$46

Komatsu WA600-6R Wheel Loader Shop Manual SEN02211-17 – PDF DOWNLOAD

Komatsu WA600-6R Wheel Loader Shop Manual SEN02211-17 – PDF DOWNLOAD

FILE DETAILS:

Komatsu WA600-6R Wheel Loader Shop Manual SEN02211-17 – PDF DOWNLOAD

Language : English

Pages : 2036

Downloadable : Yes

File Type : PDF

Size: 120 MB

DESCRIPTION:

Komatsu WA600-6R Wheel Loader Shop Manual SEN02211-17 – PDF DOWNLOAD

SERIAL NUMBERS 65001 and up

How to read the shop manual :

1. Composition of shop manual:

This shop manual contains the necessary technical information for services performed in a workshop.

For ease of understanding, the manual is divided into the following sections.

00. Index and foreword

This section explains the shop manuals list, table of contents, safety, and basic information.

01. Specification

This section explains the specifications of the machine.

10. Structure, function and maintenance standard

This section explains the structure, function, and maintenance standard values of each component.

The structure and function sub-section explains the structure and function of each component. It

serves not only to give an understanding of the structure, but also serves as reference material for

troubleshooting. The maintenance standard sub-section explains the criteria and remedies for disassembly

and service.

20. Standard value table

This section explains the standard values for new machine and judgement criteria for testing,

adjusting, and troubleshooting. This standard value table is used to check the standard values in

testing and adjusting and to judge parts in troubleshooting.

30. Testing and adjusting

This section explains measuring instruments and measuring methods for testing and adjusting, and

method of adjusting each part. The standard values and judgement criteria for testing and adjusting

are explained in Testing and adjusting.

40. Troubleshooting

This section explains how to find out failed parts and how to repair them. The troubleshooting is

divided by failure modes. The “S mode” of the troubleshooting related to the engine may be also

explained in the Chassis volume and Engine volume. In this case, see the Chassis volume.

50. Disassembly and assembly

This section explains the special tools and procedures for removing, installing, disassembling, and

assembling each component, as well as precautions for them. In addition, tightening torque and

quantity and weight of coating material, oil, grease, and coolant necessary for the work are also

explained.

90. Diagrams and drawings (chassis volume)/Repair and replacement of parts (engine volume)

q Chassis volume

This section gives hydraulic circuit diagrams and electrical circuit diagrams.

q Engine volume

This section explains the method of reproducing, repairing, and replacing parts.

TABLE OF CONTENTS:

Komatsu WA600-6R Wheel Loader Shop Manual SEN02211-17 – PDF DOWNLOAD

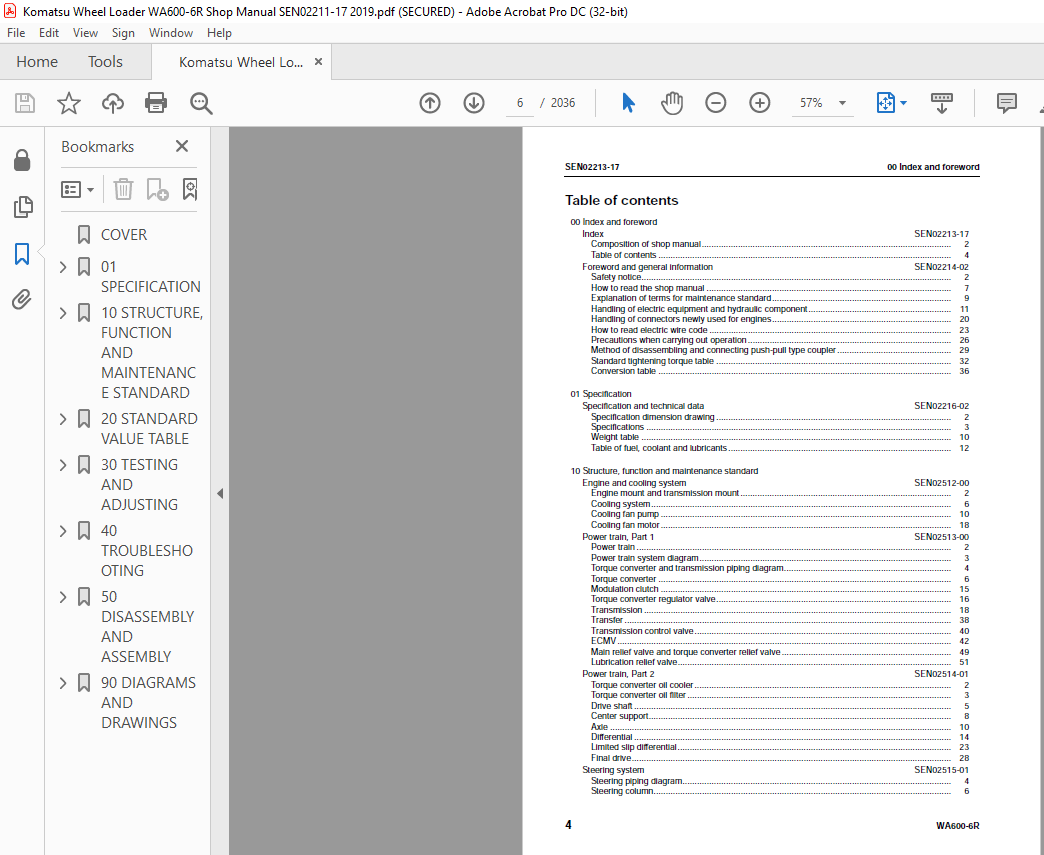

00 Index and foreword

Index SEN02213-17

Composition of shop manual 2

Table of contents 4

Foreword and general information SEN02214-02

Safety notice 2

How to read the shop manual 7

Explanation of terms for maintenance standard 9

Handling of electric equipment and hydraulic component 11

Handling of connectors newly used for engines 20

How to read electric wire code 23

Precautions when carrying out operation 26

Method of disassembling and connecting push-pull type coupler 29

Standard tightening torque table 32

Conversion table 36

01 Specification

Specification and technical data SEN02216-02

Specification dimension drawing 2

Specifications 3

Weight table 10

Table of fuel, coolant and lubricants 12

10 Structure, function and maintenance standard

Engine and cooling system SEN02512-00

Engine mount and transmission mount 2

Cooling system 6

Cooling fan pump 10

Cooling fan motor 18

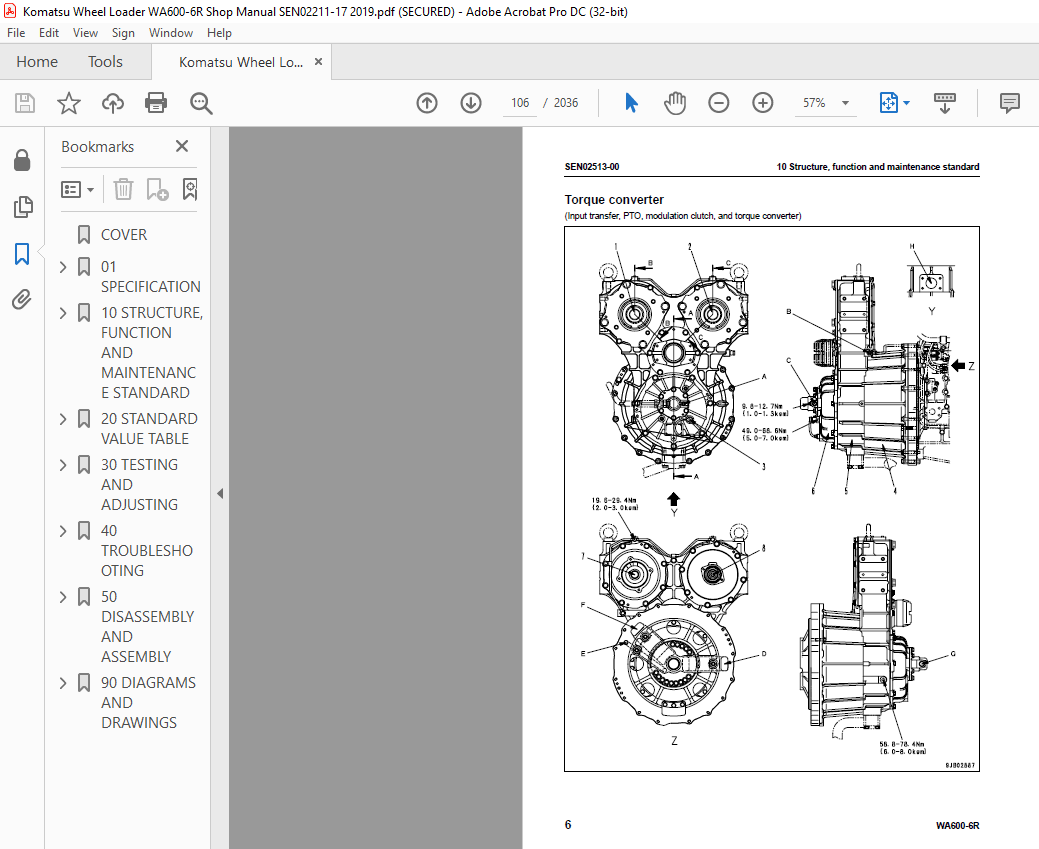

Power train, Part 1 SEN02513-00

Power train 2

Power train system diagram 3

Torque converter and transmission piping diagram 4

Torque converter 6

Modulation clutch 15

Torque converter regulator valve 16

Transmission 18

Transfer 38

Transmission control valve 40

ECMV 42

Main relief valve and torque converter relief valve 49

Lubrication relief valve 51

Power train, Part 2 SEN02514-01

Torque converter oil cooler 2

Torque converter oil filter 3

Drive shaft 5

Center support 8

Axle 10

Differential 14

Limited slip differential 23

Final drive 28

Steering system SEN02515-01

Steering piping diagram 4

Steering column 6

00 Index and foreword SEN02213-17

WA600-6R 5

Joystick steering lever linkage 7

Joystick EPC valve 8

Lock valve 9

Steering valve 10

Rotary valve 13

Steering control valve 16

Two-way restrictor valve 32

Stop valve 33

Steering pump 34

Steering cylinder 48

Emergency steering piping diagram 50

Diverter valve 51

Emergency steering pump 59

Brake system SEN02516-02

Brake piping diagram 2

Brake 4

Brake valve 8

Accumulator charge valve 16

EPC relief valve 22

Accumulator (for brake) 24

Slack adjuster 26

Parking brake 30

Parking brake solenoid valve 32

Emergency parking brake release valve 34

Brake cooling pump 35

Undercarriage and frame SEN02517-00

Axle mount 2

Center hinge pin 7

Hydraulic system, Part 1 SEN02518-00

Hydraulic piping diagram 2

Work equipment control lever linkage 4

Hydraulic tank 6

Work equipment hydraulic pump 8

Hydraulic system, Part 2 SEN02519-01

Control valve 2

CLSS 16

Each function and operation of each valve 21

Accumulator (for PPC circuit) 40

Accumulator (for ECSS) 41

Triple pump 42

Work equipment SEN02520-02

Work equipment linkage 2

Bucket 6

Bucket positioner and boom kick-out 10

Work equipment lubrication 12

Work equipment cylinder 14

Cab and its attachments SEN02521-00

ROPS cab 2

Air conditioner 4

Electrical system, Part 1 SEN02522-02

Machine monitor system 2

Machine monitor 8

Electrical system, Part 2 SEN02523-00

Work equipment control system 2

Transmission controller system 38

Electrical system, Part 3 SEN02524-02

Electric transmission control 2

SEN02213-17 00 Index and foreword

6 WA600-6R

Engine starting/stopping circuit 4

Parking brake circuit 7

Sensor 11

VHMS controller related 34

VHMS controller and wireless LAN system 35

Work equipment electric lever 41

20 Standard value table

Standard service value table SEN02580-05

Standard service value table for engine 2

Standard service value table for chassis 3

30 Testing and adjusting

Testing and adjusting, Part 1 SEN02581-05

Tools for testing, adjusting, and troubleshooting 3

Measuring engine speed 9

Measuring exhaust gas color 11

Measuring exhaust temperature 12

Adjusting valve clearance 14

Testing compression pressures 16

Measuring blow-by pressure 19

Measuring engine oil pressure 20

Measuring intake air (boost) pressure 21

Handling fuel system equipment 22

Releasing residual pressure in fuel system 22

Testing fuel pressures 23

Testing return rate and leakage 24

Bleeding air from fuel circuit 27

Testing leakage in fuel system 29

Handling reduced cylinder mode operation 30

Handling no-injection cranking operation 30

Handling controller voltage circuit 31

Replacing and adjusting alternator and air conditioner compressor belt tension 32

Adjusting modulation clutch speed sensor and speed sensor 33

Measuring directional lever (Steering wheel specification) 35

Testing and adjusting power train oil pressure 36

Flushing procedure for torque converter and transmission hydraulic circuit 50

Method of moving machine when transmission valve is broken 52

Adjusting steering stop valve 54

Testing and adjusting, Part 2 SEN02582-06

Measuring operating effort of AJSS lever (AJSS specification) 3

Testing and adjusting AJSS lever angle sensor and frame angle sensor (AJSS specification) 4

Testing and adjusting steering stopper bolt (AJSS specification) 6

Testing and adjusting steering wheel (Steering wheel specification) 8

Testing steering oil pressure 10

Bleeding air from steering cylinder circuit 14

Testing hydraulic drive fan 15

Bleeding air from hydraulic drive fan circuit 18

Measuring brake pedal 20

Measuring brake performance 21

Testing and adjusting accumulator charge pressure 22

Testing of accumulator nitrogen gas pressure and procedure for charging brake

accumulator with nitrogen gas 24

Testing wheel brake oil pressure 32

Measuring wear of wheel brake disc 34

Bleeding air from wheel brake circuit 35

Releasing residual pressure in brake accumulator circuit 36

00 Index and foreword SEN02213-17

WA600-6R 7

Testing parking brake performance 37

Measuring parking brake oil pressure 38

Testing wear of parking brake disc 41

Method of releasing parking brake manually 42

Measuring and adjusting work equipment control lever 43

Measuring work equipment oil pressure 44

Bleeding air from work equipment circuit 49

Releasing residual pressure in work equipment circuit 50

Testing of accumulator nitrogen gas pressure and procedure for charging ECSS

accumulator with nitrogen gas 52

Moving machine for removing operator cab 60

Testing and adjusting bucket positioner 62

Testing and adjusting lift arm position detecting lever 64

Checking proximity switch operation indication lamp 65

Preparations for work on troubleshooting of electric system 66

Procedure for testing diodes 70

Testing and adjusting, Part 3 SEN02583-02

Machine monitor-based adjustment at replacement, disassembly and assembly, and

additional installation for each sensor and controller 2

Special functions of machine monitor (EMMS) 5

Testing and adjusting, Part 4 SEN02584-07

VHMS controller initial setting procedure (ORBCOMM installation specification) 2

VHMS controller initial setting procedure (IRIDIUM installation specification) 24

Precautions for replacing VHMS controller 46

Initialization of VHMS wireless LAN modem and downloading of data 52

Pm-clinic inspection table 59

40 Troubleshooting

Failure code table and fuse locations SEN02585-02

Failure codes list 2

Fuse locations 14

General information on troubleshooting SEN02586-02

Points to remember when performing troubleshooting 2

How to proceed in troubleshooting 4

Testing before troubleshooting 6

Classification and procedures of troubleshooting 7

Information in troubleshooting table 11

Troubleshooting method for disconnecting wiring harness of pressure sensor system 13

Phenomena looking like troubles and troubleshooting Nos 16

Connection table for connector pin numbers 18

T- branch box and T- branch adapter table 53

Troubleshooting by failure code (Display of code), Part 1 SEN02587-01

Failure code [1500L0] TORQFLOW transmission: Double meshing 3

Failure code [15B0NX] Transmission Oil Filter Clogging 4

Failure code [15SAL1] ECMV F clutch: When command current is OFF, fill signal is ON 6

Failure code [15SALH] ECMV F clutch: When command current is ON, fill signal is OFF 8

Failure code [15SBL1] ECMV R clutch: When command current is OFF, fill signal is ON 10

Failure code [15SBLH] ECMV R clutch: When command current is ON, fill signal is OFF 12

Failure code [15SEL1] ECMV (1): When command current is OFF, fill signal is ON 14

Failure code [15SELH] ECMV (1): When command current is ON, fill signal is OFF 16

Failure code [15SFL1] ECMV (2): When command current is OFF, fill signal is ON 18

Failure code [15SFLH] ECMV (2): When command current is ON, fill signal is OFF 20

Failure code [15SGL1] ECMV (3): When command current is OFF, fill signal is ON 22

Failure code [15SGLH] ECMV (3): When command current is ON, fill signal is OFF 24

Failure code [15SHL1] ECMV (4): When command current is OFF, fill signal is ON 26

Failure code [15SHLH] ECMV (4): When command current is ON, fill signal is OFF 28

Failure code [15W0NT] Transmission modulation clutch: Overheating 30

SEN02213-17 00 Index and foreword

8 WA600-6R

Failure code [2F00MA] Parking brake: Malfunction 31

Failure code [2G42ZG] Front Accumulator Oil Pressure Low 34

Troubleshooting by failure code (Display of code), Part 2 SEN02588-02

Failure code [2G43ZG] Rear Accumulator Oil Pressure Low 4

Failure code [44K0L4] Bucket positioner: ON/OFF signals disagree 6

Failure code [A000N1] (or VHMS_LED display: “n2” → “01”) Engine: Overrun 9

Failure code [AA1ANX] Air Cleaner Clogging 10

Failure code [AB00L6] Alternator: Signal disagrees with run and stop of engine 12

Failure code [AB00MA] Alternator: Malfunction 14

Failure code [B@BAZG] Engine oil pressure: Low error 16

Failure code [B@BAZK] Eng Oil Level Low 17

Failure code [B@BCNS] Engine coolant temperature: Overheating 18

Failure code [B@BCZK] Engine coolant level low 20

Failure code [B@C7NS] Brake oil overheating 22

Failure code [b@CENS] Torque converter oil overheating 23

Failure code [B@CENS] Torque converter oil overheating 24

Failure code [B@GAZK] Low Battery Fluid Level 25

Failure code [B@HANS] Hyd Oil Overheat 27

Failure code [CA111] Abnormality in engine controller 28

Failure code [CA115] Engine Ne or Bkup speed sensor error 31

Failure code [CA122] Charge (boost) pressure sensor high error 32

Failure code [CA123] Charge (boost) pressure sensor low error 34

Failure code [CA131] Throttle sensor high error 36

Failure code [CA132] Throttle sensor low error 39

Failure code [CA135] Engine oil pressure sensor high error 42

Failure code [CA141] Engine oil pressure sensor low error 44

Failure code [CA144] Coolant temperature sensor high error 46

Failure code [CA145] Coolant temperature sensor low error 48

Failure code [CA153] Charge (boost) temperature sensor high error 50

Failure code [CA154] Charge (boost) temperature sensor low error 52

Failure code [CA187] Sensor power supply 2 low error 54

Failure code [CA212] Engine oil temperature sensor high error 56

Failure code [CA213] Engine oil temperature sensor low error 58

Failure code [CA221] Atmospheric pressure sensor high error 60

Failure code [CA222] Atmospheric pressure sensor low error 62

Failure code [CA227] Sensor power supply 2 high error 64

Troubleshooting by failure code (Display of code), Part 3 SEN02589-02

Failure code [CA234] Engine overspeed 3

Failure code [CA238] Ne speed sensor power supply error 4

Failure code [CA263] Fuel temperature sensor high error 6

Failure code [CA265] Fuel temperature sensor low error 8

Failure code [CA271] PCV1 Short circuit 10

Failure code [CA272] PCV1 Disconnection 11

Failure code [CA273] PCV2 Short circuit 12

Failure code [CA274] PCV2 Disconnection 13

Failure code [CA322] Injector #1 open/short error 14

Failure code [CA323] Injector #5 open/short error 16

Failure code [CA324] Injector #3 open/short error 18

Failure code [CA325] Injector #6 open/short error 20

Failure code [CA331] Injector #2 open/short error 22

Failure code [CA332] Injector #4 open/short error 24

Failure code [CA342] Calibration code inconsistency 26

Failure code [CA351] Injectors drive circuit error 27

Failure code [CA352] Sensor power supply 1 low error 28

Failure code [CA386] Sensor power supply 1 high error 30

Failure code [CA431] Idle validation switch error 31

Failure code [CA432] Idle validation action error 34

Failure code [CA441] Battery voltage low error 37

00 Index and foreword SEN02213-17

WA600-6R 9

Failure code [CA442] Battery voltage high error 38

Failure code [CA449] Common rail pressure high error 2 39

Failure code [CA451] Common rail pressure sensor high error 40

Failure code [CA452] Common rail pressure sensor low error 42

Failure code [CA553] Common rail pressure high error 1 44

Failure code [CA554] Common rail pressure sensor in range error 45

Failure code [CA559] Supply pump pressure very low error 1 46

Failure code [CA689] Engine Ne speed sensor error 50

Failure code [CA731] Engine Bkup speed sensor phase error 52

Failure code [CA757] All continuous data lost error 53

Failure code [CA778] Engine Bkup speed sensor error 54

Failure code [CA1633] KOMNET datalink timeout error 56

Troubleshooting by failure code (Display of code), Part 4 SEN02590-02

Failure code [CA2185] Throttle sensor supply voltage high error 4

Failure code [CA2186] Throttle sensor power supply low error 6

Failure code [CA2249] Supply pump pressure very low error 2 8

Failure code [CA2555] Intake air heater relay open circuit error 10

Failure code [CA2556] Intake air heater relay short circuit error 12

Failure code [D191KA] AJSS neutral safety relay open circuit 14

Failure code [D191KB] AJSS neutral safety relay short circuit 16

Failure code [D192KA] ECSS solenoid: Disconnection 18

Failure code [D192KB] ECSS solenoid: Short circuit 19

Failure code [D192KY] ECSS solenoid: Short circuit with power supply line 20

Failure code [D198KA] Transmission oil pressure bypass solenoid: Disconnection 21

Failure code [D198KB] Transmission oil pressure bypass solenoid: Short circuit 22

Failure code [D198KY] Transmission oil pressure bypass solenoid: Short circuit with power supply line

23

Failure code [D5ZHKA] Terminal C signal open circuit 24

Failure code [D5ZHKB] Terminal C signal short circuit 26

Failure code [D5ZHKZ] Terminal C signal open or short circuit 28

Failure code [D5ZHL6] Terminal C signal disagrees with run and stop of engine 30

Failure code [DA80L4] Auto-greasing controller disagrees with ON/OFF signal 32

Failure code [DAF3KK] Machine monitor: Source voltage low (input) 34

Failure code [DAF5KP] Machine monitor: Output voltage low 36

Failure code [DAFRKR] CAN communication with machine monitor: Communication error (Abnormality

in target component system) 38

Failure code [DAQ0KK] Transmission controller: Source voltage low 39

Failure code [DAQ0KT] Transmission controller: Defect in controller 42

Failure code [DAQ2KK] Transmission controller load power supply line: Source voltage low (Input)

43

Failure code [DAQ9KQ] Transmission controller model selection: Model selection signal disagreement

46

Failure code [DAQRKR] CAN communication with transmission controller: Communication error

(Abnormality in target component system) 47

Failure code [DAQRMA] Transmission controller (Option setting): Malfunction 52

Troubleshooting by failure code (Display of code), Part 5 SEN02592-01

Failure code [DB2RKR] CAN communication from engine controller: Communication error (Abnormality

in target component system) 4

Failure code [DB90KK] Work equipment controller: Source voltage low (input) 7

Failure code [DB90KT] Work equipment controller: Defect in controller 10

Failure code [DB92KK] Work equipment controller load power supply line: Source voltage low (input)

11

Failure code [DB95KX] Work equipment controller power supply output: Out of range 14

Failure code [DB99KQ] Work equipment controller model selection: Model selection signal disagreement

16

Failure code [DB9RKR] CAN communication with work equipment controller: Communication error

(Abnormality in target component system) 17

Failure code [DB9RMA] Work equipment controller (Option setting): Malfunction 18

SEN02213-17 00 Index and foreword

10 WA600-6R

Failure code [DB9RMC] CAN communication with transmission controller: Malfunction 19

Failure code [DBB0KK] or change of VHMS_LED display from “n9” to “01” (VHMS controller: Source

voltage low (input)) 20

Failure code [DBB0KQ] or change of VHMS_LED display from “nF” to “11” (VHMS controller: Disagreement

of model selection signals) 22

Failure code [DBB3KK] or change of VHMS_LED display from “n9” to “05” (VHMS controller battery

power supply: Source voltage low (input)) 24

Failure code [DBB5KP] or change of VHMS_LED display from “n9” to “04” (VHMS controller 5 V power

supply output: Output voltage low) 26

Failure code [DBB6KP] or change of VHMS_LED display from “n9” to “02” (VHMS controller 24V

power supply output: Output voltage low) 28

Failure code [DBB7KP] or change of VHMS_LED display from “n9” to “03” (VHMS controller 12V

power supply output: Output voltage low) 30

Failure code [DBBQKR] or change of VHMS_LED display from “n8” to “02” (CAN communication of

VHMS controller: Communication error (Abnormality in target component system)) 32

Failure code [DD15LD] t switch (Panel switch 1): Switch is kept pressed for long time 34

Failure code [DD16LD] U switch (Panel switch 2): Switch is kept pressed for long time 36

Failure code [DD17LD] < switch (Panel switch 3): Switch is kept pressed for long time 38

Failure code [DD18LD] > switch (Panel switch 4): Switch is kept pressed for long time 40

Failure code [DD1ALD] Remote positioner raise/lower set switch (raise): Switch is kept pressed for

long time 42

Failure code [DD1BLD] Remote positioner raise/lower set switch (lower): Switch is kept pressed for

long time 44

Failure code [DD1CLD] Load meter subtotal switch: Switch is kept pressed for long time 46

Failure code [DD1FLD] Load meter mode selector switch (A/B): Switch is kept pressed for long time

48

Failure code [DD1GLD] Load meter mode selector switch (+/–): Switch is kept pressed for long time

50

Troubleshooting by failure code (Display of code), Part 6 SEN02593-02

Failure code [DD1HLD] Load meter display selector switch: Switch is kept pressed for long time 4

Failure code [DDA7L4] RPM set ON/OFF switch: ON-OFF signals disagree 6

Failure code [DDA8KB] RPM set idle-up/down selector switch (idle-up): Short circuit 8

Failure code [DDA9KB] RPM set idle-up/down selector switch (idle-down): Short circuit 11

Failure code [DDB6L4] Parking brake switch (Neutralizer): ON/OFF signals disagree 14

Failure code [DDD1LD] Remote positioner bucket angle set switch: Switch is kept pressed for long

time 18

Failure code [DDDBKA] Traction adjustment dial: Disconnection 22

Failure code [DDDBKB] Traction adjustment dial: Short circuit 24

Failure code [DDE5MA] Emergency steering drive switch: Malfunction 26

Failure code [DDK4KA] AJSS FNR switch: Disconnection 28

Failure code [DDK4KB] AJSS FNR switch: Short circuit 30

Failure code [DDK5L4] AJSS shift-up/down switch: ON/OFF signals disagree 32

Failure code [DDK6KA] FNR lever switch: Disconnection 35

Failure code [DDK6KB] FNR lever switch: Short circuit 38

Failure code [DDP5KA] Lock detection pressure switch of steering lock lever: Disconnection 40

Failure code [DDT0L4] Shift mode selector switch: ON/OFF signals disagree 42

Failure code [DDW9LD] Kick-down switch: Switch is kept pressed for long time 44

Failure code [DDWLLD] Hold switch: Switch is kept pressed for long time 46

Failure code [DDY0LD] Load meter cancel switch: Switch is kept pressed for long time 48

Failure code [DF10KA] Transmission shift lever switch: Disconnection 50

Failure code [DF10KB] Transmission shift lever switch: Short circuit 54

Failure code [DGE5KX] (or VHMS_LED display: “n4” → “01”) Atmospheric temperature sensor: Out of

input signal range 56

Failure code [DGF1KA] Transmission oil temperature sensor: Disconnection 58

Failure code [DGF1KB] Transmission oil temperature sensor: Short circuit 60

Troubleshooting by failure code (Display of code), Part 7 SEN02594-01

Failure code [DGH2KX] Hydraulic oil temperature sensor: Out of input signal range 4

Failure code [DGR2KA] Rear brake oil temperature sensor: Disconnection 6

00 Index and foreword SEN02213-17

WA600-6R 11

Failure code [DGR2KX] Rear brake oil temperature sensor: Out of input signal range 8

Failure code [DGT1KA] Torque converter oil temperature sensor: Disconnection 10

Failure code [DGT1KB] Torque converter oil temperature sensor: Short circuit 11

Failure code [DGT1KX] Torque converter oil temperature sensor: Out of input signal range 12

Failure code [DGT4KA] (or VHMS_LED display: “n3” → “12”) Exhaust gas temperature sensor (F):

Disconnection 14

Failure code [DGT4KB] (or VHMS_LED display: “n3” → “11”) Exhaust gas temperature sensor (F):

Short circuit 17

Failure code [DGT5KA] (or VHMS_LED display: “n3” → “22”) Exhaust gas temperature sensor (R):

Disconnection 20

Failure code [DGT5KB] (or VHMS_LED display: “n3” → “21”) Exhaust gas temperature sensor (R):

Short circuit 23

Failure code [DH21KA] Work equipment pump oil pressure sensor: Disconnection 26

Failure code [DH21KB] Work equipment pump oil pressure sensor: Short circuit 28

Failure code [DHE5KB] (or VHMS_LED display: “n3” → “32”) Blow-by pressure sensor: Short circuit30

Failure code [DHE5KY] (or VHMS_LED display: “n3” → “31”) Blow-by pressure sensor: Short circuit

with power supply line 32

Failure code [DHPCKX] Lift arm cylinder bottom pressure sensor: Out of input signal range 34

Failure code [DHPDKX] Lift arm cylinder head pressure sensor: Out of input signal range 37

Failure code [DHT2L6] Transmission filter clogging sensor: Signal disagrees with operating state of

engine 40

Failure code [DHT8KX] (or VHMS_LED display: “n5” → “33”) Steering oil pressure sensor: Out of input

signal range 42

Failure code [DHTBKA] Modulation clutch oil pressure sensor: Disconnection 46

Failure code [DHTBKB] Modulation clutch oil pressure sensor: Short circuit 48

Failure code [DHU2KX] (or VHMS_LED display: “n7” → “11”) Front brake oil pressure sensor (F): Out

of input signal range 50

Failure code [DHU3KX] (or VHMS_LED display: “n7” → “12”) Rear brake oil pressure sensor (R): Out

of input signal range 52

Failure code [DK30KA] AJSS lever angle sensor: Disconnection 54

Failure code [DK30KY] AJSS lever angle sensor: Short circuit with power supply line 56

Troubleshooting by failure code (Display of code), Part 8 SEN02595-01

Failure code [DK59KA] Lift arm EPC lever potentiometer (Main): Disconnection 3

Failure code [DK59KY] Lift arm EPC lever potentiometer (Main): Short circuit with power supply line

6

Failure code [DK59L8] Lift arm EPC lever potentiometer (Main): Analog signals disagree 8

Failure code [DK5AKA] Lift arm EPC lever potentiometer (Sub): Disconnection 12

Failure code [DK5AKY] Lift arm EPC lever potentiometer (Sub): Short circuit with power supply line

15

Failure code [DK5BKA] Bucket EPC lever potentiometer (Main): Disconnection 18

Failure code [DK5BKY] Bucket EPC lever potentiometer (Main): Short circuit with power supply line

21

Failure code [DK5BL8] Bucket EPC lever potentiometer (Main): Analog signals disagree 23

Failure code [DK5CKA] Bucket EPC lever potentiometer (Sub): Disconnection 27

Failure code [DK5CKY] Bucket EPC lever potentiometer (Sub): Short circuit with power supply line

30

Failure code [DK5DKA] 3-spool valve (attachment) EPC lever potentiometer (Main): Disconnection

33

Failure code [DK5DKY] 3-spool valve (attachment) EPC lever potentiometer (Main): Short circuit with

power supply line 36

Failure code [DK5DL8] 3-spool valve (attachment) EPC lever potentiometer (Main): Analog signals disagree

38

Failure code [DK5EKA] 3-spool valve (attachment) EPC lever potentiometer (Sub): Disconnection

41

Failure code [DK5EKY] 3-spool valve EPC lever potentiometer (Sub): Short circuit with power supply

line 44

Failure code [DKA0KA] Lift arm angle sensor: Disconnection 46

Failure code [DKA0KX] Lift arm angle sensor: Out of input signal range 49

SEN02213-17 00 Index and foreword

12 WA600-6R

Failure code [DKA0KY] Lift arm angle sensor: Short circuit with power supply line 50

Failure code [DKA0L0] Lift arm angle sensor: Improper position 52

Troubleshooting by failure code (Display of code), Part 9 SEN02596-01

Failure code [DKD0KA] Frame angle sensor: Disconnection 4

Failure code [DKD0KY] Frame angle sensor: Short circuit with power supply line 6

Failure code [DKD0KZ] AJSS lever and frame angle sensor: Disconnection or short circuit 8

Failure code [DLFAKA] Modulation clutch output shaft speed sensor: Disconnection 12

Failure code [DLFALC] Modulation clutch output shaft speed sensor: Speed signals disagree 14

Failure code [DLT3KA] Transmission output shaft speed sensor (2): Disconnection 16

Failure code [DLT3LC] Transmission output shaft speed sensor (2): Speed signals disagree 18

Failure code [DLT4KB] Transmission output shaft speed sensor (1): Short circuit 20

Failure code [DLT4KX] Transmission output shaft speed sensor (1): Out of input signal range 22

Failure code [DUM1KB] Remote positioner raise indicator lamp: Short circuit 24

Failure code [DUM2KB] Remote positioner lower indicator lamp: Short circuit 26

Failure code [DV00KB] Alarm buzzer: Short circuit 28

Failure code [DW4PKA] Lift arm raise EPC solenoid: Disconnection 30

Failure code [DW4PKB] Lift arm raise EPC solenoid: Short circuit 32

Failure code [DW4PKY] Lift arm raise EPC solenoid: Short circuit with power supply line 33

Failure code [DW4QKA] Lift arm lower EPC solenoid: Disconnection 34

Failure code [DW4QKB] Lift arm lower EPC solenoid: Short circuit 35

Failure code [DW4QKY] Lift arm lower EPC solenoid: Short circuit with power supply line 36

Failure code [DW4RKA] Bucket tilt EPC solenoid: Disconnection 37

Failure code [DW4RKB] Bucket tilt EPC solenoid: Short circuit 38

Failure code [DW4RKY] Bucket tilt EPC solenoid: Short circuit with power supply line 39

Failure code [DW4SKA] Bucket dump EPC solenoid: Disconnection 40

Failure code [DW4SKB] Bucket dump EPC solenoid: Short circuit 41

Failure code [DW4SKY] Bucket dump EPC solenoid: Short circuit with power supply line 42

Failure code [DW7BKA] Fan reverse solenoid: Disconnection 44

Failure code [DW7BKB] Fan reverse solenoid: Short circuit 46

Failure code [DW7BKY] Fan reverse solenoid: Short circuit with power supply line 48

Failure code [DW7DKA] Hydraulic drive fan neutral solenoid: Disconnection 49

Failure code [DW7DKB] Hydraulic drive fan neutral solenoid: Short circuit 50

Failure code [DW7DKY] Hydraulic drive fan neutral solenoid: Short circuit with power supply line

51

Troubleshooting by failure code (Display of code), Part 10 SEN02597-01

Failure code [DWM1KA] Work equipment neutral lock solenoid: Disconnection 4

Failure code [DWM1KB] Work equipment neutral lock solenoid: Short circuit 6

Failure code [DWM1KY] Work equipment neutral lock solenoid: Short circuit with power supply line

8

Failure code [DWN6KA] Lift arm raise magnet detent solenoid: Disconnection 10

Failure code [DWN6KB] Lift arm raise magnet detent solenoid: Short circuit 12

Failure code [DWN6KY] Lift arm raise magnet detent solenoid: Short circuit with power supply line

14

Failure code [DWN7KA] Lift arm float magnet detent solenoid: Disconnection 16

Failure code [DWN7KB] Lift arm float magnet detent solenoid: Short circuit 18

Failure code [DWN7KY] Lift arm float magnet detent solenoid: Short circuit with power supply line

20

Failure code [DWN8KA] Bucket tilt magnet detent solenoid: Disconnection 22

Failure code [DWN8KB] Bucket tilt magnet detent solenoid: Short circuit 24

Failure code [DWN8KY] Bucket tilt magnet detent solenoid: Shorted with the power source 26

Failure code [DWNFKA] Modulation clutch cut-off release solenoid: Disconnection 28

Failure code [DWNFKB] Modulation clutch cut-off release solenoid: Short circuit 30

Failure code [DWNFKY] Modulation clutch cut-off release solenoid: Short circuit with power source line

32

Failure code [DX16KA] Fan pump EPC solenoid: Disconnection 34

Failure code [DX16KB] Fan pump EPC solenoid: Short circuit 35

Failure code [DX16KY] Fan pump EPC solenoid: Short circuit with power supply line 36

Failure code [DXA1KA] Pump PC-EPC solenoid: Disconnection 37

00 Index and foreword SEN02213-17

WA600-6R 13

Failure code [DXA1KB] Pump PC-EPC solenoid: Short circuit 38

Failure code [DXF0KA] AJSS EPC solenoid: Disconnection 39

Failure code [DXF0KB] AJSS EPC solenoid: Short circuit 40

Failure code [DXH1KA] Lockup ECMV solenoid: Disconnection 42

Failure code [DXH1KB] Lockup ECMV solenoid: Short circuit 44

Failure code [DXH1KY] Lockup ECMV solenoid: Short circuit with power supply line 46

Failure code [DXH4KA] 1st clutch ECMV solenoid: Disconnection 48

Failure code [DXH4KB] 1st clutch ECMV solenoid: Short circuit 50

Failure code [DXH4KY] 1st clutch ECMV solenoid: Short circuit with power supply line 52

Troubleshooting by failure code (Display of code), Part 11 SEN02598-02

Failure code [DXH5KA] 2nd clutch ECMV solenoid: Disconnection 4

Failure code [DXH5KB] 2nd clutch ECMV solenoid: Short circuit 6

Failure code [DXH5KY] 2nd clutch ECMV solenoid: Short circuit with power supply line 8

Failure code [DXH6KA] 3rd clutch ECMV solenoid: Disconnection 10

Failure code [DXH6KB] 3rd clutch ECMV solenoid: Short circuit 12

Failure code [DXH6KY] 3rd clutch ECMV solenoid: Short circuit with power supply line 14

Failure code [DXH7KA] R clutch ECMV solenoid: Disconnection 16

Failure code [DXH7KB] R clutch ECMV solenoid: Short circuit 18

Failure code [DXH7KY] R clutch ECMV solenoid: Short circuit with power supply line 20

Failure code [DXH8KA] F clutch ECMV solenoid: Disconnection 22

Failure code [DXH8KB] F clutch ECMV solenoid: Short circuit 24

Failure code [DXH8KY] F clutch ECMV solenoid: Short circuit with power supply line 26

Failure code [DXHHKA] 4th clutch ECMV solenoid: Disconnection 28

Failure code [DXHHKB] 4th clutch ECMV solenoid: Short circuit 30

Failure code [DXHHKY] 4th clutch ECMV solenoid: Short circuit with power supply line 32

Failure code [DXHJKA] 3-spool valve extract EPC solenoid: Disconnection 34

Failure code [DXHJKB] 3-spool valve extract EPC solenoid: Short circuit 36

Failure code [DXHJKY] 3-spool valve extract EPC solenoid: Short circuit with power

supply line 37

Failure code [DXHKKA] 3-spool valve retract EPC solenoid: Disconnection 38

Failure code [DXHKKB] 3-spool valve retract EPC solenoid: Short circuit 40

Failure code [DXHKKY] 3-spool valve retract EPC solenoid: Short circuit with power

supply line 41

Failure code [DXHPKA] Modulation clutch solenoid: Disconnection 42

Failure code [DXHPKB] Modulation clutch solenoid: Short circuit 44

Failure code [DXHPKY] Modulation clutch solenoid: Short circuit with power source line 46

Failure code [DXHPMA] Modulation clutch solenoid: Malfunction 48

Failure code [F@BBZL] (or VHMS_LED display: “n3” o “38”) Blow-by pressure: High error 50

Failure code [F@BYNR] (or VHMS_LED display: “n3” o “62”) (Exhaust gas temperature (F):

Abnormal heat) 52

Failure code [F@BYNS] (or VHMS_LED display: “n3” o “61”) (Exhaust gas temperature (F):

Overheat) 54

Failure code [F@BZNR] (or VHMS_LED display: “n3” o “72”) (Exhaust gas temperature (R):

abnormal heat) 56

Failure code [F@BZNS] (or VHMS_LED display “n3” o “71”) (Exhaust gas temperature (R):

Overheat) 58

Troubleshooting of electrical system (E-mode) SEN02599-02

Before carrying out troubleshooting of electrical system 4

Information in troubleshooting table 7

E-1 Engine does not start 8

E-2 Wiper does not operate 18

E-3 Windshield washer does not operate 26

E-4 Headlamp, clearance lamp, tail lamp, and license lamp do not light up or go off 32

E-5 Working lamp does not light up or go off 46

E-6 Step lamp does not light up or go off 52

E-7 Turn signal lamp and hazard lamp do not light up or go off 54

E-8 Brake lamp does not light or it keeps lighting up 64

E-9 Backup lamp does not light or it keeps lighting up 66

SEN02213-17 00 Index and foreword

14 WA600-6R

E-10 Backup buzzer does not sound or it keeps sounding 70

E-11 Horn does not sound or it keeps sounding 74

E-12 Alarm buzzer does not sound or it keeps sounding 78

E-13 Air conditioner does not operate or stop 80

E-14 Electric priming pump does not operate or does not stop automatically 82

E-15 When starting switch is turned to ON position, machine monitor displays nothing 84

Troubleshooting of hydraulic and mechanical system (H-mode) SEN02600-00

Method of using troubleshooting chart 4

Table of failure modes and causes 6

H-1 Machine does not start 10

H-2 Torque converter lockup is not switched (engine stalls) 12

H-3 Torque converter lockup is not turned on 13

H-4 Travel speed is slow, thrusting force is weak, uphill traveling power is weak, and

gear is not shifted 14

H-5 Shocks are large at the times of starting and shifting gear 16

H-6 Time lag is large at the times of starting and shifting gear 18

H-7 Torque converter oil temperature is high 20

H-8 Steering does not turn [machine with steering wheel] 21

H-9 Steering does not turn [machine with AJSS] 22

H-10 Turning, response of steering is poor [machine with steering wheel] 23

H-11 Turning, response of AJSS is poor [machine with AJSS] 24

H-12 Steering is heavy [machine with steering wheel] 25

H-13 When machine turns, it shakes or makes large shocks [machine with steering wheel] 26

H-14 When machine turns, it shakes or makes large shocks [machine with AJSS] 27

H-15 Wheel brake does not work or does not work well 28

H-16 Wheel brake is not released or it drags 29

H-17 Parking brake does not work or does not work well 30

H-18 Parking brake is not released or it drags (including emergency release system) 31

H-19 Lift arm does not rise 32

H-20 Lift arm speed is low or rising force of lift arm is insufficient 33

H-21 When rising, lift arm comes to move slowly at specific height 34

H-22 Lift arm cylinder cannot hold down bucket (Bucket floats) 34

H-23 Hydraulic drifts of lift arm occur often 34

H-24 Lift arm wobbles during operation 34

H-25 Bucket does not tilt back 35

H-26 Bucket speed is low or tilting back force is insufficient 36

H-27 Bucket comes to operate slowly in the midst of tilting-back 37

H-28 Bucket cylinder cannot hold down bucket 37

H-29 Hydraulic drifts of bucket occur often 37

H-30 Bucket wobbles during travel with cargo (Work equipment valve is set to “HOLD”) 37

H-31 During operation of machine, engine speed lowers remarkably or engine stalls 38

H-32 Large shocks are made when work equipment starts and stops 38

H-33 When work equipment circuit is relieved singly, other work equipment moves 38

H-34 ECSS does not operate, and pitching bouncing occurs 39

H-35 Fan speed is abnormal (Fan sound and vibration are abnormally large or

engine overheats) 40

Troubleshooting of engine (S-mode) SEN02601-02

Method of using troubleshooting chart 3

S-1 Engine does not start easily 6

S-2 Engine does not start 7

S-3 Engine does not pick up smoothly 10

S-4 Engine stops during operation 11

S-5 Engine does not rotate smoothly (Hunting occurs) 12

S-6 Engine lacks output (or lacks power) 13

S-7 Exhaust smoke is black (Incomplete combustion) 14

S-8 Oil is consumed much (or exhaust gas color is blue) 15

S-9 Engine oil becomes contaminated quickly 16

S-10 Fuel consumption is excessive 17

00 Index and foreword SEN02213-17

WA600-6R 15

S-11 Coolant contains oil (blows back or reduces) 18

S-12 Oil pressure drops 19

S-13 Oil level rises (Water, fuel in oil) 20

S-14 Coolant temperature rises too high (Overheating) 21

S-15 Abnormal noise is made 22

S-16 Vibration is excessive 23

S-17 Air cannot be bled from fuel circuit 24

50 Disassembly and assembly

General information on disassembly and assembly SEN02994-01

How to read this manual 2

Coating materials list 4

Special tool list 7

Sketches of special tools 11

Engine and cooling system, Part 1 SEN02995-00

Removal and installation of engine assembly 2

Removal and installation of radiator assembly 5

Removal and installation of air aftercooler 10

Removal and installation of cooling fan and fan motor assembly 11

Removal and installation of damper assembly 13

Disassembly and assembly of damper assembly 15

Removal and installation of fuel tank assembly 19

Removal and installation of engine hood assembly 21

Removal and installation of bulkhead assembly 23

Engine and cooling system, Part 2 SEN02996-02

Removal and installation of fuel supply pump assembly 2

Removal and installation of cylinder head assembly 8

Removal and installation of fuel injector assembly 23

Removal and installation of engine front seal 27

Removal and installation of engine rear seal 30

Power train, Part 1 SEN02997-01

Removal and installation of parking brake assembly 2

Removal and installation of torque converter and transmission assembly 4

Power train, Part 2 SEN02998-02

Disassembly and assembly of torque converter assembly 2

Disassembly and assembly of transmission assembly 29

Disassembly and assembly of transfer assembly 56

Disassembly and assembly of parking brake assembly 72

Power train, Part 3 SEN02999-03

Removal and installation of front axle assembly 2

Removal and installation of rear axle assembly 4

Removal and installation of center support assembly 6

Disassembly and assembly of center support assembly 8

Disassembly and assembly of differential assembly 12

Power train, Part 4 SEN03000-00

Removal and installation of final drive carrier assembly 2

Disassembly and assembly of final drive carrier assembly 4

Removal and installation of front final drive brake assembly 5

Disassembly and assembly of final drive assembly 7

Brake system SEN03001-01

Disassembly and assembly of brake assembly 2

Removal and installation of brake valve assembly 10

Disassembly and assembly of accumulator and charge valve assembly 11

Disassembly and assembly of slack adjustor assembly 14

Undercarriage and frame SEN03002-00

Removal and installation of center hinge pin 2

SEN02213-17 00 Index and foreword

16 WA600-6R

Removal and installation of counterweight assembly 9

Hydraulic system SEN03003-02

Removal and installation of hydraulic tank assembly 2

Removal and installation of hydraulic pump assembly 4

Removal and installation of control valve assembly 8

Disassembly and assembly of control valve assembly 10

Removal and installation of steering valve assembly 15

Removal and installation of ECSS accumulator assembly 16

Disassembly and assembly of hydraulic cylinder assembly 17

Work equipment SEN03004-00

Removal and installation of work equipment assembly 2

Cab and its attachments SEN03005-01

Removal and installation of operator’s cab assembly 2

Removal and installation of operator’s cab glass (stuck glass) 6

Removal and installation of floor frame assembly 14

Removal and installation of AJSS lever switch assembly 17

Electrical system SEN03006-02

Removal and installation of engine controller assembly 2

Removal and installation of transmission controller assembly 4

Removal and installation of loader controller assembly 4

Removal and installation of VHMS controller assembly 5

Removal and installation of monitor assembly 6

Removal and installation of printer assembly 9

Removal and installation of air conditioner unit assembly 10

90 Diagrams and drawings

Hydraulic diagrams and drawings SEN02525-02

Power train hydraulic circuit diagram 2

Brake hydraulic circuit diagram 3

Work equipment hydraulic circuit diagram 5

Electrical diagrams and drawings SEN02526-03

Air conditioner electrical circuit diagram 3

Steering wheel specification

Electrical circuit diagram (1/10) 5

Electrical circuit diagram (2/10) 7

Electrical circuit diagram (3/10) 9

Electrical circuit diagram (4/10) 11

Electrical circuit diagram (5/10) 13

Electrical circuit diagram (6/10) 15

Electrical circuit diagram (7/10) 17

Electrical circuit diagram (8/10) 19

Electrical circuit diagram (9/10) 21

Electrical circuit diagram (10/10) 23

AJSS (Advanced Joystick Steering System) specification

Electrical circuit diagram (1/10) 25

Electrical circuit diagram (2/10) 27

Electrical circuit diagram (3/10) 29

Electrical circuit diagram (4/10) 31

Electrical circuit diagram (5/10) 33

Electrical circuit diagram (6/10) 35

Electrical circuit diagram (7/10) 37

Electrical circuit diagram (8/10) 39

Electrical circuit diagram (9/10) 41

Electrical circuit diagram (10/10) 43

Connector arrangement diagram 45

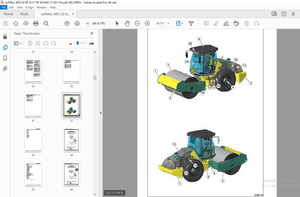

VIDEO PREVIEW OF THE MANUAL:

IMAGES PREVIEW OF THE MANUAL: