$36

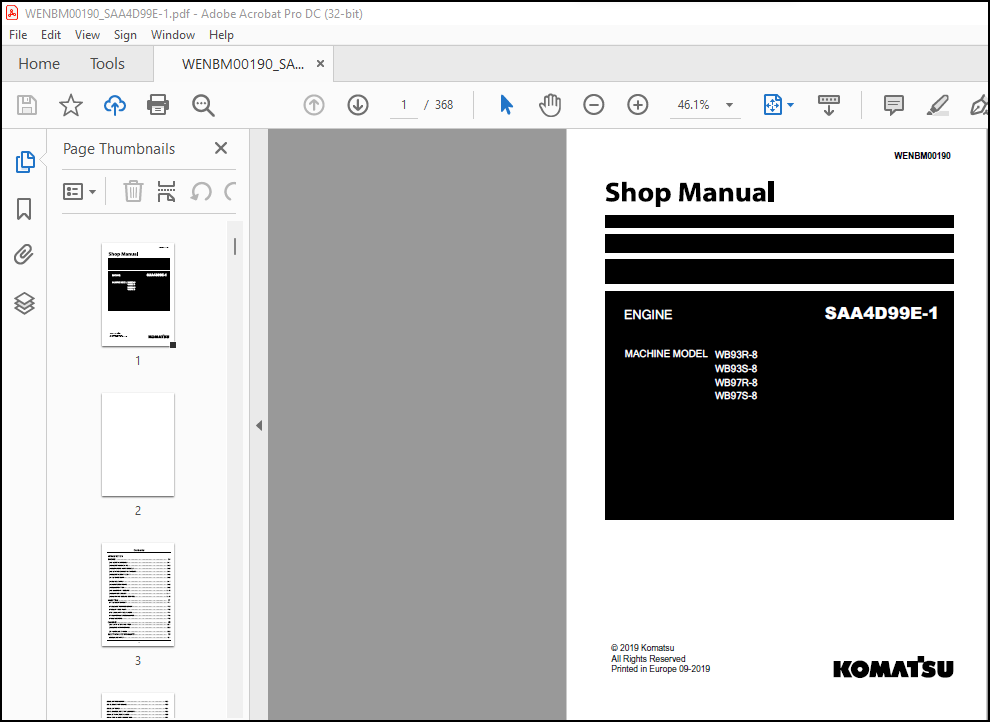

Komatsu WB93R-8 WB93S-8 WB97R-8 WB97S-8 Engine Shop Manual – PDF DOWNLOAD

Komatsu WB93R-8 WB93S-8 WB97R-8 WB97S-8 Engine Shop Manual – PDF DOWNLOAD

FILE DETAILS:

Komatsu WB93R-8 WB93S-8 WB97R-8 WB97S-8 Engine Shop Manual – PDF DOWNLOAD

Language : English

Pages : 368

Downloadable : Yes

File Type : PDF

Size: 30.6 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu WB93R-8 WB93S-8 WB97R-8 WB97S-8 Engine Shop Manual – PDF DOWNLOAD

- The Komatsu WB93R-8, WB93S-8, WB97R-8, and WB97S-8 are four models of backhoe loaders with different engine specifications. The engine shop manual for these models covers the Komatsu SAA4D95LE-3 engine, which is a four-stroke, four-cylinder diesel engine with a displacement of 3.26 liters. The manual provides detailed information on the maintenance, repair, and troubleshooting of the engine, including specifications, testing procedures, and adjustments.

- The manual is organized into sections covering different aspects of the engine. The first section provides general information on the engine, including specifications, system configuration, and service standards. The second section covers the structure and function of the engine components, including the engine block, cylinder head, fuel system, lubrication system, cooling system, and electrical system.

- The third section covers the engine testing and adjusting procedures, including inspection and measurement, testing of engine components, and adjustment of engine settings. This section provides detailed step-by-step instructions and illustrations for all testing and adjusting procedures.

- The fourth section covers the engine troubleshooting procedures, including diagnosing and correcting problems with the engine components and systems. This section provides a detailed troubleshooting chart with step-by-step procedures for identifying and correcting engine problems.

- The fifth section covers the engine disassembly and assembly procedures, including removal and installation of major engine components. This section provides detailed step-by-step instructions and illustrations for all disassembly and assembly procedures.

- The sixth section covers the engine maintenance procedures, including routine maintenance tasks such as oil and filter changes, and the replacement of parts such as belts, hoses, and filters.

- Overall, the Komatsu WB93R-8, WB93S-8, WB97R-8, and WB97S-8 Engine Shop Manual is a comprehensive guide to the maintenance, repair, and troubleshooting of the SAA4D95LE-3 engine, providing detailed information on all aspects of the engine’s operation and maintenance.

TABLE OF CONTENTS:

Komatsu WB93R-8 WB93S-8 WB97R-8 WB97S-8 Engine Shop Manual – PDF DOWNLOAD

INTRODUCTION………………………………………………………………………………………………………….. 5

Foreword …………………………………………………………………………………………………………. 7

International symbols ……………………………………………………………………………………………… 9

SYMBOLS – WARNINGS……………………………………………………………………………………………… 9

Grouped Safety Message …………………………………………………………………………………………….. 10

Grouped Safety Message …………………………………………………………………………………………….. 12

Grounding and screening…………………………………………………………………………………………. 12

Optional electrical and mechanical parts installations……………………………………………………………… 14

Safety rules ……………………………………………………………………………………………………… 15

Standard safety precautions……………………………………………………………………………………… 15

Accident prevention…………………………………………………………………………………………….. 15

During maintenance……………………………………………………………………………………………… 15

Protection of the environment……………………………………………………………………………………. 16

Conversion factors ………………………………………………………………………………………………… 17

Conversions between the main units of measurements of the international system and the most commonly used derived units……. 17

Power…………………………………………………………………………………………………………. 17

Torque………………………………………………………………………………………………………… 17

Rpm…………………………………………………………………………………………………………… 17

Pressure………………………………………………………………………………………………………. 17

Temperature……………………………………………………………………………………………………. 17

Product identification Identification plate ………………………………………………………………………….. 18

Product identification – Correspondence between technical codes and commercial codes ……………………………………… 19

Product identification – Technical coding ……………………………………………………………………………. 20

Product identification – Commercial coding …………………………………………………………………………… 21

Scheduled maintenance ……………………………………………………………………………………………… 22

Introduction…………………………………………………………………………………………………… 22

Checks and scheduled maintenance procedures……………………………………………………………………….. 22

Scheduled maintenance ATS system ……………………………………………………………………………………. 24

ATS system maintenance services schedule………………………………………………………………………….. 24

ENGINE……………………………………………………………………………………………………………….. 25

ENGINE ASSEMBLY……………………………………………………………………………………………………. 25

ENGINE………………………………………………………………………………………………………… 25

540110 ENGINE – Engine horse power ……………………………………………………………………….. 30

Characteristic curves 75kw……………………………………………………………………………….. 30

540110 ENGINE – Technical Data …………………………………………………………………………… 30

GENERAL CHARACTERISTICS………………………………………………………………………………….. 30

540110 ENGINE – Technical Data and assembly clearances ……………………………………………………… 33

540110 ENGINE – Torque ………………………………………………………………………………….. 37

ENGINE………………………………………………………………………………………………………… 25

540110 ENGINE – External view ……………………………………………………………………………. 42

ISOMETRIC VIEW………………………………………………………………………………………….. 42

540110 ENGINE – External view F5BFL413G*B001 ………………………………………………………………. 44

LEFT SIDE VIEW………………………………………………………………………………………….. 44

RIGHT SIDE VIEW…………………………………………………………………………………………. 45

FRONT VIEW……………………………………………………………………………………………… 46

REAR VIEW………………………………………………………………………………………………. 47

TOP VIEW……………………………………………………………………………………………….. 48

540110 ENGINE – Component localisation ……………………………………………………………………. 49

Location of engine electrical components…………………………………………………………………… 49

540110 ENGINE – Component localisation – ATS system ………………………………………………………… 51

Location of the ATS system electrical components……………………………………………………………. 51

ENGINE………………………………………………………………………………………………………… 25

540110 ENGINE – Disassemble ……………………………………………………………………………… 53

Assembly on the stand and draining of the engine lubricant…………………………………………………… 53

Engine cable removal…………………………………………………………………………………….. 55

Removal of the glow plug bridle…………………………………………………………………………… 56

Removal of the electric starter motor……………………………………………………………………… 57

Removal of speed and timing sensor………………………………………………………………………… 57

Removal of boost pressure and exhaust gas absolute pressure sensors…………………………………………… 57

Air pressure control valve removal………………………………………………………………………… 58

Removal of the coolant inlet pipe…………………………………………………………………………. 59

Removal of the turbocharger oil pipes……………………………………………………………………… 59

Removal of temperature sensor and thermostat……………………………………………………………….. 60

Removal of the EGR system………………………………………………………………………………… 60

Turbocharger and exhaust manifold removal………………………………………………………………….. 62

Removal of the air accumulator……………………………………………………………………………. 63

Removal of the water pump/alternator drive belt…………………………………………………………….. 63

Alternator removal………………………………………………………………………………………. 64

Removal of the lower alternator mount……………………………………………………………………… 64

Fuel filter removal……………………………………………………………………………………… 64

Removal of the fuel filter support………………………………………………………………………… 64

Fuel pipes removal………………………………………………………………………………………. 65

Removal of the common rail……………………………………………………………………………….. 66

Removal of the injector fuel return pipe…………………………………………………………………… 67

Removing the oil filter and bracket……………………………………………………………………….. 67

Blow-by filter removal…………………………………………………………………………………… 68

Removing the power take-off (PTO)…………………………………………………………………………. 69

Removal of the high pressure fuel pump…………………………………………………………………….. 69

Removal of the crankshaft pulley………………………………………………………………………….. 70

Water pump removal………………………………………………………………………………………. 70

Removal of the fan drive pulley…………………………………………………………………………… 70

Removal of the engine lubricant heat exchanger……………………………………………………………… 71

Crankshaft front gasket removal…………………………………………………………………………… 71

Front cover removal……………………………………………………………………………………… 71

Removal of the engine air intake………………………………………………………………………….. 72

Throttle body removal (TVA)………………………………………………………………………………. 72

Intake manifold removal………………………………………………………………………………….. 72

Removal of glow plugs……………………………………………………………………………………. 73

Removal of electronic injectors…………………………………………………………………………… 73

Removal of head cover……………………………………………………………………………………. 74

Overhead removal………………………………………………………………………………………… 74

Rocker arms assembly removal……………………………………………………………………………… 75

Cylinder head removal……………………………………………………………………………………. 75

Idle gear removal……………………………………………………………………………………….. 76

Removal of the timing gear……………………………………………………………………………….. 76

Removal of the gear case…………………………………………………………………………………. 77

Removing the oil pump……………………………………………………………………………………. 77

Oil sump removal………………………………………………………………………………………… 77

Removal of the oil intake suction strainer…………………………………………………………………. 78

Removal of complete flywheel……………………………………………………………………………… 78

Crankshaft rear gasket removal……………………………………………………………………………. 79

Flywheel housing removal…………………………………………………………………………………. 79

Piston removal………………………………………………………………………………………….. 80

Connecting rod removal…………………………………………………………………………………… 80

Big-end bearings removal…………………………………………………………………………………. 80

Crankshaft removal………………………………………………………………………………………. 81

Main bearings removal……………………………………………………………………………………. 82

Sprayer removal…………………………………………………………………………………………. 82

Camshaft of distribution removal………………………………………………………………………….. 82

Tappet removal………………………………………………………………………………………….. 83

Removal of piston-connecting rod assembly………………………………………………………………….. 83

Piston rings removal…………………………………………………………………………………….. 84

Removal of rail pressure sensor…………………………………………………………………………… 84

Removal of pressure relief valve on rail…………………………………………………………………… 84

Valve removal…………………………………………………………………………………………… 85

540110 ENGINE – Check …………………………………………………………………………………… 86

Cylinder liner measurement……………………………………………………………………………….. 86

Checking cylinder block head contact surface……………………………………………………………….. 88

TIMING GEAR…………………………………………………………………………………………….. 88

Camshaft of distribution measurement………………………………………………………………………. 88

Checking cam lift and journals alignment…………………………………………………………………… 89

Check and measurement of camshaft bushes…………………………………………………………………… 89

Camshaft bushes replacement………………………………………………………………………………. 90

Tappet measurement………………………………………………………………………………………. 91

Crankshaft measurement…………………………………………………………………………………… 91

MAIN CRANKSHAFT TOLERANCES……………………………………………………………………………….. 93

CLASS OF IMPORTANCE……………………………………………………………………………………… 93

Checking crankshaft shoulder clearance…………………………………………………………………….. 95

Piston, pin and circlip main data…………………………………………………………………………. 95

Measuring the piston diameter…………………………………………………………………………….. 96

NO TITLE……………………………………………………………………………………………….. 0

Piston pin measurement…………………………………………………………………………………… 96

Conditions for correct pin/piston coupling…………………………………………………………………. 97

Measuring seal rings…………………………………………………………………………………….. 97

Connecting rod measurement……………………………………………………………………………….. 98

Connecting rod small end bush check……………………………………………………………………….. 99

Connecting rod axes parallelism check………………………………………………………………………100

Torsion check……………………………………………………………………………………………100

Bending check……………………………………………………………………………………………101

Cylinder head hydraulic seal check…………………………………………………………………………101

Cylinder head contact surface check………………………………………………………………………..102

Cleaning and testing valves……………………………………………………………………………….103

Measuring valves…………………………………………………………………………………………103

Checking clearance between valve stem and valve guide and centring valves………………………………………103

Measuring valve guides……………………………………………………………………………………104

Replacing the valve guides………………………………………………………………………………..105

Boring the valve guides…………………………………………………………………………………..106

Regrinding – replacing the valve seats……………………………………………………………………..106

Checking valve recessing………………………………………………………………………………….108

Valve spring check……………………………………………………………………………………….108

Rod check……………………………………………………………………………………………….108

Rocker assembly check…………………………………………………………………………………….109

540110 ENGINE – Assemble …………………………………………………………………………………110

Tappet installation………………………………………………………………………………………112

Fitting camshaft…………………………………………………………………………………………113

Oil sprayer assembly……………………………………………………………………………………..114

Main bearings assembly……………………………………………………………………………………114

Crankshaft assembly………………………………………………………………………………………115

Finding main journals clearance……………………………………………………………………………115

Conditions………………………………………………………………………………………………115

Piston assembly………………………………………………………………………………………….117

Fitting piston rings……………………………………………………………………………………..118

Big-end bearings assembly…………………………………………………………………………………118

Fitting the connecting rod-piston assembly into the cylinder liners……………………………………………118

Crankpin assembly clearance measurement…………………………………………………………………….120

Piston protrusion check…………………………………………………………………………………..121

Rail pressure sensor assembly……………………………………………………………………………..122

Assembly of pressure relief valve on rail…………………………………………………………………..122

Valve fitting……………………………………………………………………………………………122

Flywheel housing assembly…………………………………………………………………………………123

Crankshaft rear gasket assembly……………………………………………………………………………124

Engine flywheel assembly………………………………………………………………………………….124

Oil intake suction strainer assembly……………………………………………………………………….125

Oil sump assembly………………………………………………………………………………………..126

Installing the oil pump…………………………………………………………………………………..126

Gear case assembly……………………………………………………………………………………….127

Assembly of the timing gear……………………………………………………………………………….128

Idle gear assembly……………………………………………………………………………………….129

Assembly of the high pressure fuel pump ……………………………………………………………………129

Assembling the power take-off (PTO)………………………………………………………………………..130

Assembling the front cover………………………………………………………………………………..130

Crankshaft front gasket installation……………………………………………………………………….131

Assembly of the engine lubricant heat exchanger……………………………………………………………..131

Cylinder head installation………………………………………………………………………………..132

Rocker arms assembly installation …………………………………………………………………………134

Overhead assembly………………………………………………………………………………………..135

Installation of head cover………………………………………………………………………………..135

Assembling electro-injectors ……………………………………………………………………………..136

Assembly of the injector fuel return pipe…………………………………………………………………..136

Inlet manifold assembly ………………………………………………………………………………….137

Throttle body assembly (TVA)………………………………………………………………………………137

Assembly of the engine air intake………………………………………………………………………….138

Assembly of the crankshaft pulley………………………………………………………………………….138

Assembly of the fan drive pulley…………………………………………………………………………..138

Water pump assembly ……………………………………………………………………………………..139

Blow-by filter assembly ………………………………………………………………………………….139

Glow plug assembly……………………………………………………………………………………….140

Oil filter and mount assembly……………………………………………………………………………..140

Installation of the common rail……………………………………………………………………………141

Fuel pipe assembly……………………………………………………………………………………….142

Assembly of the fuel filter mount………………………………………………………………………….143

Fuel filter assembly……………………………………………………………………………………..143

Assembly of the air accumulator……………………………………………………………………………144

Assembly of the lower alternator mount …………………………………………………………………….144

Alternator assembly………………………………………………………………………………………144

Assembly of the water pump/alternator drive belt…………………………………………………………….144

Auxiliary members’ belt tension……………………………………………………………………………145

Turbocharger and exhaust manifold assembly………………………………………………………………….146

Assembly of the EGR system………………………………………………………………………………..146

Thermostat and temperature sensor assembly………………………………………………………………….148

Assembly of the turbocharger oil pipes …………………………………………………………………….149

Assembly of the coolant inlet pipe…………………………………………………………………………149

Air pressure control valve assembly………………………………………………………………………..149

Assembly of the exhaust gas and air temperature sensors………………………………………………………150

Assembly of the engine speed and timing sensors……………………………………………………………..151

Mounting the electric starter motor………………………………………………………………………..151

Assembly of the glow plug bridle…………………………………………………………………………..151

Fitting the engine cable………………………………………………………………………………….152

Removal of rotating stand…………………………………………………………………………………154

ENGINE MOUNTING……………………………………………………………………………………………………. 25

OIL SUMP………………………………………………………………………………………………………. 25

540430 OIL SUMP – Overview ……………………………………………………………………………….156

ENGINE BREATHER………………………………………………………………………………………………… 25

540480 ENGINE BREATHER – Overview – Oil vapour recirculation system …………………………………………..157

Blow-by filter…………………………………………………………………………………………..158

OIL SUMP………………………………………………………………………………………………………. 25

540430 OIL SUMP – Remove …………………………………………………………………………………159

540430 OIL SUMP – Install ………………………………………………………………………………..160

CRANKSHAFT FRONT SEAL…………………………………………………………………………………………… 26

540442 CRANKSHAFT FRONT SEAL – Remove ……………………………………………………………………..161

Crankshaft front seal ring removal…………………………………………………………………………161

540442 CRANKSHAFT FRONT SEAL – Install …………………………………………………………………….162

Crankshaft front seal ring refitting……………………………………………………………………….162

CRANKSHAFT REAR SEAL……………………………………………………………………………………………. 26

540462 CRANKSHAFT REAR SEAL – Remove ………………………………………………………………………163

Crankshaft rear seal ring removal………………………………………………………………………….163

540462 CRANKSHAFT REAR SEAL – Install ……………………………………………………………………..164

Crankshaft rear seal ring refitting………………………………………………………………………..164

ENGINE BREATHER………………………………………………………………………………………………… 26

540480 ENGINE BREATHER – Remove …………………………………………………………………………..165

Blow-by filter removal……………………………………………………………………………………165

540480 ENGINE BREATHER – Install ………………………………………………………………………….166

Blow-by filter refitting………………………………………………………………………………….166

FILTER ELEMENT…………………………………………………………………………………………………. 26

540486 FILTER ELEMENT – Replace …………………………………………………………………………..167

Blow-by filter change…………………………………………………………………………………….167

CYLINDER HEAD ASSEMBLY……………………………………………………………………………………………… 26

CYLINDER HEAD………………………………………………………………………………………………….. 26

540610 CYLINDER HEAD – Remove …………………………………………………………………………….168

540610 CYLINDER HEAD – Install ……………………………………………………………………………169

ROCKER COVER…………………………………………………………………………………………………… 26

540630 ROCKER COVER – Remove ……………………………………………………………………………..172

540630 ROCKER COVER – Install …………………………………………………………………………….173

INTAKE+EXHAUST MANIFOLDS……………………………………………………………………………………………. 26

EGR ASSEMBLY…………………………………………………………………………………………………… 26

540740 EGR ASSEMBLY – Overview ……………………………………………………………………………174

Operation diagram………………………………………………………………………………………..175

MODULATING SOLENOID VALVE……………………………………………………………………………………….. 26

540746 MODULATING SOLENOID VALVE – Overview ………………………………………………………………..176

Exhaust gas valve (EGR)…………………………………………………………………………………..176

Sensor-actuator pin-out…………………………………………………………………………………..176

ABSOLUTE PRESSURE SENSOR………………………………………………………………………………………… 26

540751 ABSOLUTE PRESSURE SENSOR – Overview …………………………………………………………………177

Absolute exhaust gas pressure sensor……………………………………………………………………….177

Sensor pin-out…………………………………………………………………………………………..177

THROTTLE VALVE POS SENSOR……………………………………………………………………………………….. 26

540762 THROTTLE VALVE POS SENSOR – Overview ………………………………………………………………..178

Throttle body (TVA)………………………………………………………………………………………178

Sensor-actuator pin-out…………………………………………………………………………………..178

INTAKE MANIFOLDS……………………………………………………………………………………………….. 26

540710 INTAKE MANIFOLDS – Remove ………………………………………………………………………….179

540710 INTAKE MANIFOLDS – Install …………………………………………………………………………180

EXHAUST MANIFOLD……………………………………………………………………………………………….. 26

540720 EXHAUST MANIFOLD – Remove ………………………………………………………………………….181

540720 EXHAUST MANIFOLD – Install …………………………………………………………………………182

EGR ASSEMBLY…………………………………………………………………………………………………… 26

540740 EGR ASSEMBLY – Remove ……………………………………………………………………………..183

540740 EGR ASSEMBLY – Install …………………………………………………………………………….185

ENGINE COMPONENTS………………………………………………………………………………………………….. 27

CRANKSHAFT PULLEY………………………………………………………………………………………………. 27

540821 CRANKSHAFT PULLEY – Remove …………………………………………………………………………187

540821 CRANKSHAFT PULLEY – Install ………………………………………………………………………..188

FLYWHEEL ASSEMBLY………………………………………………………………………………………………. 27

540850 FLYWHEEL ASSEMBLY – Remove …………………………………………………………………………189

540850 FLYWHEEL ASSEMBLY – Install ………………………………………………………………………..190

TIMING GEAR……………………………………………………………………………………………………….. 27

ROCKER ARM ASSY………………………………………………………………………………………………… 27

541230 ROCKER ARM ASSY – Remove …………………………………………………………………………..191

541230 ROCKER ARM ASSY – Install ………………………………………………………………………….192

FUEL SUPPLY……………………………………………………………………………………………………….. 27

FUEL SUPPLY……………………………………………………………………………………………………. 27

5420 FUEL SUPPLY – Overview ………………………………………………………………………………193

SUPPLY SYSTEM……………………………………………………………………………………………193

Fuel system diagram………………………………………………………………………………………193

5420 FUEL SUPPLY – Overview – Electrical system …………………………………………………………….195

Air pressure/temperature sensor……………………………………………………………………………196

Engine oil temperature and pressure sensor………………………………………………………………….196

Fuel pressure sensor……………………………………………………………………………………..196

Fuel temperature sensor…………………………………………………………………………………..196

Coolant temperature sensor………………………………………………………………………………..196

Crankshaft sensor………………………………………………………………………………………..196

Timing sensor……………………………………………………………………………………………196

Self-diagnostics…………………………………………………………………………………………196

Engine pre-heating resistance management……………………………………………………………………196

Synchronisation search……………………………………………………………………………………196

Injection control………………………………………………………………………………………..196

Closed loop injection pressure check……………………………………………………………………….197

Pilot and main injection advance control……………………………………………………………………197

Idle speed control……………………………………………………………………………………….197

Maximum speed limiting……………………………………………………………………………………197

Cut Off…………………………………………………………………………………………………197

Smokiness on acceleration control………………………………………………………………………….197

Checking fuel temperature…………………………………………………………………………………197

After Run……………………………………………………………………………………………….197

5420 FUEL SUPPLY – Overview – Hydraulic system ……………………………………………………………..198

HYDRAULIC SYSTEM…………………………………………………………………………………………198

FILTER ASSEMBLY………………………………………………………………………………………………… 27

542010 FILTER ASSEMBLY – Overview …………………………………………………………………………200

Fuel filter……………………………………………………………………………………………..200

FILTER ASSEMBLY………………………………………………………………………………………………… 27

542010 FILTER ASSEMBLY – Replace ………………………………………………………………………….201

Fuel filter replacement…………………………………………………………………………………..201

542010 FILTER ASSEMBLY – Remove …………………………………………………………………………..203

542010 FILTER ASSEMBLY – Install ………………………………………………………………………….204

FILTER SUPPORT…………………………………………………………………………………………………. 27

542014 FILTER SUPPORT – Remove ……………………………………………………………………………205

Removal of fuel filter support…………………………………………………………………………….205

542014 FILTER SUPPORT – Install …………………………………………………………………………..206

Fuel filter support refitting……………………………………………………………………………..206

PIPES…………………………………………………………………………………………………………. 27

542020 PIPES – Remove ……………………………………………………………………………………207

Removal of fuel pipes…………………………………………………………………………………….207

542020 PIPES – Install …………………………………………………………………………………..209

Refitting fuel pipes……………………………………………………………………………………..209

SUPERCHARGING……………………………………………………………………………………………………… 27

SUPERCHARGING………………………………………………………………………………………………….. 28

5424 SUPERCHARGING – Overview …………………………………………………………………………….211

TURBO CHARGER………………………………………………………………………………………………….. 28

542410 TURBO CHARGER – Overview …………………………………………………………………………..212

Waste Gate Valve…………………………………………………………………………………………213

PRESS.LIMITING SWITCH…………………………………………………………………………………………… 28

542419 PRESS.LIMITING SWITCH – Overview ……………………………………………………………………214

V.G.T.DRIVE ACTUATOR……………………………………………………………………………………………. 28

542451 V.G.T.DRIVE ACTUATOR – Overview …………………………………………………………………….215

TURBO CHARGER………………………………………………………………………………………………….. 28

542410 TURBO CHARGER – Remove …………………………………………………………………………….216

542410 TURBO CHARGER – Install ……………………………………………………………………………217

542410 TURBO CHARGER – Visual inspection …………………………………………………………………..218

Turbocharger visual inspection…………………………………………………………………………….218

LUBRICATION……………………………………………………………………………………………………….. 28

LUBRICATION……………………………………………………………………………………………………. 28

5430 LUBRICATION – Overview ………………………………………………………………………………219

LUBRICATION CIRCUIT………………………………………………………………………………………219

Lubrication system diagram………………………………………………………………………………..219

Lubrication circuit ……………………………………………………………………………………..221

OIL PUMP………………………………………………………………………………………………………. 28

543010 OIL PUMP – Overview ……………………………………………………………………………….222

Oil pump cross-section……………………………………………………………………………………222

FILTER CARTRIDGE……………………………………………………………………………………………….. 28

543070 FILTER CARTRIDGE – Overview ………………………………………………………………………..223

Engine oil filter………………………………………………………………………………………..223

OIL PRESSURE REGUL.VALVE………………………………………………………………………………………… 28

543075 OIL PRESSURE REGUL.VALVE – Overview …………………………………………………………………224

Oil pressure regulating valves (4 – 10bar)………………………………………………………………….224

Oil pressure regulating valve (4bar)……………………………………………………………………….224

Safety valve (10bar)……………………………………………………………………………………..225

FILTER CARTRIDGE……………………………………………………………………………………………….. 28

543070 FILTER CARTRIDGE – Check …………………………………………………………………………..226

Engine lubricant oil level check…………………………………………………………………………..226

543070 FILTER CARTRIDGE – Change fluid …………………………………………………………………….227

Engine lubricant oil replacement…………………………………………………………………………..227

543070 FILTER CARTRIDGE – Replace …………………………………………………………………………228

543070 FILTER CARTRIDGE – Remove ………………………………………………………………………….230

543070 FILTER CARTRIDGE – Install …………………………………………………………………………231

FILTER SUPPORT…………………………………………………………………………………………………. 28

543072 FILTER SUPPORT – Remove – Oil filter bracket …………………………………………………………232

543072 FILTER SUPPORT – Install – Oil filter bracket ………………………………………………………..233

LUBRICANT COOLING………………………………………………………………………………………………….. 28

HEAT EXCHANGER…………………………………………………………………………………………………. 28

543110 HEAT EXCHANGER – Overview ………………………………………………………………………….234

HEAT EXCHANGER…………………………………………………………………………………………………. 29

543110 HEAT EXCHANGER – Remove ……………………………………………………………………………235

543110 HEAT EXCHANGER – Install …………………………………………………………………………..236

WATER COOLING……………………………………………………………………………………………………… 29

WATER COOLING………………………………………………………………………………………………….. 29

5432 WATER COOLING – Overview – Cooling circuit …………………………………………………………….237

Cooling system diagram with ………………………………………………………………………………237

WATER PUMP ASSEMBLY…………………………………………………………………………………………….. 29

543210 WATER PUMP ASSEMBLY – Overview ……………………………………………………………………..239

Section on water pump…………………………………………………………………………………….239

THERMOSTAT…………………………………………………………………………………………………….. 29

543250 THERMOSTAT – Overview ……………………………………………………………………………..240

Thermostat operating diagram………………………………………………………………………………240

Operation……………………………………………………………………………………………….240

functional diagram……………………………………………………………………………………….241

WATER PUMP ASSEMBLY…………………………………………………………………………………………….. 29

543210 WATER PUMP ASSEMBLY – Remove ……………………………………………………………………….242

543210 WATER PUMP ASSEMBLY – Install ………………………………………………………………………243

543210 WATER PUMP ASSEMBLY – Check ………………………………………………………………………..244

Water pump………………………………………………………………………………………………244

THERMOSTAT…………………………………………………………………………………………………….. 29

543250 THERMOSTAT – Remove ……………………………………………………………………………….245

543250 THERMOSTAT – Install ………………………………………………………………………………246

FAN AND COOLING CONTROL…………………………………………………………………………………………….. 29

WATER PUMP DRIVE BELT…………………………………………………………………………………………… 29

543411 WATER PUMP DRIVE BELT – Check ………………………………………………………………………247

Main activity……………………………………………………………………………………………247

Auxiliary members’ belt tension……………………………………………………………………………247

543411 WATER PUMP DRIVE BELT – Replace …………………………………………………………………….249

Auxiliary members’ belt replacement………………………………………………………………………..249

Auxiliary members’ belt tension……………………………………………………………………………249

543411 WATER PUMP DRIVE BELT – Remove ……………………………………………………………………..251

Removal…………………………………………………………………………………………………251

543411 WATER PUMP DRIVE BELT – Install …………………………………………………………………….252

INJECTION……………………………………………………………………………………………………………..257

INJECTION PUMP……………………………………………………………………………………………………..257

INJECTION PUMP ASSY……………………………………………………………………………………………..257

771010 INJECTION PUMP ASSY – Overview – High pressure pump BOSCH CP4.1 ………………………………………..259

High pressure pump CP4.1 operating diagrams…………………………………………………………………261

HIGH PRESSURE ADJ UNIT…………………………………………………………………………………………..257

771034 HIGH PRESSURE ADJ UNIT – Overview …………………………………………………………………..263

High pressure fuel pump dosing unit………………………………………………………………………..263

Valve pin-out……………………………………………………………………………………………264

INJECTION PUMP ASSY……………………………………………………………………………………………..257

771010 INJECTION PUMP ASSY – Remove ……………………………………………………………………….265

High-pressure pump removal………………………………………………………………………………..265

771010 INJECTION PUMP ASSY – Install ………………………………………………………………………268

High-pressure pump refitting………………………………………………………………………………268

ELECTRONIC GOVERNOR…………………………………………………………………………………………………257

AIR PRESSURE SENSOR……………………………………………………………………………………………..257

772646 AIR PRESSURE SENSOR – Overview ……………………………………………………………………..271

Air temperature and boost pressure sensor…………………………………………………………………..271

Sensor pin-out…………………………………………………………………………………………..271

FUEL TEMPERATURE SENSOR………………………………………………………………………………………….257

772656 FUEL TEMPERATURE SENSOR – Overview ………………………………………………………………….272

Fuel temperature sensor…………………………………………………………………………………..272

Sensor pin-out…………………………………………………………………………………………..272

LIFT FEED PUMP……………………………………………………………………………………………………..257

FEED PUMP ASSY………………………………………………………………………………………………….257

773010 FEED PUMP ASSY – Overview Checking the mechanical feed pump (ZP18) ……………………………………..273

AUXILIARY FUEL FILTERS………………………………………………………………………………………………257

FUEL PRE-FILTER…………………………………………………………………………………………………257

773110 FUEL PRE-FILTER – Check ……………………………………………………………………………274

Check for water in fuel pre-filter…………………………………………………………………………274

HYDRAULIC ACCUMULATOR……………………………………………………………………………………………….258

HIGH PRESS ACCUMULATOR…………………………………………………………………………………………..258

774510 HIGH PRESS ACCUMULATOR – Overview …………………………………………………………………..275

PRESSURE SENSOR…………………………………………………………………………………………………258

774511 PRESSURE SENSOR – Overview …………………………………………………………………………276

Fuel pressure sensor on rail………………………………………………………………………………276

HIGH PRESS ACCUMULATOR…………………………………………………………………………………………..258

774510 HIGH PRESS ACCUMULATOR – Remove …………………………………………………………………….277

Common Rail removal………………………………………………………………………………………277

774510 HIGH PRESS ACCUMULATOR – Install ……………………………………………………………………278

INJECTORS………………………………………………………………………………………………………….258

INJECTOR……………………………………………………………………………………………………….258

775010 INJECTOR – Overview ……………………………………………………………………………….279

Electro-injectors………………………………………………………………………………………..279

Start of injection……………………………………………………………………………………….279

End of injection…………………………………………………………………………………………279

Electro-injector pin – out………………………………………………………………………………..279

INJECTOR……………………………………………………………………………………………………….258

775010 INJECTOR – Remove …………………………………………………………………………………281

775010 INJECTOR – Install ………………………………………………………………………………..282

CHASSIS……………………………………………………………………………………………………………….285

AIR FILTERS AND PIPES……………………………………………………………………………………………….285

AIR FILTERS AND PIPES……………………………………………………………………………………………285

5051 AIR FILTERS AND PIPES – Check ………………………………………………………………………..287

Check of the air filter…………………………………………………………………………………..287

RADIATOR AND PIPES………………………………………………………………………………………………….285

RADIATOR……………………………………………………………………………………………………….285

506010 RADIATOR – Check ………………………………………………………………………………….288

Checking the engine coolant level………………………………………………………………………….288

506010 RADIATOR – Cleaning ……………………………………………………………………………….289

506010 RADIATOR – Cleaning – Clean/replace radiator pressure cap ……………………………………………..290

506010 RADIATOR – Change fluid ……………………………………………………………………………291

Replacing engine coolant………………………………………………………………………………….291

AD-BLUE SYSTEM……………………………………………………………………………………………………..285

AD-BLUE UNIT PUMP MODULE…………………………………………………………………………………………285

507410 AD-BLUE UNIT PUMP MODULE – Technical Data ……………………………………………………………292

AdBlue module connector…………………………………………………………………………………..292

AdBlue supply module pin-out………………………………………………………………………………292

AD-BLUE SYSTEM………………………………………………………………………………………………….285

5074 AD-BLUE SYSTEM – Overview ……………………………………………………………………………293

ATS system heating/cooling system………………………………………………………………………….296

AdBlue specifications…………………………………………………………………………………….298

5074 AD-BLUE SYSTEM – Component localisation ……………………………………………………………….299

Location of the ATS system filters…………………………………………………………………………299

AD-BLUE UNIT PUMP MODULE…………………………………………………………………………………………285

507410 AD-BLUE UNIT PUMP MODULE – Overview DeNOx 2.2 (SM) ……………………………………………………300

Supply module……………………………………………………………………………………………300

AD-BLUE TANK……………………………………………………………………………………………………285

507420 AD-BLUE TANK – Overview ……………………………………………………………………………302

AD-BLUE INDICATOR……………………………………………………………………………………………….285

507424 AD-BLUE INDICATOR – Overview ……………………………………………………………………….303

AdBlue level multifunction unit (MFU)………………………………………………………………………303

Functional wiring diagram…………………………………………………………………………………304

AD-BLUE METERING DEV MODU………………………………………………………………………………………..285

507431 AD-BLUE METERING DEV MODU – Overview Dosing module 2.5 ………………………………………………..305

CROSSOVER VALVE…………………………………………………………………………………………………285

507433 CROSSOVER VALVE – Overview …………………………………………………………………………306

Engine coolant 3-way valve (component not supplied by FPT)……………………………………………………306

TEMPERATURE SENSOR………………………………………………………………………………………………286

507434 TEMPERATURE SENSOR – Overview – Exhaust gas temperature sensor …………………………………………307

Sensor pin-out…………………………………………………………………………………………..308

507434 TEMPERATURE SENSOR – Overview – Air temperature sensor ………………………………………………..309

Sensor pin-out…………………………………………………………………………………………..309

NOX DETECTION SENSOR…………………………………………………………………………………………….286

507435 NOX DETECTION SENSOR – Overview …………………………………………………………………….310

Nitrogen oxide detecting sensor …………………………………………………………………………..310

NOx control unit…………………………………………………………………………………………311

Upstream NOx sensor pin-out……………………………………………………………………………….312

Pin-Out NOx sensor downstream……………………………………………………………………………..312

NOx Sensor………………………………………………………………………………………………312

Technical specifications………………………………………………………………………………….312

NH3 DETECTION SENSOR…………………………………………………………………………………………….286

507437 NH3 DETECTION SENSOR – Overview …………………………………………………………………….314

Ammonia detection sensor NH3………………………………………………………………………………314

Technical specifications………………………………………………………………………………….314

NH3 SENSOR CONTROL UNIT………………………………………………………………………………………….286

507439 NH3 SENSOR CONTROL UNIT – Overview ………………………………………………………………….316

Ammonia detection control unit (NH3)……………………………………………………………………….316

NH3 control unit…………………………………………………………………………………………316

Recommended assembly position……………………………………………………………………………..317

Technical specifications………………………………………………………………………………….317

Pin – out……………………………………………………………………………………………….317

PIPES AND SLEEVES……………………………………………………………………………………………….286

507467 PIPES AND SLEEVES – Overview – Exhaust gas mixer pipe between the turbocharger and DOC catalytic converter ….319

AD-BLUE FILTER………………………………………………………………………………………………….286

507413 AD-BLUE FILTER – Replace …………………………………………………………………………..320

Removal…………………………………………………………………………………………………320

Assembly………………………………………………………………………………………………..322

ELECTRICAL COMPONENTS…………………………………………………………………………………………………..325

ALTERNATOR…………………………………………………………………………………………………………325

ALTERNATOR ASSEMBLY……………………………………………………………………………………………..325

760310 ALTERNATOR ASSEMBLY – Overview ……………………………………………………………………..327

Alternator………………………………………………………………………………………………327

Technical view…………………………………………………………………………………………..327

Characteristic curves…………………………………………………………………………………….327

Characteristics………………………………………………………………………………………….328

ALTERNATOR ASSEMBLY……………………………………………………………………………………………..325

760310 ALTERNATOR ASSEMBLY – Remove ……………………………………………………………………….329

760310 ALTERNATOR ASSEMBLY – Install ………………………………………………………………………330

760310 ALTERNATOR ASSEMBLY – Visual inspection ……………………………………………………………..331

STARTER MOTOR………………………………………………………………………………………………………325

STARTER MOTOR ASSY………………………………………………………………………………………………325

760810 STARTER MOTOR ASSY – Overview ………………………………………………………………………332

Technical view…………………………………………………………………………………………..332

Electric diagram…………………………………………………………………………………………332

Characteristics………………………………………………………………………………………….332

Tightening torques……………………………………………………………………………………….333

STARTER MOTOR ASSY………………………………………………………………………………………………325

760810 STARTER MOTOR ASSY – Remove ………………………………………………………………………..334

760810 STARTER MOTOR ASSY – Install ……………………………………………………………………….335

760810 STARTER MOTOR ASSY – Check …………………………………………………………………………336

Starter motor inspection………………………………………………………………………………….336

COLD START DEVICE…………………………………………………………………………………………………..325

PREHEATER PLUGS…………………………………………………………………………………………………325

761915 PREHEATER PLUGS – Overview …………………………………………………………………………337

Pre-heating glow plugs……………………………………………………………………………………337

Glow plug section pin – out……………………………………………………………………………….337

Glow plug control unit……………………………………………………………………………………338

Technical specifications………………………………………………………………………………….338

Glow plug control unit Pin – Out…………………………………………………………………………..338

PREHEATER PLUGS…………………………………………………………………………………………………325

761915 PREHEATER PLUGS – Remove – Glow plugs bridle …………………………………………………………339

761915 PREHEATER PLUGS – Install – Glow plugs bridle ………………………………………………………..340

BATTERIES………………………………………………………………………………………………………….326

BATTERY………………………………………………………………………………………………………..326

762010 BATTERY – Check – Battery check …………………………………………………………………….341

GAUGES,INDICATORS,SENDERS……………………………………………………………………………………………326

OIL PRESSURE SENDER……………………………………………………………………………………………..326

764251 OIL PRESSURE SENDER – Overview ……………………………………………………………………..342

Low engine oil pressure sensor…………………………………………………………………………….342

Sensor pin-out…………………………………………………………………………………………..342

WATER TEMPERATURE SENDER…………………………………………………………………………………………326

764254 WATER TEMPERATURE SENDER – Overview …………………………………………………………………344

Coolant temperature sensor………………………………………………………………………………..344

Sensor pin-out…………………………………………………………………………………………..344

REV.COUNTER SENDER………………………………………………………………………………………………326

764263 REV.COUNTER SENDER – Overview ………………………………………………………………………345

Crankshaft speed sensor (incremental speed)…………………………………………………………………345

Sensor pin-out…………………………………………………………………………………………..345

CAMSHAFT SPEED SENDER……………………………………………………………………………………………326

764264 CAMSHAFT SPEED SENDER – Overview ……………………………………………………………………346

Camshaft timing sensor (segmental speed)……………………………………………………………………346

Sensor pin-out…………………………………………………………………………………………..346

CTR UNIT,RESIST,FUSES……………………………………………………………………………………………….326

ENGINE DRIVE CONTR.UNIT………………………………………………………………………………………….326

766161 ENGINE DRIVE CONTR.UNIT – Overview ………………………………………………………………….347

electronic control unitEDC 17C49 ………………………………………………………………………….347

Location of the EDC 17C49 control unit connectors …………………………………………………………..348

System functionsEDC 17C49 ………………………………………………………………………………..348

Fuel metering……………………………………………………………………………………………349

Correcting flow rate according to water temperature………………………………………………………….349

De-rating……………………………………………………………………………………………….349

Closed loop injection pressure check……………………………………………………………………….349

Injection advance electronic check…………………………………………………………………………350

Engine speed limiter……………………………………………………………………………………..350

Starting the engine ……………………………………………………………………………………..350

Cold starting……………………………………………………………………………………………350

Warm starting……………………………………………………………………………………………350

Run Up………………………………………………………………………………………………….350

After run……………………………………………………………………………………………….351

Cut-off…………………………………………………………………………………………………351

Cylinder Balancing……………………………………………………………………………………….351

Synchronisation Search……………………………………………………………………………………351

766161 ENGINE DRIVE CONTR.UNIT – Overview – Pin out …………………………………………………………352

Colour key………………………………………………………………………………………………352

Pin Out connector 60 Pin………………………………………………………………………………….352

766161 ENGINE DRIVE CONTR.UNIT – Electrical schema ………………………………………………………….354

EDC 17C49 electric control unit diagram (60 pin connector)……………………………………………………354

KEY…………………………………………………………………………………………………….354

Glow plug pre-heating system electrical connection…………………………………………………………..356

DeNOx 6.5 power supply module electrical connection………………………………………………………….357

NH₃ – NOx system ATS (SCR) sensors electrical connection……………………………………………………..358

ATS (SCR) system temperature sensors electrical connection……………………………………………………359

Pin Out 94 Pin connector for parts not provided by FPT……………………………………………………….360

CABLES AND CONNECTIONS………………………………………………………………………………………………326

ENGINE CABLES…………………………………………………………………………………………………..326

769140 ENGINE CABLES – Overview …………………………………………………………………………..361

Cable on engine………………………………………………………………………………………….361

ENGINE CABLES…………………………………………………………………………………………………..326

769140 ENGINE CABLES – Remove …………………………………………………………………………….363

769140 ENGINE CABLES – Install ……………………………………………………………………………364