$31

Komatsu WD500-3 Dozer Shop Manual SEBMW00300 – PDF DOWNLOAD

Komatsu WD500-3 Dozer Shop Manual SEBMW00300 – PDF DOWNLOAD

FILE DETAILS:

Komatsu WD500-3 Dozer Shop Manual SEBMW00300 – PDF DOWNLOAD

Language : English

Pages : 115

Downloadable : Yes

File Type : PDF

Size: 5.88 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu WD500-3 Dozer Shop Manual SEBMW00300 – PDF DOWNLOAD

GENERAL PRECAUTIONS:

Mistakes in operation are extremely dangerous. Read the Operation and Maintenance Manual carefully BEFORE operating the machine.1 .Before carrying out any greasing or repairs, read all the precautions given on the decals which are fixed to the machine.

2.When carrying out any operation, always wear safety shoes and helmet. Do not wear loose work clothes, or clothes with buttons missing.

- Always wear safety glasses when hitting parts with a hammer.

- Always wear safety glasses when grinding parts with a grinder, etc.

3. If welding repairs are needed, always have a trained, experienced welder carry out the work. When carrying out welding work, always wear welding gloves, apron, glasses, cap and other clothes suited for welding work.4.When carrying out any operation with two or more workers, always agree on the op- erating procedure before starting. Always inform your fellow workers before starting any step of the operation. Before starting work, hang UNDER REPAIR signs on the controls in the operator’s compartment.

TABLE OF CONTENTS:

Komatsu WD500-3 Dozer Shop Manual SEBMW00300 – PDF DOWNLOAD

COVER……………………………………………………………… 1

CONTENTS…………………………………………………………… 2

01 GENERAL…………………………………………………………. 23

GENERAL ASSEMBLY DRAWING…………………………………………. 24

SPECIFICATIONS………………………………………………….. 25

WEIGHT TABLE……………………………………………………. 27

LIST OF LUBRICANT AND WATER………………………………………. 28

10 STRUCTURE AND FUNCTION……………………………………………. 30

WORK EQUIPMENT LEVER LINKAGE……………………………………… 31

HYDRAULIC TANK………………………………………………….. 32

PPC VALVE………………………………………………………. 35

MAIN CONTROL VALVE………………………………………………. 40

WORK EQUIPMENT LINKAGE…………………………………………… 51

MACHINE MONITOR SYSTEM…………………………………………… 53

MAIN MONITOR……………………………………………………. 54

MAINTENANCE MONITOR……………………………………………… 59

ALL-RANGE ELECTRONIC CONTROL AUTOMATIC TRANSMISSION SYSTEM…………… 61

TRANSMISSION CONTROLLER………………………………………….. 71

ELECTRIC TRANSMISSION CONTROL…………………………………….. 73

KICK-DOWN, HOLD SWITCH…………………………………………… 76

20 TESTING AND ADJUSTING…………………………………………….. 77

TABLE OF JUDGEMENT STANDARD VALUE…………………………………. 78

TOOL LIST FOR TESTING AND ADJUSTING……………………………….. 79

MEASURING PITCH, TILT AND LIFT CONTROL LEVERS………………………. 80

ADJUSTING PPC VALVE LINKAGE………………………………………. 81

TESTING AND ADJUSTING PPC OIL PRESSURE…………………………….. 82

TESTING AND ADJUSTING WORK EQUIPMENT HYDRAULIC PRESSURE……………… 84

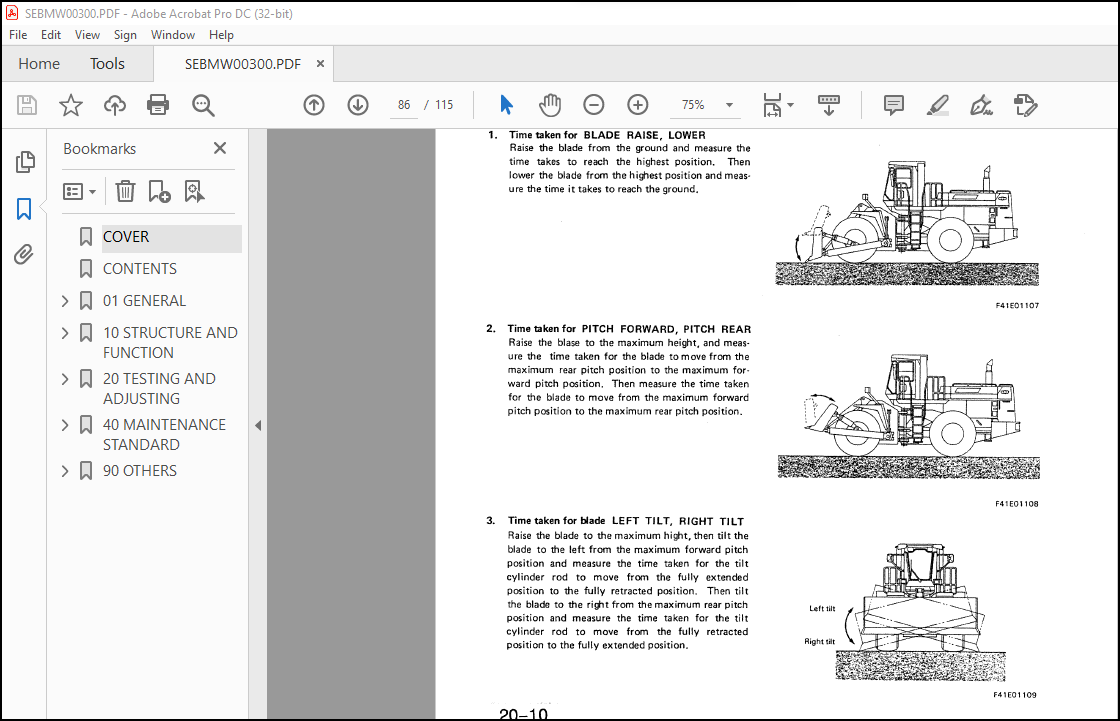

MEASURING WORK EQUIPMENT SPEED……………………………………. 86

MEASURING HYDRAULIC DRIFT OF WORK EQUIPMENT CYLINDER………………… 87

CONNECTOR TYPES AND MOUNTING LOCATIONS…………………………….. 88

H-1 BLADE DOES NOT RISE………………………………………….. 89

H-2 BLADE MOVES SLOWLY OR DOES NOT HAVE SUFFICIENT LIFTING POWER……… 90

H-3 WHEN RAISING BLADE, BECOMES SLOW AT CERTAIN HEIGHT………………. 91

H-4 LIFT CYLINDER CANNOT HOLD DOWN BLADE…………………………… 91

H-5 BLADE HAS LARGE AMOUNT OF HYDRAULIC DRIFT………………………. 91

H-6 BLADE FLUCTUATES WHILE WORKING………………………………… 92

H-7 BLADE DROPS MOMENTARILY WHEN LEVER IS OPERATED FROM HOLD TO RAISE…. 92

H-8 BLADE DOES NOT TILT………………………………………….. 93

H-9 BLADE MOVES SLOWLY OR HAS INSUFFICIENT TILT POWER……………….. 94

H-10 BLADE MOVEMENT BECOMES SLOW DURING TILT……………………….. 95

H-11 LIFT CYLINDER CANNOT HOLD DOWN BLADE………………………….. 95

H-12 BLADE HAS LARGE AMOUNT OF HYDRAULIC DRIFT……………………… 95

H-13 BLADE CONTROL LEVER DO NOT MOVE SMOOTHLY………………………. 96

H-14 BLADE TILT AND BLADE PITCH DO NOT CHANGE………………………. 97

40 MAINTENANCE STANDARD……………………………………………… 98

TRANSMISSION ………………………………………………….. 99

HYDRAULIC PUMP…………………………………………………..103

MAIN CONTROL VALVE……………………………………………….104

HYDRAULIC CYLINDERS………………………………………………106

BLADE…………………………………………………………..108

90 OTHERS…………………………………………………………..112

HYDRAULIC PIPING…………………………………………………113

WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM……………………………114

ELECTRIC CIRCUIT DIAGRAM(TILT AND PITCH CONTROL)…………………….115