$46

Komatsu WA380-5 Wheel Loader Shop Manual SEBM024713 – PDF DOWNLOAD

Komatsu WA380-5 Wheel Loader Shop Manual SEBM024713 – PDF DOWNLOAD

FILE DETAILS:

Komatsu WA380-5 Wheel Loader Shop Manual SEBM024713 – PDF DOWNLOAD

Language : English

Pages : 1240

Downloadable : Yes

File Type : PDF

Size: 80 MB

DESCRIPTION:

Komatsu WA380-5 Wheel Loader Shop Manual SEBM024713 – PDF DOWNLOAD

Machine model Serial number

WA380-5 60001 and up

GENERAL PRECAUTIONS:

Mistakes in operation are extremely dangerous. Read the Operation and Maintenance Manual carefully BEFORE operating the machine.1. Before carrying out any greasing or repairs, read all the precautions given on the decals which are fixed to the machine.2. When carrying out any operation, always wear safety shoes and helmet. Do not wear loose work clothes, or clothes with buttons missing.• Always wear safety glasses when hitting parts with a hammer.• Always wear safety glasses when grinding parts with a grinder, etc.3. If welding repairs are needed, always have a trained, experienced welder carry out the work. When carrying out welding work, always wear welding gloves, apron, hand shield, cap and other clothes suited for welding work.4. When carrying out any operation with two or more workers, always agree on the operating procedure before starting. Always inform your fellow workers before starting any step of the operation. Before starting work, hang UNDER REPAIR signs on the controls in the operator’s compartment.5. Keep all tools in good condition and learn the correct way to use them.6. Decide a place in the repair workshop to keep tools and removed parts. Always keep the tools and parts in their correct places. Always keep the work area clean and make sure that there is no dirt or oil on the floor. Smoke only in the areas provided for smoking. Never smoke while working.

PREPARATIONS FOR WORK:

- 7. Before adding oil or making any repairs, park the machine on hard, level ground, and block the wheels or tracks to prevent the machine from moving.

- 8. Before starting work, lower blade, ripper, bucket or any other work equipment to the ground. If this is not possible, insert the safety pin or use blocks to prevent the work equipment from falling. In addition, be sure to lock all the control levers and hang warning signs on them.

- 9. When disassembling or assembling, support the machine with blocks, jacks or stands before starting work.

- 10.Remove all mud and oil from the steps or other places used to get on and off the machine. Always use the handrails, ladders or steps when getting on or off the machine. Never jump on or off the machine. If it is impossible to use the handrails, ladders or steps, use a stand to provide safe footing.

FOREWORD

GENERAL

This shop manual has been prepared as an aid to improve the quality of repairs by giving the serviceman an

accurate understanding of the product and by showing him the correct way to perform repairs and make judgements.

Make sure you understand the contents of this manual and use it to full effect at every opportunity.

This shop manual mainly contains the necessary technical information for operations performed in a service

workshop. For ease of understanding, the manual is divided into the following chapters; these chapters are further

divided into the each main group of components.

STRUCTURE AND FUNCTION

This section explains the structure and function of each component. It serves not only to give an understanding

of the structure, but also serves as reference material for troubleshooting.

In addition, this section may contain hydraulic circuit diagrams, electric circuit diagrams, and maintenance

standards.

TESTING AND ADJUSTING

This section explains checks to be made before and after performing repairs, as well as adjustments to

be made at completion of the checks and repairs.

Troubleshooting charts correlating “Problems” with “Causes” are also included in this section.

DISASSEMBLY AND ASSEMBLY

This section explains the procedures for removing, installing, disassembling and assembling each component,

as well as precautions for them.

MAINTENANCE STANDARD

This section gives the judgment standards for inspection of disassembled parts.

The contents of this section may be described in STRUCTURE AND FUNCTION.

OTHERS

This section mainly gives hydraulic circuit diagrams and electric circuit diagrams.

In addition, this section may give the specifications of attachments and options together.

TABLE OF CONTENTS:

Komatsu WA380-5 Wheel Loader Shop Manual SEBM024713 – PDF DOWNLOAD

COVER 1

CONTENTS 2

LIST OF REVISED PAGES 3

SAFETY 9

SAFETY NOTICE 9

FOREWORD 11

GENERAL 11

HOW TO READ THE SHOP MANUAL 12

HOISTING INSTRUCTIONS 13

METHOD OF DISASSEMBLING, CONNECTING PUSH-PULL TYPE COUPLER 14

COATING MATERIALS 16

STANDARD TIGHTENING TORQUE 18

ELECTRIC WIRE CODE 21

CONVERSION TABLE 22

UNITS 28

01 GENERAL 29

GENERAL ASSEMBLY DRAWING 30

SPECIFICATIONS 31

WEIGHT TABLE 35

LIST OF LUBRICANT AND COOLANT 37

10 STRUCTURE AND FUNCTION, MAINTENANCE STANDARD 39

COOLING SYSTEM 40

ENGINE MOUNT, TRANSMISSION MOUNT 41

POWER TRAIN 42

POWER TRAIN SYSTEM DIAGRAM 43

DRIVE SHAFT (PROPELLER SHAFT) 46

TORQUE CONVERTER, TRANSMISSION PIPING 47

TORQUE CONVERTER 48

TRANSMISSION 56

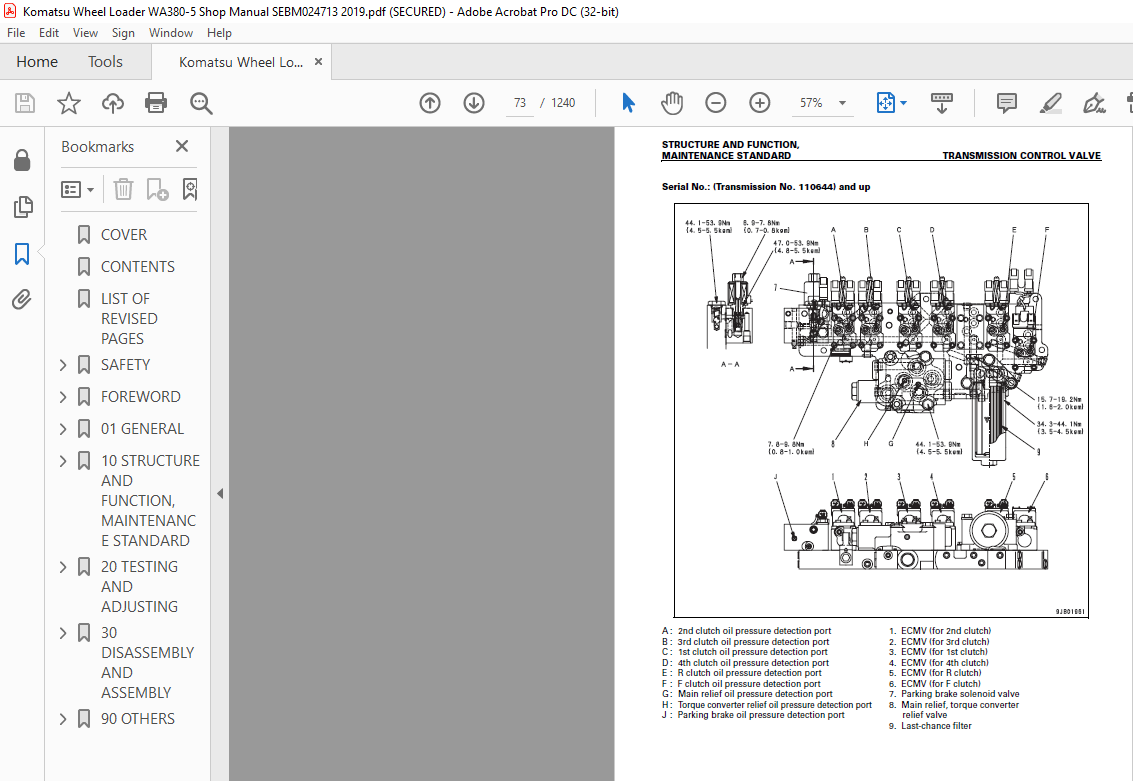

TRANSMISSION CONTROL VALVE 72

AXLE 90

DIFFERENTIAL 92

FINAL DRIVE 101

AXLE MOUNTING,CENTER HINGE PIN 104

STEERING PIPING 108

STEERING COLUMN, ORBIT-ROLL 109

STEERING VALVE 110

ORBIT-ROLL VALVE 125

STOP VALVE 129

STEERING PUMP, SWITCH PUMP 130

EMERGENCY STEERING PUMP (IF EQUIPPED) 132

EMERGENCY STEERING MOTOR (IF EQUIPPED) 133

STEERING CYLINDER 134

JOYSTICK STEERING LEVER (IF EQUIPPED) 136

STEERING LEVER (IF EQUIPPED) 137

STEERING SWITCH VALVE (IF EQUIPPED) 139

BRAKE PIPING 140

BRAKE VALVE 142

CHARGE VALVE 149

ACCUMULATOR (FOR BRAKE) 153

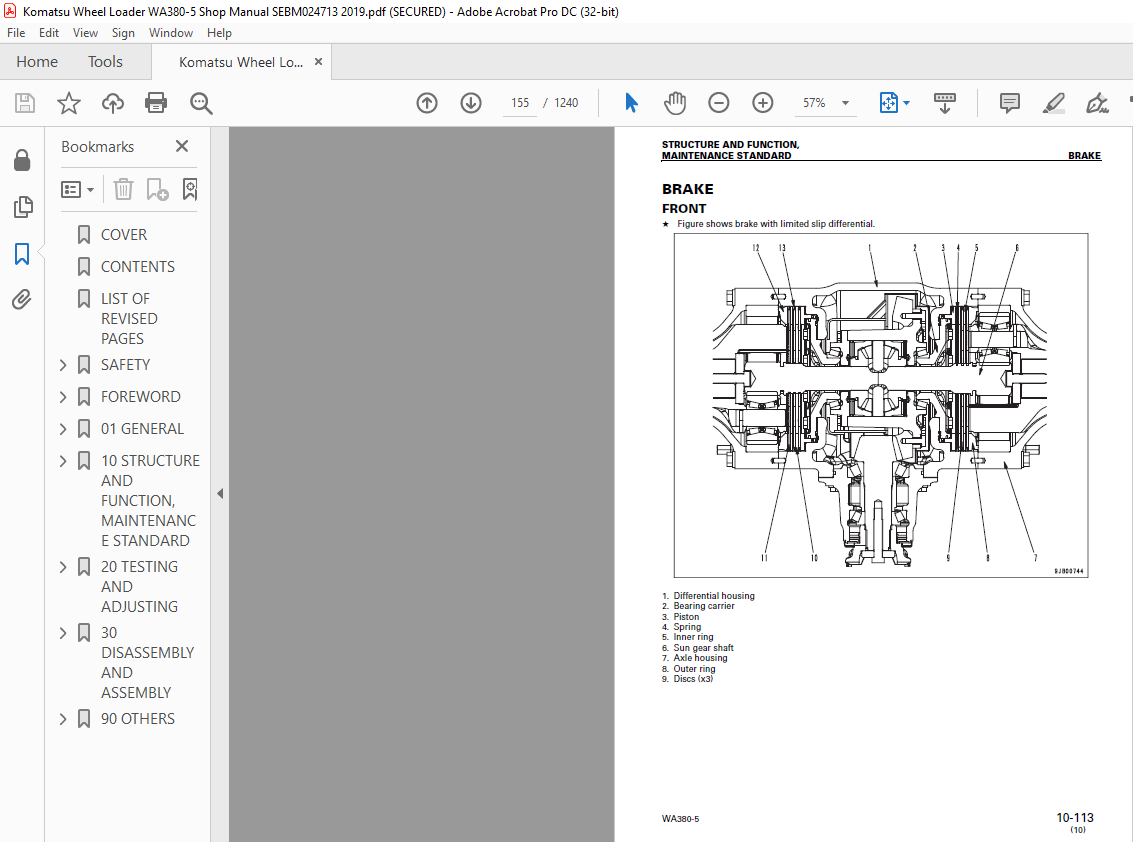

BRAKE 155

PARKING BRAKE CONTROL 160

PARKING BRAKE 161

PARKING BRAKE SOLENOID VALVE 163

PARKING BRAKE EMERGENCY RELEASE VALVE 165

HYDRAULI PIPING 166

WORK EQUIPMENT CONTROL LEVER 169

HYDRAULIC TANK 171

TORQUE CONVERTER CHARGING, WORK EQUIPMENT, AND PILOT CONTROL PUMPS 173

PPC RELIEF VALVE 175

E C S S VALVE (IF EQUIPPED) 177

WORK EQUIPMENT CONTROL VALVE 179

WORK EQUIPMENT PPC VALVE 196

PPC VALVE (FOR MULTI FUNCTION MONO LEVER) 202

EPC SOLENOID VALVE (IF EQUIPPED) 208

SHUT OFF VALVE (IF EQUIPPED) 211

ATTACHMENT PPC VALVE (IF EQUIPPED) 212

COOLING FAN MOTOR 216

COOLING FAN MOTOR DRIVE PUMP 221

WORK EQUIPMENT LINKAGE 229

BUCKET 231

BUCKET POSITIONER, LIFT ARM KICK-OUT 232

WORK EQUIPMENT CYLINDER 238

CAB 239

AIR CONDITIONER (IF EQUIPPED) 240

MACHINE MONITORING SYSTEM 241

MACHINE MONITOR 248

TRANSMISSION CONTROL SYSTEM 318

TRANSMISSION CONTROLLER 346

WORK EQUIPMENT CONTROL SYSTEM (IF EQUIPPED) 348

WORK EQUIPMENT CONTROLLER (IF EQUIPPED) 364

ELECTRIC TRANSMISSION CONTROL 366

KICK DOWN, HOLD SWITCH 370

ENGINE STARTING CIRCUIT 371

ENGINE STOP CIRCUIT 373

PREHEATING CIRCUIT 374

ENGINE POWER MODE SELECTOR CIRCUIT 375

PARKING BRAKE CIRCUIT 376

SENSORS 380

20 TESTING AND ADJUSTING 391

STANDARD VALUE TABLE FOR ENGINE 392

STANDARD VALUE TABLE FOR CHASSIS 393

TESTING AND ADJUSTING 401

TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING 403

MEASURING ENGINE SPEED 404

MEASURING EXHAUST COLOR 406

MEASURING EXHAUST TEMPERATURE 407

ADJUSTING VALVE CLEARANCE 408

MEASURING COMPRESSION PRESSURE 410

MEASURING BLOW-BY PRESSURE 411

MEASURING ENGINE OIL PRESSURE 412

MEASURING INTAKE AIR PRESSURE (BOOST PRESSURE) 413

TESTING AND ADJUSTING FUEL INJECTION TIMING 414

ADJUSTING ENGINE SPEED SENSOR 415

BLEEDING AIR FROM FUEL CIRCUIT 416

ADJUSTING ENGINE STOP SOLENOID 417

ADJUSTING ACCELERATOR PEDAL 419

ADJUSTING TRANSMISSION SPEED SENSOR 421

TESTING AND ADJUSTING POWER TRAIN OIL PRESSURE 422

DRAWING OF SPECIAL TOOL 426

PROCEDURE FOR FLUSHING TORQUE CONVERTER, TRANSMISSION HYDRAULIC CIRCUIT 427

PROCEDURE FOR MOVING MACHINE WHEN TRANSMISSION VALVE FAILS 428

TESTING AND ADJUSTING STEERING CONTROL 430

TESTING AND ADJUSTING STEERING OIL PRESSURE 431

TESTING HYDRAULIC FAN 433

MEASURING BRAKE OIL PRESSURE 434

TESTING WEAR OF WHEEL BRAKE DISC 436

BLEEDING AIR FROM BRAKE CIRCUIT 437

TESTING WEAR OF PARKING BRAKE DISC 438

MANUAL RELEASE METHOD FOR PARKING BRAKE 439

TESTING AND ADJUSTING ACCUMULATOR CHARGE PRESSURE 440

TESTING AND ADJUSTING WORKING EQUIPMENT PPC OIL PRESSURE 442

TESTING AND ADJUSTING WORK EQUIPMENT HYDRAULIC PRESSURE 444

TESTING AND ADJUSTING BUCKET POSITIONER 446

TESTING AND ADJUSTING LIFT ARM KICK-OUT 447

CHECKING PROXIMITY SWITCH ACTUATION PILOT LAMP 448

ADJUSTING MACHINE MONITOR 449

TESTING AND ADJUSTING LOAD METER 452

BLEEDING AIR 456

RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT 457

RELEASING REMAINING PRESSURE IN E C S S CIRCUIT 457

PM CLINIC INSPECTION TABLE 458

TROUBLESHOOTING 461

POINTS TO REMEMBER WHEN TROUBLESHOOTING 462

SEQUENCE OF EVENTS IN TROUBLESHOOTING 463

PRECAUTIONS WHEN CARRYING OUT MAINTENANCE 464

CHECKS BEFORE TROUBLESHOOTING 472

SPECIAL FUNCTIONS OF MACHINE MONITOR 474

CATEGORIES, PROCEDURE, AND METHOD OF USING TROUBLESHOOTING CHARTS 509

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS 518

T-ADAPTER TABLE 541

TROUBLESHOOTING OF TRANSMISSION CONTROL SYSTEM (TM MODE) 545

CONNECTOR TYPES AND MOUNTING LOCATIONS 549

CONNECTOR LAYOUT DRAWING 558

TRANSMISSION CONTROL SYSTEM DIAGRAM 564

ERROR CODE [1500L1] (DOUBLE ENGAGEMENT DETECTED) IS DISPLAYED 567

ERROR CODE [15SAL1] (F_ECMV FILL SWITCH SYSTEM SHORT-CIRCUITED) IS DISPLAYED 568

ERROR CODE [15SALH] (F_ECMV FILL SWITCH SYSTEM DISCONNECTED) IS DISPLAYED 569

ERROR CODE [15SBL1] (R_ECMV FILL SWITCH SYSTEM SHORT-CIRCUITED) IS DISPLAYED 570

ERROR CODE [15SBLH] (R_ECMV FILL SWITCH SYSTEM DISCONNECTED) IS DISPLAYED 571

ERROR CODE [15SEL1] (1ST_ECMV FILL SWITCH SYSTEM SHORT-CIRCUITED) IS DISPLAYED 572

ERROR CODE [15SELH] (1ST_ECMV FILL SWITCH SYSTEM DISCONNECTED) IS DISPLAYED 573

ERROR CODE [15SFL1] (2ND_ECMV FILL SWITCH SYSTEM SHORT-CIRCUITED) IS DISPLAYED 574

ERROR CODE [15SFLH] (2ND_ECMV FILL SWITCH SYSTEM DISCONNECTED) IS DISPLAYED 575

ERROR CODE [15SGL1] (3RD_ECMV FILL SWITCH SYSTEM SHORT-CIRCUITED) IS DISPLAYED 576

ERROR CODE [15SGLH] (3RD_ECMV FILL SWITCH SYSTEM DISCONNECTED) IS DISPLAYED 577

ERROR CODE [15SHL1] (4TH_ECMV FILL SWITCH SYSTEM SHORT-CIRCUITED) IS DISPLAYED 578

ERROR CODE [15SHLH] (4TH_ECMV FILL SWITCH SYSTEM DISCONNECTED) IS DISPLAYED 579

ERROR CODE [15SJL1] (LOCKUP_ECMV FILL SWITCH SYSTEM SHORT-CIRCUITED) IS DISPLAYED 580

ERROR CODE [15SJLH] (LOCKUP_ECMV FILL SWITCH SYSTEM DISCONNECTED) IS DISPLAYED 581

ERROR CODE [989F00] (TRANSMISSION PROTECTION CAUTION) IS DISPLAYED 582

ERROR CODE [B@C7NS] (REAR BRAKE COOLING OIL OVERHEAT) IS DISPLAYED 584

ERROR CODE [D150KA] (EMERGENCY STEERING RELAY OUTPUT SYSTEM DISCONNECTED) IS DISPLAYED 585

ERROR CODE [D150KB] (EMERGENCY STEERING RELAY OUTPUT SYSTEM GROUNDED) IS DISPLAYED 586

ERROR CODE [D160KA] (BACKUP LAMP RELAY OUTPUT SYSTEM DISCONNECTED) IS DISPLAYED 587

ERROR CODE [D160KB] (BACKUP LAMP RELAY OUTPUT SYSTEM GROUNDED) IS DISPLAYED 588

ERROR CODE [D191KA] (NEUTRAL SAFETY RELAY OUTPUT SYSTEM DISCONNECTED) IS DISPLAYED 590

ERROR CODE [D191KB] (NEUTRAL SAFETY RELAY OUTPUT SYSTEM GROUNDED) IS DISPLAYED 592

ERROR CODE [D192KA] (E C S S R RELAY OUTPUT SYSTEM DISCONNECTED) IS DISPLAYED 594

ERROR CODE [D192KB] (E C S S RELAY OUTPUT SYSTEM GROUNDED) IS DISPLAYED 595

ERROR CODE [D198KB] (GROUND FAULT IN THE LOW TEMPERATURE BYPASS RELAY SYSTEM) IS DISPLAYED 596

ERROR CODE [D198KY] (HOT-SHORT IN THE LOW-TEMPERATURE BYPASS RELAY SYSTEM) IS DISPLAYED 597

ERROR CODE [DAQ0KK] (CONTROLLER POWER SUPPLY VOLTAGE LOWERED) IS DISPLAYED 598

ERROR CODE [DAQ2KK] (DEFECTIVE SOLENOID POWER SUPPLY SYSTEM) IS DISPLAYED 599

ERROR CODE [DAQ9KQ] (MODEL SELECTION SIGNAL MISMATCH) IS DISPLAYED 600

ERROR CODE [DDK3KA] (RIGHT FNR SWITCH SIGNAL NOT INPUT) IS DISPLAYED 602

ERROR CODE [DDK3KB] (MULTIPLE RIGHT FNR SWITCH SIGNAL INPUT) IS DISPLAYED 604

ERROR CODE [DDK4KA] (JOYSTICK FORWARD/REVERSE SWITCH SIGNAL IS NOT INPUT) IS DISPLAYED 607

ERROR CODE [DDK4KB] (MULTIPLE JOYSTICK FORWARD/REVERSE SWITCH SIGNALS ARE INPUT) IS DISPLAYED 609

ERROR CODE [DDK5LD] (SHORT CIRCUIT WITH POWER SOURCE IN JOYSTICK SHIFT_UP/SHIFT_DOWN SWITCH) IS DISPLAYED 611

ERROR CODE [DDK6KA] (FORWARD-REVERSE LEVER SIGNAL NOT INPUT) IS DISPLAYED 612

ERROR CODE [DDK6KB] (MULTIPLE FORWARD-REVERSE LEVER SIGNAL INPUT) IS DISPLAYED 614

ERROR CODE [DDS5KA] (STEERING PRESSURE SWITCH DISCONNECTED) IS DISPLAYED 616

ERROR CODE [DDS5KB] (STEERING PRESSURE SWITCH GROUNDED) IS DISPLAYED 617

ERROR CODE [DDT0L4] (MANUAL/AUTO-SHIFT SELECTOR SWITCH SELECTION FAILURE) IS DISPLAYED 618

ERROR CODE [DDT4LD] (GROUND FAULT OF TRANSMISSION CUT-OFF SETTING SWITCH) IS DISPLAYED 620

ERROR CODE [DDW9LD] (GROUND FAULT OF KICKDOWN SWITCH SYSTEM) IS DISPLAYED 621

ERROR CODE [DDWLLD] (GROUND FAULT OF HOLD SWITCH SYSTEM) IS DISPLAYED 624

ERROR CODE [DF10KA] (NO INPUT OF GEAR SHIFT LEVER SIGNAL) IS DISPLAYED 626

ERROR CODE [DF10KB] (INPUT OF MULTIPLE GEAR SHIFT LEVER SIGNALS) IS DISPLAYED 628

ERROR CODE [DGF1KX] (TRANSMISSION OIL TEMPERATURE SENSOR SYSTEM FAILURE) IS DISPLAYED 630

ERROR CODE [DGR2KA] (REAR BRAKE OIL TEMPERATURE SENSOR SYSTEM DISCONNECTION) IS DISPLAYED 631

ERROR CODE [DGR2KB] (GROUND FAULT OF REAR BRAKE OIL TEMPERATURE SENSOR SYSTEM) IS DISPLAYED 632

ERROR CODE [DHT1KX] (TRANSMISSION CUT-OFF (LEFT BRAKE PRESSURE SENSOR) SIGNAL DISCONTINUITY) IS DISPLAYED 633

ERROR CODE [DLE2KA] (ENGINE REVOLUTION SENSOR SYSTEM DISCONTINUITY) IS DISPLAYED 634

ERROR CODE [DLE2LC] (ENGINE REVOLUTION SENSOR FAILURE) IS DISPLAYED 635

ERROR CODE [DLT3KA] (SPEED SENSOR (TRANSMISSION OUTPUT SHAFT REVOLUTION) SYSTEM DISCONTINUITY) IS DISPLAYED 636

ERROR CODE [DT20KB] (GROUND FAULT OF BUILT-IN INDICATOR LAMP SYSTEM OF TRANSMISSION CUT-OFF SWITCH) IS DISPLAYED 637

ERROR CODE [DW7BKA] (FAN PUMP REVERSE SOLENOID SYSTEM DISCONTINUITY) IS DISPLAYED 638

ERROR CODE [DW7BKB] (FAN PUMP REVERSE SOLENOID SYSTEM SHORT-CIRCUITING) IS DISPLAYED 639

ERROR CODE [DW7CKA] (SWITCH PUMP CUT-OFF RELAY DISCONTINUITY) IS DISPLAYED 640

ERROR CODE [DW7CKB] (SWITCH PUMP CUT-OFF RELAY GROUND FAULT) IS DISPLAYED 641

ERROR CODE [DX16KA] (FAN PUMP EPC SOLENOID SYSTEM DISCONTINUITY) IS DISPLAYED 642

ERROR CODE [DX16KB] (FAN PUMP EPC SOLENOID SYSTEM GROUND FAULT) IS DISPLAYED 643

ERROR CODE [DXH1KA] (LOCK-UP CLUTCH_ECMV SOLENOID SYSTEM DISCONTINUITY) IS DISPLAYED 644

ERROR CODE [DXH1KB] (LOCK-UP CLUTCH_ECMV SOLENOID SYSTEM SHORT-CIRCUITING) IS DISPLAYED 645

ERROR CODE [DXH4KA] (1ST_ECMV SOLENOID SYSTEM DISCONTINUITY) IS DISPLAYED 646

ERROR CODE [DXH4KB] (1ST_ECMV SOLENOID SYSTEM SHORT-CIRCUITING) IS DISPLAYED 647

ERROR CODE [DXH5KA] (2ND_ECMV SOLENOID SYSTEM DISCONTINUITY) IS DISPLAYED 648

ERROR CODE [DXH5KB] (2ND_ECMV SOLENOID SYSTEM SHORT-CIRCUITING) IS DISPLAYED 649

ERROR CODE [DXH6KA] (3RD_ECMV SOLENOID SYSTEM DISCONTINUITY) IS DISPLAYED 650

ERROR CODE [DXH6KB] (3RD_ECMV SOLENOID SYSTEM SHORT-CIRCUITING) IS DISPLAYED 651

ERROR CODE [DXH7KA] (R_ECMV SOLENOID SYSTEM DISCONTINUITY) IS DISPLAYED 652

ERROR CODE [DXH7KB] (R_ECMV SOLENOID SYSTEM GROUND FAULT) IS DISPLAYED 653

ERROR CODE [DXH8KA] (F_ECMV SOLENOID SYSTEM DISCONTINUITY) IS DISPLAYED 654

ERROR CODE [DXH8KB] (F_ECMV SOLENOID SYSTEM GROUND FAULT) IS DISPLAYED 655

ERROR CODE [DXHHKA] (4TH_ECMV SOLENOID SYSTEM DISCONTINUITY) IS DISPLAYED 656

ERROR CODE [DXHHKB] (4TH_ECMV SOLENOID SYSTEM SHORT-CIRCUITING) IS DISPLAYED 657

ERROR CODE [DY30MA] (MOTOR-DRIVEN EMERGENCY STEERING PUMP FAILURE (MALFUNCTION IN MANUAL MODE)) 658

ERROR CODE [DY30MC] (MOTOR-DRIVEN EMERGENCY STEERING PUMP FAILURE (MALFUNCTION IN MANUAL MODE)) 660

TROUBLESHOOTING CODE [TM-1] DISCONTINUITY OR HOT SHORT-CIRCUITING OF KICKDOWN SWITCH SYSTEM 662

TROUBLESHOOTING CODE [TM-2] HOLD SWITCH SYSTEM DISCONTINUITY OR HOT SHORT-CIRCUITING 664

TROUBLESHOOTING CODE [TM-3] TORQUE CONVERTER LOCK-UP SWITCH SYSTEM FAILURE 666

TROUBLESHOOTING CODE [TM-4] NEUTRALIZER SIGNAL (PARKING BRAKE SWITCH SIGNAL) SYSTEM FAILURE 668

TROUBLESHOOTING CODE [TM-5] EMERGENCY STEERING SWITCH (MOTOR-DRIVEN EMERGENCY STEERING OPERATION SWITCH) SIGNAL SYSTEM FAILURE 670

TROUBLESHOOTING CODE [TM-6] TRANSMISSION CUT-OFF SWITCH SYSTEM DISCONTINUITY OR GROUND FAULT 672

TROUBLESHOOTING CODE [TM-7] TRANSMISSION CUT-OFF SETTING SWITCH SYSTEM DISCONTINUITY OR HOT SHORT-CIRCUITING 673

TROUBLESHOOTING CODE [TM-8] TRANSMISSION CUT-OFF (LEFT BRAKE SENSOR) SIGNAL SHORT-CIRCUITING 674

TROUBLESHOOTING CODE [TM-9a] JOYSTICK SHIFT_UP/SHIFT_DOWN SWITCH SYSTEM FAILURE (DISCONTINUITY OR GROUND FAULT) 675

TROUBLESHOOTING CODE [TM-9b] JOYSTICK ON/OFF CHANGE OVER SWITCH SYSTEM FAILURE 676

TROUBLESHOOTING CODE [TM-10] FNR SWITCH MODE CHANGE OVER SWITCH SYSTEM FAILURE 678

TROUBLESHOOTING CODE [TM-11] STARTING SWITCH “C” (IGN_C) SIGNAL SYSTEM FAILURE 680

TROUBLESHOOTING CODE [TM-12] ENGINE POWER MODE SWITCH DISCONTINUITY OR GROUND FAULT 682

TROUBLESHOOTING CODE [TM-13] TRAVEL DAMPER ON/OFF SWITCH DISCONTINUITY OR GROUND FAULT 683

TROUBLESHOOTING CODE [TM-14] HYDRAULIC FAN REVERSE SWITCH SIGNAL SYSTEM HOT SHORT-CIRCUITING OR DISCONTINUITY 684

TROUBLESHOOTING CODE [TM-15] MOTOR-DRIVEN EMERGENCY STEERING RELAY OUTPUT SYSTEM HOT SHORT-CIRCUITING 685

TROUBLESHOOTING CODE [TM-16] TRAVEL DAMPER RELAY OUTPUT SYSTEM HOT SHORT-CIRCUITING 686

TROUBLESHOOTING CODE [TM-17] SWITCH PUMP CUT-OFF RELAY OUTPUT SYSTEM HOT SHORT-CIRCUITING 687

TROUBLESHOOTING CODE [TM-18] BACK LAMP RELAY OUTPUT SYSTEM HOT SHORT-CIRCUITING 688

TROUBLESHOOTING CODE [TM-19] NEUTRAL OUTPUT SYSTEM HOT SHORT-CIRCUITING 689

TROUBLESHOOTING CODE [TM-20] FECMV SOLENOID SYSTEM HOT SHORT-CIRCUITING 690

TROUBLESHOOTING CODE [TM-21] RECMV SOLENOID SYSTEM HOT SHORT-CIRCUITING 691

TROUBLESHOOTING CODE [TM-22] 1ST ECMV SOLENOID SYSTEM HOT SHORT-CIRCUITING 692

TROUBLESHOOTING CODE [TM-23] 2ND ECMV SOLENOID SYSTEM HOT SHORT-CIRCUITING 693

TROUBLESHOOTING CODE [TM-24] 3RD ECMV SOLENOID SYSTEM HOT SHORT-CIRCUITING 694

TROUBLESHOOTING CODE [TM-25] 4TH ECMV SOLENOID SYSTEM HOT SHORT-CIRCUITING 695

TROUBLESHOOTING CODE [TM-26] LOCK-UP ECMV SOLENOID SYSTEM HOT SHORT-CIRCUITING 696

TROUBLESHOOTING CODE [TM-27] FAN PUMP EPC SOLENOID SYSTEM HOT SHORT-CIRCUITING 697

TROUBLESHOOTING CODE [TM-28] FAN REVERSE SOLENOID SYSTEM HOT SHORT-CIRCUITING 698

TROUBLESHOOTING CODE [TM-29] SPEED SENSOR (TRANSMISSION OUTPUT SHAFT REVOLUTION) SYSTEM FAILURE 699

TROUBLESHOOTING CODE [TM-30] E C S S SOLENOID SYSTEM DISCONTINUITY OR GROUND FAULT 700

TROUBLESHOOTING OF WORK EQUIPMENT CONTROL SYSTEM (WRK MODE) 701

CONNECTOR TYPES AND MOUNTING LOCATIONS 705

CONNECTOR LAYOUT DRAWING 714

WORK EQUIPMENT CONTROL SYSTEM DIAGRAM 722

FAILURE CODE [D193KA] (DEFECTIVE JOYSTICK STEERING CUT RELAY SYSTEM (MAIN SYSTEM DISCONNECTED)) IS DISPLAYED 725

FAILURE CODE [D193KB] (THE JOYSTICK SOLENOID CUT RELAY OUTPUT SYSTEM IS GROUNDED PROPERLY) IS DISPLAYED 726

FAILURE CODE [DB90KK] (LOWERING WORK EQUIPMENT CONTROLLER POWER SUPPLY) IS DISPLAYED 727

FAILURE CODE [DB92KK] (DEFECTIVE SOLENOID ELECTRIC POWER SUPPLY SYSTEM) IS DISPLAYED 728

FAILURE CODE [DB95KX] (DEFECTIVE 5 V ELECTRIC POWER SUPPLY SYSTEM) IS DISPLAYED 730

FAILURE CODE [DD1ALD] (DEFECTIVE REMOTE POSITIONER UP SET SWITCH (GROUND FAULT)) IS DISPLAYED 732

FAILURE CODE [DD1BLD] (DEFECTIVE REMOTE POSITIONER DOWN SET SWITCH (GROUND FAULT)) IS DISPLAYED 733

FAILURE CODE [DFA0KM] (DEFECTIVE NEUTRAL CAUTION FOR JOYSTICK WORK EQUIPMENT LEVER) IS DISPLAYED 734

FAILURE CODE [DK59KA] (DEFECTIVE LIFT ARM EPC LEVER POTENTIOMETER SYSTEM (MAIN CIRCUIT DISCONTINUITY OR GROUND FAULT)) IS DISPLAYED 735

FAILURE CODE [DK59KY] (DEFECTIVE LIFT ARM EPC LEVER POTENTIOMETER SYSTEM (MAIN SHORT CIRCUIT)) IS DISPLAYED 736

FAILURE CODE [DK59L8] (DEFECTIVE LIFT ARM EPC POTENTIOMETER SYSTEM (DISPLACEMENT OF MAIN AND SUB-CIRCUIT)) IS DISPLAYED 737

FAILURE CODE [DK5AKA] (DEFECTIVE LIFT ARM EPC LEVER POTENTIOMETER SYSTEM (DISCONNECTION OF MAIN) (DISCONNECTION,GROUND OF SUB)) IS DISPLAYED 738

FAILURE CODE [DK5AKY] (DEFECTIVE LIFT ARM EPC LEVER POTENTIOMETER SYSTEM (SHORT SUB-CIRCUIT)) IS DISPLAYED 739

FAILURE CODE [DK5BKA] (DEFECTIVE BUCKET EPC LEVER POTENTIOMETER SYSTEM (MAIN CIRCUIT DISCONTINUITY OR GROUND FAULT)) IS DISPLAYED 740

FAILURE CODE [DK5BKY] (DEFECTIVE BUCKET EPC LEVER POTENTIOMETER SYSTEM (MAIN SHORTED)) IS DISPLAYED 741

FAILURE CODE [DK5BL8] (DEFECTIVE INPUT SIGNAL FOR BUCKET EPC LEVER POTENTIOMETER SYSTEM (DISPLACEMENT OF MAIN AND SUB-CIRCUIT)) IS DISPLAYED 742

FAILURE CODE [DK5CKA] (DEFECTIVE BUCKET EPC LEVER POTENTIOMETER SYSTEM (SUB-CIRCUIT DISCONTINUITY OR GROUND FAULT)) IS DISPLAYED 743

FAILURE CODE [DK5CKY] (DEFECTIVE BUCKET EPC LEVER POTENTIOMETER SYSTEM (SHORT SUB-CIRCUIT)) IS DISPLAYED 744

FAILURE CODE [DK5DKA] (DEFECTIVE 3RD VALVE LEVER POTENTIOMETER SYSTEM (MAIN CIRCUIT DISCONTINUITY OR GROUND FAULT)) IS DISPLAYED 745

FAILURE CODE [DK5DKY] (DEFECTIVE 3RD VALVE LEVER POTENTIOMETER SYSTEM (MAIN CIRCUIT SHORT CIRCUIT)) IS DISPLAYED 746

FAILURE CODE [DK5DL8] (DEFECTIVE 3RD VALVE EPC LEVER POTENTIOMETER SYSTEM INPUT SIGNAL (DISPLACEMENT OF MAIN AND SUB-CIRCUIT)) IS DISPLAYED 747

FAILURE CODE [DK5EKA] (DEFECTIVE 3RD VALVE EPC LEVER POTENTIOMETER SYSTEM (SUB-CIRCUIT DISCONTINUITY OR GROUND FAULT)) IS DISPLAYED 748

FAILURE CODE [DK5EKY] (DEFECTIVE 3RD VALVE EPC LEVER POTENTIOMETER SYSTEM (SHORT SUB-CIRCUIT)) IS DISPLAYED 749

FAILURE CODE [DK5FKA] (DEFECTIVE JOYSTICK STEERING EPC LEVER POTENTIOMETER SYSTEM (MAIN CIRCUIT DISCONTINUITY OR GROUND FAULT)) IS DISPLAYED 750

FAILURE CODE [DK5FKY] (DEFECTIVE JOYSTICK STEERING EPC LEVER POTENTIOMETER SYSTEM (MAIN CIRCUIT SHORTED)) IS DISPLAYED 751

FAILURE CODE [DK5FKM] (JOYSTICK STEERING EPC LEVER NEUTRAL SYSTEM CAUTION) IS DISPLAYED 752

FAILURE CODE [DK5FL8] (DEFECTIVE JOYSTICK STEERING EPC LEVER POTENTIOMETER SYSTEM INPUT SIGNAL (DEVIATION OF POSITIONAL SIGNALS OF MAIN AND SUB-CIRCUITS)) IS DISPLAYED 753

FAILURE CODE [DG5GKA] (DEFECTIVE JOYSTICK STEERING EPC LEVER POTENTIOMETER SYSTEM (DISCONNECTION OR GROUND FAULT OF SUB-CIRCUIT)) IS DISPLAYED 754

FAILURE CODE [DK5GKY] (DEFECTIVE JOYSTICK STEERING EPC LEVER POTENTIOMETER SYSTEM (SUB-CIRCUIT SHORT CIRCUIT)) IS DISPLAYED 755

FAILURE CODE [DKA0KA] (DEFECTIVE LIFT ARM ANGLE SENSOR SYSTEM (DISCONNECTION OR GROUND FAULT)) IS DISPLAYED 756

FAILURE CODE [DKA0KY] (DEFECTIVE LIFT ARM ANGLE SENSOR SYSTEM (SHORT CIRCUIT)) IS DISPLAYED 757

FAILURE CODE [DLE2LC] (DEFECTIVE ENGINE SPEED SENSOR SYSTEM) IS DISPLAYED 758

FAILURE CODE [DLT3LC] (DEFECTIVE TRANSMISSION OUTPUT AXIS SPEED SENSOR SYSTEM (DISCONNECTED)) IS DISPLAYED 759

FAILURE CODE [DUM1KB] (REMOTE POSITIONER RAISE LAMP SYSTEM GROUND FAULT) IS DISPLAYED 760

FAILURE CODE [DUM2KB] (REMOTE POSITIONER LOWER LAMP SYSTEM GROUND FAULT) IS DISPLAYED 761

FAILURE CODE [DW4PKA] (DISCONNECTED LIFT ARM RAISE EPC SOLENOID SYSTEM) IS DISPLAYED 762

FAILURE CODE [DW4PKB] (LIFT ARM RAISE EPC SOLENOID SYSTEM GROUND FAULT) IS DISPLAYED 763

FAILURE CODE [DW4QKA] (DISCONNECTED LIFT ARM LOWER EPC SOLENOID SYSTEM) IS DISPLAYED 764

FAILURE CODE [DW4QKB] (LIFT ARM LOWER EPC SOLENOID SYSTEM GROUND FAULT) IS DISPLAYED 765

FAILURE CODE [DW4RKA] (DISCONNECTED BUCKET TILT EPC SOLENOID SYSTEM) IS DISPLAYED 766

FAILURE CODE [DW4RKB] (BUCKET TILT EPC SOLENOID SYSTEM GROUND FAULT) IS DISPLAYED 767

FAILURE CODE [DW4SKA] (BUCKET DUMP EPC SOLENOID SYSTEM DISCONNECTION) IS DISPLAYED 768

FAILURE CODE [DW4SKB] (BUCKET DUMP EPC SOLENOID SYSTEM GROUND FAULT) IS DISPLAYED 769

FAILURE CODE [DWM1KA] (WORK EQUIPMENT NEUTRAL LOCK SOLENOID SYSTEM DISCONNECTION) IS DISPLAYED 770

FAILURE CODE [DWM1KB] (WORK EQUIPMENT NEUTRAL LOCK SOLENOID SYSTEM GROUND FAULT) IS DISPLAYED 771

FAILURE CODE [DWN6KA] (LIFT ARM RAISE MAGNET DETENT SYSTEM DISCONNECTION) IS DISPLAYED 772

FAILURE CODE [DWN6KB] (LIFT ARM RAISE MAGNET DETENT SYSTEM GROUND FAULT) IS DISPLAYED 773

FAILURE CODE [DWN7KA] (LIFT ARM FLOATING MAGNET DETENT SYSTEM DISCONNECTION) IS DISPLAYED 774

FAILURE CODE [DWN7KB] (LIFT ARM FLOATING MAGNET DETENT SYSTEM GROUND FAULT) IS DISPLAYED 775

FAILURE CODE [DWN8KA] (BUCKET TILT MAGNET DETENT SYSTEM DISCONNECTION) IS DISPLAYED 776

FAILURE CODE [DWN8KB] (BUCKET TILT MAGNET DETENT SYSTEM FAILURE (POWER SUPPLY SYSTEM GROUND FAULT)) IS DISPLAYED 777

FAILURE CODE [DXHJKA] (3RD VALVE EXTENSION EPC SOLENOID SYSTEM DISCONNECTION) IS DISPLAYED 778

FAILURE CODE [DXHJKB] (3RD VALVE EXTENSION EPC SOLENOID SYSTEM GROUND FAULT) IS DISPLAYED 779

FAILURE CODE [DXHKKA] (3RD VALVE RETRACTION EPC SOLENOID SYSTEM DISCONNECTION) IS DISPLAYED 780

FAILURE CODE [DXHKKB] (3RD VALVE RETRACTION EPC SOLENOID SYSTEM GROUND FAULT) IS DISPLAYED 781

FAILURE CODE [DXHLKA] (JOYSTICK STEERING RIGHT-HAND EPC SOLENOID SYSTEM DISCONNECTION) IS DISPLAYED 782

FAILURE CODE [DXHLKB] (JOYSTICK STEERING RIGHT-HAND EPC SOLENOID SYSTEM GROUND FAULT) IS DISPLAYED 783

FAILURE CODE [DXHMKA] (JOYSTICK STEERING LEFT-HAND EPC SOLENOID SYSTEM DISCONNECTION) IS DISPLAYED 784

FAILURE CODE [DXHMKB] (JOYSTICK STEERING LEFT-HAND EPC SOLENOID SYSTEM GROUND FAULT) IS DISPLAYED 785

TROUBLESHOOTING CODE [WRK-1] DEFECTIVE LIFT ARM LOCK SWITCH SYSTEM 786

TROUBLESHOOTING CODE [WRK-2] DEFECTIVE REMOTE POSITIONER RAISE SETTING SWITCH SYSTEM 787

TROUBLESHOOTING CODE [WRK-3] DEFECTIVE REMOTE POSITIONER LOWER SETTING SWITCH SYSTEM 788

TROUBLESHOOTING CODE [WRK-4] DEFECTIVE REMOTE POSITIONER RAISE SELECTION SWITCH SYSTEM 790

TROUBLESHOOTING CODE [WRK-5] DEFECTIVE REMOTE POSITIONER LOWER ON/OFF SWITCH SYSTEM 792

TROUBLESHOOTING CODE [WRK-6] DEFECTIVE BUCKET CYLINDER PROXIMITY SWITCH SYSTEM 794

TROUBLESHOOTING CODE [WRK-7] DEFECTIVE BUCKET CYLINDER FULL STROKE DETECTION SWITCH SYSTEM 796

TROUBLESHOOTING CODE [WRK-8] DEFECTIVE SEMI-AUTOMATIC DIGGING HARD SELECTION SWITCH SYSTEM 797

TROUBLESHOOTING CODE [WRK-9] DEFECTIVE SEMI-AUTOMATIC DIGGING SOFT SELECTION SWITCH SYSTEM 798

TROUBLESHOOTING CODE [WRK-10] DEFECTIVE JOYSTICK ON/OFF SWITCH SYSTEM 800

TROUBLESHOOTING CODE [WRK-11] DEFECTIVE JOYSTICK STEERING SPEED HI/LO SWITCH SYSTEM 802

TROUBLESHOOTING CODE [WRK-12] DEFECTIVE JOYSTICK SOLENOID CUT RELAY OUTPUT SYSTEM 803

TROUBLESHOOTING CODE [WRK-13] HOT SHORT-CIRCUITED LIFT ARM RAISE MAGNET DETENT OUTPUT SYSTEM 804

TROUBLESHOOTING CODE [WRK-14] HOT SHORT-CIRCUITED LIFT ARM FLOATING MAGNET DETENT OUTPUT SYSTEM 805

TROUBLESHOOTING CODE [WRK-15] HOT SHORT-CIRCUITED BUCKET TILT MAGNET DETENT OUTPUT SYSTEM 806

TROUBLESHOOTING CODE [WRK-16] HOT SHORT-CIRCUITED WORK EQUIPMENT NEUTRAL LOCK SOLENOID OUTPUT SYSTEM 807

TROUBLESHOOTING CODE [WRK-17] HOT SHORT-CIRCUITED LIFT ARM RAISE EPC SOLENOID SYSTEM 808

TROUBLESHOOTING CODE [WRK-18] HOT SHORT-CIRCUITED LIFT ARM LOWER EPC SOLENOID SYSTEM 809

TROUBLESHOOTING CODE [WRK-19] HOT SHORT-CIRCUITED BUCKET TILT EPC SOLENOID SYSTEM 810

TROUBLESHOOTING CODE [WRK-20] HOT SHORT-CIRCUITED BUCKET DUMP EPC SOLENOID SYSTEM 811

TROUBLESHOOTING CODE [WRK-21] HOT SHORT-CIRCUITED 3 VALVES EXTENSION EPC SOLENOID SYSTEM 812

TROUBLESHOOTING CODE [WRK-22] HOT SHORT-CIRCUITED 3 VALVES RETRACTION EPC SOLENOID SYSTEM 813

TROUBLESHOOTING CODE [WRK-23] HOT SHORT-CIRCUITED JOYSTICK STEERING RIGHT EPC SOLENOID SYSTEM 814

TROUBLESHOOTING CODE [WRK-24] HOT SHORT-CIRCUITED JOYSTICK STEERING LEFT EPC SOLENOID SYSTEM 815

TROUBLESHOOTING CODE [WRK-25] DEFECTIVE BUCKET POSITIONER, LIFT ARM KICK-OUT AND FLOATING HOLDING FUNCTION 816

TROUBLESHOOTING CODE [WRK-26] DEFECTIVE LIFT ARM KICK-OUT FUNCTION AND CANCELLATION 818

TROUBLESHOOTING CODE [WRK-27] DEFECTIVE BUCKET LEVELER FUNCTION AND CANCELLATION 820

TROUBLESHOOTING CODE [WRK-28] DEFECTIVE LIFT ARM FLOATING HOLDING AND CANCELLATION 822

TROUBLESHOOTING OF MONITOR SYSTEM (MON MODE) 823

CONNECTOR TYPES AND MOUNTING LOCATIONS 825

CONNECTOR LAYOUT DRAWING 834

MONITOR SYSTEM DIAGRAM 840

FAILURE CODE [2F00MA] DRAGGING OF PARKING BRAKE 844

FAILURE CODE [2G42ZG] ACCUMULATOR OIL PRESSURE (FRONT CIRCUIT) LOW 846

FAILURE CODE [2G43ZG] ACCUMULATOR OIL PRESSURE (REAR BRAKE CIRCUIT) LOW 847

FAILURE CODE [AA1ANX] AIR CLEANER 1 CLOGGED 848

FAILURE CODE [AB00L6] DEFECTIVE BATTERY CHARGING CIRCUIT (ALTERNATOR TERMINAL R SIGNAL DETECTED WHEN ENGINE STOPPED 850

FAILURE CODE [AB00MA] DEFECTIVE BATTERY CHARGING CIRCUIT (NO ALTERNATOR TERMINAL R SIGNAL DETECTED, DETECTION FAILURE) 851

FAILURE CODE [B@BAZG] ENGINE OIL PRESSURE LOW 852

FAILURE CODE [B@BAZK] ENGINE OIL LEVEL LOW 853

FAILURE CODE [B@BCNS] ENGINE WATER TEMPERATURE OVERHEATING 854

FAILURE CODE [B@BCZK] ALARM INDICATING LOW COOLANT LEVEL 855

FAILURE CODE [B@HANS] HYDRAULIC OIL TEMPERATURE OVERHEATING 856

FAILURE CODE [B@CENS] TORQUE CONVERTER OIL TEMPERATURE OVERHEATING 857

FAILURE CODE [D182KZ] THE PREHEATER RELAY COIL IS DISCONNECTED OR SHIRT-CIRCUITED 858

FAILURE CODE [D5ZHL6] STARTING SWITCH C (IGN”C”) INPUT FAILURE 860

FAILURE CODE [DA80L4] AUTO GREASE INPUT FAILURE 861

FAILURE CODE [DAF3KK] SW POWER SUPPLY (FOR OPERATION) = ON AND NSW POWER SUPPLY (FOR MEMORY) IS OFF 862

FAILURE CODE [DAF5KP] 5V POWER SUPPLY OUTPUT FAILURE 864

FAILURE CODE [DAF6KP] 24V POWER SUPPLY OUTPUT FAILURE 866

FAILURE CODE [DAFBKM] WRONG INFORMATION ON MODEL SELECTION 868

FAILURE CODE [DAFSKQ] WRONG INFORMATION ON METER DISPLAY SELECTION 869

FAILURE CODE [DAQSKR] S-NET COMMUNICATION FAILURE (BETWEEN MONITOR PANEL AND TRANSMISSION CONTROLLER) 870

FAILURE CODE [DBQSKR] S-NET COMMUNICATION FAILURE (BETWEEN MONITOR PANEL AND WORK EQUIPMENT CONTROLLER) 872

FAILURE CODE [DB9SKR] S-NET COMMUNICATION FAILURE (BETWEEN MONITOR PANEL AND WORK EQUIPMENT CONTROLLER) 873

FAILURE CODE [DD15LD] MONITOR PANEL MODE SELECTOR SWITCH 1 (PANEL SW1) INPUT ERROR 874

FAILURE CODE [DD16LD] MONITOR PANEL MODE SELECTOR SWITCH 1 (PANEL SW2) INPUT ERROR 875

FAILURE CODE [DD17LD] THE MONITOR PANEL MODE SELECTOR SWITCH 2 (PANEL SW3) INPUT CIRCUIT REMAINS CLOSED FOR MORE THAN ONE MINUTE 876

FAILURE CODE [DD18LD] MONITOR PANEL MODE SELECTOR SWITCH 2 (PANEL SW4) INPUT ERROR 877

FAILURE CODE [DD1CLD] SUB-TOTAL SWITCH FAILURE 878

FAILURE CODE [DDS5L6] DECREASED STEERING OIL PRESSURE 880

FAILURE CODE [DDY0LD] CANCEL SWITCH FAILURE 882

FAILURE CODE [DGE2KX] ENGINE WATER TEMPERATURE SENSOR SYSTEM FAILURE 884

FAILURE CODE [DGE3L6] ABNORMAL CONNECTION OF ENGINE WATER TEMPERATURE (LOW TEMPERATURE) SENSOR SYSTEM 885

FAILURE CODE [DGH2KX] HYDRAULIC OIL TEMPERATURE SENSOR SYSTEM FAILURE 886

FAILURE CODE [DGT1KX] TORQUE CONVERTER OIL TEMPERATURE SENSOR SYSTEM FAILURE 887

FAILURE CODE [DHE4L6] ENGINE OIL PRESSURE SENSOR SYSTEM FAILURE 888

FAILURE CODE [DHPCKX] BOTTOM PRESSURE SENSOR FAILURE 890

FAILURE CODE [DHPDKX] HEAD PRESSURE SENSOR FAILURE 892

FAILURE CODE [DKA0KX] LIFT ARM ANGLE SENSOR FAILURE 894

FAILURE CODE [DV00KB] SHORT-CIRCUITED ALARM BUZZER OUTPUT SYSTEM 895

FAILURE CODE [DY30ME] THE EMERGENCY STEERING REMAINS ACTUATED FOR MORE THAN ONE MINUTE 896

TROUBLESHOOTING CODE [MON-1] THE PARKING BRAKE INDICATOR LAMP DOES NOT LIGHT UP WHEN THE PARKING BRAKE SWITCH IS TURNED ON (THE PARKING BRAKE INDICATOR SWITCH CIRCUIT SUFFERS A GROUND FAULT) 898

TROUBLESHOOTING CODE [MON-2] THE BRAKE OIL PRESSURE CAUTION LAMP DOES NOT LIGHT UP WHEN THE EMERGENCY BRAKE IS APPLIED (FRONT CIRCUIT) 900

TROUBLESHOOTING CODE [MON-3] THE BRAKE OIL PRESSURE CAUTION LAMP DOES NOT LIGHT UP WHEN THE EMERGENCY BRAKE IS APPLIED (REAR CIRCUIT) 901

TROUBLESHOOTING CODE [MON-4] THE AIR CLEANER CLOGGING INDICATOR LAMP DOES NOT LIGHT ON 902

TROUBLESHOOTING CODE [MON-5] THE ENGINE HYDRAULIC CAUTION LAMP DOES NOT LIGHT ON 904

TROUBLESHOOTING CODE [MON-6] THE ENGINE OIL LEVEL CAUTION LAMP DOES NOT LIGHT ON 905

TROUBLESHOOTING CODE [MON-7] THE ENGINE WATER TEMPERATURE CAUTION LAMP DOES NOT LIGHT ON 906

TROUBLESHOOTING CODE [MON-8] THE RADIATOR WATER VOLUME CAUTION LAMP DOES NOT LIGHT ON 907

TROUBLESHOOTING CODE [MON-9] THE HYDRAULIC OIL TEMPERATURE CAUTION LAMP DOES NOT LIGHT ON 908

TROUBLESHOOTING CODE [MON-10] THE TORQUE CONVERTER OIL TEMPERATURE CAUTION LAMP DOES NOT LIGHT ON 909

TROUBLESHOOTING CODE [MON-11] THE STEERING HYDRAULIC CAUTION LAMP DOES NOT LIGHT ON 910

TROUBLESHOOTING CODE [MON-12] INPUT FAULT IN MONITOR PANEL MODE SWITCH 1 (PANEL SW1) 911

TROUBLESHOOTING CODE [MON-13] INPUT FAULT IN MONITOR PANEL MODE SWITCH 1 (PANEL SW2) 912

TROUBLESHOOTING CODE [MON-14] INPUT FAULT IN MONITOR PANEL MODE SWITCH 2 (PANEL SW3) 913

TROUBLESHOOTING CODE [MON-15] INPUT FAULT IN MONITOR PANEL MODE SWITCH 2 (PANEL SW4) 914

TROUBLESHOOTING CODE [MON-16] DEFECTIVE SUBTOTAL SWITCH 915

TROUBLESHOOTING CODE [MON-17] DEFECTIVE CANCEL SWITCH 916

TROUBLESHOOTING CODE [MON-18] DEFECTIVE BOTTOM PRESSURE SENSOR (HOT SHORT FAULT) 917

TROUBLESHOOTING CODE [MON-19] DEFECTIVE HEAD SENSOR 918

TROUBLESHOOTING CODE [MON-20] THE ALARM BUZZER DOES NOT SOUND OR STOP (DISCONNECTION OR SHORT CIRCUIT WITH CHASSIS GROUND IN BUZZER OUTPUT SYSTEM) 919

TROUBLESHOOTING OF HYDRAULIC, MECHANICAL SYSTEM (H MODE) 921

H-1 THE MACHINE DOES NOT START 922

H-2 THE LOCK-UP CLUTCH IS NOT RELEASED (THE ENGINE STOPS) (WHEN THE LOCK-UP CLUTCH IS PROVIDED) 924

H-3 925

a THE TRAVEL SPEED IS SLOW, THE THRUSTING FORCE IS WEAK, THE UPHILL TRAVELING POWER IS WEAK, AND THE GEAR IS NOT SHIFTED 925

b THE TORQUE CONVERTER LOCK-UP CLUTCH IS NOT LET IN (IF THE LOCK-UP CLUTCH IS EQUIPPED) 927

H-4 SHOCKS ARE LARGE AT THE TIMES OF STARTING AND SHIFTING GEAR 928

H-5 TIME LAG IS LARGE AT THE TIMES OF STARTING AND SHIFTING GEAR 930

H-6 THE TORQUE CONVERTER OIL TEMPERATURE IS HIGH 932

H-7 THE STEERING WHEEL DOES NOT TURN 933

H-8 THE STEERING WHEEL IS HEAVY 934

H-9 THE STEERING WHEEL FLUCTUATES OR IS STRONGLY SHOCKED 935

H-10 THE MACHINE STEERS TO ONE SIDE WHEN STAVELING 935

H-11 THE RIGHT AND LEFT SWING RADII ARE DIFFERENT 935

H-12 THE BRAKE DOES NOT WORK OR DOES NOT WORK WELL 936

H-13 THE BRAKE IS NOT RELEASED OR IS DRAGGED 937

H-14 THE BRAKE IS NOT RELEASED OR DRAGGED 938

H-15 THE LIFT ARM DOES NOT RISE 939

H-16 THE LIFT ARM MOVES SLOWLY OR THE LIFT ARM RISING FORCE IS INSUFFICIENT 940

H-17 WHEN RISING,THE LIFT ARM COMES TO MOVE SLOWLY AT SPECIFIC HEIGHT 941

H-18 THE LIFT ARM CYLINDER CANNOT HOLD DOWN THE BUCKET (THE BUCKET RISES IN THE AIR) 941

H-19 HYDRAULIC DRIFTS OF THE BOOM OCCUR OFTEN 941

H-20 THE LIFT ARM WOBBLES DURING OPERATION 941

H-21 WHEN THE CONTROL LEVER IS SWITCHED FROM “HOLD” TO “RAISE”, THE LIFT ARM FALLS TEMPORARILY 942

H-22 THE BUCKET DOES NOT TILT BACK 943

H-23 THE BUCKET MOVES SLOWLY OR THE TILTING-BACK FORCE IS INSUFFICIENT 944

H-24 THE BUCKET COMES TO OPERATE SLOWLY IN HE MIDST OF TILTING-BACK 945

H-25 THE BUCKET CYLINDER CANNOT HOLD DOWN THE BUCKET 945

H-26 HYDRAULIC DRIFTS OF THE BUCKET OCCUR OFTEN 945

H-27 THE BUCKET WOBBLES DURING TRAVEL CARGO (THE WORK EQUIPMENT VALVE IS SET TO “HOLD”) 946

H-28 WHEN THE CONTROL LEVER IS SWITCHED FROM “HOLD” TO “TILT”, THE BUCKET FALLS TEMPORARILY 946

H-29 THE CONTROL LEVERS OF LIFT ARM AND BUCKET DO NOT MOVE SMOOTHLY AND HEAVY 947

H-30 E C S S DOES NOT WORK, AND THERE IS PITCING AND BOUNCING 948

TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE) 949

CONNECTOR TYPES AND MOUNTING LOCATIONS 951

CONNECTOR LAYOUT DRAWING 960

ELECTRICAL SYSTEM DIAGRAM 966

TROUBLESHOOTING CODE [E-1-a] (THE ENGINE DOES NOT START (STARTING SYSTEM)) 968

TROUBLESHOOTING CODE [E-1-b] (THE ENGINE DOES NOT START (ENGINE STOP SOLENOID SYSTEM)) 972

TROUBLESHOOTING CODE [E-2] (THE ENGINE DOES NOT STOP) 974

TROUBLESHOOTING CODE [E-3] (PREHEATING IS IMPOSSIBLE OR CONSTANT) 976

TROUBLESHOOTING CODE [E-4] (THE ENGINE POWER MODES CANNOT BE SELECTED) 978

TROUBLESHOOTING CODE [E-5] (THE FRONT WIPER DOES NOT FUNCTION) 980

TROUBLESHOOTING CODE [E-6] (THE REAR WIPER DOES NOT FUNCTION) 983

TROUBLESHOOTING CODE [E-7] (THE SIDE WIPER DOES NOT FUNCTION (IF EQUIPPED)) 984

TROUBLESHOOTING CODE [E-8] (THE WIND WASHER DOES NOT FUNCTION) 985

TROUBLESHOOTING CODE [E-9] (THE HEADLAMP (LO BEAM) DOES NOT LIGHT ON) 988

TROUBLESHOOTING CODE [E-10] (THE HEADLAMP (HI BEAM) DOES NOT FUNCTION) 991

TROUBLESHOOTING CODE [E-11] (THE CLEARANCE LAMP DOES NOT LIGHT ON (SMALL LAMP)) 993

TROUBLESHOOTING CODE [E-12] (THE TURN SIGNAL DOES NOT BLINK) 994

TROUBLESHOOTING CODE [E-13] (THE HORN DOES NOT SOUND) 996

TROUBLESHOOTING CODE [E-14] (THE AIR CONDITIONER DOES NOT WORK OR DOES NOT STOP) 998

TROUBLESHOOTING OF ENGINE (S MODE) 1001

METHOD OF USING TROUBLESHOOTING CHARTS 1002

S-1 STARTING PREFORMANCE IS POOR (STARTING ALWAYS TAKES TIME) 1006

S-2 ENGINE DOES NOT START 1007

(1) ENGINE DOES NOT TURN 1007

(2) ENGINE TURN BUT NO EXHAUST SMOKE COMES OUT (FUEL IS BEING INJECTED) 1008

(3) EXHAUST SMOKE COMES OUT BUT ENGINE DOES NOT START (FUEL IS BEING INJECTED) 1009

S-3 ENGINE DOES NOT PICK UP SMOOTHLY (FOLLOW-UP IS POOR) 1010

S-4 ENGINE STOPS DURING OPERATIONS 1011

S-5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING) 1012

S-6 ENGINE LACKS OUTPUT (OR LACKS POWER) 1013

S-7 EXHAUST SMOKE IS BLACK (INCOMPLATE COMBUSTION) 1014

S-8 OIL CONSUMPTION IS ESCESSIVE (OR EXHAUST SMOKE IS BLUE) 1015

S-9 OIL BECOMES CONTAMINATED QUICKLY 1016

S-10 FUEL CONSUMPTION IS EXCESSIVE 1017

S-11 OIL IS IN COOLING COOLANT, OR COOLANT SPURTS BACK, OR COOLANT LEVEL GOES DOWN 1018

S-12 OIL PRESSURE CAUTION LAMP LIGHTS UP (DROP IN OIL PRESSURE) 1019

S-13 OIL LEVEL RISES (WATER, FUEL IN OIL) 1020

S-14 COOLANT TEMPERATURE BECOMES TOO HIGH (OVERHEATING) 1021

S-15 ABNORMAL NOISE IS MADE 1022

S-16 VIBRATION IS EXCESSIVE 1023

30 DISASSEMBLY AND ASSEMBLY 1025

METHOD OF USING MANUAL 1026

PRECAUTIONS WHEN CARRYING OUT OPERATION 1028

SPECIAL TOOL LIST 1031

REMOVAL AND INSTALLATION OF ENGINE ASSEMBLY 1043

REMOVAL AND INSTALLATION OF CYLINDER HEAD ASSEMBLY 1047

REMOVAL AND INSTALLATION OF RADIATOR AND FAN MOTOR ASSEMBLY 1052

REMOVAL AND INSTALLATION OF AFTERCOOLER ASSEMBLY 1054

REMOVAL AND INSTALLATION OF FUEL INJECTION PUMP 1054

REMOVAL AND INSTALLATION OF NOZZLE HOLDER ASSEMBLY 1057

REMOVAL AND INSTALLATION OF FAN AND MOTOR ASSEMBLY 1059

REMOVAL AND INSTALLATION OF FUEL TANK ASSEMBLY 1060

REMOVAL AND INSTALLATION OF PARKING BRAKE DISC PLATE 1062

REMOVAL AND INSTALLATION OF TORQUE CONVERTER AND TRANSMISSION ASSEMBLY 1065

DISASSEMBLY AND ASSEMBLY OF TRANSMISSION ASSEMBLY 1069

DISASSEMBLY AND ASSEMBLY OF TRANSMISSION CLUTCH PACK ASSEMBLY 1081

DISASSEMBLY AND ASSEMBLY OF PARKING BRAKE ASSEMBLY 1096

DISASSEMBLY AND ASSEMBLY OF TORQUE CONVERTER ASSEMBLY (STANDARD SPECIFICATION) 1104

DISASSEMBLY AND ASSEMBLY OF TORQUE CONVERTER ASSEMBLY (LOCK-UP SPECIFICATION) 1108

REMOVAL AND INSTALLATION OF REAR AXLE ASSEMBLY 1114

REMOVAL AND INSTALLATION OF FRONT AXLE ASSEMBLY 1117

DISASSEMBLY AND ASSEMBLY OF AXLE HOUSING ASSEMBLY 1118

DISASSEMBLY AND ASSEMBLY OF DIFFERENTIAL ASSEMBLY 1126

REMOVAL AND INSTALLATION OF CENTER HINGE PIN 1145

REMOVAL AND INSTALLATION OF CAB ASSEMBLY 1152

REMOVAL AND INSTALLATION OF CAB AND FLOOR FRAME ASSEMBLY 1153

REMOVAL AND INSTALLATION OF TRANSMISSION OF OPERATOR’S CAB GLASS (STUCK GLASS) 1156

REMOVAL AND INSTALLATION OF TRANSMISSION, WORK EQUIPMENT, AND PPC PUMP ASSEMBLY 1164

REMOVAL AND INSTALLATION OF STEERING, SWITCHING, AND FAN PUMP ASSEMBLY 1165

REMOVAL AND INSTALLATION OF STEERING DEMAND VALVE ASSEMBLY 1166

REMOVAL AND INSTALLATION OF STEERING VALVE OIL SEAL 1167

REMOVAL AND INSTALLATION OF E C S S VALVE ASSEMBLY 1169

REMOVAL AND INSTALLATION OF WORK EQUIPMENT VALVE ASSEMBLY 1170

DISASSEMBLY AND ASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY (STEERING, LIFT, AND BUCKET CYLINDER ASSEMBLY) 1172

REMOVAL AND INSTALLATION OF HYDRAULIC TANK ASSEMBLY 1180

REMOVAL AND INSTALLATION OF WORK EQUIPMENT ASSEMBLY 1182

REMOVAL AND INSTALLATION OF COUNTER WEIGHT 1186

REMOVAL AND INSTALLATION OF AIR CONDITIONER UNIT ASSEMBLY 1187

REMOVAL AND INSTALLATION OF AIR CONDITIONER COMPRESSOR ASSEMBLY 1190

DISASSEMBLY, ASSEMBLY OF OPERATOR’S SEAT ASSEMBLY 1191

90 OTHERS 1201

POWER TRAIN OIL CIRCUIT DIAGRAM (WITHOUT TORQUE CONVERTER LOCKUP CLUTCH) 1203

POWER TRAIN OIL CIRCUIT DIAGRAM (WITH TORQUE CONVERTER LOCKUP CLUTCH) 1205

BRAKE OIL CIRCUIT DIAGRAM 1207

WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM 1209

WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM (FOR ELECTRIC WORK EQUIPMENT LEVER) 1211

ELECTRICAL CIRCUIT DIAGRAM 1213

1/8 (1/4) 1213

1/8 (2/4) 1215

1/8 (3/4) 1217

1/8 (4/4) 1219

2/8 (1/4) 1221

2/8 (2/4) 1223

2/8 (3/4) 1225

2/8 (4/4) 1227

3/8 1229

4/8 1231

5/8 1233

6/8 1235

7/8 1237

8/8 1239

VIDEO PREVIEW OF THE MANUAL:

IMAGES PREVIEW OF THE MANUAL: