$41

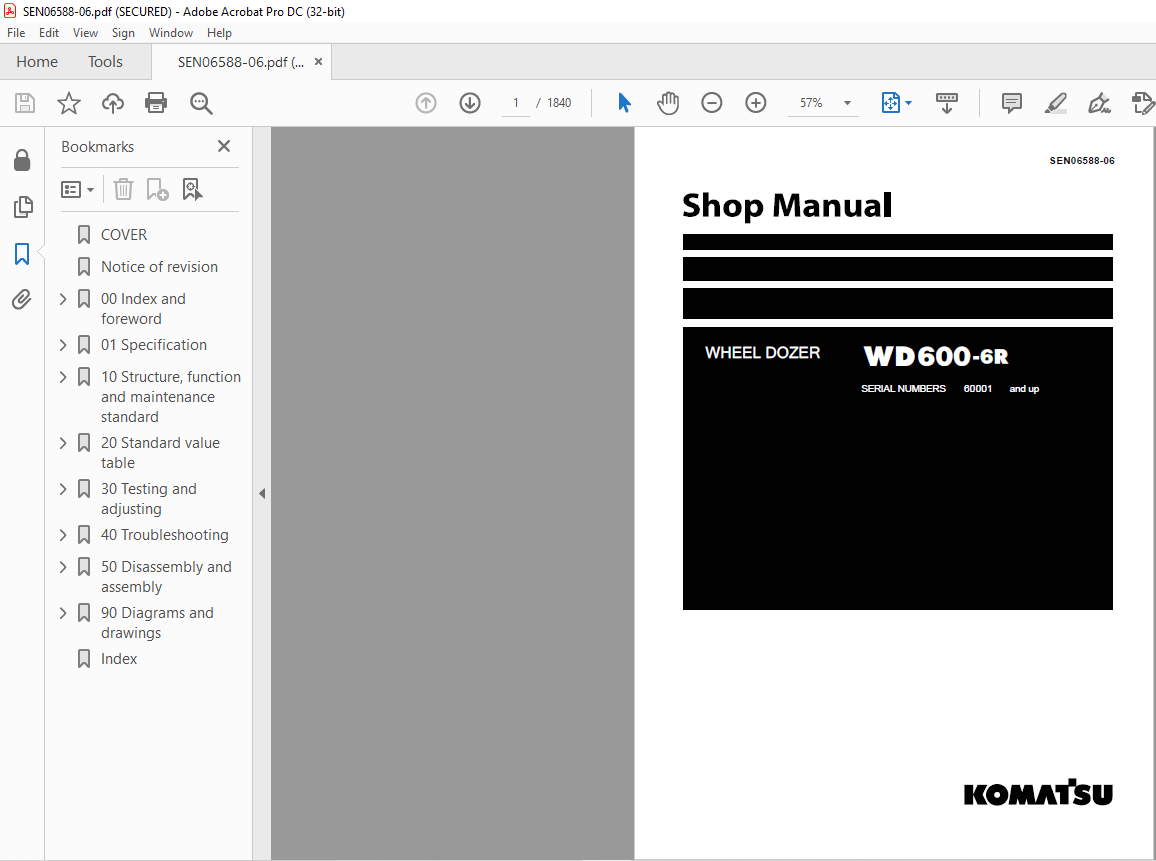

Komatsu WD600-6R Wheel Dozer Shop Manual SEN06588-06 – PDF DOWNLOAD

Komatsu WD600-6R Wheel Dozer Shop Manual SEN06588-06 – PDF DOWNLOAD

FILE DETAILS:

Komatsu WD600-6R Wheel Dozer Shop Manual SEN06588-06 – PDF DOWNLOAD

Language : English

Pages : 1840

Downloadable : Yes

File Type : PDF

Size: 135.6 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Komatsu WD600-6R Wheel Dozer Shop Manual SEN06588-06 – PDF DOWNLOAD

SERIAL NUMBERS 60001 and up

Foreword and general information :

Safety notice :

Important safety notice:

Proper service and repair are extremely important for safe machine operation. The service and repair

techniques recommended by Komatsu and described in this manual are both effective and safe.

Some of these techniques require the use of tools specially designed by Komatsu for the specific

purpose.

To prevent injury to workers, the symbol k is used to mark safety precautions in this manual. The

cautions accompanying these symbols should always be followed carefully. If any dangerous situation

arises or may possibly arise, first consider safety, and take the necessary actions to deal with

the situation.

1. General precautions :

1) Before carrying out any greasing or repairs, read all the safety labels stuck to the machine. For the locations of the safety labels and detailed explanation of precautions, see the Operation and Maintenance Manual.2) Decide a place in the repair workshop to keep tools and removed parts. Always keep the tools and parts in their correct places. Always keep the work area clean and make sure that there is no dirt, water, or oil on the floor. Smoke only in the areas provided for smoking. Never smoke while working.

3) When carrying out any operation, always wear safety shoes and helmet. Do not wear loose work clothes, or clothes with buttons missing.

- Always wear safety glasses when hitting parts with a hammer.

- Always wear safety glasses when grinding parts with a grinder, etc.

4) When carrying out any operation with 2 or more workers, always agree on the operating procedure before starting. Always inform your fellow workers before starting any step of the operation. Before starting work, hang UNDER REPAIR warning signs in the operator’s compartment.5) Only qualified workers must carry out work and operation which require license or qualification. 6) Keep all tools in good condition, learn the correct way to use them, and use the proper ones of them. Before starting work, thoroughly check the tools, machine, forklift, service car, etc.

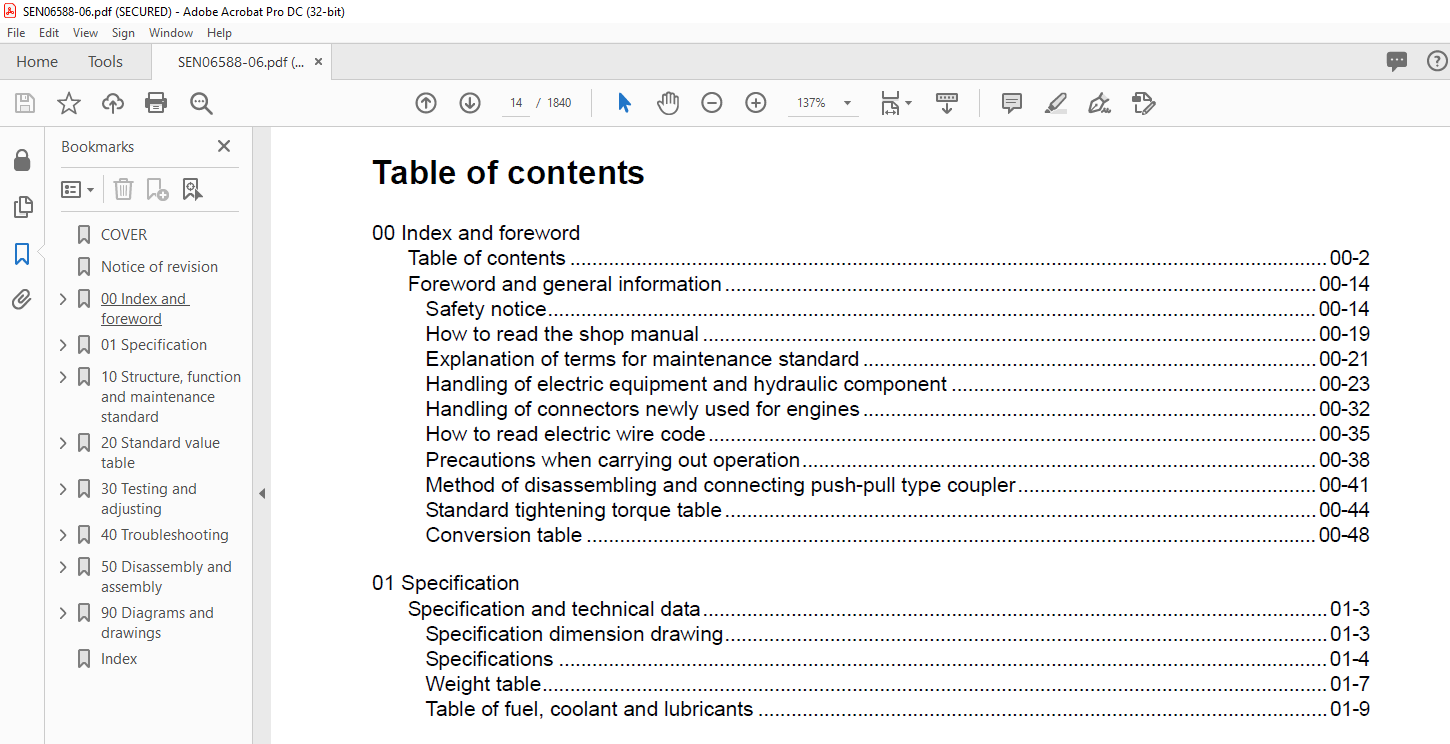

TABLE OF CONTENTS:

Komatsu WD600-6R Wheel Dozer Shop Manual SEN06588-06 – PDF DOWNLOAD

00 Index and foreword

Table of contents ………………………………………………………………………………………………………………………..00-2

Foreword and general information……………………………………………………………………………………………..00-14

Safety notice………………………………………………………………………………………………………………………….00-14

How to read the shop manual …………………………………………………………………………………………………00-19

Explanation of terms for maintenance standard ……………………………………………………………………….00-21

Handling of electric equipment and hydraulic component …………………………………………………………00-23

Handling of connectors newly used for engines ……………………………………………………………………….00-32

How to read electric wire code………………………………………………………………………………………………..00-35

Precautions when carrying out operation…………………………………………………………………………………00-38

Method of disassembling and connecting push-pull type coupler………………………………………………00-41

Standard tightening torque table……………………………………………………………………………………………..00-44

Conversion table ……………………………………………………………………………………………………………………00-48

01 Specification

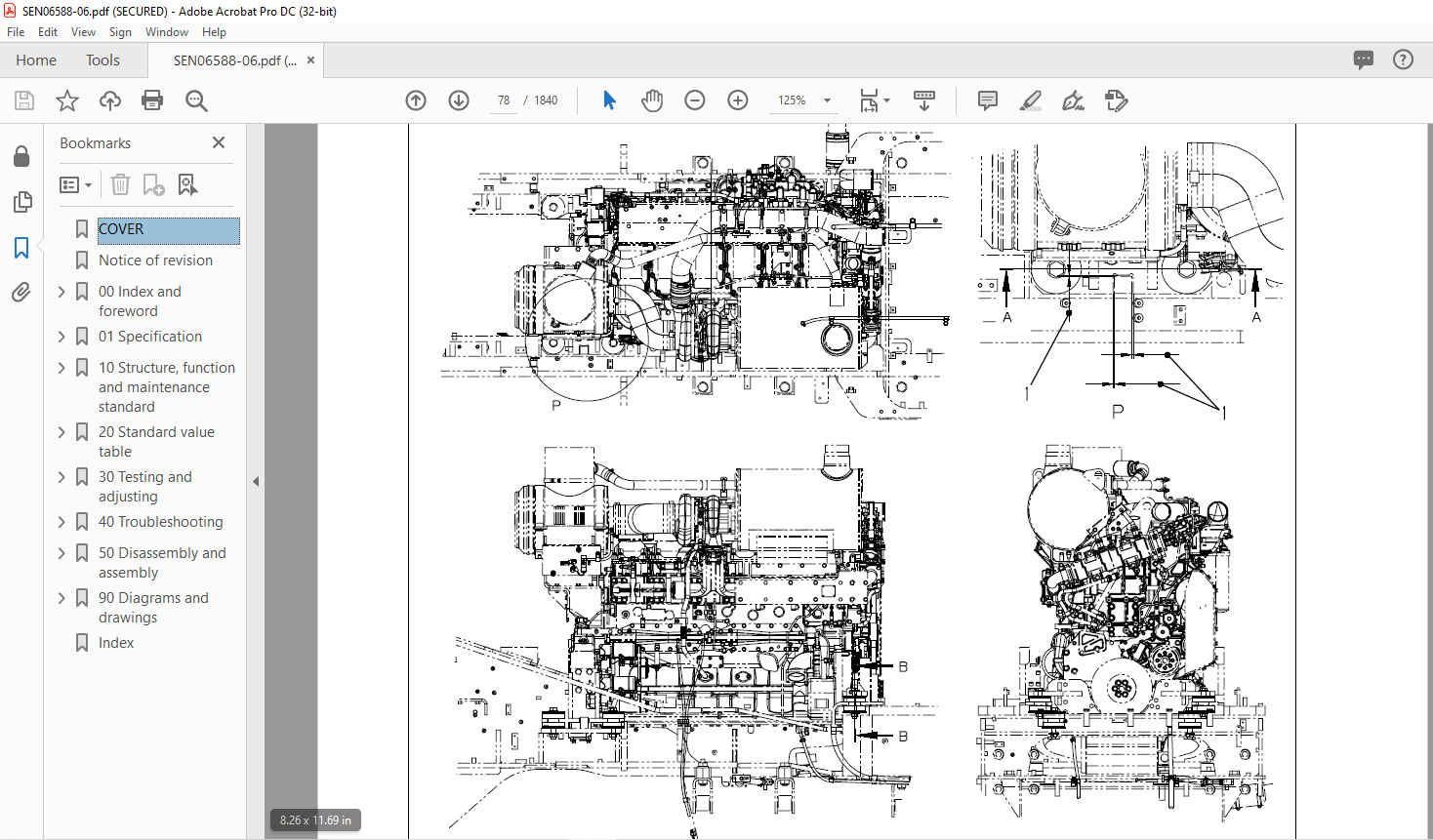

Specification and technical data…………………………………………………………………………………………………..01-3

Specification dimension drawing……………………………………………………………………………………………….01-3

Specifications ………………………………………………………………………………………………………………………….01-4

Weight table…………………………………………………………………………………………………………………………….01-7

Table of fuel, coolant and lubricants ………………………………………………………………………………………….01-9

10 Structure, function and maintenance standard

Engine and cooling system………………………………………………………………………………………………………….10-4

Engine mount and transmission mount……………………………………………………………………………………..10-4

Damper …………………………………………………………………………………………………………………………………..10-6

Cooling system………………………………………………………………………………………………………………………..10-8

Cooling fan pump………………………………………………………………………………………………………………….. 10-12

Cooling fan motor………………………………………………………………………………………………………………….. 10-20

Power train……………………………………………………………………………………………………………………………….10-26

Power train ……………………………………………………………………………………………………………………………10-26

Power train system diagram……………………………………………………………………………………………………10-27

Torque converter and transmission piping diagram…………………………………………………………………..10-28

Torque converter ……………………………………………………………………………………………………………………10-30

Modulation clutch ………………………………………………………………………………………………………………….. 10-39

Torque converter regulator valve …………………………………………………………………………………………….10-40

Transmission …………………………………………………………………………………………………………………………10-42

Transfer…………………………………………………………………………………………………………………………………10-62

Transmission control valve……………………………………………………………………………………………………..10-64

ECMV……………………………………………………………………………………………………………………………………10-66

Main relief valve and torque converter relief valve ……………………………………………………………………10-73

Lubrication relief valve……………………………………………………………………………………………………………10-75

Torque converter oil cooler ……………………………………………………………………………………………………..10-76

Torque converter oil filter ………………………………………………………………………………………………………..10-77

Drive shaft……………………………………………………………………………………………………………………………..10-79

Center support……………………………………………………………………………………………………………………….10-82

Axle ………………………………………………………………………………………………………………………………………10-84

Differential……………………………………………………………………………………………………………………………..10-88

Limited slip differential ……………………………………………………………………………………………………………10-97

Final drive ……………………………………………………………………………………………………………………………10-102

Steering system………………………………………………………………………………………………………………………10-106

Steering piping diagram………………………………………………………………………………………………………..10-106

Steering column ………………………………………………………………………………………………………………….. 10-108

Joystick steering lever linkage ………………………………………………………………………………………………10-109

Joystick EPC valve ……………………………………………………………………………………………………………… 10-110

Lock valve…………………………………………………………………………………………………………………………….10-111

Steering valve……………………………………………………………………………………………………………………… 10-112

WD600-6R 00-3

(05)

00 Index and foreword

Rotary valve …………………………………………………………………………………………………………………………10-115

Steering control valve……………………………………………………………………………………………………………10-118

Two-way restrictor valve ……………………………………………………………………………………………………….10-134

Stop valve ……………………………………………………………………………………………………………………………10-135

Steering pump………………………………………………………………………………………………………………………10-136

Steering cylinder …………………………………………………………………………………………………………………..10-150

Emergency steering piping diagram ………………………………………………………………………………………10-151

Diverter valve……………………………………………………………………………………………………………………….10-152

Emergency steering pump…………………………………………………………………………………………………….10-160

Brake system ………………………………………………………………………………………………………………………….10-162

Brake piping diagram……………………………………………………………………………………………………………10-162

Brake …………………………………………………………………………………………………………………………………..10-164

Brake valve ………………………………………………………………………………………………………………………….10-168

Accumulator charge valve …………………………………………………………………………………………………….10-176

EPC relief valve ……………………………………………………………………………………………………………………10-182

Accumulator (for brake) ………………………………………………………………………………………………………..10-184

Slack adjuster ………………………………………………………………………………………………………………………10-186

Parking brake……………………………………………………………………………………………………………………….10-190

Parking brake solenoid valve…………………………………………………………………………………………………10-192

Emergency parking brake release valve…………………………………………………………………………………10-194

Brake cooling pump ……………………………………………………………………………………………………………..10-195

Undercarriage and frame …………………………………………………………………………………………………………10-196

Axle mount …………………………………………………………………………………………………………………………..10-196

Center hinge pin …………………………………………………………………………………………………………………..10-201

Hydraulic system …………………………………………………………………………………………………………………….10-204

Hydraulic piping diagram ………………………………………………………………………………………………………10-204

Work equipment control lever linkage…………………………………………………………………………………….10-206

Hydraulic tank ………………………………………………………………………………………………………………………10-208

Work equipment pump………………………………………………………………………………………………………….10-210

Control valve………………………………………………………………………………………………………………………..10-230

CLSS…………………………………………………………………………………………………………………………………..10-244

Functions and operation by valve ………………………………………………………………………………………….10-248

Accumulator (for PPC circuit) ………………………………………………………………………………………………..10-258

Triple pump ………………………………………………………………………………………………………………………….10-259

Work equipment………………………………………………………………………………………………………………………10-260

Work equipment linkage ……………………………………………………………………………………………………….10-260

Cutting edge and end bit……………………………………………………………………………………………………….10-263

Work equipment lubrication …………………………………………………………………………………………………..10-265

Hydraulic cylinder …………………………………………………………………………………………………………………10-268

Cab and its attachments…………………………………………………………………………………………………………..10-270

ROPS cab ……………………………………………………………………………………………………………………………10-270

Air conditioner………………………………………………………………………………………………………………………10-272

Electrical system……………………………………………………………………………………………………………………..10-276

Machine monitor system……………………………………………………………………………………………………….10-276

Machine monitor …………………………………………………………………………………………………………………..10-282

Work equipment control system…………………………………………………………………………………………….10-330

Transmission controller system……………………………………………………………………………………………..10-356

Electric transmission control………………………………………………………………………………………………….10-388

Engine starting/stopping circuit ……………………………………………………………………………………………..10-390

Parking brake circuit……………………………………………………………………………………………………………..10-393

Sensor …………………………………………………………………………………………………………………………………10-397

VHMS controller related………………………………………………………………………………………………………..10-418

VHMS controller and wireless LAN system …………………………………………………………………….10-419-1

Electric lever (Work equipment) …………………………………………………………………………………………….10-423

20 Standard value table

Standard service value table………………………………………………………………………………………………………..20-3

Standard service value table for engine……………………………………………………………………………………..20-3

00-4 WD600-6R

(05)

00 Index and foreword

Standard service value table for chassis…………………………………………………………………………………… 20-4

30 Testing and adjusting

Related information on testing and adjusting……………………………………………………………………………….. 30-4

Tools for testing, adjusting, and troubleshooting ……………………………………………………………………….. 30-4

Engine and cooling system…………………………………………………………………………………………………………. 30-9

Measuring engine speed …………………………………………………………………………………………………………. 30-9

Measuring exhaust gas color …………………………………………………………………………………………………. 30-11

Measuring exhaust temperature …………………………………………………………………………………………….. 30-12

Adjusting valve clearance………………………………………………………………………………………………………. 30-14

Testing compression pressures ……………………………………………………………………………………………… 30-16

Measuring blowby pressure …………………………………………………………………………………………………… 30-19

Measuring engine oil pressure……………………………………………………………………………………………….. 30-20

Measuring intake air (boost) pressure…………………………………………………………………………………….. 30-21

Handling fuel system equipment…………………………………………………………………………………………….. 30-22

Releasing residual pressure in fuel system …………………………………………………………………………….. 30-22

Testing fuel pressures……………………………………………………………………………………………………………. 30-23

Testing return rate and leakage ……………………………………………………………………………………………… 30-24

Bleeding air from fuel circuit…………………………………………………………………………………………………… 30-27

Testing leakage in fuel system……………………………………………………………………………………………….. 30-29

Handling reduced cylinder mode operation …………………………………………………………………………….. 30-30

Handling no-injection cranking operation ………………………………………………………………………………… 30-30

Handling controller voltage circuit…………………………………………………………………………………………… 30-31

Replacing and adjusting alternator and air conditioner compressor belt tension………………………… 30-32

Power train………………………………………………………………………………………………………………………………. 30-33

Adjusting modulation clutch speed sensor and speed sensor…………………………………………………… 30-33

Measuring directional lever and gear shift lever (Steering wheel specification)………………………….. 30-35

Testing and adjusting power train oil pressure…………………………………………………………………………. 30-36

Flushing procedure for torque converter and transmission hydraulic circuit ………………………………. 30-50

Method of moving machine when transmission valve is broken ……………………………………………….. 30-52

Moving method of machine disabled by short-to-power failure in work equipment potentiometer .. 30-54

Steering system……………………………………………………………………………………………………………………….. 30-56

Adjusting steering stop valve …………………………………………………………………………………………………. 30-56

Measuring operating effort of AJSS lever (AJSS specification) ………………………………………………… 30-57

Testing and adjusting AJSS lever angle sensor and frame angle sensor (AJSS specification)……. 30-58

Testing and adjusting steering stopper bolt (AJSS specification)………………………………………………. 30-60

Testing and adjusting steering wheel (Steering wheel specification) …………………………………………. 30-62

Testing steering oil pressure ………………………………………………………………………………………………….. 30-64

Bleeding air from steering cylinder circuit ……………………………………………………………………………….. 30-68

Testing hydraulic drive fan……………………………………………………………………………………………………… 30-69

Bleeding air from hydraulic drive fan circuit …………………………………………………………………………….. 30-72

Brake system…………………………………………………………………………………………………………………………… 30-74

Measuring brake pedal ………………………………………………………………………………………………………….. 30-74

Measuring brake performance ……………………………………………………………………………………………….. 30-75

Testing and adjusting accumulator charge pressure………………………………………………………………… 30-76

Testing of accumulator nitrogen gas pressure and procedure for charging brake

accumulator with nitrogen gas ……………………………………………………………………………………………..30-77-1

Testing wheel brake oil pressure ……………………………………………………………………………………………. 30-78

Measuring wear of wheel brake disc ………………………………………………………………………………………. 30-80

Bleeding air from wheel brake circuit………………………………………………………………………………………. 30-81

Releasing residual pressure in brake accumulator circuit ………………………………………………………… 30-82

Testing parking brake performance ………………………………………………………………………………………… 30-83

Measuring parking brake oil pressure …………………………………………………………………………………….. 30-84

Testing wear of parking brake disc …………………………………………………………………………………………. 30-87

Method of releasing parking brake manually …………………………………………………………………………… 30-88

Hydraulic system ……………………………………………………………………………………………………………………… 30-89

Measuring and adjusting work equipment control lever……………………………………………………………. 30-89

Measuring work equipment oil pressure …………………………………………………………………………………. 30-90

WD600-6R 00-5

(05)

00 Index and foreword

Releasing residual pressure in work equipment circuit………………………………………………………. 30-94-1

Bleeding air from work equipment circuit………………………………………………………………………………….30-95

Cab and its attachments…………………………………………………………………………………………………………….30-96

Moving machine for removing operator cab……………………………………………………………………………..30-96

Electrical system……………………………………………………………………………………………………………………….30-98

Preparations for work on troubleshooting of electric system………………………………………………………30-98

Procedure for testing diodes………………………………………………………………………………………………….30-102

Machine monitor-based adjustment at replacement, disassembly and assembly, and additional

installation for each sensor and controller……………………………………………………………………………….. 30-103

Special functions of machine monitor (EMMS) ……………………………………………………………………….30-107

VHMS controller initial setting procedure (ORBCOMM installation specification) …………………….30-176

VHMS controller initial setting procedure (IRIDIUM installation specification)……………………….30-197-1

Precautions for replacing VHMS controller…………………………………………………………………………30-198

Initialization of VHMS wireless LAN modem and downloading of data………………………………..30-203-1

Pm-clinic…………………………………………………………………………………………………………………………………30-204

Pm-clinic inspection table ……………………………………………………………………………………………………..30-204

40 Troubleshooting

Related information on troubleshooting ………………………………………………………………………………………..40-9

Points to remember when performing troubleshooting………………………………………………………………..40-9

How to proceed in troubleshooting ………………………………………………………………………………………….40-11

Testing before troubleshooting ………………………………………………………………………………………………..40-13

Classification and procedures of troubleshooting ……………………………………………………………………..40-14

Failure codes list…………………………………………………………………………………………………………………….40-18

Information in troubleshooting table…………………………………………………………………………………………40-30

Troubleshooting method for disconnecting wiring harness of pressure sensor system………………..40-32

Connection table for connector pin numbers…………………………………………………………………………….40-35

T- branch box and T- branch adapter table ………………………………………………………………………………40-71

Fuse locations………………………………………………………………………………………………………………………..40-74

Troubleshooting by failure code (Display of code) ……………………………………………………………………….40-77

Failure code [1500L0] TORQFLOW transmission: Double meshing…………………………………………..40-77

Failure code [15B0NX] Transmission Oil Filter Clogging …………………………………………………………..40-78

Failure code [15SAL1] ECMV F clutch: When command current is OFF, fill signal is ON…………….40-80

Failure code [15SALH] ECMV F clutch: When command current is ON, fill signal is OFF …………..40-82

Failure code [15SBL1] ECMV R clutch: When command current is OFF, fill signal is ON……………40-84

Failure code [15SBLH] ECMV R clutch: When command current is ON, fill signal is OFF …………..40-86

Failure code [15SEL1] ECMV (1): When command current is OFF, fill signal is ON……………………40-88

Failure code [15SELH] ECMV (1): When command current is ON, fill signal is OFF …………………..40-90

Failure code [15SFL1] ECMV (2): When command current is OFF, fill signal is ON ……………………40-92

Failure code [15SFLH] ECMV (2): When command current is ON, fill signal is OFF …………………..40-94

Failure code [15SGL1] ECMV (3): When command current is OFF, fill signal is ON……………………40-96

Failure code [15SGLH] ECMV (3): When command current is ON, fill signal is OFF…………………..40-98

Failure code [15SHL1] ECMV (4): When command current is OFF, fill signal is ON………………….40-100

Failure code [15SHLH] ECMV (4): When command current is ON, fill signal is OFF…………………40-102

Failure code [15W0NT] Transmission modulation clutch: Overheating …………………………………….40-104

Failure code [2F00MA] Parking brake: Malfunction…………………………………………………………………40-105

Failure code [2G42ZG] Front Accumulator Oil Pressure Low…………………………………………………..40-108

Failure code [2G43ZG] Rear Accumulator Oil Pressure Low…………………………………………………..40-110

Failure code [A000N1] (or VHMS_LED display: “n2” → “01”) Engine: Overrun…………………………40-113

Failure code [AA1ANX] Air Cleaner Clogging …………………………………………………………………………40-114

Failure code [AB00L6] Alternator: Signal disagrees with run and stop of engine ………………………40-116

Failure code [AB00MA] Alternator: Malfunction ………………………………………………………………………40-118

Failure code [B@BAZG] Engine oil pressure: Low error………………………………………………………….40-120

Failure code [B@BAZK] Eng Oil Level Low……………………………………………………………………………40-121

Failure code [B@BCNS] Engine coolant temperature: Overheating…………………………………………40-122

Failure code [B@BCZK] Engine coolant level low…………………………………………………………………..40-124

Failure code [B@C7NS] Brake oil overheating……………………………………………………………………….40-126

Failure code [b@CENS] Torque converter oil overheating ………………………………………………………40-127

00-6 WD600-6R

(05)

00 Index and foreword

Failure code [B@CENS] Torque converter oil overheating……………………………………………………… 40-128

Failure code [B@GAZK] Low Battery Fluid Level ………………………………………………………………….. 40-129

Failure code [B@HANS] Hyd Oil Overheat……………………………………………………………………………. 40-130

Failure code [CA111] Abnormality in engine controller …………………………………………………………… 40-132

Failure code [CA115] Engine Ne or Bkup speed sensor error…………………………………………………. 40-135

Failure code [CA122] Charge (boost) pressure sensor high error …………………………………………… 40-136

Failure code [CA123] Charge (boost) pressure sensor low error…………………………………………….. 40-138

Failure code [CA131] Throttle sensor high error ……………………………………………………………………. 40-140

Failure code [CA132] Throttle sensor low error……………………………………………………………………… 40-143

Failure code [CA135] Engine oil pressure sensor high error…………………………………………………… 40-146

Failure code [CA141] Engine oil pressure sensor low error ……………………………………………………. 40-148

Failure code [CA144] Coolant temperature sensor high error…………………………………………………. 40-150

Failure code [CA145] Coolant temperature sensor low error ………………………………………………….. 40-152

Failure code [CA153] Charge (boost) temperature sensor high error………………………………………. 40-154

Failure code [CA154] Charge (boost) temperature sensor low error ……………………………………….. 40-156

Failure code [CA187] Sensor power supply 2 low error………………………………………………………….. 40-158

Failure code [CA212] Engine oil temperature sensor high error ……………………………………………… 40-160

Failure code [CA213] Engine oil temperature sensor low error……………………………………………….. 40-162

Failure code [CA221] Atmospheric pressure sensor high error ………………………………………………. 40-164

Failure code [CA222] Atmospheric pressure sensor low error………………………………………………… 40-166

Failure code [CA227] Sensor power supply 2 high error ………………………………………………………… 40-168

Failure code [CA234] Engine overspeed ………………………………………………………………………………. 40-169

Failure code [CA238] Ne speed sensor power supply error……………………………………………………. 40-170

Failure code [CA263] Fuel temperature sensor high error ……………………………………………………… 40-172

Failure code [CA265] Fuel temperature sensor low error……………………………………………………….. 40-174

Failure code [CA271] PCV1 Short circuit ………………………………………………………………………………. 40-176

Failure code [CA272] PCV1 Disconnection …………………………………………………………………………… 40-177

Failure code [CA273] PCV2 Short circuit ………………………………………………………………………………. 40-178

Failure code [CA274] PCV2 Disconnection …………………………………………………………………………… 40-179

Failure code [CA322] Injector #1 open/short error …………………………………………………………………. 40-180

Failure code [CA323] Injector #5 open/short error …………………………………………………………………. 40-182

Failure code [CA324] Injector #3 open/short error …………………………………………………………………. 40-184

Failure code [CA325] Injector #6 open/short error …………………………………………………………………. 40-186

Failure code [CA331] Injector #2 open/short error …………………………………………………………………. 40-188

Failure code [CA332] Injector #4 open/short error …………………………………………………………………. 40-190

Failure code [CA342] Calibration code inconsistency…………………………………………………………….. 40-192

Failure code [CA351] Injectors drive circuit error …………………………………………………………………… 40-193

Failure code [CA352] Sensor power supply 1 low error………………………………………………………….. 40-194

Failure code [CA386] Sensor power supply 1 high error ………………………………………………………… 40-196

Failure code [CA431] Idle validation switch error …………………………………………………………………… 40-197

Failure code [CA432] Idle validation action error……………………………………………………………………. 40-200

Failure code [CA441] Battery voltage low error ……………………………………………………………………… 40-203

Failure code [CA442] Battery voltage high error ……………………………………………………………………. 40-204

Failure code [CA449] Common rail pressure high error 2 ………………………………………………………. 40-205

Failure code [CA451] Common rail pressure sensor high error ………………………………………………. 40-206

Failure code [CA452] Common rail pressure sensor low error ……………………………………………….. 40-208

Failure code [CA553] Common rail pressure high error 1 ………………………………………………………. 40-210

Failure code [CA554] Common rail pressure sensor in range error ………………………………………… 40-211

Failure code [CA559] Supply pump pressure very low error 1………………………………………………… 40-212

Failure code [CA689] Engine Ne speed sensor error …………………………………………………………….. 40-216

Failure code [CA731] Engine Bkup speed sensor phase error ……………………………………………….. 40-218

Failure code [CA757] All continuous data lost error ……………………………………………………………….. 40-219

Failure code [CA778] Engine Bkup speed sensor error………………………………………………………….. 40-220

Failure code [CA1633] KOMNET datalink timeout error …………………………………………………………. 40-222

Failure code [CA2185] Throttle sensor supply voltage high error ……………………………………………. 40-224

Failure code [CA2186] Throttle sensor power supply low error ………………………………………………. 40-226

Failure code [CA2249] Supply pump pressure very low error 2………………………………………………. 40-228

Failure code [CA2555] Intake air heater relay open circuit error……………………………………………… 40-230

WD600-6R 00-7

(05)

00 Index and foreword

Failure code [CA2556] Intake air heater relay short circuit error ………………………………………………40-232

Failure code [D191KA] AJSS neutral safety relay open circuit…………………………………………………40-234

Failure code [D191KB] AJSS neutral safety relay short circuit…………………………………………………40-236

Failure code [D198KA] Transmission oil pressure bypass solenoid: Disconnection…………………..40-238

Failure code [D198KB] Transmission oil pressure bypass solenoid: Short circuit………………………40-239

Failure code [D198KY] Transmission oil pressure bypass solenoid: Short circuit with power supply line

……………………………………………………………………………………………………………………………………………40-240

Failure code [D5ZHKA] Terminal C signal open circuit…………………………………………………………….40-242

Failure code [D5ZHKB] Terminal C signal short circuit…………………………………………………………….40-244

Failure code [D5ZHKZ] Terminal C signal open or short circuit………………………………………………..40-246

Failure code [D5ZHL6] Terminal C signal disagrees with run and stop of engine………………………40-248

Failure code [DA80L4] Auto-greasing controller disagrees with ON/OFF signal ……………………….40-250

Failure code [DAF3KK] Machine monitor: Source voltage low (input) ………………………………………40-252

Failure code [DAF5KP] Machine monitor: Output voltage low………………………………………………….40-254

Failure code [DAFRKR] CAN communication with machine monitor: Communication error (Abnormality

in target component system) …………………………………………………………………………………………………40-256

Failure code [DAQ0KK] Transmission controller: Source voltage low ………………………………………40-257

Failure code [DAQ0KT] Transmission controller: Defect in controller ……………………………………….40-260

Failure code [DAQ2KK] Transmission controller load power supply line: Source voltage low (Input)

……………………………………………………………………………………………………………………………………………40-262

Failure code [DAQ9KQ] Transmission controller model selection: Model selection signal disagreement

……………………………………………………………………………………………………………………………………………40-265

Failure code [DAQRKR] CAN communication with transmission controller: Communication error

(Abnormality in target component system)……………………………………………………………………………..40-266

Failure code [DAQRMA] Transmission controller (Option setting): Malfunction…………………………40-271

Failure code [DB2RKR] CAN communication from engine controller: Communication error (Abnormality

in target component system) …………………………………………………………………………………………….40-272

Failure code [DB90KK] Work equipment controller: Source voltage low (input) ………………………..40-275

Failure code [DB90KT] Work equipment controller: Defect in controller……………………………………40-278

Failure code [DB92KK] Work equipment controller load power supply line: Source voltage low (input)

……………………………………………………………………………………………………………………………………………40-279

Failure code [DB95KX] Work equipment controller power supply output: Out of range ……………..40-282

Failure code [DB99KQ] Work equipment controller model selection: Model selection signal disagreement……………………………………………………………………………………………………

……………………………….40-284

Failure code [DB9RKR] CAN communication with work equipment controller: Communication error

(Abnormality in target component system)……………………………………………………………………………..40-285

Failure code [DB9RMA] Work equipment controller (Option setting): Malfunction……………………..40-286

Failure code [DB9RMC] CAN communication with transmission controller: Malfunction ……………40-287

Failure code [DBB0KK] or change of VHMS_LED display from “n9” to “01” (VHMS controller: Source

voltage low (input)) ……………………………………………………………………………………………………………….40-288

Failure code [DBB0KQ] or change of VHMS_LED display from “nF” to “11” (VHMS controller: Disagreement

of model selection signals) …………………………………………………………………………………..40-290

Failure code [DBB3KK] or change of VHMS_LED display from “n9” to “05” (VHMS controller battery

power supply: Source voltage low (input))………………………………………………………………………………40-292

Failure code [DBB5KP] or change of VHMS_LED display from “n9” to “04” (VHMS controller 5 V power

supply output: Output voltage low)…………………………………………………………………………………………40-294

Failure code [DBB6KP] or change of VHMS_LED display from “n9” to “02” (VHMS controller 24V

power supply output: Output voltage low) ………………………………………………………………………………40-296

Failure code [DBB7KP] or change of VHMS_LED display from “n9” to “03” (VHMS controller 12V

power supply output: Output voltage low) ………………………………………………………………………………40-298

Failure code [DBBQKR] or change of VHMS_LED display from “n8” to “02” (CAN communication of

VHMS controller: Communication error (Abnormality in target component system))………………….40-300

Failure code [DD15LD] t switch (Panel switch 1): Switch is kept pressed for long time ……………40-302

Failure code [DD16LD] U switch (Panel switch 2): Switch is kept pressed for long time …………..40-304

Failure code [DD17LD] < switch (Panel switch 3): Switch is kept pressed for long time …………….40-306

Failure code [DD18LD] > switch (Panel switch 4): Switch is kept pressed for long time …………….40-308

Failure code [DDA7L4] RPM set ON/OFF switch: ON-OFF signals disagree ……………………………40-310

Failure code [DDA8KB] RPM set idle-up/down selector switch (idle-up): Short circuit……………….40-312

00-8 WD600-6R

(05)

00 Index and foreword

Failure code [DDA9KB] RPM set idle-up/down selector switch (idle-down): Short circuit………….. 40-315

Failure code [DDB6L4] Parking brake switch (Neutralizer): ON/OFF signals disagree……………… 40-318

Failure code [DDD1LD] Pitch operation switch: Switch is kept pressed for long time……………….. 40-322

Failure code [DDDBKA] Traction adjustment dial: Disconnection……………………………………………. 40-324

Failure code [DDDBKB] Traction adjustment dial: Short circuit……………………………………………….. 40-326

Failure code [DDE5MA] Emergency steering drive switch: Malfunction…………………………………… 40-328

Failure code [DDK4KA] AJSS FNR switch: Disconnection……………………………………………………… 40-330

Failure code [DDK4KB] AJSS FNR switch: Short circuit ………………………………………………………… 40-332

Failure code [DDK5L4] AJSS shift-up/down switch: ON/OFF signals disagree………………………… 40-334

Failure code [DDK6KA] FNR lever switch: Disconnection………………………………………………………. 40-337

Failure code [DDK6KB] FNR lever switch: Short circuit………………………………………………………….. 40-340

Failure code [DDP5KA] Lock detection pressure switch of steering lock lever: Disconnection….. 40-342

Failure code [DDT0L4] Shift mode selector switch: ON/OFF signals disagree…………………………. 40-344

Failure code [DDW9LD] Kick-down switch: Switch is kept pressed for long time……………………… 40-346

Failure code [DDWLLD] Hold switch: Switch is kept pressed for long time ……………………………… 40-348

Failure code [DF10KA] Transmission shift lever switch: Disconnection …………………………………… 40-350

Failure code [DF10KB] Transmission shift lever switch: Short circuit ………………………………………. 40-354

Failure code [DGE5KX] (or VHMS_LED display: “n4” → “01”) Atmospheric temperature sensor: Out of

input signal range………………………………………………………………………………………………………………… 40-356

Failure code [DGF1KA] Transmission oil temperature sensor: Disconnection …………………………. 40-358

Failure code [DGF1KB] Transmission oil temperature sensor: Short circuit …………………………….. 40-360

Failure code [DGH2KX] Hydraulic oil temperature sensor: Out of input signal range ……………….. 40-362

Failure code [DGR2KA] Rear brake oil temperature sensor: Disconnection…………………………….. 40-364

Failure code [DGR2KX] Rear brake oil temperature sensor: Out of input signal range …………….. 40-366

Failure code [DGT1KA] Torque converter oil temperature sensor: Disconnection ……………………. 40-368

Failure code [DGT1KB] Torque converter oil temperature sensor: Short circuit ……………………….. 40-370

Failure code [DGT1KX] Torque converter oil temperature sensor: Out of input signal range)……. 40-372

Failure code [DGT4KA] (or VHMS_LED display: “n3” → “12”) Exhaust gas temperature sensor (F):

Disconnection……………………………………………………………………………………………………………………… 40-374

Failure code [DGT4KB] (or VHMS_LED display: “n3” → “11”) Exhaust gas temperature sensor (F):

Short circuit…………………………………………………………………………………………………………………………. 40-377

Failure code [DGT5KA] (or VHMS_LED display: “n3” → “22”) Exhaust gas temperature sensor (R):

Disconnection……………………………………………………………………………………………………………………… 40-380

Failure code [DGT5KB] (or VHMS_LED display: “n3” → “21”) Exhaust gas temperature sensor (R):

Short circuit…………………………………………………………………………………………………………………………. 40-383

Failure code [DH21KA] Work equipment pump oil pressure sensor: Disconnection…………………. 40-386

Failure code [DH21KB] Work equipment pump oil pressure sensor: Short circuit…………………….. 40-388

Failure code [DHE5KB] (or VHMS_LED display: “n3” → “32”) Blow-by pressure sensor: Short circuit

…………………………………………………………………………………………………………………………………………… 40-390

Failure code [DHE5KY] (or VHMS_LED display: “n3” → “31”) Blow-by pressure sensor: Short circuit

with power supply line………………………………………………………………………………………………………….. 40-392

Failure code [DHT2L6] Transmission filter clogging sensor: Signal disagrees with operating state of

engine ………………………………………………………………………………………………………………………………… 40-394

Failure code [DHT8KX] (or VHMS_LED display: “n5” → “33”) Steering oil pressure sensor: Out of input

signal range………………………………………………………………………………………………………………………… 40-396

Failure code [DHTBKA] Modulation clutch oil pressure sensor: Disconnection………………………… 40-400

Failure code [DHTBKB] Modulation clutch oil pressure sensor: Short circuit……………………………. 40-402

Failure code [DHU2KX] (or VHMS_LED display: “n7” → “11”) Front brake oil pressure sensor (F): Out

of input signal range ……………………………………………………………………………………………………………. 40-404

Failure code [DHU3KX] (or VHMS_LED display: “n7” → “12”) Rear brake oil pressure sensor (R): Out

of input signal range ……………………………………………………………………………………………………………. 40-406

Failure code [DK30KA] AJSS lever angle sensor: Disconnection……………………………………………. 40-408

Failure code [DK30KY] AJSS lever angle sensor: Short circuit with power supply line …………….. 40-410

Failure code [DK59KA] Lift EPC lever potentiometer (Main): Disconnection ……………………………. 40-412

Failure code [DK59KY] Lift EPC lever potentiometer (Main): Short circuit with power supply line 40-416

Failure code [DK59L8] Lift EPC lever potentiometer (Main): Analog signals disagree ……………… 40-418

Failure code [DK5AKA] Lift EPC lever potentiometer (Sub): Disconnection …………………………….. 40-421

Failure code [DK5AKY] Lift EPC lever potentiometer (Sub): Short circuit with power supply line. 40-424

WD600-6R 00-9

(05)

00 Index and foreword

Failure code [DK5BKA] Tilt & pitch EPC lever potentiometer (Main): Disconnection …………………40-426

Failure code [DK5BKY] Tilt & pitch EPC lever potentiometer (Main): Short circuit with power supply line

……………………………………………………………………………………………………………………………………………40-430

Failure code [DK5BL8] Tilt & pitch EPC lever potentiometer (Main): Analog signals disagree……40-432

Failure code [DK5CKA] Tilt & pitch EPC lever potentiometer (Sub): Disconnection…………………..40-435

Failure code [DK5CKY] Tilt & pitch EPC lever potentiometer (Sub): Short circuit with power supply line

……………………………………………………………………………………………………………………………………………40-438

Failure code [DKD0KA] Frame angle sensor: Disconnection …………………………………………………..40-440

Failure code [DKD0KY] Frame angle sensor: Short circuit with power supply line…………………….40-442

Failure code [DKD0KZ] AJSS lever and frame angle sensor: Disconnection or short circuit………40-444

Failure code [DLFAKA] Modulation clutch output shaft speed sensor: Disconnection ……………….40-448

Failure code [DLFALC] Modulation clutch output shaft speed sensor: Speed signals disagree ….40-450

Failure code [DLT3KA] Transmission output shaft speed sensor (2): Disconnection …………………40-452

Failure code [DLT3LC] Transmission output shaft speed sensor (2): Speed signals disagree ……40-454

Failure code [DLT4KB] Transmission output shaft speed sensor (1): Short circuit …………………….40-456

Failure code [DLT4KX] Transmission output shaft speed sensor (1): Out of input signal range….40-458

Failure code [DV00KB] Alarm buzzer: Short circuit …………………………………………………………………40-460

Failure code [DW4PKA] Blade raise EPC solenoid: Disconnection ………………………………………….40-462

Failure code [DW4PKB] Blade raise EPC solenoid: Short circuit……………………………………………..40-464

Failure code [DW4PKY] Blade raise EPC solenoid: Short circuit with power supply line……………40-465

Failure code [DW4QKA] Blade lower EPC solenoid: Disconnection…………………………………………40-466

Failure code [DW4QKB] Blade lower EPC solenoid: Short circuit…………………………………………….40-467

Failure code [DW4QKY] Blade lower EPC solenoid: Short circuit with power supply line…………..40-468

Failure code [DW4RKA] Tilt & pitch EPC solenoid: Disconnection …………………………………………..40-469

Failure code [DW4RKB] Tilt & pitch EPC solenoid: Short circuit ………………………………………………40-470

Failure code [DW4RKY] Tilt & pitch EPC solenoid: Short circuit with power supply line …………….40-471

Failure code [DW4SKA] Tilt & pitch EPC solenoid: Disconnection …………………………………………..40-472

Failure code [DW4SKB] Tilt & pitch EPC solenoid: Short circuit ………………………………………………40-473

Failure code [DW4SKY] Tilt & pitch EPC solenoid: Short circuit with power supply line …………….40-474

Failure code [DW7BKA] Fan reverse solenoid: Disconnection…………………………………………………40-476

Failure code [DW7BKB] Fan reverse solenoid: Short circuit ……………………………………………………40-478

Failure code [DW7BKY] Fan reverse solenoid: Short circuit with power supply line ………………….40-480

Failure code [DWM1KA] Work equipment neutral lock solenoid: Disconnection ……………………….40-482

Failure code [DWM1KB] Work equipment neutral lock solenoid: Short circuit …………………………..40-484

Failure code [DWM1KY] Work equipment neutral lock solenoid: Short circuit with power supply line

……………………………………………………………………………………………………………………………………………40-486

Failure code [DWN7KA] Blade float magnet detent solenoid: Disconnection ……………………………40-488

Failure code [DWN7KB] Blade float magnet detent solenoid: Short circuit ……………………………….40-490

Failure code [DWN7KY] Blade float magnet detent solenoid: Short circuit with power supply line

……………………………………………………………………………………………………………………………………………40-492

Failure code [DWNFKA] Modulation clutch cut-off release solenoid: Disconnection………………….40-494

Failure code [DWNFKB] Modulation clutch cut-off release solenoid: Short circuit……………………..40-496

Failure code [DWNFKY] Modulation clutch cut-off release solenoid: Short circuit with power source line

……………………………………………………………………………………………………………………………………………40-498

Failure code [DX16KA] Fan pump EPC solenoid: Disconnection …………………………………………….40-500

Failure code [DX16KB] Fan pump EPC solenoid: Short circuit ………………………………………………..40-501

Failure code [DX16KY] Fan pump EPC solenoid: Short circuit with power supply line ………………40-502

Failure code [DXA1KA] Pump PC-EPC solenoid: Disconnection……………………………………………..40-503

Failure code [DXA1KB] Pump PC-EPC solenoid: Short circuit ………………………………………………..40-504

Failure code [DXF0KA] AJSS EPC solenoid: Disconnection……………………………………………………40-505

Failure code [DXF0KB] AJSS EPC solenoid: Short circuit……………………………………………………….40-506

Failure code [DXH1KA] Lockup ECMV solenoid: Disconnection………………………………………………40-508

Failure code [DXH1KB] Lockup ECMV solenoid: Short circuit …………………………………………………40-510

Failure code [DXH1KY] Lockup ECMV solenoid: Short circuit with power supply line ……………….40-512

Failure code [DXH4KA] 1st clutch ECMV solenoid: Disconnection…………………………………………..40-514

Failure code [DXH4KB] 1st clutch ECMV solenoid: Short circuit………………………………………………40-516

Failure code [DXH4KY] 1st clutch ECMV solenoid: Short circuit with power supply line ……………40-518

Failure code [DXH5KA] 2nd clutch ECMV solenoid: Disconnection …………………………………………40-520

00-10 WD600-6R

(05)

00 Index and foreword

Failure code [DXH5KB] 2nd clutch ECMV solenoid: Short circuit……………………………………………. 40-522

Failure code [DXH5KY] 2nd clutch ECMV solenoid: Short circuit with power supply line………….. 40-524

Failure code [DXH6KA] 3rd clutch ECMV solenoid: Disconnection…………………………………………. 40-526

Failure code [DXH6KB] 3rd clutch ECMV solenoid: Short circuit…………………………………………….. 40-528

Failure code [DXH6KY] 3rd clutch ECMV solenoid: Short circuit with power supply line…………… 40-530

Failure code [DXH7KA] R clutch ECMV solenoid: Disconnection……………………………………………. 40-532

Failure code [DXH7KB] R clutch ECMV solenoid: Short circuit ………………………………………………. 40-534

Failure code [DXH7KY] R clutch ECMV solenoid: Short circuit with power supply line …………….. 40-536

Failure code [DXH8KA] F clutch ECMV solenoid: Disconnection ……………………………………………. 40-538

Failure code [DXH8KB] F clutch ECMV solenoid: Short circuit……………………………………………….. 40-540

Failure code [DXH8KY] F clutch ECMV solenoid: Short circuit with power supply line……………… 40-542

Failure code [DXHHKA] 4th clutch ECMV solenoid: Disconnection ………………………………………… 40-544

Failure code [DXHHKB] 4th clutch ECMV solenoid: Short circuit ……………………………………………. 40-546

Failure code [DXHHKY] 4th clutch ECMV solenoid: Short circuit with power supply line ………….. 40-548

Failure code [DXHJKA] RH pitch REAR EPC solenoid: Disconnection……………………………………. 40-550

Failure code [DXHJKB] RH pitch REAR EPC solenoid: Short circuit ………………………………………. 40-551

Failure code [DXHJKY] RH pitch REAR EPC solenoid: Short circuit with power supply line …….. 40-552

Failure code [DXHKKA] RH pitch FORWARD EPC solenoid: Disconnection …………………………… 40-553

Failure code [DXHKKB] RH pitch FORWARD EPC solenoid: Short circuit ………………………………. 40-554

Failure code [DXHKKY] RH pitch FORWARD EPC solenoid: Short circuit with power supply line

…………………………………………………………………………………………………………………………………………… 40-555

Failure code [DXHPKA] Modulation clutch solenoid: Disconnection ……………………………………….. 40-556

Failure code [DXHPKB] Modulation clutch solenoid: Short circuit …………………………………………… 40-558

Failure code [DXHPKY] Modulation clutch solenoid: Short circuit with power source line…………. 40-560

Failure code [DXHPMA] Modulation clutch solenoid: Malfunction …………………………………………… 40-562

Failure code [F@BBZL] (or VHMS_LED display: “n3” → “38”) Blow-by pressure: High error ……. 40-564

Failure code [F@BYNR] (or VHMS_LED display: “n3” → “62”) Exhaust gas temperature (F): Abnormal

heat ……………………………………………………………………………………………………………………………………. 40-566

Failure code [F@BYNS] (or VHMS_LED display: “n3” → “61”) Exhaust gas temperature (F): Overheat

…………………………………………………………………………………………………………………………………………… 40-568

Failure code [F@BZNR] (or VHMS_LED display: “n3” → “72”) Exhaust gas temperature (R): abnormal

heat ……………………………………………………………………………………………………………………………………. 40-570

Failure code [F@BZNS] (or VHMS_LED display “n3” → “71”) Exhaust gas temperature (R): Overheat

…………………………………………………………………………………………………………………………………………… 40-572

Troubleshooting of electrical system (E-mode)…………………………………………………………………………. 40-574

E-1 Engine does not start…………………………………………………………………………………………………….. 40-574

E-2 Wiper does not operate …………………………………………………………………………………………………. 40-584

E-3 Windshield washer does not operate ……………………………………………………………………………… 40-592

E-4 Headlamp, clearance lamp, tail lamp, and license lamp do not light up or go off ……………….. 40-598

E-5 Working lamp does not light up or go off…………………………………………………………………………. 40-614

E-6 Step lamp does not light up or go off ………………………………………………………………………………. 40-622

E-7 Turn signal lamp and hazard lamp do not light up or go off………………………………………………. 40-624

E-8 Brake lamp does not light or it keeps lighting up. …………………………………………………………….. 40-634

E-9 Backup lamp does not light or it keeps lighting up. ………………………………………………………….. 40-638

E-10 Backup buzzer does not sound or it keeps sounding……………………………………………………… 40-642

E-11 Horn does not sound or it keeps sounding…………………………………………………………………….. 40-646

E-12 Alarm buzzer does not sound or it keeps sounding ……………………………………………………….. 40-650

E-13 Air conditioner does not operate or stop ……………………………………………………………………….. 40-652

E-14 Electric priming pump does not operate or does not stop automatically ………………………….. 40-654

E-15 When starting switch is turned to ON position, machine monitor displays nothing……………. 40-656

Troubleshooting of hydraulic and mechanical system (H-mode)………………………………………………… 40-660

Method of using troubleshooting chart ………………………………………………………………………………….. 40-660

Table of failure modes and causes ……………………………………………………………………………………….. 40-662

H-1 Machine does not start ………………………………………………………………………………………………….. 40-666

H-2 Torque converter lockup is not switched (engine stalls)……………………………………………………. 40-668

H-3 Torque converter lockup is not turned on………………………………………………………………………… 40-669

H-4 Travel speed is slow, thrusting force is weak, uphill traveling power is weak, and gear is not shifted

…………………………………………………………………………………………………………………………………………… 40-670

WD600-6R 00-11

(05)

00 Index and foreword

H-5 Shocks are large at the times of starting and shifting gear ………………………………………………..40-672

H-6 Time lag is large at the times of starting and shifting gear …………………………………………………40-674

H-7 Torque converter oil temperature is high ………………………………………………………………………….40-676

H-8 Steering does not turn [machine with steering wheel] ……………………………………………………….40-677

H-9 Steering does not turn [machine with AJSS]…………………………………………………………………….40-678

H-10 Turning, response of steering is poor [machine with steering wheel] ……………………………….40-679

H-11 Turning, response of AJSS is poor [machine with AJSS]…………………………………………………40-680

H-12 Steering is heavy [machine with steering wheel] …………………………………………………………….40-681

H-13 When machine turns, it shakes or makes large shocks [machine with steering wheel] ……..40-682

H-14 When machine turns, it shakes or makes large shocks [machine with AJSS] …………………..40-683

H-15 Wheel brake does not work or does not work well ………………………………………………………….40-684

H-16 Wheel brake is not released or it drags………………………………………………………………………….40-685

H-17 Parking brake does not work or does not work well ………………………………………………………..40-686

H-18 Parking brake is not released or it drags (including emergency release system) ………………40-687

H-19 Blade does not rise ………………………………………………………………………………………………………40-688

H-20 Blade speed is low or rising force of lift is insufficient ……………………………………………………..40-689

H-21 When rising, blade comes to move slowly at specific height ……………………………………………40-690

H-22 Lift cylinder cannot hold down blade (Blade floats) …………………………………………………………40-690

H-23 Hydraulic drifts of blade occur often……………………………………………………………………………….40-690

H-24 Blade wobbles during operation…………………………………………………………………………………….40-690

H-25 Blade does not tilt and pitch ………………………………………………………………………………………….40-691

H-26 Blade speed is low or tilt and pitch force is insufficient ……………………………………………………40-692

H-27 Blade comes to operate slowly in the midst of tilt and pitch …………………………………………….40-693

H-28 Tilt & pitch cylinder cannot hold down blade…………………………………………………………………..40-693

H-29 Hydraulic drifts of blade occur often……………………………………………………………………………….40-693

H-30 Blade wobbles during travel when loaded (Work equipment valve is set to “HOLD”) ………..40-693

H-31 During operation of machine, engine speed lowers remarkably or engine stalls ……………….40-694

H-32 Large shocks are made when work equipment starts and stops………………………………………40-694

H-33 When work equipment circuit is relieved singly, other work equipment moves………………….40-694

H-34 Fan speed is abnormal (Fan sound and vibration are abnormally large or engine overheats)

……………………………………………………………………………………………………………………………………………40-695

Troubleshooting of engine (S-mode)…………………………………………………………………………………………40-697

Method of using troubleshooting chart……………………………………………………………………………………40-697

S-1 Engine does not start easily…………………………………………………………………………………………….40-700

S-2 Engine does not start ……………………………………………………………………………………………………..40-701

S-3 Engine does not pick up smoothly …………………………………………………………………………………..40-704

S-4 Engine stops during operation…………………………………………………………………………………………40-705

S-5 Engine does not rotate smoothly (Hunting occurs)……………………………………………………………40-706

S-6 Engine lacks output (or lacks power) ……………………………………………………………………………….40-707

S-7 Exhaust smoke is black (Incomplete combustion)…………………………………………………………….40-708

S-8 Oil is consumed much (or exhaust gas color is blue) ………………………………………………………..40-709

S-9 Engine oil becomes contaminated quickly………………………………………………………………………..40-710

S-10 Fuel consumption is excessive………………………………………………………………………………………40-711

S-11 Coolant contains oil (blows back or reduces) ………………………………………………………………….40-712

S-12 Oil pressure drops ………………………………………………………………………………………………………..40-713

S-13 Oil level rises (Water, fuel in oil) …………………………………………………………………………………….40-714

S-14 Coolant temperature rises too high (Overheating)…………………………………………………………..40-715

S-15 Abnormal noise is made ……………………………………………………………………………………………….40-716

S-16 Vibration is excessive……………………………………………………………………………………………………40-717

S-17 Air cannot be bled from fuel circuit…………………………………………………………………………………40-718

50 Disassembly and assembly

General information on disassembly and assembly ………………………………………………………………………50-4

How to read this manual …………………………………………………………………………………………………………..50-4

Coating materials list………………………………………………………………………………………………………………..50-6

Special tools list ……………………………………………………………………………………………………………………….50-9

Sketches of special tools ………………………………………………………………………………………………………..50-13

00-12 WD600-6R

(05)

00 Index and foreword

Engine and cooling system……………………………………………………………………………………………………….. 50-21

Removal and installation of engine assembly………………………………………………………………………….. 50-21

Removal and installation of radiator assembly ………………………………………………………………………… 50-24

Removal and installation of air aftercooler ………………………………………………………………………………. 50-29

Removal and installation of cooling fan and fan motor assembly ……………………………………………… 50-30

Removal and installation of damper assembly ………………………………………………………………………… 50-32

Disassembly and assembly of damper assembly…………………………………………………………………….. 50-34

Removal and installation of fuel tank assembly……………………………………………………………………….. 50-38

Removal and installation of engine hood assembly …………………………………………………………………. 50-40

Removal and installation of bulkhead assembly………………………………………………………………………. 50-42

Removal and installation of fuel supply pump assembly ………………………………………………………….. 50-46

Removal and installation of cylinder head assembly………………………………………………………………… 50-52

Removal and installation of fuel injector assembly…………………………………………………………………… 50-67

Removal and installation of engine front seal ………………………………………………………………………….. 50-71

Removal and installation of engine rear seal …………………………………………………………………………… 50-74

Power train………………………………………………………………………………………………………………………………. 50-78

Removal and installation of parking brake assembly ……………………………………………………………….. 50-78

Removal and installation of torque converter and transmission assembly…………………………………. 50-80

Disassembly and assembly of torque converter assembly……………………………………………………….. 50-85

Disassembly and assembly of transmission assembly …………………………………………………………… 50-112

Disassembly and assembly of transfer assembly…………………………………………………………………… 50-139

Disassembly and assembly of parking brake assembly …………………………………………………………. 50-154

Removal and installation of front axle assembly ……………………………………………………………………. 50-161

Removal and installation of rear axle assembly …………………………………………………………………….. 50-163

Removal and installation of center support assembly…………………………………………………………….. 50-165

Disassembly and assembly of center support assembly ………………………………………………………… 50-167

Disassembly and assembly of differential assembly………………………………………………………………. 50-171

Removal and installation of final drive carrier assembly …………………………………………………………. 50-185

Disassembly and assembly of final drive carrier assembly …………………………………………………….. 50-187

Removal and installation of front final drive brake assembly…………………………………………………… 50-188

Disassembly and assembly of final drive assembly ……………………………………………………………….. 50-190

Brake system…………………………………………………………………………………………………………………………. 50-193

Disassembly and assembly of brake assembly……………………………………………………………………… 50-193

Removal and installation of brake valve assembly…………………………………………………………………. 50-201

Disassembly and assembly of accumulator and charge valve assembly…………………………………. 50-202

Disassembly and assembly of slack adjustor assembly …………………………………………………………. 50-205

Undercarriage and frame………………………………………………………………………………………………………… 50-207

Removal and installation of center hinge pin …………………………………………………………………………. 50-207

Removal and installation of counterweight assembly …………………………………………………………….. 50-214

Hydraulic system ……………………………………………………………………………………………………………………. 50-215

Removal and installation of hydraulic tank assembly……………………………………………………………… 50-215

Removal and installation of hydraulic pump assembly …………………………………………………………… 50-217

Removal and installation of control valve assembly……………………………………………………………….. 50-221

Disassembly and assembly of control valve assembly …………………………………………………………… 50-223

Removal and installation of steering valve assembly……………………………………………………………… 50-228

Disassembly and assembly of hydraulic cylinder assembly ……………………………………………………. 50-229

Work equipment …………………………………………………………………………………………………………………….. 50-234

Removal and installation of work equipment assembly ………………………………………………………….. 50-234

Cab and its attachments …………………………………………………………………………………………………………. 50-238

Removal and installation of operator’s cab assembly …………………………………………………………….. 50-238

Removal and installation of operator’s cab glass (stuck glass) ……………………………………………….. 50-242

Removal and installation of floor frame assembly………………………………………………………………….. 50-250

Disassembly and assembly of operator’s seat assembly ……………………………………………………….. 50-253

Removal and installation of air conditioner unit assembly ………………………………………………………. 50-286

Removal and installation of AJSS lever switch assembly……………………………………………………..50-288-1

Electrical system ……………………………………………………………………………………………………………………. 50-289

Removal and installation of engine controller assembly …………………………………………………………. 50-289

Removal and installation of transmission controller assembly ………………………………………………… 50-291

WD600-6R 00-13

(05)

00 Index and foreword

Removal and installation of loader controller assembly …………………………………………………………..50-291

Removal and installation of VHMS controller assembly…………………………………………………………..50-292

Removal and installation of machine monitor assembly ………………………………………………………….50-293

90 Diagrams and drawings

Hydraulic diagrams and drawings ………………………………………………………………………………………………..90-3

Symbols used in hydraulic circuit diagrams ……………………………………………………………………………….90-3

Power train hydraulic circuit diagram…………………………………………………………………………………………90-5

Brake hydraulic circuit diagram…………………………………………………………………………………………………90-6

Work equipment hydraulic circuit diagram…………………………………………………………………………………90-9

Electrical diagrams and drawings……………………………………………………………………………………………….90-11

Symbols used in electric circuit diagrams…………………………………………………………………………………90-11

Air conditioner electrical circuit diagram…………………………………………………………………………………. 90-15

Electrical circuit diagram …………………………………………………………………………………………………………… 90-17

KOMTRAX electrical circuit diagram (GPRS type) ………………………………………………………………….. 90-37

Connector list and layout ………………………………………………………………………………………………………. 90-39

Index ……………………………………………………………………………………………………………………………………… 1