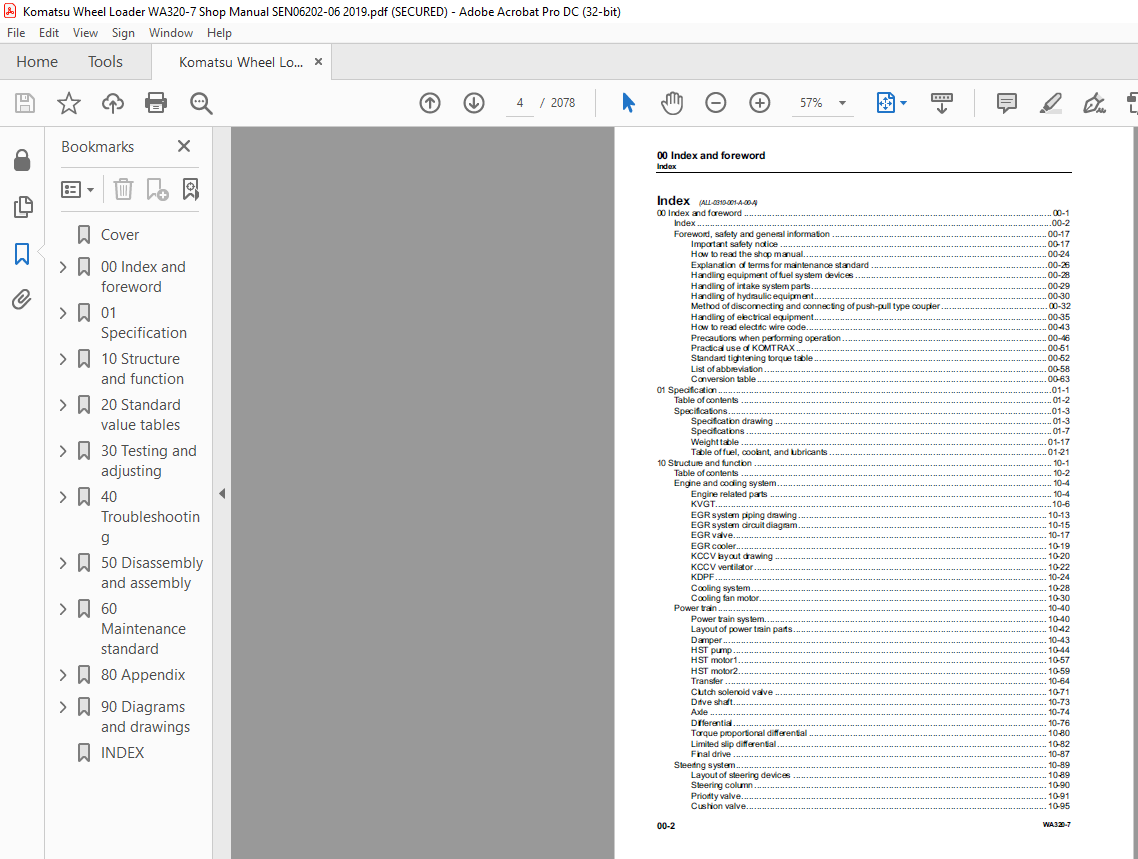

TABLE OF CONTENTS:

Komatsu WA320-7 Wheel Loader Shop Manual SEN06202-06 – PDF DOWNLOAD

Cover 1

00 Index and foreword 3

Index 4

Foreword, safety and general information 19

Important safety notice 19

How to read the shop manual 26

Explanation of terms for maintenance standard 28

Handling equipment of fuel system devices 30

Handling of intake system parts 31

Handling of hydraulic equipment 32

Method of disconnecting and connecting of push-pull type coupler 34

Handling of electrical equipment 37

How to read electric wire code 45

Precautions when performing operation 48

Practical use of KOMTRAX 53

Standard tightening torque table 54

List of abbreviation 60

Conversion table 65

01 Specification 71

Table of contents 72

Specifications 73

Specification drawing 73

Specifications 77

Weight table 87

Table of fuel, coolant, and lubricants 91

10 Structure and function 93

Table of contents 94

Engine and cooling system 96

Engine related parts 96

KVGT 98

EGR system piping drawing 105

EGR system circuit diagram 107

EGR valve 109

EGR cooler 111

KCCV layout drawing 112

KCCV ventilator 114

KDPF 116

Cooling system 120

Cooling fan motor 122

Power train 132

Power train system 132

Layout of power train parts 134

Damper 135

HST pump 136

HST motor1 149

HST motor2 151

Transfer 156

Clutch solenoid valve 163

Drive shaft 165

Axle 166

Differential 168

Torque proportional differential 172

Limited slip differential 174

Final drive 179

Steering system 181

Layout of steering devices 181

Steering column 182

Priority valve 183

Cushion valve 187

Emergency steering valve 188

Orbitrol valve 191

Brake system 197

Layout of brake parts 197

Brake accumulator charge valve 199

Brake valve 204

Brake accumulator 208

Slack adjuster 209

Brake 211

Parking brake control 214

Parking brake 215

Parking brake solenoid valve 216

Undercarriage and frame 218

Axle mount 218

Center hinge pin 220

Tire 221

Hydraulic system 223

Hydraulic component layout 223

Work equipment control 225

Hydraulic tank 226

Double type gear pump 229

Steering and work equipment pump 230

Control valve 242

CLSS 252

Hydraulic circuit diagram and names of valves 256

Self-pressure reducing valve 269

Work equipment PPC valve 274

Work equipment lock solenoid valve 282

PPC circuit accumulator 283

ECSS accumulator 284

Work equipment 285

Work equipment linkage 285

Bucket 286

Cab and its attachments 287

ROPS cab 287

Cab mount 289

Electrical system 290

Engine control system 290

Preheating system 293

Engine output limit function 295

Automatic warm-up function 296

Parking brake control system 297

System operating lamp function 301

Battery disconnect switch function 302

HST controller system 304

Machine monitor system 344

Rearview monitor system 365

KOMTRAX system 368

System component parts 371

Sensor 394

20 Standard value tables 415

Table of contents 416

Standard service value table 417

Standard value table for engine 417

Standard value table for machine 419

Standard value table for electrical system 431

30 Testing and adjusting 441

Table of contents 442

Related information on testing and adjusting 444

Tools for testing and adjusting 444

Sketch of tools for testing and adjusting 450

Engine and cooling system 451

Testing engine speed 451

Testing boost pressure 452

Testing exhaust gas temperature 454

Testing exhaust gas color 455

Testing and adjusting valve clearance 457

Testing compression pressure 460

Testing blowby pressure 464

Testing engine oil pressure 465

Testing EGR valve and KVGT oil pressures 466

Testing fuel pressure 467

Testing fuel discharge, return and leakage 472

Bleeding air from fuel system 477

Testing fuel circuit for leakage 479

Handling cylinder cutout mode operation 480

Handling no-injection cranking operation 481

Testing of KDPF and muffler stack for looseness and damage 482

Testing of installed condition of cylinder heads and manifolds 483

Testing engine piping for damage and looseness 484

Testing and adjusting air conditioner compressor belt tension 485

Check alternator belt, replace 486

Check auto-tensioner, replace 488

Writing compensation amount for soot accumulation caused by ash on engine controller 490

Power train 492

Testing oil leakage from axle final drive 492

Testing drive shaft for looseness, backlash, and damage 493

Testing accelerator pedal 494

Testing and adjusting HST oil pressure 495

Testing transfer clutch control pressure 498

Steering system 499

Testing directional lever 499

Testing steering wheel 500

Testing work equipment control lever 502

Testing and adjusting steering circuit oil pressure 504

Bleeding air from steering cylinder circuit 506

Brake system 507

Testing brake pedal 507

Testing braking performance 508

Testing and adjusting of accumulator charge pressure 509

Testing wheel brake oil pressure 511

Testing lowering of wheel brake pressure 512

Testing wear of wheel brake disc 514

Bleeding air from wheel brake circuit 515

Releasing remaining pressure in brake accumulator circuit 516

Testing parking brake performance 517

Testing wear of parking brake disc 518

Testing parking brake release pressure 519

Method of releasing parking brake manually 520

Hydraulic system 521

Testing cooling fan speed 521

Testing cooling fan pump circuit oil pressure 522

Bleeding air from hydraulic fan circuit 524

Testing and adjusting work equipment PPC oil pressure 525

Testing and adjusting work equipment oil pressure 527

Bleeding air from work equipment circuit 531

Releasing remaining pressure from work equipment circuit 532

Testing ECSS accumulator nitrogen gas pressure and procedure for charging accumulator with nitrogen gas 534

Work equipment 538

Testing and adjusting bucket positioner and bucket proximity switch 538

Testing and adjusting boom position detection lever 540

Electrical system 541

Adjusting replaced, reassembled or added sensor, controller, etc with machine monitor 541

Special functions of machine monitor 542

Adjusting rearview camera angle 621

Handling voltage circuit of engine controller 622

Handling battery disconnect switch 623

Testing diodes 624

Pm clinic 625

Pm Clinic service 625

Check sheet 626

40 Troubleshooting 633

Table of contents 634

Related information on troubleshooting 643

Troubleshooting points 643

Sequence of events in troubleshooting 645

Checks before troubleshooting 647

Inspection procedure before troubleshooting 649

Preparation for troubleshooting of electrical system 666

Classification and procedures for troubleshooting 672

Symptom and troubleshooting numbers 675

Information in troubleshooting table 678

Procedure for troubleshooting wiring harness of pressure sensor system for open circuit 680

Connector list and layout 683

Connector contact identification 697

T-branch box and T-branch adapter table 736

Fuse location table 741

Precautions for KDPF (KCSF and KDOC) Cleaning and Replacement 744

Precautions when performing troubleshooting of machine monitor 747

Processing procedure of harness checker for troubleshooting of machine monitor LCD unit 749

Preparation of dummy temperature sensor (for KDOC and KDPF temperature sensors) 754

Preparation of short circuit electrical connector (for failure codes [CA1883] and [CA3135]) 755

Failure codes table 756

Troubleshooting by failure code (Display of code) 768

Failure code [2F00MA] Failure of Parking Brake Circuit 768

Failure code [2F00MB] Malfunction of Parking Brake 771

Failure code [2G42ZG] Accumulator Oil Pressure Low (Front) 773

Failure code [2G43ZG] Accumulator Oil Pressure Low (Rear) 775

Failure code [6091NX] HST Oil Filter Clogging 777

Failure code [7RHYKA] Disconnection of Fan Variable Control Sol 779

Failure code [7RHYKB] Ground Fault of Fan Variable Control Sol 781

Failure code [7RHYKY] Hot Short of Fan Variable Control Sol 783

Failure code [879AKA] A/C Inner Sensor Open Circuit 785

Failure code [879AKB] A/C Inner Sensor Short Circuit 786

Failure code [879BKA] A/C Outer Sensor Open Circuit 787

Failure code [879BKB] A/C Outer Sensor Short Circuit 788

Failure code [879CKA] Ventilating Sensor Open Circuit 789

Failure code [879CKB] Ventilating Sensor Short Circuit 790

Failure code [879DKZ] Sunlight Sensor Open or Short Circuit 791

Failure code [879EMC] Ventilation Damper Abnormality 792

Failure code [879FMC] Air Mix Damper Abnormality 793

Failure code [989L00] Engine Controller Lock Caution 1 794

Failure code [989M00] Engine Controller Lock Caution 2 795

Failure code [989N00] Engine Controller Lock Caution 3 796

Failure code [A1U0N3] HC Desorb Request 1 797

Failure code [A1U0N4] HC Desorb Request 2 799

Failure code [AA10NX] Air Cleaner Clogging 801

Failure code [AB00KE] Charge Voltage Low 803

Failure code [AB00KY] Hot Short of Alternator R Terminal 804

Failure code [B@BAZG] Eng Oil Press Low 805

Failure code [B@BAZK] Engine Oil Level Low 806

Failure code [B@BCNS] Eng Water Overheat 808

Failure code [B@BCZK] Eng Water Level Low 809

Failure code [B@CRNS] HST Oil Temp Overheat 811

Failure code [CA115] Eng Ne and Bkup Speed Sens Error 812

Failure code [CA122] Chg Air Press Sensor High Error 813

Failure code [CA123] Chg Air Press Sensor Low Error 815

Failure code [CA131] Throttle Sensor High Error 817

Failure code [CA132] Throttle Sensor Low Error 819

Failure code [CA144] Coolant Temp Sens High Error 821

Failure code [CA145] Coolant Temp Sens Low Error 823

Failure code [CA153] Chg Air Temp Sensor High Error 825

Failure code [CA154] Chg Air Temp Sensor Low Error 827

Failure code [CA187] Sensor 2 Supply Volt Low Error 829

Failure code [CA221] Ambient Press Sensor High Error 831

Failure code [CA222] Ambient Press Sensor Low Error 833

Failure code [CA227] Sensor 2 Supply Volt High Error 835

Failure code [CA234] Eng Overspeed 836

Failure code [CA238] Ne Speed Sensor Supply Volt Error 837

Failure code [CA239] Ne Speed Sens Supply Volt High Error 838

Failure code [CA271] IMV/PCV1 Short Error 839

Failure code [CA272] IMV/PCV1 Open Error 841

Failure code [CA295] Ambient Press Sens In Range Error 843

Failure code [CA322] Inj #1(L#1) Open/Short Error 844

Failure code [CA323] Inj #5(L#5) Open/Short Error 846

Failure code [CA324] Inj #3(L#3) Open/Short Error 848

Failure code [CA325] Inj #6(L#6) Open/Short Error 850

Failure code [CA331] Inj #2(L#2) Open/Short Error 852

Failure code [CA332] Inj #4(L#4) Open/Short Error 854

Failure code [CA343] ECM Critical Internal Failure 856

Failure code [CA351] Injectors Drive Circuit Error 857

Failure code [CA352] Sensor 1 Supply Volt Low Error 858

Failure code [CA356] Mass Air Flow Sensor High Error 860

Failure code [CA357] Mass Air Flow Sensor Low Error 862

Failure code [CA386] Sensor 1 Supply Volt High Error 864

Failure code [CA428] Water in Fuel Sensor High Error 865

Failure code [CA429] Water in Fuel Sensor Low Error 867

Failure code [CA431] Idle Validation Sw Error 869

Failure code [CA432] Idle Validation Process Error 872

Failure code [CA435] Eng Oil Press Sw Error 875

Failure code [CA441] Battery Voltage Low Error 876

Failure code [CA442] Battery Voltage High Error 878

Failure code [CA449] Rail Press Very High Error 879

Failure code [CA451] Rail Press Sensor High Error 880

Failure code [CA452] Rail Press Sensor Low Error 882

Failure code [CA488] Chg Air Temp High Torque Derate 884

Failure code [CA515] Rail Press Sens Sup Volt High Error 885

Failure code [CA516] Rail Press Sens Sup Volt Low Error 887

Failure code [CA553] Rail Press High Error 889

Failure code [CA555] Crankcase Press High Error 1 890

Failure code [CA556] Crankcase Press High Error 2 891

Failure code [CA559] Rail Press Low Error 892

Failure code [CA595] Turbo Speed High Error 2 894

Failure code [CA687] Turbo Speed Low Error 895

Failure code [CA689] Eng Ne Speed Sensor Error 897

Failure code [CA691] Intake Air Temp Sens High Error 899

Failure code [CA692] Intake Air Temp Sens Low Error 901

Failure code [CA697] ECM Internal Temp Sensor High Error 903

Failure code [CA698] ECM Int Temp Sensor Low Error 904

Failure code [CA731] Eng Bkup Speed Sens Phase Error 905

Failure code [CA778] Eng Bkup Speed Sensor Error 907

Failure code [CA1117] Persistent Data Lost Error 912

Failure code [CA1664] KDOC Malfunction 913

Failure code [CA1691] Regeneration Ineffective 916

Failure code [CA1695] Sensor 5 Supply Volt High Error 919

Failure code [CA1696] Sensor 5 Supply Volt Low Error 920

Failure code [CA1843] Crankcase Press Sens High Error 922

Failure code [CA1844] Crankcase Press Sens Low Error 924

Failure code [CA1879] KDPF Delta P Sensor High Error 926

Failure code [CA1881] KDPF Delta P Sensor Low Error 928

Failure code [CA1883] KDPF Delta P Sens In Range Error 930

Failure code [CA1921] KDPF Soot Load High Error 1 934

Failure code [CA1922] KDPF Soot Load High Error 2 937

Failure code [CA1942] Crankcase Press Sens In Range Error 942

Failure code [CA1993] KDPF Delta Pressure Low Error 943

Failure code [CA2185] Throt Sensor Sup Volt High Error 946

Failure code [CA2186] Throt Sensor Sup Volt Low Error 948

Failure code [CA2249] Rail Press Very Low Error 950

Failure code [CA2271] EGR Valve Pos Sens High Error 951

Failure code [CA2272] EGR Valve Pos Sens Low Error 953

Failure code [CA2288] Turbo Speed High Error 1 956

Failure code [CA2311] IMV Solenoid Error 957

Failure code [CA2349] EGR Valve Solenoid Open Error 958

Failure code [CA2353] EGR Valve Solenoid Short Error 960

Failure code [CA2357] EGR Valve Servo Error 962

Failure code [CA2373] Exhaust Manifold Press Sens High error 963

Failure code [CA2374] Exhaust Manifold Press Sens Low error 965

Failure code [CA2375] EGR Orifice Temp Sens High Error 967

Failure code [CA2376] EGR Orifice Temp Sens Low Error 969

Failure code [CA2381] KVGT Pos Sens High Error 971

Failure code [CA2382] KVGT Pos Sens Low Error 973

Failure code [CA2383] KVGT Solenoid Open Error 976

Failure code [CA2386] KVGT Solenoid Short Error 978

Failure code [CA2387] KVGT Servo Error 980

Failure code [CA2554] Exh Manifold Press Sens In Range Error 981

Failure code [CA2555] Grid Htr Relay Volt Low Error 982

Failure code [CA2556] Grid Htr Relay Volt High Error 984

Failure code [CA2637] KDOC Face Plugging 986

Failure code [CA2639] Manual Stationary Regeneration Request 988

Failure code [CA2961] EGR Orifice Temp High Error 1 991

Failure code [CA2973] Chg Air Press Sensor In Range Error 992

Failure code [CA3133] KDPF Outlet Press Sens High Error 993

Failure code [CA3134] KDPF Outlet Press Sens Low Error 995

Failure code [CA3135] KDPF Outlet Press Sens In Range Error 997

Failure code [CA3251] KDOC Inlet Temp High Error 1001

Failure code [CA3253] KDOC Temp Error – Non Regeneration 1004

Failure code [CA3254] KDOC Outlet Temp High Error 1 1008

Failure code [CA3255] KDPF Temp Error – Non Regeneration 1011

Failure code [CA3256] KDPF Outlet Temp High Error 1 1015

Failure code [CA3311] KDOC Outlet Temp High Error 2 1018

Failure code [CA3312] KDPF Outlet Temp High Error 2 1022

Failure code [CA3313] KDOC Inlet Temp Sensor Low Error 1026

Failure code [CA3314] KDOC Inlet Temp Sens High Error 1029

Failure code [CA3315] KDOC Inlet Temp Sens In Range Error 1032

Failure code [CA3316] KDOC Outlet Temp Sens Low Error 1036

Failure code [CA3317] KDOC Outlet Temp Sens High Error 1039

Failure code [CA3318] KDOC Outlet Temp Sens In Range Error 1042

Failure code [CA3319] KDPF Outlet Temp Sens High Error 1046

Failure code [CA3321] KDPF Outlet Temp Sens Low Error 1049

Failure code [CA3322] KDPF Outlet Temp Sens In Range Error 1052

Failure code [CA3419] Mass Air Flow Sensor Sup Volt High Error 1056

Failure code [CA3421] Mass Air Flow Sensor Sup Volt Low Error 1058

Failure code [CA3741] Rail Press Valve Trip Error 1060

Failure code [D110L4] Disconnection of Battery Relay Signal 1061

Failure code [D160KA] Disconnection of Backup Lamp Relay Output 1063

Failure code [D160KY] Hot Short of Backup Lamp Relay Output 1065

Failure code [D191KA] Disconnection of Neutral Output Relay 1067

Failure code [D191KB] Ground Fault of Neutral Output Relay 1069

Failure code [D191KY] Hot Short of Neutral Output Relay 1071

Failure code [D192KA] Disconnection of ECSS Solenoid 1073

Failure code [D192KB] Ground Fault of ECSS Solenoid 1075

Failure code [D192KY] Hot Short of ECSS Solenoid 1076

Failure code [D19JKZ] Personal Code Relay Abnormality 1077

Failure code [D1B0KA] Disconnection of HST Safety Relay 1079

Failure code [D1B0KB] Ground Fault of HST Safety Relay 1081

Failure code [D1B0KY] Hot Short of HST Safety Relay 1083

Failure code [D1B0MC] Malfunction of HST Safety Relay 1085

Failure code [D1E6KA] Disconnection of Parking Brake Relay 1086

Failure code [D1E6KB] Ground Fault of Parking Brake Relay 1088

Failure code [D1E6KY] Hot Short of Parking Brake Relay 1090

Failure code [D5ZHKA] Failure of Key SW C Signal 1092

Failure code [D5ZHKB] Key SW C Signal Short Circuit 1094

Failure code [D5ZHL6] Disconnection of Key SW C 1096

Failure code [D811MC] KOMTRAX Error 1097

Failure code [D862KA] GPS Antenna Open Circuit 1098

Failure code [D8ALKA] Operating Lamp Open Circuit (KOMTRAX) 1099

Failure code [D8ALKB] Operating Lamp Short Circuit (KOMTRAX) 1101

Failure code [D8AQK4] CAN2 Discon (KOMTRAX) 2 1103

Failure code [D8AQKR] CAN2 Discon (KOMTRAX) 1104

Failure code [DAF0KT] Abnormality of Non-volatile Memory (MON) 1106

Failure code [DAF0MB] Monitor ROM Abnormality 1107

Failure code [DAF0MC] Monitor Error 1108

Failure code [DAF3KK] Controller Power Source Low (MON) 1109

Failure code [DAF8KB] Camera Power Supply Short Circuit 1111

Failure code [DAFDKB] Monitor 12V Power Output Short Circuit 1112

Failure code [DAFGMC] GPS Module Error 1113

Failure code [DAFLKA] Operating Lamp Open Circuit (MON) 1114

Failure code [DAFLKB] Operating Lamp Short Circuit (MON) 1116

Failure code [DAFQKR] CAN2 Discon (Monitor) 1118

Failure code [DAJ0KK] Controller Power Source Low (HST) 1119

Failure code [DAJ0KT] Abnormality of Non-volatile Memory (HST) 1122

Failure code [DAJ0MC] HST Con Error 1123

Failure code [DAJ1KA] Disconnection of Key SW ACC (HST) 1124

Failure code [DAJ2KK] Solenoid Power Source Low (HST) 1126

Failure code [DAJ4KB] Ground Fault of Sol Self-Holding Relay 1129

Failure code [DAJ4KZ] Failure of Sol Self-Holding Relay 1131

Failure code [DAJ5KX] Failure of 5V Power Source 0 1133

Failure code [DAJ6KX] Failure of 5V Power Source 1 1135

Failure code [DAJ9KQ] Inconsistency of Model Selection (HST) 1137

Failure code [DAJLKA] Operating Lamp Open Circuit (HST) 1138

Failure code [DAJLKB] Operating Lamp Short Circuit (HST) 1140

Failure code [DAJQKR] CAN2 Discon ( HST Con) 1142

Failure code [DAJRKR] CAN1 Discon ( HST Con) 1143

Failure code [DAJRMA] Inconsistency of Option Selection (HST) 1144

Failure code [DAZ9KQ] A/C Model Selection Abnormality 1145

Failure code [DAZQKR] CAN2 Discon (Aircon ECU) 1146

Failure code [DB2QKR] CAN2 Discon (Engine Con) 1147

Failure code [DB2RKR] CAN1 Discon (Engine Con) 1152

Failure code [DD1ALD] Ground Fault of Remote Positioner Set SW 1156

Failure code [DDAAL6] Discon of Engine Shutdown Secondary Switch 1158

Failure code [DDB2L4] Stop Lamp Switch Signal Malfunction 1160

Failure code [DDB6L4] Parking Brake Signal Malfunction 1162

Failure code [DDD7KA] Failure of Variable Speed Control 1165

Failure code [DDD7KY] Hot Short of Variable Speed Control 1167

Failure code [DDK3KA] FNR SW Input Signal Disconnection 1169

Failure code [DDK3KB] FNR SW Input Signal Short Circuit 1171

Failure code [DDK6KA] FNR Lever Input Signal Disconnection 1173

Failure code [DDK6KB] FNR Lever Input Signal Short Circuit 1176

Failure code [DDNRLD] Ground Fault of Work Equip Lock Switch 1178

Failure code [DF10KA] Disconnection of Speed Range Input 1180

Failure code [DF10KB] Ground Fault of Speed Range Input 1183

Failure code [DGH1KX] Out of Range of HST Oil Temp Sensor 1186

Failure code [DGR2KB] Ground Fault of Brake Oil Temp Sensor 1188

Failure code [DGR2KZ] Failure of Brake Oil Temp Sensor 1190

Failure code [DHA4KA] Failure of Air Cleaner Sensor Circuit 1192

Failure code [DHHBKA] Failure of HST Press Sens Circuit (MA) 1194

Failure code [DHHBKY] Hot Short of HST Press Sens Circuit (MA) 1196

Failure code [DHHCKA] Failure of HST Press Sens Circuit (MB) 1198

Failure code [DHHCKY] Hot Short of HST Press Sens Circuit (MB) 1200

Failure code [DHPCKA] Failure of Boom Press Sensor (Bottom) 1202

Failure code [DHPCKY] Hot Short of Boom Press Sensor (Bottom) 1204

Failure code [DHPEKA] Failure of Steering & Loader Pump Press 1206

Failure code [DHPEKY] Hot Short of Steering & Loader Pump Press 1208

Failure code [DHS8KA] Failure of Boom Raise PPC Sens Circuit 1210

Failure code [DHS8KY] Hot Short of Boom Raise PPC Sens Circuit 1212

Failure code [DHS9KA] Failure of Boom Lower PPC Sens Circuit 1214

Failure code [DHS9KY] Hot Short of Boom Lower PPC Sens Circuit 1216

Failure code [DHSDKA] Failure of Bucket Dump PPC Sens Circuit 1218

Failure code [DHSDKY] Hot Short of Bucket Dump PPC Sens Circuit 1220

Failure code [DHSNKA] Failure of Bucket Tilt PPC Sens Circuit 1222

Failure code [DHSNKY] Hot Short of Bucket Tilt PPC Sens Circuit 1224

Failure code [DHT8ZG] Steering Oil Pressure Low 1226

Failure code [DHTCL6] Failure of HST Oil Filter Sensor Circuit 1227

Failure code [DJF1KA] Disconnection of Fuel Level Sensor 1229

Failure code [DK55KA] Failure of FNR Lever Potentio 1231

Failure code [DK55KY] Hot Short of FNR Lever Potentio Circuit 1234

Failure code [DK55L5] Failure of FNR Lever Potentio 1236

Failure code [DK5DKA] Failure of 3rd Lever Potentio (Main) 1237

Failure code [DK5DKY] Hot Short of 3rd Lever Potentio (Main) 1240

Failure code [DK5DL8] 3rd Lever Potentio (Main & Sub) Disagree 1243

Failure code [DK5EKA] Failure of 3rd Lever Potentio (Sub) 1246

Failure code [DK5EKY] Hot Short of 3rd Lever Potentio (Sub) 1249

Failure code [DK70KA] Failure of inching sensor Circuit 1252

Failure code [DK70KY] Hot Short of inching sensor Circuit 1255

Failure code [DKA0KA] Failure of Boom Angle Sensor 1257

Failure code [DKA0KY] Hot Short of Boom Angle Sensor Circuit 1259

Failure code [DKA0L0] Boom Angle Sensor Dislocation 1261

Failure code [DLM3KA] Disconnection of Radiator Fan Speed Sensor 1263

Failure code [DLM3LC] Failure of Radiator Fan Speed Sensor 1265

Failure code [DLT3KX] Vehicle Speed Sensor Circuit Failure (B) 1266

Failure code [DLT4KX] Vehicle Speed Sensor Circuit Failure (A) 1268

Failure code [DLT4L0] Vehicle Speed Sensor Failure (A & B) 1270

Failure code [DLT4LC] Vehicle Speed Sensor Failure (A or B) 1273

Failure code [DPQ1KR] LIN Discon (Switch Panel) 1275

Failure code [DPQ2KR] LIN Discon (LED Unit) 1278

Failure code [DPQ3KR] LIN Discon (Rear View Monitor) 1281

Failure code [DSJ0KR] CAN2 Discon (Meter Unit) 1284

Failure code [DT22KB] Ground Fault of Work Equip Lock Indic 1286

Failure code [DV00KB] Ground Fault of Buzzer Output 1288

Failure code [DW26KA] Disconnection of Motor 2 Solenoid 1290

Failure code [DW26KB] Ground Fault of Motor 2 Solenoid 1292

Failure code [DW26KY] Hot Short of Motor 2 Solenoid 1294

Failure code [DW4BKA] Disconnection of Parking Brake Valve 1296

Failure code [DW4BKB] Ground Fault of Parking Brake Valve 1298

Failure code [DW4BKY] Hot Short of Parking Brake Valve 1300

Failure code [DW4RKA] Disconnection of Bucket EPC Sol (Tilt) 1301

Failure code [DW4RKB] Ground Fault of Bucket EPC Solenoid (Tilt) 1303

Failure code [DW4RKY] Hot Short of Bucket EPC Solenoid (Tilt) 1305

Failure code [DWM1KA] Disconnection of Neutral Lock Solenoid 1306

Failure code [DWM1KB] Ground Fault of Neutral Lock Solenoid 1308

Failure code [DWM1KY] Hot Short of Neutral Lock Solenoid 1310

Failure code [DWN6KA] Disconnection of Detent Solenoid (Boom) 1311

Failure code [DWN6KB] Ground Fault of Detent Solenoid (Boom) 1313

Failure code [DWN6KY] Hot Short of Detent Solenoid (Boom) 1315

Failure code [DWN8KA] Disconnection of Detent Solenoid (Bucket) 1317

Failure code [DWN8KB] Ground Fault of Detent Solenoid (Bucket) 1319

Failure code [DWN8KY] Hot Short of Detent Solenoid (Bucket) 1321

Failure code [DX19KA] Disconnection of Motor 1 Solenoid 1322

Failure code [DX19KB] Ground Fault of Motor 1 Solenoid 1324

Failure code [DX19KY] Hot Short of Motor 1 Solenoid 1326

Failure code [DX20KA] Disconnection of Clutch Control Solenoid 1328

Failure code [DX20KB] Ground Fault of Clutch Control Solenoid 1330

Failure code [DX20KY] Hot Short of Clutch Control Solenoid 1332

Failure code [DXAWKA] Disconnection of HST Pump EPC Sol 1334

Failure code [DXAWKB] Ground Fault of HST Pump EPC Sol 1336

Failure code [DXAWKY] Hot Short of HST Pump EPC Sol 1338

Failure code [DXH7KA] Disconnection of Reverse Solenoid 1340

Failure code [DXH7KB] Ground Fault of Reverse Solenoid 1342

Failure code [DXH7KY] Hot Short of Reverse Solenoid 1344

Failure code [DXH8KA] Disconnection of Forward Solenoid 1346

Failure code [DXH8KB] Ground Fault of Forward Solenoid 1348

Failure code [DXH8KY] Hot Short of Forward Solenoid 1350

Failure code [DXHJKA] Disconnection of 3rd EPC Solenoid (EXT) 1352

Failure code [DXHJKB] Ground Fault of 3rd EPC Solenoid (EXT) 1354

Failure code [DXHJKY] Hot Short of 3rd EPC Solenoid (EXT) 1356

Failure code [DXHKKA] Disconnection of 3rd EPC Solenoid (RET) 1357

Failure code [DXHKKB] Ground Fault of 3rd EPC Solenoid (RET) 1359

Failure code [DXHKKY] Hot Short of 3rd EPC Solenoid (RET) 1361

Failure code [H2K0KA] Failure of Quick Coupler Lock Signal 1362

Failure code [H2K0KY] Hot Short of Quick Coupler Lock Signal 1365

Failure code [J141N1] Steering Pump Over Run 1367

Failure code [LA00L3] Failure of Fan Reverse 1368

Failure code [M100N1] HST Pump Over Run 1369

Failure code [M400N1] HST Motor 1 Over Run 1370

Troubleshooting of electrical system (E-mode) 1371

E-1 Engine does not start 1371

E-2 Manual preheating system does not work 1378

E-3 Automatic preheating system does not work 1381

E-4 While preheating is working, preheating monitor does not light up 1383

E-5 All of LCD unit, LED unit, and meter unit on machine monitor display nothing 1385

E-6 LCD unit on machine monitor displays nothing 1388

E-7 Backlight of LCD unit on machine monitor is abnormal (Backlight goes out or flickers) 1390

E-8 LCD on machine monitor does not display properly 1392

E-9 Meter unit display on machine monitor is abnormal 1394

E-10 Night lighting lamp of meter unit on machine monitor is abnormal 1397

E-11 Caution LED on machine monitor is abnormal 1400

E-12 LED of switch panel on machine monitor is abnormal or switches does not operate properly 1402

E-13 Two switches operation of switch panel on machine monitor does not function 1404

E-14 Switch panel buzzer of machine monitor is abnormal 1407

E-15 Rearview monitor does not light up or backlight flickers 1409

E-16 Rearview monitor images are not displayed clearly 1412

E-17 Rearview monitor brightness cannot be adjusted 1415

E-18 Night lighting lamp of rearview monitor is abnormal 1418

E-19 Some items of gauges and caution lamps on machine monitor are not displayed properly 1420

E-20 Parking brake indicator lamp does not light when the parking brake is set to ON (Parking) position 1421

E-21 When brake accumulator oil pressure drops, the brake oil pressure caution lamp does not light 1425

E-22 Air cleaner clogging indicator lamp does not light 1427

E-23 Radiator coolant level caution lamp does not light 1429

E-24 Indication of HST oil temperature gauge does not increase, or HST oil temperature caution lamp does not light 1431

E-25 When brake pedal (inching pedal) is depressed, inching function does not work (travel speed or traction force does not lower), or while not depressed, inching function operates 1432

E-26 Fuel level gauge does not indicate correct level 1434

E-27 Seat belt caution lamp indication is abnormal 1436

E-28 Horn does not sound 1437

E-29 Horn does not stop sounding 1440

E-30 Alarm buzzer does not sound 1442

E-31 When starting switch is in ON position, alarm buzzer does not stop sounding 1444

E-32 When emergency HST pump drive switch is operated, emergency HST pump does not work or when emergency HST pump drive switch is not operated, emergency HST pump works 1445

E-33 Setting does not change while operating traction control switch 1447

E-34 Parking brake does not work even if it is applied, or the brake drags when parking brake is released and FR drive is operated 1449

E-35 Remote positioner does not work or cannot be released 1452

E-36 Bucket positioner does not work or cannot be released 1454

E-37 Direction selector (FNR) switch mode is not selected or not released 1457

E-38 PZ auto tilt-in does not work 1459

E-39 Tracktion level does not display MAX when max traction switch is turned ON 1462

E-40 ECSS function cannot be selected or cannot be released 1464

E-41 None of headlamp, clearance lamp, and tail lamp lights 1466

E-42 Clearance lamp ,tail lamp and license plate lamp do not light up or go out 1468

E-43 Both High and Low beams of headlamp do not light up or go out 1472

E-44 Low beam of headlamp does not light up or go out 1476

E-45 High beam of headlamp does not light up or go out 1478

E-46 Front working lamp does not light up or go out 1480

E-47 Rear working lamp does not light up or go out 1484

E-48 All of turn signal lamps and hazard lamps do not flash or go out 1488

E-49 Turn signal lamps do not flash or go out 1491

E-50 Hazard lamp does not flash or go out 1494

E-51 Brake lamp does not light or stays lighted 1497

E-52 Backup lamp does not light up or does not go out 1500

E-53 Backup buzzer does not sound or continues to sound 1503

E-54 Front wiper does not operate 1505

E-55 Rear wiper does not operate 1508

E-56 Window washer does not operate 1510

E-57 KOMTRAX system does not operate normally 1513

Troubleshooting of hydraulic and mechanical system (H-mode) 1515

Information described in troubleshooting table (H-mode) 1515

System chart of hydraulic and mechanical systems 1516

Failure mode and cause table 1518

H-1 Machine does not travel forward or backward 1524

H-2 Machine does not travel forward (Machine travels backward normally) 1527

H-3 Machine does not travel backward (Machine travels forward normally) 1528

H-4 Machine does not travel forward or backward fast 1529

H-5 Machine does not travel forward fast (Machine travel backward fast) 1533

H-6 Machine does not travel backward fast (Machine travel forward fast) 1534

H-7 Machine lacks power neither when traveling forward nor backward 1535

H-8 Machine lacks power when traveling forward (Machine has sufficient power when traveling backward) 1538

H-9 Machine lacks power when traveling backward (Machine have sufficient power when traveling forward) 1539

H-10 Engine stalls during travel or engine speed drops significantly 1540

H-11 Steering wheel is too heavy to turn 1541

H-12 Steering wheel is heavy to turn 1543

H-13 Machine sways or large shocks are made while machine turns 1544

H-14 Machine unintentionally turns when machine travels 1545

H-15 Wheel brakes do not work or are weak 1546

H-16 Wheel brakes are not released or drag 1547

H-17 Parking brake does not work or it is weak 1548

H-18 Parking brake is not released or drags 1549

H-19 Boom does not rise 1550

H-20 Boom moves slow or boom lacks lifting force 1552

H-21 Rising boom slows down at certain height 1554

H-22 Lift cylinders do not serve to hold bucket (bucket rises off ground) 1555

H-23 Hydraulic drift of boom is large 1556

H-24 Boom moves up and down during operation 1557

H-25 Bucket does not tilt back 1558

H-26 Bucket moves slow or lacks tilt force 1560

H-27 Bucket decelerates during tilt-back operation 1562

H-28 Bucket cylinder does not hold bucket on ground 1563

H-29 Hydraulic drift of bucket is large 1564

H-30 Bucket tilts back and forth during carrying load 1565

H-31 Boom and bucket control levers do not move smoothly and are heavy to move 1566

H-32 Operating work equipment causes engine speed to lower significantly or engine to stall 1567

H-33 Large shocks are made when work equipment starts to move and stops 1568

H-34 When certain work equipment is relieved hydraulically, other work equipment moves 1569

H-35 E C S S (travel damper) does not work and machine pitches and bounces 1570

H-36 Fan speed is abnormal (too high or low, or fan does not rotate) 1571

H-37 Unusual noise is heard from around fan 1573

Troubleshooting of engine (S-mode) 1574

Information described in troubleshooting table (S mode) 1574

S-1 Engine does not crank when starting switch is turned to START position 1575

S-2 Engine cranks but no exhaust smoke comes out 1576

S-3 Fuel is being injected but engine does not start (misfiring: engine cranks but does not start) 1577

S-4 Engine startability is poor 1578

S-5 Engine does not pick up smoothly 1580

S-6 Engine stops during operation 1582

S-7 Engine runs rough or is unstable 1584

S-8 Engine lacks power 1585

S-9 KDPF gets clogged in a short time 1587

S-10 Engine oil consumption is excessive 1589

S-11 Engine oil becomes contaminated early 1590

S-12 Fuel consumption is excessive 1591

S-13 Oil is in coolant (or coolant spurts or coolant level goes down) 1592

S-14 Oil pressure drops 1593

S-15 Fuel mixes into engine oil 1594

S-16 Water mixes into engine oil (milky) 1595

S-17 Coolant temperature rises too high (overheating) 1596

S-18 Unusual noise is heard 1597

S-19 Vibration is excessive 1598

S-20 Air cannot be bled from fuel circuit 1600

S-21 Active regeneration is executed frequently 1601

S-22 Active regeneration takes time 1602

S-23 White smoke is exhausted during active regeneration 1603

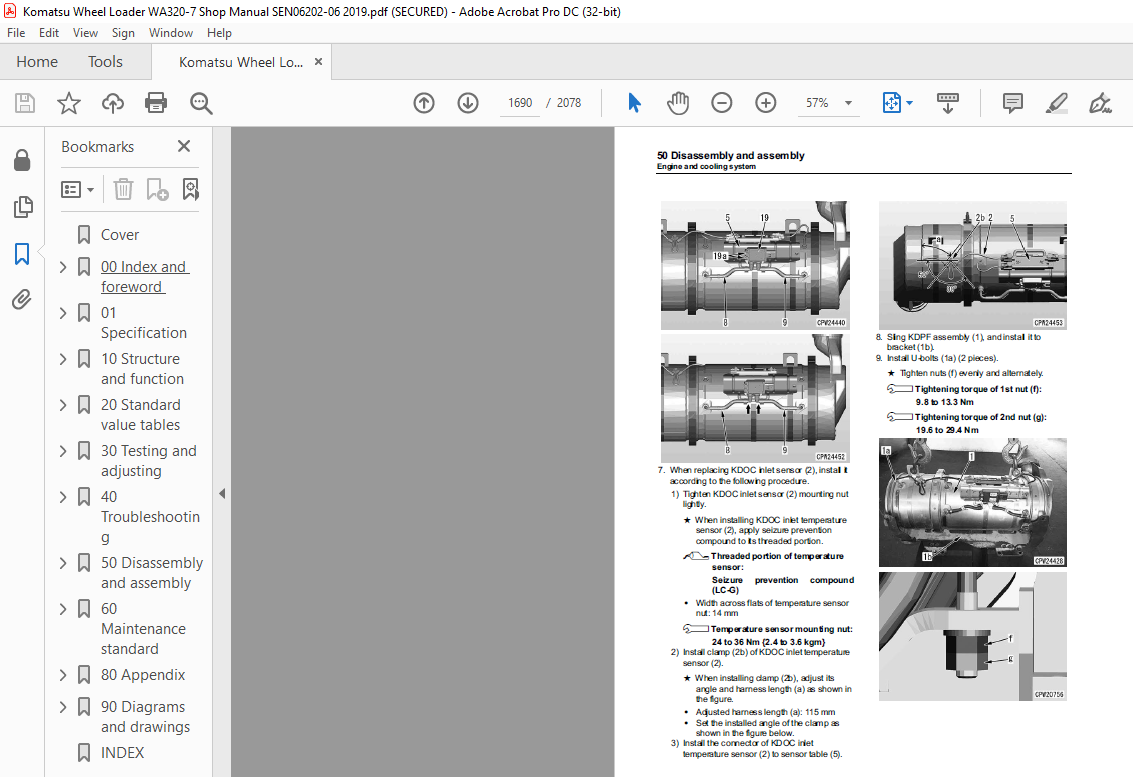

50 Disassembly and assembly 1605

Table of contents 1606

Related information on disassembly and assembly 1608

How to read this manual 1608

Coating materials list 1610

Special tools list 1614

Sketches of special tools 1619

Engine and cooling system 1632

Removal and installation of supply pump assembly 1632

Removal and installation of injector assembly 1635

Removal and installation of cylinder head assembly 1644

Removal and installation of engine hood assembly 1657

Removal and installation of radiator core assembly 1659

Removal and installation of aftercooler 1661

Removal and installation of hydraulic oil cooler 1662

Removal and installation of engine assembly 1663

Removal and installation of engine front oil seal 1671

Removal and installation of engine rear oil seal 1674

Removal and installation of cooling fan and fan motor assembly 1677

Removal and installation of KDPF assembly 1679

Disassembly and assembly of KDPF assembly 1682

Removal and installation of KCCV assembly 1691

Removal and installation of air cleaner assembly 1692

Removal and installation of KVGT assembly 1693

Removal and installation of EGR (Exhaust Gas Recirculation) valve assembly 1696

Removal and installation of EGR (Exhaust Gas Recirculation) cooler assembly 1698

Removal and installation of alternator belt 1700

Removal and installation of fuel tank assembly 1701

Power train 1704

Removal and installation of transfer assembly 1704

Disassembly and assembly of transfer assembly 1708

Removal and installation of front axle assembly 1739

Removal and installation of rear axle assembly 1741

Disassembly and assembly of axle housing assembly 1744

Disassembly and assembly of differential assembly 1756

Undercarriage and frame 1778

Removal and installation of center hinge pin 1778

Removal and installation of counterweight assembly 1787

Hydraulic system 1791

Removal and installation of hydraulic tank assembly 1791

Removal and installation of control valve assembly 1795

Disassembly and assembly of control valve assembly 1799

Removal and installation of hydraulic pump assembly 1802

Removal and installation of HST motor1 assembly 1807

Removal and installation of HST motor2 assembly 1809

Disassembly and assembly of hydraulic cylinder assembly 1811

Work equipment 1818

Removal and installation of work equipment assembly 1818

Cab and its attachments 1824

Removal and installation of operator’s cab and floor frame assembly 1824

Removal and installation of operator’s cab glass (adhered glass) 1829

Removal and installation of operator’s seat assembly 1837

Removal and installation of seat belt 1839

Removal and installation of air conditioner unit assembly 1840

Removal and installation of air conditioner compressor 1845

Removal and installation of air conditioner condenser 1847

Electrical system 1849

Removal and installation of machine monitor assembly 1849

Removal and installation of engine controller assembly 1851

Removal and installation of HST controller assembly 1853

Removal and installation of air conditioner controller assembly 1855

Removal and installation of monitor controller assembly 1856

Removal and installation of mass air flow and temperature sensor 1858

Removal and installation of KOMTRAX terminal assembly 1859

60 Maintenance standard 1861

Table of contents 1862

Engine and cooling system 1863

Engine related parts 1863

Cooling fan motor 1864

Power train 1866

Damper 1866

Transfer 1867

Drive shaft 1874

Axle 1875

Differential 1877

Limited slip differential 1881

Final drive 1883

Steering system 1885

Steering column 1885

Priority valve 1886

Emergency steering valve 1887

Steering cylinder 1888

Brake system 1890

Brake accumulator charge valve 1890

Slack adjuster 1891

Brake 1892

Parking brake 1894

Parking brake solenoid valve 1895

Undercarriage and frame 1896

Axle mount 1896

Center hinge pin 1898

Hydraulic system 1901

Hydraulic tank 1901

Double type gear pump 1902

Steering and work equipment pump 1903

Control valve 1907

Self-pressure reducing valve 1920

Work equipment PPC valve 1922

Work equipment lock solenoid valve 1924

Work equipment 1925

Work equipment linkage 1925

Bucket 1929

Work equipment cylinder 1931

Cab and its attachments 1932

Cab mount 1932

Electrical system 1933

Bucket positioner 1933

Fork positioner 1934

Remote boom positioner 1935

80 Appendix 1937

Table of contents 1938

Air conditioner components 1939

Precautions for refrigerant 1939

Air conditioner component 1940

Configuration and function of refrigeration cycle 1942

Outline of refrigeration cycle 1943

Air conditioner unit 1945

Dual pressure switch 1950

Air conditioner controller 1951

Compressor 1952

Condenser 1953

Receiver drier 1954

Sunlight sensor 1956

Outer temperature sensor (outside air temperature sensor) 1957

Procedure for testing and troubleshooting 1958

Circuit diagram and arrangement of connector pins 1960

System diagram 1963

Parts and connectors layout 1966

Testing with self-diagnosis function 1971

How to open the electrical system abnormality record screen in service mode of the machine monitor 1972

Testing temperature control system 1974

Testing vent (mode) changeover 1976

Testing FRESH/RECIRC air changeover 1978

Testing evaporator temperature sensor 1980

Testing relays 1982

Troubleshooting chart 1 1984

Troubleshooting chart 2 1985

Information in troubleshooting table 1987

Failure code list related to air conditioner 1988

Failure code [879AKA] A/C Inner Sensor Open Circuit 1989

Failure code [879AKB] A/C Inner Sensor Short Circuit 1991

Failure code [879BKA] A/C Outer Sensor Open Circuit 1993

Failure code [879BKB] A/C Outer Sensor Short Circuit 1995

Failure code [879CKA] Ventilating Sensor Open Circuit 1997

Failure code [879CKB] Ventilating Sensor Short Circuit 1999

Failure code [879DKZ] Sunlight Sensor Open or Short Circuit 2001

Failure code [879EMC] Ventilation Damper Abnormality 2003

Failure code [879FMC] Air Mix Damper Abnormality 2006

A-1 Troubleshooting for power supply and CAN communication system (Air conditioner does not operate) 2009

A-2 Troubleshooting for compressor and refrigerant system (Air is not cooled) 2012

A-3 Troubleshooting for blower motor system (No air comes out or air flow is abnormal) 2015

A-4 Troubleshooting for FRESH/RECIRC air changeover 2018

Troubleshooting with gauge pressure 2020

Connection of service tool 2023

Precautions for disconnecting and connecting hoses and tubes in air conditioner circuit 2025

Handling of compressor oil 2027

90 Diagrams and drawings 2029

Table of contents 2030

Hydraulic circuit diagram 2031

Symbols in hydraulic circuit diagram 2031

Hydraulic circuit diagram 2035

Electric circuit diagram 2037

Symbols in electric circuit diagram 2037

Electrical circuit diagram of machine body 2041

Electrical circuit diagram of floor 2051

INDEX 2067

IMAGES PREVIEW OF THE MANUAL: