$46

Komatsu WA470-5 WA480-5 Wheel Loader Shop Manual SEBM024416 – PDF DOWNLOAD

Komatsu WA470-5 WA480-5 Wheel Loader Shop Manual SEBM024416 – PDF DOWNLOAD

FILE DETAILS:

Komatsu WA470-5 WA480-5 Wheel Loader Shop Manual SEBM024416 – PDF DOWNLOAD

Language : English

Pages : 1312

Downloadable : Yes

File Type : PDF

Size: 90.8 MB

DESCRIPTION:

Komatsu WA470-5 WA480-5 Wheel Loader Shop Manual SEBM024416 – PDF DOWNLOAD

MACHINE MODEL SERIAL NUMBER

WA480-5 80001 and up

GENERAL PRECAUTIONS:

Mistakes in operation are extremely dangerous. Read the Operation and Maintenance Manual carefully BEFORE operating the machine.1. Before carrying out any greasing or repairs, read all the precautions given on the decals which are fixed to the machine.2. When carrying out any operation, always wear safety shoes and helmet. Do not wear loose work clothes, or clothes with buttons missing.• Always wear safety glasses when hitting parts with a hammer.• Always wear safety glasses when grinding parts with a grinder, etc.3. If welding repairs are needed, always have a trained, experienced welder carry out the work. When carrying out welding work, always wear welding gloves, apron, hand shield, cap and other clothes suited for welding work.4. When carrying out any operation with two or more workers, always agree on the operating procedure before starting. Always inform your fellow workers before starting any step of the operation. Before starting work, hang UNDER REPAIR signs on the controls in the operator’s compartment.5. Keep all tools in good condition and learn the correct way to use them.

6. Decide a place in the repair workshop to keep tools and removed parts. Always keep the tools and parts in their correct places. Always keep the work area clean and make sure that there is no dirt or oil on the floor. Smoke only in the areas provided for smoking. Never smoke while working.

PREPARATIONS FOR WORK:

- 7. Before adding oil or making any repairs, park the machine on hard, level ground, and block the wheels or tracks to prevent the machine from moving.

- 8. Before starting work, lower blade, ripper, bucket or any other work equipment to the ground. If this is not possible, insert the safety pin or use blocks to prevent the work equipment from falling. In addition, be sure to lock all the control levers and hang warning signs on them.

- 9. When disassembling or assembling, support the machine with blocks, jacks or stands before starting work.

- 10.Remove all mud and oil from the steps or other places used to get on and off the machine. Always use the handrails, ladders or steps when getting on or off the machine. Never jump on or off the machine. If it is impossible to use the handrails, ladders or steps, use a stand to provide safe footing.

FOREWORD

GENERAL

This shop manual has been prepared as an aid to improve the quality of repairs by giving the serviceman an

accurate understanding of the product and by showing him the correct way to perform repairs and make judgements.

Make sure you understand the contents of this manual and use it to full effect at every opportunity.

This shop manual mainly contains the necessary technical information for operations performed in a service

workshop. For ease of understanding, the manual is divided into the following chapters; these chapters are further

divided into the each main group of components.

STRUCTURE AND FUNCTION

This section explains the structure and function of each component. It serves not only to give an understanding

of the structure, but also serves as reference material for troubleshooting.

In addition, this section may contain hydraulic circuit diagrams, electric circuit diagrams, and maintenance

standards.

TESTING AND ADJUSTING

This section explains checks to be made before and after performing repairs, as well as adjustments to

be made at completion of the checks and repairs.

Troubleshooting charts correlating “Problems” with “Causes” are also included in this section.

DISASSEMBLY AND ASSEMBLY

This section explains the procedures for removing, installing, disassembling and assembling each component,

as well as precautions for them.

MAINTENANCE STANDARD

This section gives the judgment standards for inspection of disassembled parts.

The contents of this section may be described in STRUCTURE AND FUNCTION.

OTHERS

This section mainly gives hydraulic circuit diagrams and electric circuit diagrams.

In addition, this section may give the specifications of attachments and options together.

TABLE OF CONTENTS:

Komatsu WA470-5 WA480-5 Wheel Loader Shop Manual SEBM024416 – PDF DOWNLOAD

COVER 1

CONTENTS 2

LIST OF REVISED PAGES 3

SAFETY 9

SAFETY NOTICE 9

FOREWORD 11

GENERAL 11

HOW TO READ THE SHOP MANUAL 12

HOISTING INSTRUCTIONS 13

METHOD OF DISASSEMBLING, CONNECTING PUSH-PULL TYPE COUPLER 14

COATING MATERIALS 16

STANDARD TIGHTENING TORQUE 18

ELECTRIC WIRE CODE 21

CONVERSION TABLE 22

UNITS 28

01 GENERAL 29

GENERAL ASSEMBLY DRAWING 30

SPECIFICATIONS 31

WEIGHT TABLE 35

LIST OF LUBRICANT AND COOLANT 37

10 STRUCTURE AND FUNCTION, MAINTENANCE STANDARD 39

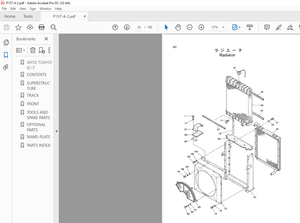

RADIATOR, OIL COOLER 40

ENGINE MOUNT, TRANSMISSION MOUNT 41

POWER TRAIN 42

POWER TRAIN SYSTEM DIAGRAM 43

DRIVE SHAFT 46

TORQUE CONVERTER,TRANSMISSION PIPING 47

TORQUE CONVERTER 48

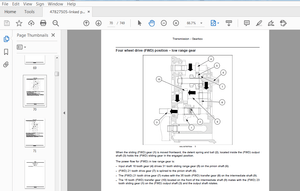

TRANSMISSION 58

TRANSMISSION CONTROL VALVE 76

AXLE 94

DIFFERENTIAL 98

FINAL DRIVE 110

AXLE MOUNTING,CENTER HINGE PIN 116

STEERING PIPING 120

STEERING COLUMN, ORBIT-ROLL 121

STEERING VALVE 122

ORBIT-ROLL VALVE 138

STOP VALVE 142

STEERING PUMP, SWITCH PUMP 144

EMERGENCY STEERING PUMP (IF EQUIPPED) 146

EMERGENCY STEERING MOTOR (IF EQUIPPED) 147

STEERING CYLINDER 148

JOYSTICK STEERING LEVER (IF EQUIPPED) 150

STEERING LEVER (IF EQUIPPED) 152

STEERING SWITCH VALVE (IF EQUIPPED) 154

BRAKE PIPING 156

BRAKE VALVE 158

CHARGE VALVE 166

ACCUMULATOR (FOR BRAKE) 170

SLACK ADJUSTER 172

BRAKE 174

PARKING BRAKE CONTROL 180

PARKING BRAKE 182

PARKING BRAKE SOLENOID VALVE 184

PARKING BRAKE EMERGENCY RELEASE VALVE 186

HYDRAULIC PIPING 188

WORK EQUIPMENT CONTROL LEVER 192

HYDRAULIC TANK 194

TORQUE CONVERTER CHARGING,WORK EQUIPMENT,AND PPC PUMPS 196

PPC RELIEF VALVE 198

ECSS VALVE (IF EQUIPPED) 200

WORK EQUIPMENT CONTROL VALVE 202

PPC VALVE 222

PPC VALVE (FOR MULTI FUNCTION MONO LEVER) 228

WORK EQUIPMENT CONTROL EPC VALVE (IF EQUIPPED) 234

SHUT OFF VALVE (IF EQUIPPED) 237

COOLING FAN MOTOR 238

COOLING FAN MOTOR DRIVE PUMP 244

WORK EQUIPMENT LINKAGE 252

BUCKET 254

BUCKET POSITIONER, BOOM KICK-OUT 256

WORK EQUIPMENT CYLINDER 262

CAB 264

AIR CONDITIONER (IF EQUIPPED) 265

MACHINE MONITORING SYSTEM 266

MACHINE MONITOR 274

TRANSMISSION CONTROL SYSTEM 344

TRANSMISSION CONTROLLER 372

WORK EQUIPMENT CONTROL SYSTEM (IF EQUIPPED) 374

WORK EQUIPMENT CONTROLLER (IF EQUIPPED) 390

ELECTRIC TRANSMISSION CONTROL 392

KICK DOWN, HOLD SWITCH 396

ENGINE STARTING CIRCUIT 398

ENGINE STOP CIRCUIT 400

PARKING BRAKE CIRCUIT 402

SENSORS 406

20 TESTING AND ADJUSTING 417

STANDARD VALUE TABLE 418

STAND ARD VALUE TABLE FOR ENGINE 418

STANDARD VALUE TABLE FOR CHASSIS 419

TESTING AND ADJUSTING 427

TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING 428

MEASURING ENGINE SPEED 430

MEASURING EXHAUST COLOR 432

MEASURING EXHAUST TEMPERATURE 433

ADJUSTING VALVE CLEARANCE 434

MEASURING COMPRESSION PRESSURE 436

MEASURING BLOW-BY PRESSURE 438

MEASURING ENGINE OIL PRESSURE 439

MEASURING AIR SUPPLY PRESSURE (BOOST PRESSURE) 440

MEASURING FUEL PRESSURE 440

TESTING LEAKAGE THROUGH PRESSURE LIMITER AND RETURN RATE FROM INJECTOR 442

HANDLING EQUIPMENT IN FUEL SYSTEM 446

RELEASING REMAINING PRESSURE IN FUEL SYSTEM 446

BLEEDING AIR FROM FUEL CIRCUIT 447

REDUCED CYLINDER MODE OPERATION FOR ENGINE 449

CHECKING FOR LEAKAGE IN FUEL SYSTEM 451

ADJUSTING ACCELERATOR PEDAL POTENTIOMETER 452

ADJUSTING ACCELERATOR PEDAL MICROSWITCH 453

ADJUSTING TRANSMISSION SPEED SENSOR 454

TESTING AND ADJUSTING POWER TRAIN OIL PRESSURE 455

PROCEDURE FOR FLUSHING TORQUE CONVERTER, TRANSMISSION HYDRAULIC CIRCUIT 459

PROCEDURE FOR MOVING MACHINE WHEN TRANSMISSION VALVE FAILS 460

TESTING AND ADJUSTING STEERING CONTROL 462

TESTING AND ADJUSTING STEERING OIL PRESSURE 463

TESTING HYDRAULIC FAN 465

MEASURING BRAKE OIL PRESSURE 466

TESTING WEAR OF WHEEL BRAKE DISC 468

BLEEDING AIR FROM BRAKE CIRCUIT 469

TESTING WEAR OF PARKING BRAKE DISC 470

MANUAL RELEASE METHOD FOR PARKING BRAKE 471

TESTING AND ADJUSTING ACCUMULATOR CHARGE PRESSURE 472

TESTING AND ADJUSTING PPC OIL PRESSURE 474

TESTING AND ADJUSTING WORK EQUIPMENT HYDRAULIC PRESSURE 476

TESTING AND ADJUSTING BUCKET POSITIONER 478

TESTING AND ADJUSTING LIFT ARM KICK-OUT 479

CHECKING PROXIMITY SWITCH ACTUATION PILOT LAMP 480

ADJUSTING MACHINE MONITOR 481

TESTING AND ADJUSTING LOAD METER 484

BLEEDING AIR 488

RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT 489

RELEASING REMAINING PRESSURE IN ECSS DAMPER CIRCUIT 489

HANDLING CONTROLLER HIGH-VOLTAGE CIRCUIT 490

INDICATOR LAMPS OF KOMTRAX TERMINAL 491

PM-CLINIC INSPECTION TABLE 497

TROUBLESHOOTING 499

POINTS TO REMEMBER WHEN TROUBLESHOOTING 500

SEQUENCE OF EVENTS IN TROUBLESHOOTING 501

PRECAUTIONS WHEN CARRYING OUT MAINTENANCE 502

CHECKS BEFORE TROUBLESHOOTING 510

SPECIAL FUNCTIONS OF MACHINE MONITOR 512

CATEGORIES,PROCEDURE,AND METHOD OF USING TROUBLESHOOTING CHARTS 549

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS 558

T-ADAPTER TABLE 581

CONNECTOR TYPES AND INSTALLATION POSITIONS 585

CONNECTORS LAYOUT DRAWING 594

TROUBLESHOOTING OF ENGINE CONTROL SYSTEM (ENG MODE) 603

ENGINE CONTROL SYSTEM DIAGRAM 604

FAILURE CODE [A000N1] (ENGINE OVERRUN (N1)) IS DISPLAYED 606

FAILURE CODE [AD00L2] (COMMON RAIL IS HIGHER THAN MAXIMUM SET VALUE) IS DISPLAYED 607

FAILURE CODE [AD00MA] (FUNCTION OF COMMON RAIL IS DEFECTIVE) IS DISPLAYED 608

FAILURE CODE [AD10L3] (FUEL SUPPLY PUMP CANNOT BE CONTROLLED) IS DISPLAYED 609

FAILURE CODE [AD10MA] (FUNCTION OF FUEL SUPPLY PUMP IS DEFECTIVE) IS DISPLAYED 613

FAILURE CODE [AD10MB] (FUNCTION OF FUEL SUPPLY PUMP IS LOWERED) IS DISPLAYED 614

FAILURE CODE [AD11KA] (DISCONNECTION IN FUEL SUPPLY PUMP PVC1 SYSTEM) IS DISPLAYED 615

FAILURE CODE [AD11KB] (SHORT CIRCUIT IN FUEL SUPPLY PUMP PVC1 SYSTEM) IS DISPLAYED 616

FAILURE CODE [AD51KA] (DISCONNECTION IS FUEL SUPPLY PUMP PCV2 SYSTEM) IS DISPLAYED 617

FAILURE CODE [AD51KB] (SHORT CIRCUIT IN FUEL SUPPLY PUMP PVC2 SYSTEM) IS DISPLAYED 618

FAILURE CODE [ADA1KA] (DISCONNECTION IN NO 1 INJECTOR SOLENOID VALVE SYSTEM) IS DISPLAYED) 619

FAILURE CODE [ADAZKB] (SHORT CIRCUIT IN NO 1,2,3 INJECTOR SOLENOID VALVE SYSTEM) IS DISPLAYED 620

FAILURE CODE [ADB1KA] (DISCONNECTION IN NO 2 INJECTOR SOLENOID VALVE SYSTEM) IS DISPLAYED 622

FAILURE CODE [ADC1KA] (DISCONNECTION IN NO 3 INJECTOR SOLENOID VALVE SYSTEM) IS DISPLAYED 623

FAILURE CODE [ADD1KA] (DISCONNECTION IN NO 4 INJECTOR SOLENOID VALVE SYSTEM) IS DISPLAYED 624

FAILURE CODE [ADDZKB] (SHORT CIRCUIT IN NO 4,5,6 INJECTOR SOLENOID VALVE SYSTEM) IS DISPLAYED 626

FAILURE CODE [ADE1KA] (DISCONNECTION IN NO 5 INJECTOR SOLENOID VALVE SYSTEM) IS DISPLAYED 628

FAILURE CODE [ADF1KA] (DISCONNECTION IN NO 6 INJECTOR SOLENOID VALVE SYSTEM) IS DISPLAYED 629

FAILURE CODE [D182KZ] (DISCONNECTION OR SHORT CIRCUIT IN PRE-HEATING RELAY COIL) ID DISPLAYED 630

FAILURE CODE [D1D0KB] (SHORT CIRCUIT IN VOLTAGE LOAD POWER SUPPLY OF ENGINE CONTROLLER POWER SUPPLY (SW) CIRCUIT) IS DISPLAYED 632

FAILURE CODE [DB20KT] (TROUBLE IN CONTROLLER) IS DISPLAYED 634

FAILURE CODE [DB22KK] (TROUBLE IN POWER SUPPLY OF ENGINE CONTROLLER LOAD POWER SUPPLY (SW) 1) IS DISPLAYED 636

FAILURE CODE [DB29KQ] (NONCONFORMANCE OF MODEL SELECTION SIGNALS IN ENGINE CONTROLLER CONNECTING WIRING HARNESS) IS DISPLAYED 638

FAILURE CODE [DB2AMA] (FUNCTION OF Q ADJUSTMENT SWITCH OF ENGINE CONTROLLER IS DEFECTIVE) IS DISPLAYED 640

FAILURE CODE [DD11KB] (TROUBLE IN INPUT OF STARTING SWITCH C (IGN C)) IS DISPLAYED 642

FAILURE CODE [DGE3L6] (TROUBLE IN WATER TEMPERATURE (LOW TEMPERATURE) SENSOR SYSTEM) IS DISPLAYED 644

FAILURE CODE [DGE4KX] (TROUBLE IN FUEL TEMPERATURE SENSOR SYSTEM) ID DISPLAYED 645

FAILURE CODE [DH30KX] (TROUBLE IN BOOST PRESSURE SENSOR SYSTEM) ID DISPLAYED 646

FAILURE CODE [DH40KX] (TROUBLE IN COMMON RAIL FUEL PRESSURE SENSOR SYSTEM) IS DISPLAYED 647

FAILURE CODE [DK10KX] (TROUBLE IN THROTTLE (ACCELERATION) SENSOR SYSTEM) IS DISPLAYED 648

FAILURE CODE [DLE3LC] (TROUBLE IN ENGINE NE SPEED SENSOR SYSTEM) IS DISPLAYED 649

FAILURE CODE [DLH1LC] (TROUBLE IN ENGINE G SPEED SYSTEM) IS DISPLAYED 650

TROUBLESHOOTING CODE [ENG-1] (ENGINE DOED NOT START) IS DISPLAYED 651

TROUBLESHOOTING OF TRANSMISSION CONTROL SYSTEM (TM MODE) 657

TRANSMISSION CONTROL SYSTEM DIAGRAM 660

FAILURE CODE [1500L1] (DOUBLE ENGAGEMENT DETECTED) IS DISPLAYED 663

FAILURE CODE [15SAL1] (F_ECMV F_ECMV FILL SWITCH SYSTEM SHORT-CIRCUITED) IS DISPLAYED 664

FAILURE CODE [15SALH] (F_ECMV FILL SWITCH SYSTEM DISCONNECTED) IS DISPLAYED 665

FAILURE CODE [15SBL1] (R_ECMV FILL SWITCH SYSTEM SHORT-CIRCUITED) IS DISPLAYED 666

FAILURE CODE [15SBLH] (R_ECMV FILL SWITCH SYSTEM DISCONNECTED) IS DISPLAYED 667

FAILURE CODE [15SEL1] (1ST_ECMV FILL SWITCH SYSTEM SHORT-CIRCUITED) IS DISPLAYED 668

FAILURE CODE [15SELH] (1ST_ECMV FILL SWITCH SYSTEM DISCONNECTED) IS DISPLAYED 669

FAILURE CODE [15SFL1] (2ND_ECMV FILL SWITCH SYSTEM SHORT-CIRCUITED) IS DISPLAYED 670

FAILURE CODE [15SFLH] (2ND_ECMV FILL SWITCH SYSTEM DISCONNECTED) IS DISPLAYED 671

FAILURE CODE [15SGL1] (3RD_ECMV FILL SWITCH SYSTEM SHORT-CIRCUITED) IS DISPLAYED 672

FAILURE CODE [15SGLH] (3RD_ECMV FILL SWITCH SYSTEM DISCONNECTED) IS DISPLAYED 673

FAILURE CODE [15SHL1] (4TH_ECMV FILL SWITCH SYSTEM SHORT-CIRCUITED) IS DISPLAYED 674

FAILURE CODE [15SHLH] (4TH_ECMV FILL SWITCH SYSTEM DISCONNECTED) IS DISPLAYED 675

FAILURE CODE [15SJL1] (LOCKUP_ECMV FILL SWITCH SYSTEM SHORT-CIRCUITED) IS DISPLAYED 676

FAILURE CODE [15SJLH] (LOCKUP_ECMV FILL SWITCH SYSTEM DISCONNECTED) IS DISPLAYED 677

FAILURE CODE [989F00] (TRANSMISSION PROTECTION CAUTION) IS DISPLAYED 678

FAILURE CODE [B@C7NS] (REAR BRAKE COOLING OIL OVERHEAT) IS DISPLAYED 680

FAILURE CODE [D150KA] (EMERGENCY STEERING RELAY OUTPUT SYSTEM DISCONNECTED) IS DISPLAYED 681

FAILURE CODE [D150KB] (EMERGENCY STEERING RELAY OUTPUT SYSTEM GROUNDED) IS DISPLAYED 682

FAILURE CODE [D160KA] (BACKUP LAMP RELAY OUTPUT SYSTEM DISCONNECTED) IS DISPLAYED 683

FAILURE CODE [D160KB] (BACKUP LAMP RELAY OUTPUT SYSTEM GROUNDED) IS DISPLAYED 684

FAILURE CODE [D191KA] (NEUTRAL SAFETY RELAY OUTPUT SYSTEM DISCONNECTED) IS DISPLAYED 686

FAILURE CODE [D191KB] (NEUTRAL SAFETY RELAY OUTPUT SYSTEM GROUNDED) IS DISPLAYED 688

FAILURE CODE [D192KA] (TRAVEL DAMPER RELAY OUTPUT SYSTEM DISCONNECTED) IS DISPLAYED 690

FAILURE CODE [D192KB] (TRAVEL DAMPER RELAY OUTPUT SYSTEM GROUNDED) IS DISPLAYED 691

FAILURE CODE [DAQ0KK] (CONTROLLER POWER SUPPLY VOLTAGE LOWERED) IS DISPLAYED 692

FAILURE CODE [DAQ2KK] (DEFECTIVE SOLENOID POWER SUPPLY SYSTEM) IS DISPLAYED 693

FAILURE CODE [DAQ9KQ] (MODEL SELECTION SIGNAL MISMATCH) IS DISPLAYED 694

FAILURE CODE [DDK3KA] (RIGHT FNR SWITCH SIGNAL NOT INPUT) IS DISPLAYED 696

FAILURE CODE [DDK3KB] (MULTIPLE RIGHT FNR SWITCH OR MULTI FUNCTION MONO LEVER FNR SWITCH SIGNAL INPUT) IS DISPLAYED 698

FAILURE CODE [DDK6KA] (FORWARD-REVERSE LEVER SIGNAL NOT INPUT) IS DISPLAYED 700

FAILURE CODE [DDK6KB] (MULTIPLE FORWARD-REVERSE LEVER SIGNAL INPUT) IS DISPLAYED 702

FAILURE CODE [DDS5KA] (STEERING PRESSURE SWITCH DISCONNECTED) IS DISPLAYED 704

FAILURE CODE [DDS5KB] (STEERING PRESSURE SWITCH GROUNDED) IS DISPLAYED 705

FAILURE CODE [DDT0L4] (MANUAL/AUTO-SHIFT SELECTOR SWITCH SELECTION FAILURE) IS DISPLAYED 706

FAILURE CODE [DDT4LD] (GROUND FAULT OF TRANSMISSION CUT-OFF SETTING SWITCH) IS DISPLAYED 708

FAILURE CODE [DDW9LD] (GROUND FAULT OF KICKDOWN SWITCH SYSTEM) IS DISPLAYED 709

FAILURE CODE [DDWLLD] (GROUND FAULT OF HOLD SWITCH SYSTEM) IS DISPLAYED 712

FAILURE CODE [DF10KA] (NO INPUT OF GEAR SHIFT LEVER SIGNAL) IS DISPLAYED 714

FAILURE CODE [DF10KB] (INPUT OF MULTIPLE GEAR SHIFT LEVER SIGNALS) IS DISPLAYED 716

FAILURE CODE [DGF1KX] (TRANSMISSION OIL TEMPERATURE SENSOR SYSTEM FAILURE) IS DISPLAYED 718

FAILURE CODE [DGR2KA] (REAR BRAKE OIL TEMPERATURE SENSOR SYSTEM DISCONNECTION) IS DISPLAYED 719

FAILURE CODE [DGR2KB] (GROUND FAULT OF REAR BRAKE OIL TEMPERATURE SENSOR SYSTEM) IS DISPLAYED 720

FAILURE CODE [DHT1KX] (TRANSMISSION CUT-OFF (LEFT BRAKE PRESSURE SENSOR) SIGNAL DISCONTINUITY) IS DISPLAYED 721

FAILURE CODE [DLE2KA] (ENGINE REVOLUTION SENSOR SYSTEM DISCONTINUITY) IS DISPLAYED 722

FAILURE CODE [DLE2LC] (ENGINE REVOLUTION SENSOR FAILURE) IS DISPLAYED 723

FAILURE CODE [DLT3KA] (SPEED SENSOR SYSTEM DISCONTINUITY (TRANSMISSION REVOLUTION SENSOR FAILURE)) IS DISPLAYED 724

FAILURE CODE [DT20KB] (GROUND FAULT OF BUILT-IN INDICATOR LAMP SYSTEM OF TRANSMISSION CUT-OFF SWITCH) IS DISPLAYED 725

FAILURE CODE [DW7BKA] (FAN PUMP REVERSE SOLENOID SYSTEM DISCONTINUITY) IS DISPLAYED 726

FAILURE CODE [DW7BKB] (FAN PUMP REVERSE SOLENOID SYSTEM SHORT-CIRCUITING) IS DISPLAYED 727

FAILURE CODE [DW7CKA] (SWITCH PUMP CUT-OFF RELAY DISCONTINUITY) IS DISPLAYED 728

FAILURE CODE [DW7CKB] (SWITCH PUMP CUT-OFF RELAY GROUND FAULT) IS DISPLAYED 729

FAILURE CODE [DX16KA] (FAN PUMP EPC SOLENOID SYSTEM DISCONTINUITY) IS DISPLAYED 730

FAILURE CODE [DX16KB] (FAN PUMP EPC SOLENOID SYSTEM GROUND FAULT) IS DISPLAYED 731

FAILURE CODE [DXH1KA] (LOCK-UP CLUTCH_ECMV SOLENOID SYSTEM DISCONTINUITY) IS DISPLAYED 732

FAILURE CODE [DXH1KB] (LOCK-UP CLUTCH_ECMV SOLENOID SYSTEM SHORT-CIRCUITING) IS DISPLAYED 733

FAILURE CODE [DXH4KA] (1ST_ECMV SOLENOID SYSTEM DISCONTINUITY) IS DISPLAYED 734

FAILURE CODE [DXH4KB] (1ST_ECMV SOLENOID SYSTEM SHORT-CIRCUITING) IS DISPLAYED 735

FAILURE CODE [DXH5KA] (2ND_ECMV SOLENOID SYSTEM DISCONTINUITY) IS DISPLAYED 736

FAILURE CODE [DXH5KB] (2ND_ECMV SOLENOID SYSTEM SHORT-CIRCUITING) IS DISPLAYED 737

FAILURE CODE [DXH6KA] (3RD_ECMV SOLENOID SYSTEM DISCONTINUITY) IS DISPLAYED 738

FAILURE CODE [DXH6KB] (3RD_ECMV SOLENOID SYSTEM SHORT-CIRCUITING) IS DISPLAYED 739

FAILURE CODE [DXH7KA] (R_ECMV SOLENOID SYSTEM DISCONTINUITY) IS DISPLAYED 740

FAILURE CODE [DXH7KB] (3RD_ECMV SOLENOID SYSTEM GROUND FAULT) IS DISPLAYED 741

FAILURE CODE [DXH8KA] (F_ECMV SOLENOID SYSTEM DISCONTINUITY) IS DISPLAYED 742

FAILURE CODE [DXH8KB] (F_ECMV SOLENOID SYSTEM GROUND FAULT) IS DISPLAYED 743

FAILURE CODE [DXHHKA] (4TH_ECMV SOLENOID SYSTEM DISCONTINUITY) IS DISPLAYED 744

FAILURE CODE [DXHHKB] (4TH_ECMV SOLENOID SYSTEM SHORT-CIRCUITING) IS DISPLAYED 745

FAILURE CODE [DY30MA] (MOTOR-DRIVEN EMERGENCY STEERING PUMP ERROR (MALFUNCTION IN MANUAL MODE)) 746

FAILURE CODE [DY30MC] (MOTOR-DRIVEN EMERGENCY STEERING PUMP ERROR (MALFUNCTION IN MANUAL MODE)) 748

TROUBLESHOOTING CODE [TM-1] DISCONTINUITY OR HOT SHORT-CIRCUITING OF KICKDOWN SWITCH SYSTEM 750

TROUBLESHOOTING CODE [TM-2] HOLD SWITCH SYSTEM DISCONTINUITY OR HOT SHORT-CIRCUITING (NO HOLD CONTROL PERFORMED BY PRESSING HOLD SWITCH) 752

TROUBLESHOOTING CODE [TM-3] TORQUE CONVERTER LOCK-UP SWITCH SYSTEM FAILURE (NO LOCK-UP PERFORMED OR NO LOCK-UP CANCELLATION PERFORMED) 754

TROUBLESHOOTING CODE [TM-4] NEUTRALIZER SIGNAL (PARKING BRAKE SWITCH SIGNAL) SYSTEM FAILURE 756

TROUBLESHOOTING CODE [TM-5] EMERGENCY STEERING SWITCH (MOTOR-DRIVEN EMERGENCY STEERING OPERATION SWITCH) SIGNAL SYSTEM FAILURE 758

TROUBLESHOOTING CODE [TM-6] TRANSMISSION CUT-OFF SWITCH SYSTEM DISCONTINUITY OR GROUND FAULT 760

TROUBLESHOOTING CODE [TM-7] TRANSMISSION CUT-OFF SETTING SWITCH SYSTEM DISCONTINUITY OR HOT SHORT-CIRCUITING 761

TROUBLESHOOTING CODE [TM-8] TRANSMISSION CUT-OFF (LEFT BRAKE SENSOR) SIGNAL SHORT-CIRCUITING 762

TROUBLESHOOTING CODE [TM-9-a] JOYSTICK SHIFT_UP/SHIFT_DOWN SWITCH SYSTEM FAILURE (DISCONTINUITY OR GROUND FAULT) 763

TROUBLESHOOTING CODE [TM-9-b] (FNR SWITCH MODE CHANGE OVER SWITCH SYSTEM FAILURE) 764

TROUBLESHOOTING CODE [TM-10] (STARTING SWITCH “C” (IGN_C) SIGNAL SYSTEM FAILURE) 766

TROUBLESHOOTING CODE [TM-11] (JOYSTICK ON/OFF CHANGE OVER SWITCH SYSTEM FAILURE) 768

TROUBLESHOOTING CODE [TM-12] (ENGINE POWER MODE SWITCH DISCONTINUITY OR GROUND FAULT) 770

TROUBLESHOOTING CODE [TM-13] (TRAVEL DAMPER NO/OFF SWITCH DISCONTINUITY OR GROUND FAULT) 771

TROUBLESHOOTING CODE [TM-14] (HYDRAULIC FAN REVERSE SWITCH SIGNAL SYSTEM HOT SHORT-CIRCUITING OR DISCONTINUITY) 772

TROUBLESHOOTING CODE [TM-15] (MOTOR-DRIVEN EMERGENCY STEERING RELAY OUTPUT SYSTEM HOT SHORT-CIRCUITING) 774

TROUBLESHOOTING CODE [TM-16] (TRAVEL DAMPER RELAY OUTPUT SYSTEM HOT SHORT-CIRCUITING) 775

TROUBLESHOOTING CODE [TM-17] (SWITCH PUMP CUT-OFF RELAY OUTPUT SYSTEM HOT SHORT-CIRCUITING) 776

TROUBLESHOOTING CODE [TM-18] (BACK LAMP RELAY OUTPUT SYSTEM HOT SHORT-CIRCUITING) 777

TROUBLESHOOTING CODE [TM-19] (NEUTRAL OUTPUT SYSTEM HOT SHORT-CIRCUITING) 778

TROUBLESHOOTING CODE [TM-20] (F ECMV SOLENOID SYSTEM HOT SHORT-CIRCUITING) 779

TROUBLESHOOTING CODE [TM-21] (R ECMV SOLENOID SYSTEM HOT SHORT-CIRCUITING) 780

TROUBLESHOOTING CODE [TM-22] (1ST ECMV SOLENOID SYSTEM HOT SHORT-CIRCUITING) 781

TROUBLESHOOTING CODE [TM-23] (2ND ECMV SOLENOID SYSTEM HOT SHORT-CIRCUITING) 782

TROUBLESHOOTING CODE [TM-24] (3RD ECMV SOLENOID SYSTEM HOT SHORT-CIRCUITING) 783

TROUBLESHOOTING CODE [TM-25] (4TH ECMV SOLENOID SYSTEM HOT SHORT-CIRCUITING) 784

TROUBLESHOOTING CODE [TM-26] (LOCK-UP ECMV SOLENOID SYSTEM HOT SHORT-CIRCUITING) 785

TROUBLESHOOTING CODE [TM-27] (FAN PUMP EPC SOLENOID SYSTEM HOT SHORT-CIRCUITING) 786

TROUBLESHOOTING CODE [TM-28] (FAN REVERSE SOLENOID SYSTEM HOT SHORT-CIRCUITING) 787

TROUBLESHOOTING CODE [TM-29] (SPEED SENSOR (TRANSMISSION OUTPUT SHAFT REVOLUTION) SYSTEM FAILURE) 788

TROUBLESHOOTING CODE [TM-30] (ECSS SOLENOID SYSTEM DISCONTINUITY OR GROUND FAULT) 789

TROUBLESHOOTING OF WORK EQUIPMENT CONTROL SYSTEM (WRK MODE) 791

WORK EQUIPMENT CONTROL SYSTEM DIAGRAM 794

FAILURE CODE [D193KA] (DEFECTIVE JOYSTICK STEERING CUT RELAY SYSTEM (MAIN SYSTEM DISCONNECTED)) IS DISPLAYED 797

FAILURE CODE [D193KB] (DEFECTIVE JOYSTICK SOLENOID CUT RELAY SYSTEM (GROUND FAULT)) IS DISPLAYED 798

FAILURE CODE [DB90KK] (LOWERING VOLTAGE OF WORK EQUIPMENT CONTROLLER POWER SUPPLY) IS DISPLAYED 799

FAILURE CODE [DB92KK] (DEFECTIVE SOLENOID ELECTRIC POWER SUPPLY SYSTEM) IS DISPLAYED 800

FAILURE CODE [DB95KX] (DEFECTIVE 5V ELECTRIC POWER SUPPLY SYSTEM) IS DISPLAYED 802

FAILURE CODE [DD1ALD] (DEFECTIVE REMOTE POSITIONER UP SET SWITCH (GROUND FAULT)) IS DISPLAYED 804

FAILURE CODE [DD1BLD] (DEFECTIVE REMOTE POSITIONER DOWN SET SWITCH (GROUND FAULT)) IS DISPLAYED 805

FAILURE CODE [DFAOKM] (DEFECTIVE NEUTRAL CAUTION FOR JOYSTICK WORK EQUIPMENT LEVER) IS DISPLAYED 806

FAILURE CODE [DK59KA] (DEFECTIVE LIFT ARM EPC LEVER POTENTIOMETER SYSTEM (MAIN CIRCUIT DISCONTINUITY OR GROUND FAULT)) IS DISPLAYED 807

FAILURE CODE [DK59KY] (DEFECTIVE LIFT ARM EPC LEVER POTENTIOMETER SYSTEM (MAIN SHORT CIRCUIT)) IS DISPLAYED 808

FAILURE CODE [DK59L8] (DEFECTIVE LIFT ARM EPC POTENTIOMETER SYSTEM (DISPLACEMENT OF MAIN AND SUB-CIRCUIT)) IS DISPLAYED 809

FAILURE CODE [DK5AKA] (DEFECTIVE LIFT ARM EPC LEVER POTENTIOMETER SYSTEM (DISCONNECTION OF MAIN) (DISCONNECTION, GROUND OF SUB)) IS DISPLAYED 810

FAILURE CODE [DK5AKY] (DEFECTIVE LIFT ARM EPC LEVER POTENTIOMETER SYSTEM (SHORT SUB-CIRCUIT)) IS DISPLAYED 811

FAILURE CODE [DK5BKA] (DEFECTIVE BUCKET EPC LEVER POTENTIOMETER SYSTEM (MAIN CIRCUIT DISCONTINUITY OR GROUND FAULT)) IS DISPLAYED 812

FAILURE CODE [DK5BKY] (DEFECTIVE BUCKET EPC LEVER POTENTIOMETER SYSTEM (MAIN CIUCUIT SHORTED)) IS DISPLAYED 813

FAILURE CODE [DK5BL8] (DEFECTIVE INPUT SIGNAL FOR BUCKET EPC LEVER POTENTIOMETER SYSTEM (DISPLACEMENT OF MAIN AND SUB CIRCUIT)) IS DISPLAYED 814

FAILURE CODE [DK5CKA] (DEFECTIVE BUCKET EPC LEVER POTENTIOMETER SYSTEM (SUB CIRCUIT DISCONTINUITY OR GROUND FAULT)) IS DISPLAYED 815

FAILURE CODE [DK5CKY] (DEFECTIVE BUCKET EPC LEVER POTENTIOMETER SYSTEM (SHORT SUB CIRCUIT)) IS DISPLAYED 816

FAILURE CODE [DK5DKA] (DEFECTIVE 3RD VALVE LEVER POTENTIOMETER SYSTEM (MAIN CIRCUIT DISCONTINUITY OR GROUND FAULT)) IS DISPLAYED 817

FAILURE CODE [DK5DKY] (DEFECTIVE 3RD VALVE LEVER POTENTIOMETER SYSTEM (MAIN CIRCUIT SHORTED)) IS DISPLAYED 818

FAILURE CODE [DK5DL8] (DEFECTIVE 3RD VALVE EPC LEVER POTENTIOMETER SYSTEM INPUT SIGNAL (DISPLACEMENT OF MAIN AND SUB CIRCUIT)) IS DISPLAYED 819

FAILURE CODE [DK5EKA] (DEFECTIVE 3RD VALVE EPC LEVER POTENTIOMETER SYSTEM (SUB CIRCUIT DISCONTINUITY OR GROUND FAULT)) IS DISPLAYED 820

FAILURE CODE [DK5EKY] (DEFECTIVE 3RD VALVE EPC LEVER POTENTIOMETER SYSTEM (SHORT SUB CIRCUIT)) IS DISPLAYED 821

FAILURE CODE [DK5FKA] (DEFECTIVE JOYSTICK STEERING EPC LEVER POTENTIOMETER SYSTEM (MAIN CIRCUIT DISCONTINUITY OR GROUND FAULT)) IS DISPLAYED 822

FAILURE CODE [DK5FKY] (DEFECTIVE JOYSTICK STEERING EPC LEVER POTENTIOMETER SYSTEM (MAIN CIRCUIT SHORTED)) IS DISPLAYED 823

FAILURE CODE [DK5FKM] (JOYSTICK STEERING EPC LEVER NEUTRAL SYSTEM) IS DISPLAYED 824

FAILURE CODE [DK5FL8] (DEFECTIVE JOYSTICK STEERING EPC LEVER POTENTIOMETER SYSTEM (DEVIATION OF POSITIONAL SIGNALS OF MAIN AND SUB CIRCUITS)) IS DISPLAYED 825

FAILURE CODE [DK5GKA] (DEFECTIVE JOYSTICK STEERING EPC LEVER POTENTIOMETER SYSTEM (DISCONNECTION OR GROUND FAULT OF SUB CIRCUIT)) IS DISPLAYED 826

FAILURE CODE [DK5GKY] (DEFECTIVE JOYSTICK STEERING EPC LEVER POTENTIOMETER SYSTEM (SUB CIRCUIT SHORT CIRCUIT)) IS DISPLAYED 827

FAILURE CODE [DKAOKA] (DEFECTIVE LIFT ARM ANGLE SENSOR SYSTEM (OUTSIDE OF SIGNAL VOLTAGE AREA: DISCONNECTION OR GROUND FAULT)) IS DISPLAYED 828

FAILURE CODE [DKAOKY] (DEFECTIVE LIFT ARM ANGLE SENSOR SYSTEM (SHORT CIRCUIT)) IS DISPLAYED 829

FAILURE CODE [DLE2LC] (DEFECTIVE ENGINE SPEED SENSOR SYSTEM) IS DISPLAYED 830

FAILURE CODE [DLT3LC] (DEFECTIVE TRANSMISSION OUTPUT AXIS SPEED SENSOR SYSTEM (DISCONNECTED)) IS DISPLAYED 831

FAILURE CODE [DUM1KB] (REMOTE POSITIONER RAISE LAMP SYSTEM GROUND FAULT) IS DISPLAYED 832

FAILURE CODE [DUM2KB] (REMOTE POSITIONER LOWER LAMP SYSTEM GROUND FAULT) IS DISPLAYED 833

FAILURE CODE [DW4PKA] (DISCONNECTED LIFT ARM RAISE EPC SOLENOID SYSTEM) IS DISPLAYED 834

FAILURE CODE [DW4PKB] (LIFT ARM RAISE EPC SOLENOID SYSTEM GROUND FAULT) IS DISPLAYED 835

FAILURE CODE [DW4QKA] (DISCONNECTED LIFT ARM LOWER EPC SOLENOID SYSTEM) IS DISPLAYED 836

FAILURE CODE [DW4QKB] (LIFT ARM LOWER EPC SOLENOID SYSTEM GROUND FAULT) IS DISPLAYED 837

FAILURE CODE [DW4RKA] (DISCONNECTED BUCKET TILT EPC SOLENOID SYSTEM) IS DISPLAYED 838

FAILURE CODE [DW4RKB] (BUCKET TILT EPC SOLENOID SYSTEM GROUND FAULT) IS DISPLAYED 839

FAILURE CODE [DW4SKA] (BUCKET DUMP EPC SOLENOID SYSTEM DISCONNECTION) IS DISPLAYED 840

FAILURE CODE [DW4SKB] (BUCKET DUMP EPC SOLENOID SYSTEM GROUND FAULT) IS DISPLAYED 841

FAILURE CODE [DWM1KA] (WORK EQUIPMENT NEUTRAL LOCK SOLENOID SYSTEM DISCONNECTION) IS DISPLAYED 842

FAILURE CODE [DWM1KB] (WORK EQUIPMENT NEUTRAL LOCK SOLENOID SYSTEM GROUND FAULT) IS DISPLAYED 843

FAILURE CODE [DWN6KA] (LIFT ARM RAISE MAGNET DETENT SYSTEM DISCONNECTION) IS DISPLAYED 844

FAILURE CODE [DWN6KB] (LIFT ARM RAISE MAGNET DETENT SYSTEM GROUND FAULT) IS DISPLAYED 845

FAILURE CODE [DWN7KA] (LIFT ARM FLOATING MAGNET DETENT SYSTEM DISCONNECTION) IS DISPLAYED 846

FAILURE CODE [DWN7KB] (LIFT ARM FLOATING MAGNET DETENT SYSTEM GROUND FAULT) IS DISPLAYED 847

FAILURE CODE [DWN8KA] (BUCKET TILT MAGNET DETENT SYSTEM DISCONNECTION) IS DISPLAYED 848

FAILURE CODE [DWN8KB] (BUCKET TILT MAGNET DETENT SYSTEM FAILURE (POWER SUPPLY SYSTEM GROUND FAULT)) IS DISPLAYED 849

FAILURE CODE [DXHJKA] (3RD VALVE EXTENSION EPC SOLENOID SYSTEM DISCONNECTION) IS DISPLAYED 850

FAILURE CODE [DXHJKB] (3RD VALVE EXTENSION EPC SOLENOID SYSTEM GROUND FAULT) IS DISPLAYED 851

FAILURE CODE [DXHKKA] (3RD VALVE RETRACTION EPC SOLENOID SYSTEM DISCONNECTION) IS DISPLAYED 852

FAILURE CODE [DXHKKB] (3RD VALVE RETRACTION EPC SOLENOID SYSTEM GROUND FAULT) IS DISPLAYED 853

FAILURE CODE [DXHLKA] (JOYSTICK STEERING RIGHT-HAND EPC SOLENOID SYSTEM DISCONNECTION) IS DISPLAYED 854

FAILURE CODE [DXHLKB] (JOYSTICK STEERING RIGHT-HAND EPC SOLENOID SYSTEM GROUND FAULT) IS DISPLAYED 855

FAILURE CODE [DXHMKA] (JOYSTICK STEERING LEFT-HAND EPC SOLENOID SYSTEM DISCONNECTION) IS DISPLAYED 856

FAILURE CODE [DXHMKB] (JOYSTICK STEERING LEFT-HAND EPC SOLENOID SYSTEM GROUND FAULT) IS DISPLAYED 857

TROUBLESHOOTING CODE [WRK-1] DEFECTIVE LIFT ARM LOCK SWITCH SYSTEM 858

TROUBLESHOOTING CODE [WRK-2] DEFECTIVE REMOTE POSITIONER RAISE SETTING SWITCH SYSTEM 859

TROUBLESHOOTING CODE [WRK-3] DEFECTIVE REMOTE POSITIONER LOWER SETTING SWITCH SYSTEM 860

TROUBLESHOOTING CODE [WRK-4] DEFECTIVE REMOTE POSITIONER RAISE SELECTION SWITCH SYSTEM 862

TROUBLESHOOTING CODE [WRK-5] DEFECTIVE REMOTE POSITIONER LOWER ON/OFF SWITCH SYSTEM 864

TROUBLESHOOTING CODE [WRK-6] DEFECTIVE BUCKET CYLINDER PROXIMITY SWITCH SYSTEM 866

TROUBLESHOOTING CODE [WRK-7] DEFECTIVE BUCKET CYLINDER FULL STROKE DETECTION SYSTEM 868

TROUBLESHOOTING CODE [WRK-8] DEFECTIVE SEMI-AUTOMATIC DIGGING HARDWARE SELECTION SWITCH SYSTEM 869

TROUBLESHOOTING CODE [WRK-9] DEFECTIVE SEMI-AUTOMATIC DIGGING SOFTWARE SELECTION SWITCH SYSTEM 870

TROUBLESHOOTING CODE [WRK-10] DEFECTIVE JOYSTICK ON/OFF SWITCH SYSTEM 872

TROUBLESHOOTING CODE [WRK-11] DEFECTIVE JOYSTICK STEERING SPEED HI/LO SWITCH SYSTEM 874

TROUBLESHOOTING CODE [WRK-12] DEFECTIVE JOYSTICK SOLENOID CUT RELAY OUTPUT SYSTEM 875

TROUBLESHOOTING CODE [WRK-13] SHORT-CIRCUITED LIFT ARM RAISE MAGNET DETENT OUTPUT SYSTEM 876

TROUBLESHOOTING CODE [WRK-14] SHORT-CIRCUITED LIFT ARM FLOATING MAGNET DETENT OUTPUT SYSTEM 877

TROUBLESHOOTING CODE [WRK-15] SHORT-CIRCUITED BUCKET TILT MAGNET DETENT OUTPUT SYSTEM 878

TROUBLESHOOTING CODE [WRK-16] SHORT-CIRCUITED WORK EQUIPMENT NEUTRAL LOCK SOLENOID OUTPUT SYSTEM 879

TROUBLESHOOTING CODE [WRK-17] SHORT-CIRCUITED LIFT ARM RAISE EPC SOLENOID SYSTEM 880

TROUBLESHOOTING CODE [WRK-18] SHORT-CIRCUITED LIFT ARM LOWER EPC SOLENOID SYSTEM 881

TROUBLESHOOTING CODE [WRK-19] SHORT-CIRCUITED BUCKET TILT EPC SOLENOID SYSTEM 882

TROUBLESHOOTING CODE [WRK-20] SHORT-CIRCUITED BUCKET DUMP EPC SOLENOID SYSTEM 883

TROUBLESHOOTING CODE [WRK-21] SHORT-CIRCUITED 3 VALVES EXTENSION EPC SOLENOID SYSTEM 884

TROUBLESHOOTING CODE [WRK-22] SHORT-CIRCUITED 3 VALVES RETRACTION EPC SOLENOID SYSTEM 885

TROUBLESHOOTING CODE [WRK-23] SHORT-CIRCUITED JOYSTICK STEERING RIGHT EPC SOLENOID SYSTEM 886

TROUBLESHOOTING CODE [WRK-24] SHORT-CIRCUITED JOYSTICK STEERING LEFT EPC SOLENOID SYSTEM 887

TROUBLESHOOTING CODE [WRK-25] DEFECTIVE BUCKET POSITIONER,LIFT ARM KICK-OUT AND FLOATING MAINTENANCE FUNCTION 888

TROUBLESHOOTING CODE [WRK-26] DEFECTIVE LIFT ARM KICK-OUT FUNCTION AND CANCELLATION 890

TROUBLESHOOTING CODE [WRK-27] DEFECTIVE BUCKET LEVELER FUNCTION AND CANCELLATION 892

TROUBLESHOOTING CODE [WRK-28] DEFECTIVE LIFT ARM FLOATING MAINTENANCE AND CANCELLATION 894

TROUBLESHOOTING OF MONITOR SYSTEM (MON MODE) 897

MONITOR SYSTEM DIAGRAM 900

FAILURE CODE [2F00MA] DEFECTIVE PARKING BRAKE SYSTEM 904

FAILURE CODE [2G42ZG] ACCUMULATOR OIL PRESSURE (FRONT CIRCUIT) LOW 906

FAILURE [2G43ZG] ACCUMULATOR OIL PRESSURE (REAR BRAKE CIRCUIT) LOW 907

FAILURE CODE [AA1ANX] AIR CLEANER 1 CLOGGED 908

FAILURE CODE [AB00L6] DEFECTIVE BATTERY CHARGING CIRCUIT (ALTERNATOR TERMINAL R SIGNAL DETECTED WHEN ENGINE STOPPED 910

FAILURE CODE [AB00MA] DEFECTIVE BATTERY CHARGING CIRCUIT (NO ALTERNATOR TERMINAL R SIGNAL DETECTED,DETECTION FAILURE) 911

FAILURE CODE [B@BAZG] ENGINE OIL PRESSURE LOW 912

FAILURE CODE [B@BAZK] ENGINE OIL LEVEL LOW 913

FAILURE CODE [B@BCNS] ENGINE WATER TEMPERATURE OVERHEATING 914

FAILURE CODE [B@BCZK] ALARM INDICATING LOW COOLANT LEVEL 915

FAILURE CODE [B@HANS] HYDRAULIC OIL TEMPERATURE OVERHEATING 916

FAILURE CODE [B@CENS] TORQUE CONVERTER OIL TEMPERATURE OVERHEATING 917

FAILURE CODE [D5ZHL6] STARTING SWITCH C (IGN”C”) INPUT FAILURE 918

FAILURE CODE [DA80L4] AUTO GREASE INPUT FAILURE 919

FAILURE CODE [DAF3KK] SW POWER SUPPLY (FOR OPERATION) = ON AND NSW POWER SUPPLY (FOR MEMORY) = OFF 920

FAILURE CODE [DAF5KP] 5-V POWER SUPPLY OUTPUT FAILURE 922

FAILURE CODE [DAF6KP] 24-V POWER SUPPLY OUTPUT FAILURE 924

FAILURE CODE [DAFBKM] WRONG INFORMATION ON MODEL SELECTION 926

FAILURE CODE [DAFSKQ] WRONG INFORMATION ON METER DISPLAY SELECTION 927

FAILURE CODE [DAQSKR] S-NET COMMUNICATION FAILURE (BETWEEN MONITOR PANEL AND TRANSMISSION CONTROLLER) SELECTION 928

FAILURE CODE [DBQSKR] S-NET COMMUNICATION FAILURE (BETWEEN MONITOR PANEL AND WORK EQUIPMENT CONTROLLER) 929

FAILURE CODE [DB9SKR] S-NET COMMUNICATION FAILURE (BETWEEN MONITOR PANEL AND WORK EQUIPMENT CONTROLLER) 930

FAILURE CODE [DD15LD] MONITOR PANEL MODE SELECTOR SWITCH 1 [■](PANEL SW1) INPUT ERROR 931

FAILURE CODE [DD16LD] MONITOR PANEL MODE SELECTOR SWITCH 1 [◇](PANEL SW2) INPUT ERROR 932

FAILURE CODE [DD17LD] MONITOR PANEL MODE SELECTOR SWITCH 2 [<](PANEL SW3) INPUT ERROR 933

FAILURE CODE [DD18LD] MONITOR PANEL MODE SELECTOR SWITCH 2 [>](PANEL SW4) INPUT ERROR 934

FAILURE CODE [DD1CLD] SUB-TOTAL SWITCH FAILURE (*) 936

FAILURE CODE [DDS5L6] DECREASED STEERING OIL PRESSURE 938

FAILURE CODE [DDY0LD] CANCEL SWITCH FAILURE (*) 940

FAILURE CODE [DGE2KX] ENGINE WATER TEMPERATURE SENSOR SYSTEM FAILURE 941

FAILURE CODE [DGH2KX] HYDRAULIC OIL TEMPERATURE SENSOR SYSTEM FAILURE 942

FAILURE CODE [DGT1KX] TORQUE CONVERTER OIL TEMPERATURE SENSOR SYSTEM FAILURE 943

FAILURE CODE [DHE4L6] ENGINE OIL PRESSURE SENSOR SYSTEM FAILURE 944

FAILURE CODE [DHPCKX] BOTTOM PRESSURE SENSOR FAILURE (*) 946

FAILURE CODE [DHPDKX] HEAD PRESSURE SENSOR FAILURE (*) 948

FAILURE CODE [DKA0KX] BOOM ANGLE SENSOR FAILURE (*) 949

FAILURE CODE [DV00KB] SHORT-CIRCUITED ALARM BUZZER OUTPUT SYSTEM 950

FAILURE CODE [DY30ME] THE EMERGENCY STEERING REMAINS ACTUATED FOR MORE THAN ONE MINUTE 952

TROUBLESHOOTING CODE [MON-1] THE PARKING BRAKE INDICATOR LAMP DOES NOT LIGHT UP WHEN THE PARKING BRAKE SWITCH IS TURNED ON (THE PARKING BRAKE INDICATOR SWITCH CIRCUIT SUFFERS A GROUND FAULT) 954

TROUBLESHOOTING CODE [MON-2] THE BRAKE OIL PRESSURE CAUTION LAMP DOES NOT LIGHT UP WHEN THE EMERGENCY BRAKE IS APPLIED (FRONT CIRCUIT) 956

TROUBLESHOOTING CODE [MON-3] THE BRAKE OIL PRESSURE CAUTION LAMP DOES NOT LIGHT UP WHEN THE EMERGENCY BRAKE IS APPLIED (REAR CIRCUIT) 957

TROUBLESHOOTING CODE [MON-4] THE AIR CLEANER CLOGGING INDICATOR LAMP DOES NOT LIGHT ON 958

TROUBLESHOOTING CODE [MON-5] THE ENGINE HYDRAULIC CAUTION LAMP DOES NOT LIGHT ON 960

TROUBLESHOOTING CODE [MON-6] THE ENGINE OIL LEVEL CAUTION LAMP DOES NOT LIGHT ON 961

TROUBLESHOOTING CODE [MON-7] THE ENGINE WATER TEMPERATURE CAUTION LAMP DOES NOT LIGHT ON 962

TROUBLESHOOTING CODE [MON-8] THE RADIATOR WATER VOLUME CAUTION LAMP DOES NOT LIGHT ON 963

TROUBLESHOOTING CODE [MON-9] THE HYDRAULIC OIL TEMPERATURE CAUTION LAMP DOES NOT LIGHT ON AFTER THE ENGINE STARTS, THE HYDRAULIC OIL TEMPERATURE GAUGE DOES NOT RISE 964

TROUBLESHOOTING CODE [MON-10] THE TORQUE CONVERTER OIL TEMPERATURE CAUTION LAMP DOES NOT LIGHT ON AFTER THE ENGINE STARTS, THE HYDRAULIC OIL TEMPERATURE GAUGE DOES NOT RISE 965

TROUBLESHOOTING CODE [MON-11] THE STEERING HYDRAULIC CAUTION LAMP DOES NOT LIGHT ON 966

TROUBLESHOOTING CODE [MON-12] INPUT FAULT IN MONITOR PANEL MODE SWITCH 1 [■] (PANEL SW1) 967

TROUBLESHOOTING CODE [MON-13] INPUT FAULT IN MONITOR PANEL MODE SWITCH 1 [◇] (PANEL SW2) 968

TROUBLESHOOTING CODE [MON-14] INPUT FAULT IN MONITOR PANEL MODE SWITCH 2 [<] (PANEL SW3) 969

TROUBLESHOOTING CODE [MON-15] INPUT FAULT IN MONITOR PANEL MODE SWITCH 2 [>] (PANEL SW4) 970

TROUBLESHOOTING CODE [MON-16] DEFECTIVE SUBTOTAL SWITCH 971

TROUBLESHOOTING CODE [MON-17] DEFECTIVE CANCEL SWITCH 972

TROUBLESHOOTING CODE [MON-18] DEFECTIVE BOTTOM PRESSURE SENSOR (HOT SHORT FAULT) 973

TROUBLESHOOTING CODE [MON-19] DEFECTIVE HEAD SENSOR 974

TROUBLESHOOTING CODE [MON-20] THE ALARM BUZZER DOES NOT SOUND OR STOP (DISCONNECTION IN ALARM BUZZER OUTPUT SYSTEM, OR GROUND FAULT) 975

TROUBLESHOOTING OF HYDRAULIC, MECHANICAL SYSTEM (H MODE) 977

H-1 THE MACHINE DOES NOT START 978

H-2 THE LOCK UP CLUTCH IS NOT RELEASED (THE ENGINE STOPS)(WHEN THE LOCK-UP CLUTCH IS PROVIDED) 980

H-3a THE TRAVEl SPEED IS SLOW,THE THRUSTING FORCE IS WEAK,THE UPHILL TRAVELING POWER IS WEAK,AND THE GEAR IS NOT SHIFTED 981

H-3b THE TORQUE CONVERTER LOCK-UP CLUTCH IS NOT LOT IN(WHEN THE LOCK-UP CLUTCH IS PROVIDED 983

H-4 SHOCKS ARE LARGE AT THE TIMES OF STARTING AND SHIFTING GEAR 984

H-5 TIME LAG IS LARGE AT THE TIMES OF STARTING AND SHIFTING GEAR 986

H-6 THE TORQUE CONVERTER OIL TEMPERATURE IS HIGH 988

H-7 THE STEERING WHEEL DOES NOT TURN 989

H-8 THE STEERING WHEEL IS HEAVY 990

H-9 THE STEERING WHEEL FLUCTUATES OR IS STRONGLY SHOCKED 991

H-10 THE MACHINE STEERS TO ONE SIDE WHEN TRAVELING 991

H-11 THE RIGHT AND LEFT SWING RADII ARE DIFFERENT 991

H-12 THE BRAKE DOES NOT WORK OR DOES NOT WORK WELL 992

H-13 THE BRAKE IS NOT RELEASED OR IS DRAGGED 993

H-14 THE BRAKE IS NOT RELEASED OR DRAGGED 994

H-15 THE LIFT ARM DOES NOT RISE 995

H-16 THE LIFT ARM MOVES SLOWLY OR THE LIFT ARM RISING FORCE IS INSUFFICIENT 996

H-17 WHEN RISING,THE LIFT ARM COMES TO MOVE SLOWLY AT SPECIFIC HEIGHT 997

H-18 THE LIFT ARM CYLINDER CANNOT HOLD DOWN THE BUCKET (THE BUCKET RISES IN THE AIR) 997

H-19 HYDRAULIC DRIFTS OF THE LIFE ARM OCCUR OFTEN 997

H-20 THE LIFT ARM WOBBLES DURING OPERATION 997

H-21 WHEN THE CONTROL LOVER IS SWITCHED FROM “HOLD” TO “RAISE,” THE LIFT ARM FALLS TEMPORARILY 998

H-22 THE BUCKET DOES NOT TILT BACK 999

H-23 THE BUCKET MOVES SLOWLY OR THE TILTING-BACK FORCE IS INSUFFICIENT 1000

H-24 THE BUCKET COMES TO OPERATE SLOWLY IN THE MIDST OF TILTING-BACK 1001

H-25 THE BUCKET CYLINDER CANNOT HOLD DOWN THE BUCKET 1001

H-26 HYDRAULIC DRIFTS OF THE BUCKET OCCUR OFTEN 1001

H-27 THE BUCKET WOBBLES DURING TRAVEL WITH CARGO (THE WORK EQUIPMENT VALVE IS SET TO “HOLD”) 1002

H-28 WHEN THE CONTROL LEVER IS SWITCHED FROM “HOLD” TO “TILT,” THE BUCKET FALLS TEMPORARILY 1002

H-29 THE CONTROL LOVERS OF LIFT ARM AND BUCKET DO NOT MOVE SMOOTHLY AND HEAVY 1003

H-30 ECSS DOES NOT WORK,AND THERE IS PITCHING AND BOUNCING 1004

TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE) 1005

ELECTRICAL SYSTEM DIAGRAM 1006

TROUBLESHOOTING CODE [E-1-a] (THE FRONT WIPER DOES NOT FUNCTION) 1007

TROUBLESHOOTING CODE [E-1-b] (THE REAR WIPER DOES NOT FUNCTION) 1010

TROUBLESHOOTING CODE [E-1-c] (THE SIDE WIPER DOES NOT FUNCTION)(IF EQUIPPED) 1011

TROUBLESHOOTING CODE [E-2] (THE WIND WASHER DOES NOT FUNCTION) 1012

TROUBLESHOOTING CODE [E-3-a] (THE HEADLAMP (LO BEAM) DOES NOT LIGHT ON) 1015

TROUBLESHOOTING CODE [E-3-b] (THE HEADLAMP (HI BEAM) DOES NOT FUNCTION) 1018

TROUBLESHOOTING CODE [E-3-c] (THE CLEARANCE LAMP DOES NOT LIGHT ON (SMALL LAMP) 1020

TROUBLESHOOTING CODE [E-3-d] (THE TURN SIGNAL DOES NOT BLINK) 1021

TROUBLESHOOTING CODE [E-4] (THE HORN DOES NOT SOUND) 1023

TROUBLESHOOTING CODE [E-5] (THE AIR CONDITIONER DOES NOT WORK OR DOES NOT STOP) 1025

TROUBLESHOOTING OF ENGINE SYSTEM (S MODE) 1029

POINTS TO REMEMBER WHEN TROUBLESHOOTING 1030

METHOD OF USING TROUBLESHOOTING CHARTS 1031

S-1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME) 1035

S-2 ENGINE DOES NOT START 1036

S-3 ENGINE DOES NOT PICK UP SMOOTHLY (FOLLOW-UP IS POOR) 1039

S-4 ENGINE STOPS DURING OPERATIONS 1040

S-5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING) 1041

S-6 ENGINE LACKS OUTPUT (OR LACKS POWER) 1042

S-7 EXHAUST SMOKE IS BLACK (INCOMPLETE COMBUSTION) 1043

S-8 OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST SMOKE IS BLUE) 1044

S-9 OIL BECOMES CONTAMINATED QUICKLY 1045

S-10 FUEL CONSUMPTION IS EXCESSIVE 1046

S-11 OIL IS IN COOLING WATER (OR WATER SPURTS BACK, OR WATER LEVEL GOES DOWN) 1047

S-12 OIL PRESSURE CAUTION LAMP LIGHTS UP (DROP IN OIL PRESSURE) 1048

S-13 OIL LEVEL RISES (COOLANT, FUEL IN OIL) 1049

S-14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING) 1050

S-15 ABNORMAL NOISE IS MADE 1051

S-16 VIBRATION IS EXCESSIVE 1052

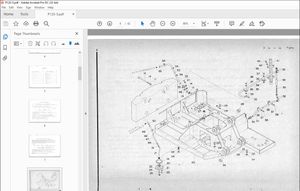

30 DISASSEMBLY AND ASSEMBLY 1053

HOW TO READ THIS MANUAL 1056

PRECAUTIONS WHEN PERFORMING OPERATION 1059

SPECIAL TOOL LIST 1062

SKETCHES OF SPECIAL TOOLS 1067

FUEL SUPPLY PUMP ASSEMBLY 1080

SPECIAL TOOLS 1080

REMOVAL 1080

INSTALLATION 1082

FUEL INJECTOR ASSEMBLY 1085

REMOVAL 1085

INSTALLATION 1087

NOZZLE TIP 1089

SPECIAL TOOL 1089

REMOVAL 1089

INSTALLATION 1090

CYLINDER HEAD ASSEMBLY 1092

SPECIAL TOOL 1092

REMOVAL 1092

INSTALLATION 1096

RADIATOR ASSEMBLY 1099

REMOVAL 1099

INSTALLATION 1100

AIR AFTERCOOLER ASSEMBLY 1101

REMOVAL 1101

INSTALLATION 1101

COOLONG FAN DRIVE MOTOR 1102

REMOVAL 1102

INSTALLATION 1102

ENGINE ASSEMBLY 1103

REMOVAL 1103

INSTALLATION 1107

STEERING, SWITCH PUMP, COOLING FAN DRIVE PUMP ASSEMBLY 1108

REMOVAL 1108

INSTALLATION 1109

TORQUE CONVERTER CHARGE, WORK EQUIPMENT AND PPC PUMP ASSEMBLY 1110

REMOVAL 1110

INSTALLATION 1110

TORQUE CONVERTER, TRANSMISSION ASSEMBLY 1111

REMOVAL 1111

INSTALLATION 1114

TORQUE CONVERTER ASSEMBLY (STANDARD SPECIFICATIONS) 1116

SPECIAL TOOLS 1116

DISASSEMBLY 1116

ASSEMBLY 1117

TORQUE CONVERTER ASSEMBLY (LOCK-UP SPECIFICATIONS) 1120

SPECIAL TOOLS 1120

DISASSEMBLY 1120

ASSEMBLY 1122

TRANSMISSION ASSEMBLY 1127

SPECIAL TOOLS 1127

DISASSEMBLY 1127

ASSEMBLY 1133

TRANSMISSION CLUTCH PACK ASSEMBLY 1143

SPECIAL TOOLS 1143

DISASSEMBLY 1143

ASSEMBLY 1149

PARKING BRAKE ASSEMBLY 1162

SPECIAL TOOLS 1162

DISASSEMBLY 1162

ASSEMBLY 1164

FRONT AXLE ASSEMBLY 1170

DISASSEMBLY 1170

ASSEMBLY 1171

REAR AXLE ASSEMBLY 1172

REMOVAL 1172

INTALLATION 1174

AXLE HOUSING ASSEMBLY 1176

SPECIAL TOOLS 1176

DISASSEMBLY 1176

ASSEMBLY 1179

DIFFERENTIAL ASSEMBLY 1186

SPECIAL TOOLS 1186

DISASSEMBLY 1186

ASSEMBLY 1193

CENTER HINGE PIN 1208

SPECIAL TOOLS 1208

REMOVAL 1208

INSTALLATION 1212

STEERING VALVE ASSEMBLY 1216

REMOVAL 1216

INSTALLATION 1217

STEERING VALVE OIL SEAL 1218

REMOVAL 1218

INSTALLATION 1219

ECSS ASSEMBLY 1220

REMOVAL 1220

INSTALLATION 1220

PARKING BRAKE DISC 1221

SPECIAL TOOLS 1221

REMOVAL 1221

INSTALLATION 1223

HYDRAULIC TANK 1224

REMOVAL 1224

INSTALLATION 1225

WORK EQUIPMENT VALVE ASSEMBLY 1226

REMOVAL 1226

INSTALLATION 1227

HYDRAULIC CYLINDER ASSEMBLY 1228

SPECIAL TOOLS 1228

DISASSEMBLY 1228

ASSWMBLY 1231

WORK EQUIPMENT ASSEMBLY 1236

REMOVAL 1236

INSTALLATION 1238

COUNTERWEIGHT 1241

REMOVAL 1241

INSTALLATION 1241

FUEL TANK ASSEMBLY 1242

REMOVAL 1242

INSTALLATION 1242

CAB ASSEMBLY 1243

REMOVAL 1243

INSTALLATION 1245

CAB, FLOOR FRAME ASSEMBLY 1246

REMOVAL 1246

INSTALLATION 1249

OPERATOR’S CAB GLASS (STUCK GLASS) 1250

SPECIAL TOOLS 1250

REMOVAL 1250

INSTALLATION 1251

AIR CONDITIONER UNIT ASSEMBLY 1258

REMOVAL 1258

INSTALLATION 1260

AIR CONDITIONER COMPRESSOR ASSEMBLY 1261

SPECIAL TOOLS 1261

REMOVAL 1261

INSTALLATION 1261

OPERATOR’S SEAT ASSEMBLY 1262

DISASSEMBLY 1262

ASSEMBLY 1267

90 OTHERS 1271

WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM 1273

WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM (FOR ELECTRIC WORK EQUIPMENT LEVER) 1275

POWER TRAIN OIL CIRCUIT DIAGRAM (WITHOUT TORQUE CONVERTER LOCKUP CLUTCH) 1277

POWER TRAIN OIL CIRCUIT DIAGRAM (WITH TORQUE CONVERTER LOCKUP CLUTCH) 1279

BRAKE OIL CIRCUIT DIAGRAM 1281

ELECTRICAL CIRCUIT DIAGRAM(1/8)(1/4) 1283

ELECTRICAL CIRCUIT DIAGRAM(1/8)(2/4) 1285

ELECTRICAL CIRCUIT DIAGRAM(1/8)(3/4) 1287

ELECTRICAL CIRCUIT DIAGRAM(1/8)(4/4) 1289

ELECTRICAL CIRCUIT DIAGRAM(2/8)(1/4) 1291

ELECTRICAL CIRCUIT DIAGRAM(2/8)(2/4) 1293

ELECTRICAL CIRCUIT DIAGRAM(2/8)(3/4) 1295

ELECTRICAL CIRCUIT DIAGRAM(2/8)(4/4) 1297

ELECTRICAL CIRCUIT DIAGRAM(3/8) 1299

ELECTRICAL CIRCUIT DIAGRAM(4/8) 1301

ELECTRICAL CIRCUIT DIAGRAM(5/8) 1303

ELECTRICAL CIRCUIT DIAGRAM(6/8) 1305

ELECTRICAL CIRCUIT DIAGRAM(7/8) 1307

ELECTRICAL CIRCUIT DIAGRAM(8/8) 1309

AXLE OIL TEMPERATURE GAUGE ELECTRICAL CIRCUIT DIAGRAM 1311

IMAGES PREVIEW OF THE MANUAL: