$47

Komatsu WA470-6R WA480-6R Wheel Loader Shop Manual SEN06594-05 – PDF DOWNLOAD

Komatsu WA470-6R WA480-6R Wheel Loader Shop Manual SEN06594-05 – PDF DOWNLOAD

FILE DETAILS:

Komatsu WA470-6R WA480-6R Wheel Loader Shop Manual SEN06594-05 – PDF DOWNLOAD

Language : English

Pages : 1854

Downloadable : Yes

File Type : PDF

Size: 128 MB

TABLE OF CONTENTS:

Komatsu WA470-6R WA480-6R Wheel Loader Shop Manual SEN06594-05 – PDF DOWNLOAD

00 Index and foreword

Table of contents 00-2

Foreword and general information 00-15

Safety notice 00-15

How to read the shop manual 00-20

Explanation of terms for maintenance standard 00-22

Handling of electric equipment and hydraulic component 00-24

Handling of connectors newly used for engines 00-33

How to read electric wire code 00-36

Precautions when carrying out operation 00-39

Method of disassembling and connecting push-pull type coupler 00-42

Standard tightening torque table 00-45

Conversion table 00-49

01 Specification

Specification and technical data 01-3

Specification dimension drawing 01-3

Specifications 01-4

Weight table 01-8

Table of fuel, coolant and lubricants 01-10

10 Structure, function and maintenance standard

Engine and cooling system 10-4

Engine mount and transmission mount 10-4

Cooling system 10-5

Cooling fan pump 10-6

Cooling fan motor 10-14

Power train 10-21

Power train 10-21

Power train system diagram 10-22

Drive shaft 10-24

Power train piping diagram 10-25

Torque converter 10-26

Transmission 10-34

Transmission control valve 10-52

ECMV 10-56

Main relief valve and torque converter relief valve 10-68

Axle 10-70

Differential 10-74

Limited slip differential 10-79

Final drive 10-86

Steering system 10-92

Steering component layout drawing 10-92

Steering column 10-93

Steering pump 10-94

Steering valve 10-107

Orbit-roll valve 10-124

Stop valve 10-132

Steering relief valve 10-133

Steering cylinder 10-134

Emergency steering motor 10-136

Emergency steering pump 10-137

WA470-6R, WA480-6R 00-3

00 Index and foreword

Joystick steering lever linkage 10-138

Electrical steering lever 10-139

Joystick EPC valve 10-140

Brake system 10-142

Brake component layout drawing 10-142

Charge valve 10-143

Brake valve 10-150

Accumulator (for brake) 10-155

Slack adjuster 10-156

Brake 10-158

Parking brake control 10-163

Parking brake 10-164

Parking brake solenoid valve 10-166

Emergency parking brake release valve 10-168

Undercarriage and frame 10-170

Axle mount and center hinge pin 10-170

Tires 10-174

Hydraulic system 10-176

Hydraulic component layout drawing 10-176

Work equipment control lever linkage 10-179

Hydraulic tank 10-182

Power train pump 10-184

Work equipment pump 10-186

Work equipment control valve 10-206

CLSS 10-217

Each function and operation of each valve 10-222

PPC valve 10-236

Accumulator (for PPC circuit) 10-244

Accumulator (for power train circuit) 10-245

Accumulator (for ECSS) 10-246

Work equipment PPC cut-off solenoid valve 10-247

Work equipment 10-250

Work equipment linkage 10-250

Bucket 10-253

Bucket positioner and boom kick-out 10-254

Work equipment cylinder 10-260

Cab and its attachments 10-261

Cab 10-261

Air conditioner 10-262

Electrical system 10-280

Machine monitor system 10-280

Machine monitor 10-284

Electrical system (Transmission controller system) 10-316

Transmission controller 10-356

Electrical system (Work equipment controller system) 10-358

Work equipment controller 10-364

Electric transmission control 10-366

Kickdown switch and hold switch 10-370

Load meter cancel switch and load meter subtotal switch 10-370

Multi-function knob 10-371

Joystick steering knob 10-372

KOMTRAX system 10-374

Engine starting circuit 10-376

Engine stopping circuit 10-378

00-4 WA470-6R, WA480-6R

00 Index and foreword

Preheating circuit 10-379

Engine power mode selector circuit 10-380

Engine output derating function 10-381

Automatic warm-up function 10-381

Parking brake circuit 10-382

Sensor 10-384

20 Standard value table

Standard service value table 20-3

Standard value table for engine 20-3

Standard value table for chassis 20-4

30 Testing and adjusting

Related information on testing and adjusting 30-4

Tools for testing, adjusting, and troubleshooting 30-4

Testing engine speed 30-9

Engine and cooling system 30-9

Testing exhaust gas color 30-11

Testing exhaust temperature 30-13

Adjusting valve clearance 30-15

Testing compression pressure 30-17

Testing blow-by pressure 30-18

Testing engine oil pressure 30-19

Testing intake air (boost) pressure 30-20

Handling fuel system equipment 30-21

Releasing residual pressure in fuel system 30-21

Testing fuel pressure 30-22

Testing fuel return and leak amount 30-23

Bleeding air from fuel circuit 30-26

Testing fuel circuit for leakage 30-28

Handling of reduced cylinder mode operation 30-29

Handling of no injection cranking operation 30-29

Handling of controller voltage circuit 30-30

Check of muffler and muffler stack for looseness and damage 30-31

Check of muffler function 30-31

Check of installed condition of cylinder head and manifolds 30-32

Check of engine piping for damage and looseness 30-32

Testing and adjusting air conditioner compressor belt tension 30-33

Testing and adjusting alternator belt tension 30-34

Power train 30-35

Adjusting transmission speed sensor 30-35

Adjusting directional lever length 30-36

Adjusting gear shift lever length 30-36

Testing FNR lever and gear shift lever 30-37

Testing and adjusting power train oil pressure 30-38

Procedure for flushing torque converter and transmission hydraulic circuit 30-52

Method of moving machine when transmission valve is broken 30-54

Check of axle final drive for oil leakage 30-57

Check of drive shafts for looseness, play and damage 30-57

Steering system 30-58

Testing and adjusting steering stop valve 30-58

Testing and adjusting steering wheel 30-60

Testing steering oil pressure 30-62

Bleeding air from steering circuit 30-65

WA470-6R, WA480-6R 00-5

00 Index and foreword

Brake system 30-66

Testing brake pedal 30-66

Testing and adjusting brake pedal linkage 30-67

Testing brake performance 30-68

Testing and adjusting accumulator charge pressure 30-69

Testing wheel brake oil pressure 30-71

Testing wear of wheel brake disc 30-73

Bleeding air from wheel brake circuit 30-74

Releasing residual pressure in brake accumulator circuit 30-75

Testing parking brake performance 30-75

Testing parking brake oil pressure 30-76

Testing wear of parking brake disc 30-78

Manual release method for parking brake 30-79

Hydraulic system 30-80

Testing hydraulic drive fan 30-80

Adjustment of hydraulic fan speed sensor 30-82

Bleeding air from hydraulic drive fan circuit 30-83

Testing and adjusting work equipment control lever 30-85

Testing and adjusting work equipment PPC oil pressure 30-86

Testing and adjusting work equipment oil pressure 30-89

Bleeding air from work equipment circuit 30-93

Releasing residual pressure in work equipment circuit 30-94

Procedure for testing of nitrogen gas pressure and charging of nitrogen gas of ECSS (Electronically

Controlled Suspension System) accumulator 30-95

Procedure for testing of nitrogen gas pressure and charging of nitrogen gas of brake accumulator

30-101

Work equipment 30-106

Testing and adjusting bucket positioner 30-106

Testing and adjusting boom kick-out 30-108

Checking proximity switch operation pilot lamp 30-109

Electrical system 30-110

Procedure for testing diodes 30-110

Preparation work for troubleshooting for electrical system 30-111

How to start KOMTRAX terminal operations 30-116

Indicator lamps of KOMTRAX terminal 30-121

Adjusting replaced, reassembled or added sensor, controller, etc with machine monitor 30-124

Special functions of machine monitor (EMMS) 30-127

Pm-clinic 30-190

Pm-clinic inspection table 30-190

40 Troubleshooting

General information on troubleshooting 40-11

Points to remember when troubleshooting 40-11

How to proceed in troubleshooting 40-12

Testing before troubleshooting 40-14

Classification and procedures of troubleshooting 40-16

Failure code table 40-20

Information in troubleshooting table 40-31

Troubleshooting method for open circuit in wiring harness of pressure sensor system 40-33

Connection table for connector pin numbers 40-35

T- branch box and T- branch adapter table 40-71

Fuse locations 40-74

Phenomena looking like troubles and troubleshooting Nos 40-77

Information contained in troubleshooting table 40-80

00-6 WA470-6R, WA480-6R

(05)

00 Index and foreword

Troubleshooting by failure code (Display of code) 40-83

Failure code [1500L0] (TORQFLOW transmission: Double meshing) 40-83

Failure code [15SAL1] (ECMV F clutch: When command current is OFF, fill signal is ON) 40-84

Failure code [15SALH] (ECMV F clutch: When command current is ON, fill signal is OFF) 40-86

Failure code [15SBL1] (ECMV R clutch: When command current is OFF, fill signal is ON) 40-88

Failure code [15SBLH] (ECMV R clutch: When command current is ON, fill signal is OFF) 40-90

Failure code [15SEL1] (ECMV 1st clutch: When command current is OFF, fill signal is ON) 40-92

Failure code [15SELH] (ECMV 1st clutch: When command current is ON, fill signal is OFF) 40-94

Failure code [15SFL1] (ECMV 2nd clutch: When command current is OFF, fill signal is ON) 40-96

Failure code [15SFLH] (ECMV 2nd clutch: When command current is ON, fill signal is OFF) 40-98

Failure code [15SGL1] (ECMV 3rd clutch: When command current is OFF, fill signal is ON) 40-100

Failure code [15SGLH] (ECMV 3rd clutch: When command current is ON, fill signal is OFF) 40-102

Failure code [15SHL1] (ECMV 4th clutch: When command current is OFF, fill signal is ON) 40-104

Failure code [15SHLH] (ECMV 4th clutch: When command current is ON, fill signal is OFF) 40-106

Failure code [2F00MA] (Parking brake: Malfunction) 40-108

Failure code [2G43ZG] (Accumulator: Low oil pressure) 40-110

Failure code [44K0L4] (Bucket positioner: ON/OFF signals disagree) 40-112

Failure code [AA1ANX] (Air cleaner: Clogging) 40-116

Failure code [AB00L6] (Alternator: Signal disagrees with operating state of engine) 40-118

Failure code [AB00MA] (Alternator: Malfunction) 40-120

Failure code [B@BAZG] (Rotation derating by low engine oil pressure) 40-122

Failure code [B@BAZK] (Engine oil: Low level) 40-125

Failure code [B@BCNS] (Coolant: Overheating) 40-126

Failure code [B@BCZK] (Coolant: Low level) 40-128

Failure code [B@C7NS] (Brake oil: Overheating) 40-130

Failure code [b@CENS] (Torque converter oil: Overheating) 40-132

Failure code [B@CENS] (Torque converter oil: Overheating) 40-134

Failure code [B@HANS] (Hydraulic oil: Overheating) 40-136

Failure code [CA111] (Abnormality in engine controller) 40-138

Failure code [CA115] (Engine Ne or Bkup speed sensor error) 40-141

Failure code [CA122] Chg Air Press Sensor High Error 40-142

Failure code [CA123] Chg Air Press Sensor Low Error 40-144

Failure code [CA131] Throttle sensor : High error 40-146

Failure code [CA132] Throttle sensor : Low error 40-148

Failure code [CA135] Eng Oil Press Sensor High Error 40-150

Failure code [CA141] Eng Oil Press Sensor Low Error 40-152

Failure code [CA144] Coolant Temp Sens High Error 40-154

Failure code [CA145] Coolant Temp Sens Low Error 40-156

Failure code [CA153] Chg Air Temp Sensor High Error 40-158

Failure code [CA154] Chg Air Temp Sensor Low Error 40-160

Failure code [CA187] Sens Supply 2 Volt Low Error 40-162

Failure code [CA221] Ambient Press Sens High Error 40-164

Failure code [CA222] Ambient Press Sens Low Error 40-166

Failure code [CA227] Sens Supply 2 Volt High Error 40-168

Failure code [CA234] Eng Overspeed 40-169

Failure code [CA238] Ne Speed Sens Supply Volt Error 40-170

Failure code [CA263] Fuel Temp Sensor High Error 40-172

Failure code [CA265] Fuel Temp Sensor Low Error 40-174

Failure code [CA271] IMV/PCV1 Short Error 40-176

Failure code [CA272] IMV/PCV1 Open Error 40-178

Failure code [CA273] PCV2 Short Error 40-180

Failure code [CA274] PCV2 Open Error 40-182

Failure code [CA322] Inj #1(L#1) Open/Short Error 40-184

Failure code [CA323] Inj #5 (L#5) Open/Short Error 40-186

WA470-6R, WA480-6R 00-7

(05)

00 Index and foreword

Failure code [CA324] Inj #3(L#3) Open/Short Error 40-188

Failure code [CA325] Inj #6 (L#6) Open/Short Error 40-190

Failure code [CA331] Inj #2(L#2) Open/Short Error 40-192

Failure code [CA332] Inj #4 (L#4) Open/Short Error 40-194

Failure code [CA342] (Calibration code inconsistency) 40-196

Failure code [CA351] Injectors Drive Circuit Error 40-197

Failure code [CA352] Sens Supply 1 Volt Low Error 40-198

Failure code [CA386] Sens Supply 1 Volt High Error 40-200

Failure code [CA431] Idle validation switch : Error 40-201

Failure code [CA432] Idle validation switch : Action error 40-204

Failure code [CA441] (Battery voltage low error) 40-206

Failure code [CA442] (Battery voltage high error) 40-208

Failure code [CA449] Rail Press Very High Error 40-210

Failure code [CA451] Rail Press Sensor High Error 40-212

Failure code [CA452] Rail Press Sensor Low Error 40-214

Failure code [CA553] (Common rail pressure high error 1) 40-216

Failure code [CA554] (Common rail pressure sensor in-range error) 40-217

Failure code [CA559] (Supply pump pressure very low error) 40-218

Failure code [CA689] Eng Ne Speed Sensor Error 40-222

Failure code [CA731] (Engine Bkup speed sensor phase error) 40-224

Failure code [CA757] (All continuous data lost error) 40-225

Failure code [CA778] Eng Bkup Speed Sensor Error 40-226

Failure code [CA1633] KOMNET Datalink Timeout Error 40-228

Failure code [CA2185] Throttle sensor power supply voltage : High error 40-230

Failure code [CA2186] Throttle sensor power supply voltage : Low error 40-232

Failure code [CA2249] (Supply pump pressure very low error 2) 40-234

Failure code [CA2555] Intake heater relay : Open circuit 40-236

Failure code [CA2556] Intake heater relay : Short circuit 40-238

Failure code [D150KA] (Emergency steering relay: Disconnection) 40-240

Failure code [D150KB] (Emergency steering relay: Short circuit) 40-242

Failure code [D150KY] (Emergency steering relay: Short circuit with power supply line) 40-244

Failure code [D160KA] (Backup lamp relay output: Disconnection) 40-246

Failure code [D160KB] (Backup lamp relay output: Short circuit) 40-248

Failure code [D191KA] (Joystick steering neutral safety relay: Disconnection) 40-250

Failure code [D191KB] (Joystick steering neutral safety relay: Short circuit) 40-252

Failure code [D191KY] (Joystick steering neutral safety relay: Short circuit with power supply line)

40-254

Failure code [D192KA] (ECSS solenoid: Disconnection) 40-256

Failure code [D192KB] (ECSS solenoid: Short circuit) 40-257

Failure code [D192KY] (ECSS solenoid: Short circuit with power supply line) 40-258

Failure code [D193KA] (Joystick steering solenoid cut-off relay: Disconnection) 40-260

Failure code [D193KB] (Joystick steering solenoid cut-off relay: Short circuit) 40-262

Failure code [D193KY] (Joystick steering solenoid cut-off relay: Short circuit with power supply line)

40-264

Failure code [D5ZHKA] (Terminal C signal: Disconnection) 40-267

Failure code [D5ZHKB] (Terminal C signal: Short circuit) 40-271

Failure code [D5ZHKZ] (Terminal C signal: Disconnection or short circuit) 40-274

Failure code [D5ZHL6] (Terminal C signal: Signal does not match engine running or stopped state)

40-279

Failure code [DA80L4] (Auto grease controller: ON/OFF signals disagree) 40-282

Failure code [DAF3KK] (Machine monitor: Low source voltage (input)) 40-284

Failure code [DAF5KP] (Machine monitor: Low output voltage) 40-286

Failure code [DAFRKR] (CAN communication with machine monitor: Defective communication

(Abnormality in target component system)) 40-288

00-8 WA470-6R, WA480-6R

(05)

00 Index and foreword

Failure code [DAQ0KK] (Transmission controller: Low source voltage) 40-290

Failure code [DAQ0KT] (Transmission controller: Abnormality in controller) 40-292

Failure code [DAQ1KA] (Terminal ACC input: Disconnection) 40-293

Failure code [DAQ2KK] (Transmission controller load power supply line: Low source voltage (input))

40-296

Failure code [DAQ9KQ] (Transmission controller model selection: Disagreement of model selection

signals) 40-298

Failure code [DAQRKR] (CAN communication with transmission controller: Defective communication

(Abnormality in target component system)) 40-299

Failure code [DAQRMA] (Transmission controller option setting: Malfunction) 40-304

Failure code [DB2RKR] (CAN communication with engine controller: Defective communication

(Abnormality in target component system) 40-305

Failure code [DB90KK] Work equipment controller: Low source voltage (input) 40-312

Failure code [DB90KT] Work equipment controller: Abnormality in controller 40-314

Failure code [DB92KK] Work equipment controller load power supply line: Low source voltage (input)

40-316

Failure code [DB95KX] Work equipment controller power supply output: Out of input signal range

40-319

Failure code [DB99KQ] (Work equipment controller model selection: Disagreement in model selection

signals) 40-322

Failure code [DB9RKR] CAN communication with work equipment controller: Defective communication

(Abnormality in target component system) 40-323

Failure code [DB9RMA] (Work equipment controller option setting: Malfunction) 40-328

Failure code [DB9RMC] (CAN communication with transmission controller, engine controller and

machine monitor: Defective operation) 40-329

Failure code [DD15LD] ■ switch (Panel switch 1): Switch is kept pressed for long time 40-330

Failure code [DD16LD] U switch (Panel switch 2): Switch is kept pressed for long time 40-332

Failure code [DD17LD] < switch (Panel switch 3): Switch is kept pressed for long time 40-334

Failure code [DD18LD] > switch (Panel switch 4): Switch is kept pressed for long time 40-336

Failure code [DD1ALD] Remote positioner raise/lower set switch (raise): Switch is kept pressed for long

time 40-338

Failure code [DD1BLD] Remote positioner raise/lower set switch (lower): Switch is kept pressed for long

time 40-340

Failure code [DD1CLD] Load meter subtotal switch: Switch is kept pressed for long time 40-342

Failure code [DD1FLD] Load meter mode selector switch (A/B): Switch is kept pressed for long time

40-344

Failure code [DD1GLD] Load meter mode selector switch (+/–): Switch is kept pressed for long time

40-346

Failure code [DD1HLD] (Load meter display selector switch: Switch is kept pressed for long time)

40-348

Failure code [DD1NLD] (Fan reverse switch: Switch is kept pressed for long time) 40-350

Failure code [DD1NL4] (Fan automatic reverse switch: Switch is kept pressed for long time) 40-352

Failure code [DDB6L4] (Parking brake switch (Neutralizer): ON/OFF signals disagree) 40-354

Failure code [DDD1LD] (Remote positioner bucket angle set switch: Switch is kept pressed for long

time) 40-358

Failure code [DDE5MA] (Emergency steering drive switch: Malfunction) 40-360

Failure code [DDK3KA] (Right FNR switch: Disconnection) 40-362

Failure code [DDK4KA] (Joystick steering FNR switch: Disconnection) 40-365

Failure code [DDK5L4] (Joystick steering shift-up/down switch: ON/OFF signals disagree) 40-368

Failure code [DDK6KA] (FNR lever switch: Disconnection) 40-370

Failure code [DDK6KB] (FNR lever switch: Short circuit) 40-374

Failure code [DDS5KA] (Steering pressure switch signal: Disconnected) 40-376

Failure code [DDS5KB] (Steering pressure switch signal: Short circuit) 40-378

Failure code [DDS5L6] (Steering: Low oil pressure) 40-380

WA470-6R, WA480-6R 00-9

(05)

00 Index and foreword

Failure code [DDT0L4] (Shift mode selector switch: ON/OFF signals disagree) 40-382

Failure code [DDT4LD] (Transmission cut-off set switch: Switch is kept pressed for long time) 40-384

Failure code [DDW9LD] (Kick-down switch: Switch is kept pressed for long time) 40-386

Failure code [DDWLLD] (Hold switch: Switch is kept pressed for long time) 40-388

Failure code [DDY0LD] (Load meter cancel switch: Switch is kept pressed for long time) 40-390

Failure code [DF10KA] (Transmission shift lever switch: Disconnected) 40-392

Failure code [DF10KB] (Transmission shift lever switch: Short circuit) 40-396

Failure code [DGF1KA] (Transmission oil temperature sensor: Disconnected) 40-400

Failure code [DGF1KB] (Transmission oil temperature sensor: Short circuit) 40-402

Failure code [DGH2KX] (Hydraulic oil temperature sensor: Out of input signal range) 40-404

Failure code [DGR2KA] (Rear brake oil temperature sensor: Disconnected) 40-406

Failure code [DGR2KX] (Rear brake oil temperature sensor: Out of input signal range) 40-408

Failure code [DGT1KX] (Torque converter oil temperature sensor: Out of input signal range) 40-410

Failure code [DH21KA] (Loader pump pressure sensor: Disconnection) 40-412

Failure code [DH21KB] (Loader pump pressure sensor: Power supply line short) 40-414

Failure code [DHPCKX] (Boom cylinder bottom pressure sensor: Out of input signal range) 40-416

Failure code [DHPDKX] (Boom cylinder head pressure sensor: Out of input signal range) 40-418

Failure code [DHT1KX] (Transmission cut-off pressure sensor: Out of input signal range) 40-420

Failure code [DHT8KA] (Steering pump pressure sensor: Disconnection) 40-422

Failure code [DHT8KB] (Steering pump pressure sensor: Short circuit) 40-424

Failure code [DK59KA] (Lift arm EPC lever potentiometer (Main): Disconnection) 40-426

Failure code [DK59KY] (Lift arm EPC lever potentiometer (Main): Short circuit with power supply line)

40-429

Failure code [DK59L8] (Lift arm EPC lever potentiometer (Main): Analog signals disagree) 40-432

Failure code [DK5AKA] (Lift arm EPC lever potentiometer (Sub): Disconnection) 40-435

Failure code [DK5AKY] (Lift arm EPC lever potentiometer (Sub): Short circuit with power supply line)

40-438

Failure code [DK5BKA] (Bucket EPC lever potentiometer (Main): Disconnection) 40-441

Failure code [DK5BKY] (Bucket EPC lever potentiometer (Main): Short circuit with power supply line)

40-444

Failure code [DK5BL8] (Bucket EPC lever potentiometer (Main): Analog signals disagree) 40-447

Failure code [DK5CKA] (Bucket EPC lever potentiometer (Sub): Disconnection) 40-450

Failure code [DK5CKY] (Bucket EPC lever potentiometer (Sub): Short circuit with power supply line)

40-453

Failure code [DK5FKA] (Joystick steering EPC lever potentiometer (Main): Disconnection) 40-456

Failure code [DK5FKY] (Joystick steering EPC lever potentiometer (Main): Short circuit with power

supply line) 40-460

Failure code [DK5FL8] (Joystick steering EPC lever potentiometer (Main): Analog signals disagree)

40-462

Failure code [DK5GKA] (Joystick steering EPC lever potentiometer (Sub): Disconnection) 40-465

Failure code [DK5GKY] (Joystick steering EPC lever potentiometer (Sub): Short circuit with power

supply line) 40-468

Failure code [DKA0KA] (Lift arm angle sensor: Disconnection) 40-470

Failure code [DKA0KX] (Lift arm angle sensor: Out of input signal range) 40-471-1

Failure code [DKA0KY] (Lift arm angle sensor: Short circuit with power supply line) 40-472

Failure code [DKA0L0] (Lift arm angle sensor: Double meshing) 40-474

Failure code [DLF1KA] (Transmission input speed sensor: Disconnection) 40-476

Failure code [DLF1LC] (Transmission input speed sensor: Short circuit) 40-477

Failure code [DLM3KA] (Fan speed sensor: Disconnection) 40-478

Failure code [DLM3LC] (Fan speed sensor: Short circuit) 40-480

Failure code [DLT3KA] (Transmission output speed sensor: Disconnection) 40-482

Failure code [DLT3LC] (Transmission output speed sensor: Out of input signal range) 40-484

Failure code [DT20KB] (Transmission cut-off indicator lamp: Short circuit) 40-486

Failure code [DUM1KB] (Remote positioner raise set indicator lamp: Short circuit) 40-488

00-10 WA470-6R, WA480-6R

(05)

00 Index and foreword

Failure code [DUM2KB] (Remote positioner lower set indicator lamp: Short circuit) 40-490

Failure code [DV00KB] (Alarm buzzer: Short circuit) 40-492

Failure code [DW4PKA] (Lift arm raise EPC solenoid: Disconnection) 40-494

Failure code [DW4PKB] (Lift arm raise EPC solenoid: Short circuit) 40-496

Failure code [DW4PKY] (Lift arm raise EPC solenoid: Short circuit with power supply line) 40-498

Failure code [DW4QKA] (Lift arm lower EPC solenoid: Disconnection) 40-500

Failure code [DW4QKB] (Lift arm lower EPC solenoid: Short circuit) 40-501

Failure code [DW4QKY] (Lift arm lower EPC solenoid: Short circuit with power supply line) 40-502

Failure code [DW4RKA] (Bucket tilt EPC solenoid: Disconnection) 40-504

Failure code [DW4RKB] (Bucket tilt EPC solenoid: Short circuit) 40-505

Failure code [DW4RKY] (Bucket tilt EPC solenoid: Short circuit with power supply line) 40-506

Failure code [DW4SKA] (Bucket dump EPC solenoid: Disconnection) 40-508

Failure code [DW4SKB] (Bucket dump EPC solenoid: Short circuit) 40-509

Failure code [DW4SKY] (Bucket dump EPC solenoid: Short circuit with power supply line) 40-510

Failure code [DW7BKA] (Fan reverse solenoid: Disconnection) 40-512

Failure code [DW7BKB] (Fan reverse solenoid: Short circuit) 40-513

Failure code [DW7BKY] (Fan reverse solenoid: Short circuit with power supply line) 40-514

Failure code [DWM1KA] (Work equipment neutral lock solenoid: Disconnection) 40-516

Failure code [DWM1KB] (Work equipment neutral lock solenoid: Short circuit) 40-518

Failure code [DWM1KY] (Work equipment neutral lock solenoid: Short circuit with power supply line)

40-520

Failure code [DWN6KA] (Lift arm raise magnet detent solenoid: Disconnection) 40-522

Failure code [DWN6KB] (Lift arm raise magnet detent solenoid: Short circuit) 40-524

Failure code [DWN6KY] (Lift arm raise magnet detent solenoid: Short circuit with power supply line)

40-526

Failure code [DWN7KA] (Lift arm float magnet detent solenoid: Disconnection) 40-528

Failure code [DWN7KB] (Lift arm float magnet detent solenoid: Short circuit) 40-530

Failure code [DWN7KY] (Lift arm float magnet detent solenoid: Short circuit with power supply line)

40-532

Failure code [DWN8KA] (Bucket tilt magnet detent solenoid: Disconnection) 40-534

Failure code [DWN8KB] (Bucket tilt magnet detent solenoid: Short circuit) 40-536

Failure code [DWN8KY] (Bucket tilt magnet detent solenoid: Shorted with the power source) 40-538

Failure code [DX16KA] (Fan pump EPC solenoid: Disconnection) 40-540

Failure code [DX16KB] (Fan pump EPC solenoid: Short circuit) 40-541

Failure code [DX16KY] (Fan pump EPC solenoid: Short circuit with power supply line) 40-542

Failure code [DXA1KA] (Loader pump PC-EPC solenoid: Disconnection) 40-544

Failure code [DXA1KB] (Loader pump PC-EPC solenoid: Short circuit) 40-546

Failure code [DXANKA] (Steering pump PC-EPC solenoid: Disconnection) 40-548

Failure code [DXANKB] (Steering pump PC-EPC solenoid: Short circuit) 40-550

Failure code [DXH1KA] (Lockup ECMV solenoid: Disconnection) 40-552

Failure code [DXH1KB] (Lockup ECMV solenoid: Short circuit) 40-554

Failure code [DXH1KY] (Lockup ECMV solenoid: Short circuit with power supply line) 40-556

Failure code [DXH4KA] (1st clutch ECMV solenoid: Disconnection) 40-558

Failure code [DXH4KB] (1st clutch ECMV solenoid: Short circuit) 40-560

Failure code [DXH4KY] (1st clutch ECMV solenoid: Short circuit with power supply line) 40-562

Failure code [DXH5KA] (2nd clutch ECMV solenoid: Disconnection) 40-564

Failure code [DXH5KB] (2nd clutch ECMV solenoid: Short circuit) 40-566

Failure code [DXH5KY] (2nd clutch ECMV solenoid: Short circuit with power supply line) 40-568

Failure code [DXH6KA] (3rd clutch ECMV solenoid: Disconnection) 40-570

Failure code [DXH6KB] (3rd clutch ECMV solenoid: Short circuit) 40-572

Failure code [DXH6KY] (3rd clutch ECMV solenoid: Short circuit with power supply line) 40-574

Failure code [DXH7KA] (R clutch ECMV solenoid: Disconnection) 40-576

Failure code [DXH7KB] (R clutch ECMV solenoid: Short circuit) 40-578

Failure code [DXH7KY] (R clutch ECMV solenoid: Short circuit with power supply line) 40-580

WA470-6R, WA480-6R 00-11

(05)

00 Index and foreword

Failure code [DXH8KA] (F clutch ECMV solenoid: Disconnection) 40-582

Failure code [DXH8KB] (F clutch ECMV solenoid: Short circuit) 40-584

Failure code [DXH8KY] (F clutch ECMV solenoid: Short circuit with power supply line) 40-586

Failure code [DXHHKA] (4th clutch ECMV solenoid: Disconnection) 40-588

Failure code [DXHHKB] (4th clutch ECMV solenoid: Short circuit) 40-590

Failure code [DXHHKY] (4th clutch ECMV solenoid: Short circuit with power supply line) 40-592

Failure code [DXHLKA] (Joystick steering right EPC solenoid: Disconnection) 40-594

Failure code [DXHLKB] (Joystick steering right EPC solenoid: Short circuit) 40-596

Failure code [DXHLKY] (Joystick steering right EPC solenoid: Short circuit with power supply line)

40-598

Failure code [DXHMKA] (Joystick steering left EPC solenoid: Disconnection) 40-600

Failure code [DXHMKB] (Joystick steering left EPC solenoid: Short circuit) 40-602

Failure code [DXHMKY] (Joystick steering left EPC solenoid: Short circuit with power supply line)

40-604

Failure code [DY30MA] Motor-driven emergency steering pump failure (During operation of machine)

40-606

Failure code [DY30MC] Motor-driven emergency steering pump failure (Malfunction in manual mode)

40-609

Failure code [DY30ME] Emergency steering: Operating for more than 1 minute 40-612

Troubleshooting of electrical system (E-mode) 40-615

Installing positions of fuses 40-615

Information in troubleshooting table 40-618

E-1 Engine does not start 40-620

E-2 Wiper does not operate 40-626

E-3 Windshield washer does not operate 40-630

E-4 Headlamp, clearance lamp, tail lamp, and license lamp do not light up or go off 40-633

E-5 Working lamp does not light up or go off 40-641

E-6 Turn signal lamp and hazard lamp do not light up or go off 40-646

E-7 Brake lamp does not light or it keeps lighting up 40-652

E-8 Backup lamp does not light or it keeps lighting up 40-654

E-9 Backup buzzer does not sound or it keeps sounding 40-656

E-10 Horn does not sound or it keeps sounding 40-658

E-11 Alarm buzzer does not sound or it keeps sounding 40-660

E-12 Air conditioner does not operate or stop 40-662

E-13 The KOMTRAX system does not work properly 40-666

E-14 When kick-down switch is turned ON, kick-down operation does not start 40-668

E-15 When hold switch is pressed, holding operation does not start 40-670

E-16 Transmission is kept in neutral, or brake drags when directional lever is operated while parking

brake is applied 40-672

E-17 Transmission cut-off mode cannot be set or reset 40-674

E-18 Transmission cut-off set cannot be reset 40-676

E-19 FNR switch mode cannot be set or reset 40-678

E-20 Fan reverse function cannot be used or reset 40-680

E-21 Discharge from loader pump does not rise from minimum level 40-682

E-22 ECSS function cannot be used or reset 40-684

E-23 When parking brake is turned ON, parking brake indicator lamp does not light up 40-686

E-24 When emergency brake operates, brake oil pressure caution lamp does not operate 40-690

E-25 Air cleaner clogging indicator lamp does not light up 40-692

E-26 Radiator coolant level caution lamp does not light up 40-694

E-27 Hydraulic oil temperature gauge does not rise and hydraulic oil temperature caution lamp does not

light up 40-695

E-28 Torque converter oil temperature gauge does not rise and torque converter oil temperature caution

lamp does not light up 40-696

E-29 Steering oil pressure caution lamp does not light up 40-698

00-12 WA470-6R, WA480-6R

(05)

00 Index and foreword

E-30 Abnormality in t switch (panel switch 1) input 40-700

E-31 Abnormality in U switch (panel switch 1) input 40-702

E-32 Abnormality in < switch (panel switch 2) input 40-704

E-33 Abnormality in > switch (panel switch 2) input 40-706

E-34 When starting switch is turned to ON position, machine monitor displays nothing 40-708

Troubleshooting of hydraulic and mechanical system (H-mode) 40-710

Method of using troubleshooting chart 40-710

Table of failure and causes 40-712

H-1 The machine does not start 40-716

H-2 Torque converter lockup is not switched off (engine stalls) [Machine with lockup clutch (if equipped)]

40-718

H-3 Torque converter lockup is not switched on [Machine with lockup clutch (if equipped)] 40-719

H-4 The travel speed is slow, the thrusting force is weak, the uphill traveling power is weak, and the gear

is not shifted 40-720

H-5 Shocks are large at the times of starting and shifting gear 40-722

H-6 Time lag is large at the times of starting and shifting gear 40-724

H-7 The torque converter oil temperature is high 40-726

H-8 Steering does not turn 40-727

H-9 Steering does not turn [Machine with joystick steering (if equipped)] 40-728

H-10 Steering response is poor 40-729

H-11 Turning, response of steering is poor [machine with joystick steering (if equipped)] 40-730

H-12 Steering is heavy 40-731

H-13 When machine turns, it shakes or makes large shocks 40-732

H-14 When machine turns, it shakes or makes large shocks [machine with joystick steering (if

equipped)] 40-733

H-15 The wheel brake does not work or does not work well 40-734

H-16 The wheel brake is not released or it drags 40-735

H-17 The parking brake does not work or does not work well 40-736

H-18 The parking brake is not released or it drags (including emergency release system) 40-737

H-19 Lift arm does not rise 40-738

H-20 Lift arm speed is low or rising force of lift arm is insufficient 40-739

H-21 When rising, the lift arm comes to move slowly at specific height 40-740

H-22 The lift arm cylinder cannot hold down the bucket (Bucket floats) 40-740

H-23 Hydraulic drift of the lift arm is large 40-740

H-24 The lift arm wobbles during operation 40-740

H-25 Bucket does not tilt back 40-741

H-26 Bucket speed is low or tilting back force is insufficient 40-742

H-27 The bucket comes to operate slowly in the midst of tilting-back 40-743

H-28 The bucket cylinder cannot hold down the bucket 40-743

H-29 Hydraulic drift of the bucket is large 40-743

H-30 The bucket wobbles during travel with cargo (The work equipment valve is set to “HOLD”)

40-743

H-31 Lift arm and bucket control levers do not move smoothly and are heavy 40-744

H-32 During operation of the machine, engine speed lowers remarkably or engine stalls 40-745

H-33 Large shock is made when work equipment starts and stops 40-745

H-34 When work equipment circuit is relieved singly, other work equipment moves 40-745

H-35 ECSS does not operate, and pitching, bouncing occur 40-746

Troubleshooting of engine (S-mode) 40-747

Method of using troubleshooting chart 40-747

S-1 Engine is hard to start 40-750

S-2 Engine does not start 40-751

S-3 Engine does not pick up smoothly 40-754

S-4 Engine stops during operation 40-755

S-5 Engine does not rotate smoothly 40-756

WA470-6R, WA480-6R 00-13

(05)

00 Index and foreword

S-6 Engine lacks output (or lacks power) 40-757

S-7 Exhaust gas color is black (incomplete combustion) 40-758

S-8 Oil consumption is excessive (or exhaust gas color is blue) 40-759

S-9 Oil gets contaminated prematurely 40-760

S-10 Fuel consumption is excessive 40-761

S-11 Coolant contains oil (blows back or reduces) 40-762

S-12 Oil pressure drops 40-763

S-13 Oil level rises (Water, fuel in oil) 40-764

S-14 Coolant temperature rises too high (overheat) 40-765

S-15 Abnormal noise comes out 40-766

S-16 Vibration is excessive 40-767

50 Disassembly and assembly

General information on disassembly and assembly 50-4

How to read this manual 50-4

Coating materials list 50-6

Special tools list 50-9

Sketches of special tools 50-14

Engine and cooling system 50-35

Removal and installation of engine assembly 50-35

Removal and installation of engine hood assembly 50-39

Removal and installation of radiator assembly 50-42

Removal and installation of aftercooler assembly 50-45

Removal and installation of oil cooler assembly 50-47

Removal and installation of cooling fan and drive motor assembly 50-49

Removal and installation of fuel supply pump assembly 50-53

Removal and installation of fuel injector assembly 50-59

Removal and installation of cylinder head assembly 50-65

Removal and installation of engine front oil seal 50-71

Removal and Installation of engine rear oil seal 50-74

Removal and installation of fuel tank assembly 50-79

Power train 50-82

Removal and installation of torque converter and transmission assembly 50-82

Disassembly and assembly of torque converter and transmission assembly 50-87

Disassembly and assembly of torque converter assembly (Standard specification) 50-120

Disassembly and assembly of torque converter assembly (Lockup specification) 50-125

Disassembly and assembly of clutch pack assembly 50-133

Removal and installation of front axle assembly 50-159

Removal and installation of rear axle assembly 50-161

Disassembly and assembly of axle housing assembly 50-167

Disassembly and assembly of differential assembly 50-176

Brake system 50-195

Removal and installation of parking brake disc and plate 50-195

Undercarriage and frame 50-198

Removal and installation of center hinge pin 50-198

Removal and installation of counterweight 50-206

Hydraulic system 50-208

Removal and installation of steering demand valve assembly 50-208

Removal and installation of work equipment valve assembly 50-211

Removal and installation of brake charge valve assembly 50-214

Removal and installation of hydraulic tank assembly 50-215

Removal and installation of steering and power train pump assembly 50-217

Removal and installation of work equipment and cooling fan pump assembly 50-218

Disassembly and assembly of hydraulic cylinder assembly 50-220

00-14 WA470-6R, WA480-6R

(05)

00 Index and foreword

Work equipment 50-228

Removal and installation of work equipment assembly 50-228

Cab and its attachments 50-232

Removal and installation of operator’s cab and floor frame assembly 50-232

Removal and installation of operator’s cab glass (stuck glass) 50-236

Disassembly and assembly of operator’s seat assembly 50-244

Removal and installation of air conditioner unit assembly 50-286

Electrical system 50-290

Removal and installation of engine controller assembly 50-290

Removal and installation of transmission controller assembly 50-291

Removal and installation of KOMTRAX terminal assembly 50-292

80 Appendix

Air conditioner 80-3

Precautions for refrigerant 80-3

Troubleshooting procedure 80-4

Circuit diagram and arrangement of connector pins 80-6

System diagram 80-11

Detail of air conditioner unit 80-13

Parts and connectors layout 80-15

Testing with self-diagnosis function (indication on control panel) 80-19

Testing temperature control 80-22

Testing vent (mode) changeover 80-23

Testing Fresh/Recirc changeover 80-25

Testing inside air temp sensor and outside air temp sensor 80-27

Testing evaporator temperature sensor 80-29

Testing sunlight sensor 80-30

Testing relays 80-31

Troubleshooting chart 1 80-32

Troubleshooting chart 2 80-33

Information in troubleshooting table 80-36

Troubleshooting for power supply system (Air conditioner does not operate) 80-37

Troubleshooting for compressor and refrigerant system (Air is not cooled) 80-40

Troubleshooting for blower motor system (No air comes out or air flow is abnormal) 80-43

Troubleshooting for temperature control 80-49

Troubleshooting for vent (mode) changeover 80-52

Troubleshooting for Fresh/Recirc air changeover 80-55

Troubleshooting with gauge pressure 80-57

Connection of service tool 80-59

Handling of compressor oil 80-60

90 Diagrams and drawings

Hydraulic diagrams and drawings 90-3

Symbols used in hydraulic circuit diagrams 90-3

Power train hydraulic circuit diagram 90-6

Automatic greasing circuit diagram 90-8

Hydraulic circuit diagram 90-11

Electrical diagrams and drawings 90-13

Symbols used in electric circuit diagrams 90-13

Electrical circuit diagram 90-17

Connector list and stereogram 90-39

Index 1

DESCRIPTION:

Komatsu WA470-6R WA480-6R Wheel Loader Shop Manual SEN06594-05 – PDF DOWNLOAD

SERIAL NUMBERS

WA470-10001 and up

WA480-10001 and up

How to read the shop manual 1

1. Composition of shop manual

This shop manual contains the necessary technical information for services performed in a workshop.

For ease of understanding, the manual is divided into the following sections.

00. Index and foreword

This section explains the shop manuals list, table of contents, safety, and basic information.

01. Specification

This section explains the specifications of the machine.

10. Structure, function and maintenance standard

This section explains the structure, function, and maintenance standard values of each component.

The structure and function sub-section explains the structure and function of each component. It

serves not only to give an understanding of the structure, but also serves as reference material for

troubleshooting. The maintenance standard sub-section explains the criteria and remedies for disassembly

and service.

20. Standard value table

This section explains the standard values for new machine and judgement criteria for testing,

adjusting, and troubleshooting. This standard value table is used to check the standard values in

testing and adjusting and to judge parts in troubleshooting.

30. Testing and adjusting

This section explains measuring instruments and measuring methods for testing and adjusting, and

method of adjusting each part. The standard values and judgement criteria for testing and adjusting

are explained in Testing and adjusting.

40. Troubleshooting

This section explains how to find out failed parts and how to repair them. The troubleshooting is

divided by failure modes. The “S mode” of the troubleshooting related to the engine may be also

explained in the Chassis volume and Engine volume. In this case, see the Chassis volume.

50. Disassembly and assembly

This section explains the special tools and procedures for removing, installing, disassembling, and

assembling each component, as well as precautions for them. In addition, tightening torque and

quantity and weight of coating material, oil, grease, and coolant necessary for the work are also

explained.

90. Diagrams and drawings (chassis volume)/Repair and replacement of parts (engine volume)

q Chassis volume

This section gives hydraulic circuit diagrams and electrical circuit diagrams.

q Engine volume

This section explains the method of reproducing, repairing, and replacing parts.

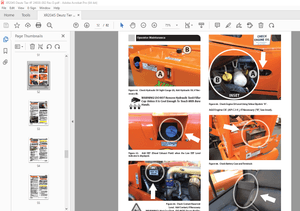

IMAGES PREVIEW OF THE MANUAL: