$45

Kramer Allrad Telehandler 2506 Service Manual PDF DOWNLOAD

Kramer Allrad Telehandler 2506 Service Manual

FILE DETAILS:

Kramer Allrad Telehandler 2506 Service Manual

Language : English

Pages : 420

Downloadable : YES

Format : PDF

Size : 18.0 MB

TABLE OF CONTENTS:

Kramer Allrad Telehandler 2506 Service Manual

1 Cab overview, use, operation

1 1 Machine outside view 1-2

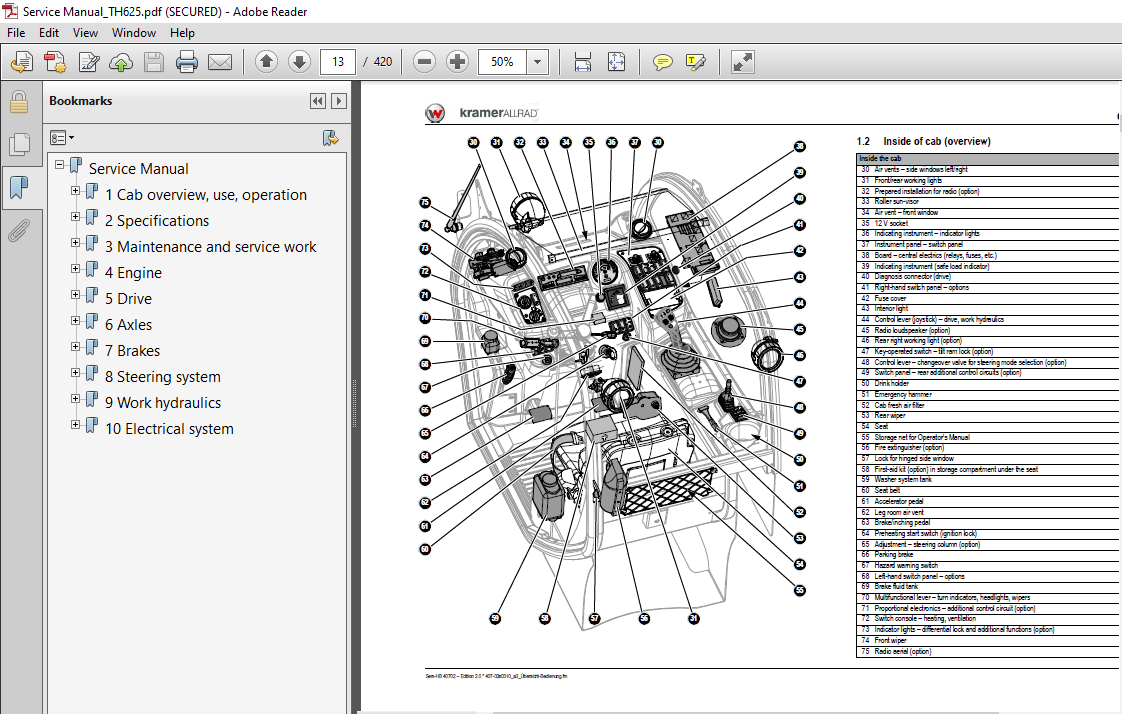

1 2 Inside of cab (overview) 1-3

1 3 Instrument panel, multifunctional lever, switch consoles (overview) 1-4

1 4 Fields of application and using a machine with an attachment 1-5

1 5 Legal regulations regarding machine operation 1-6

1 6 Type labels and component numbers 1-8

1 7 Key-based drive interlock (option) 1-11

1 8 Drive interlock with code input (option) 1-13

1 9 Battery master switch (option) 1-16

1 10 Avoiding running the engine under low-load conditions 1-17

1 11 Stopping the diesel engine 1-17

1 12 Jump-starting the diesel engine (external battery) 1-18

1 13 Pressure relief on the quickhitch couplers 1-19

1 14 Overview of steering modes (option) 1-20

1 15 Steering synchronisation (wheels front/rear axles) 1-21

1 16 Low-speed control (option) 1-23

1 17 Rear hydraulic additional control circuit (option) 1-24

1 18 Hydraulic connection for tipping trailer (option) 1-26

1 19 Autohitch trailer coupling (option) 1-27

1 20 Automatic trailer coupling (option) 1-29

1 21 Hydraulic trailer brake connection (option) 1-31

1 22 Fitting attachments from other manufacturers (option) 1-32

1 23 Towing the machine 1-35

2 Specifications

2 1 Model and trade names (overview) 2-2

2 2 Frame 2-2

2 3 Diesel engine 2-2

2 4 Drive 2-3

2 5 Axles 2-4

2 6 Service and parking brake (disc brake) 2-5

2 7 Steering system 2-5

2 8 Work hydraulics 2-6

2 9 Electrical system 2-8

2 10 Tyres 2-11

2 11 Machine weight, axle loads 2-11

2 12 Trailer couplings: trailer weight/drawbar load 2-12

2 13 Sound levels, noise 2-12

2 14 Vibrations, oscillation and acceleration values 2-13

2 15 Coolant compound table 2-13

2 16 Tightening torques 2-14

2 17 Standard bucket payloads 2-14

2 18 Pallet forks payloads 2-15

2 19 Dimensions with standard bucket 2-17

2 20 Dimensions with pallet forks 2-18

Inhaltverzeichnis

I-2 Serv-HB 40702 – Ausgabe 2 0 * 407-02s_20_enIVZ fm

Inhaltverzeichnis

3 Maintenance and service work

3 1 Explanation of symbols on the maintenance label 3-2

3 2 Maintenance label 3-3

3 3 Fluids and lubricants 3-4

3 4 Maintenance plan (overview) 3-5

3 5 Important notice regarding maintenance work 3-9

3 6 Safety strut for telescopic boom 3-10

3 7 Fuel system 3-11

3 8 Refuelling 3-12

3 9 Checking/cleaning the additional fuel filter (water separator, option) 3-12

3 10 Bleeding the fuel system 3-13

3 11 Replacing the fuel filter 3-14

3 12 Diesel engine lubrication system 3-15

3 13 Filling up engine oil 3-16

3 14 Change the engine oil 3-17

3 15 Replacing the engine oil filter cartridge 3-18

3 16 Diesel engine and hydraulics cooling system 3-19

3 17 Temperature gauge: diesel engine coolant 3-20

3 18 Filling up coolant 3-21

3 19 Cleaning the radiator fins 3-22

3 20 Draining coolant 3-23

3 21 Air filter 3-24

3 22 Replacing the filter cartridge 3-25

3 23 V-belts 3-26

3 24 Hydraulic system 3-27

3 25 Monitoring the hydraulic oil and the return filter indicator lights 3-28

3 26 Checking the hydraulic oil level once a day 3-29

3 27 Filling up hydraulic oil 3-29

3 28 Changing the filter insert 3-30

3 29 Replacing hydraulic oil 3-31

3 30 Important notices on the use of biodegradable oil 3-32

3 31 Checking hydraulic pressure lines 3-33

3 32 Oil levels: rear axle transfer gearbox 3-34

3 33 Oil levels: front and rear axle differentials 3-35

3 34 Oil levels: front and rear axle planetary drives 3-36

3 35 Lubrication work 3-37

3 36 Lubrication points on the telescopic boom (overview) 3-38

3 37 Lubricating with the central lubrication system (option) 3-40

3 38 Setting the lubrication and break times 3-41

3 39 Central lubrication system diagram 3-42

3 40 Installing the high-pressure hoses on the central lubrication system 3-43

3 41 Instructions for troubleshooting in case of central lubrication system blocking 3-44

3 42 Repairing a blocking distributor of the central lubrication system 3-45

3 43 Troubleshooting table for central lubrication system 3-46

3 44 Maintenance of the brake system 3-47

3 45 Tyres 3-48

3 46 Changing wheels 3-49

3 47 Heating/cab ventilation 3-50

3 48 Air conditioning (option): maintenance 3-51

3 49 Functional and visual checks of the air conditioning 3-52

3 50 Cleaning the heat exchanger (condenser) 3-53

3 51 Maintenance of the electrical system 3-54

3 52 Maintenance of the automatic trailer coupling (option) 3-58

3 53 General maintenance and cleaning work 3-59

3 54 Maintenance of attachments and of the work equipment 3-61

Serv-HB 40702 – Ausgabe 2 0 * 407-02s_20_enIVZ fm I-3

Inhaltverzeichnis

4 Engine

4 1 Diesel engine diagrams 4-2

4 2 Diagnosis/fuel preheater (electrical diagrams) 4-4

4 3 Manual throttle diagrams 4-6

4 4 Engine designation 4-7

4 5 Fuel specification 4-7

4 6 Coolant specification 4-7

4 7 Diesel engine TD 2009 L04 (overview) 4-8

4 8 Electric components on engine (overview) 4-9

4 9 Lube oil circuit 4-10

4 10 Cooling 4-11

4 11 Adjusting the cable pull for speed regulation 4-12

4 12 Fuel system 4-13

4 13 Replacing the cylinder head gasket 4-14

4 14 Removing/installing the fuel injection pump 4-17

4 15 Mounting the fuel injection pump 4-19

4 16 Removing/installing the fuel injectors 4-20

4 17 Sealing the coolant pump 4-21

4 18 Removing/installing the thermostat 4-21

4 19 Checking the thermostat 4-22

4 20 Assembly instructions: replacing the Visco clutch 4-23

4 21 Tightening torque table 4-26

4 22 Diesel engine malfunctions 4-28

I-4 Serv-HB 40702 – Ausgabe 2 0 * 407-02s_20_enIVZ fm

Inhaltverzeichnis

5 Drive

5 1 Drive (hydraulic diagram) 5-2

5 2 Drive diagrams 5-4

5 3 Making settings with the laptop 5-5

5 4 Error: Incorrect Tool Key 5-8

5 5 Importing new data 5-9

5 6 Drive electronics PLUS+1 mode description 5-11

5 7 Reading out/deleting the error history 5-12

5 8 Deleting the error history 5-13

5 9 Switching the inching potentiometer ON/OFF 5-14

5 10 Reading in the inching potentiometer again 5-15

5 11 Reading in the inching potentiometer 5-16

5 12 Switching the creep gear potentiometer ON/OFF 5-17

5 13 Switching ON the creep gear potentiometer 5-18

5 14 Reading in the creep gear potentiometer 5-19

5 15 Modifying the load stabiliser settings 5-20

5 16 Error code table 5-21

5 17 Towing and transporting the machine 5-23

5 18 Hydraulic pump H1 (model 407 02) test ports and HP valves (overview) 5-23

5 19 Hydraulic pump H1 (model 407 02) proportional valve and electronics

(overview) 5-24

5 20 Variable displacement motor H1 110 cm3/rev (overview) 5-25

5 21 Variable displacement motor H1B (overview) 5-26

5 22 Model 407 02 test report 5-27

5 23 Error description for test report model 407 02 5-28

5 24 Drive with hydraulic pump H1 (hydraulic circuit) 5-29

5 25 Checking the idling speed 5-30

5 26 Checking/adjusting starting speed 5-31

5 27 Adjusting boost pressure 5-32

5 28 Checking high pressure 5-33

5 29 Checking driving direction identification 5-34

5 30 Checking the energisation of the driving direction identification 5-35

5 31 Checking engine droop (variable displacement pump) 5-36

5 32 Setting the pump droop speed 5-37

5 33 Setting engine droop/control initiation of the hydraulic motor 5-38

5 34 Setting maximum speed 5-39

5 35 Troubleshooting boost-pressure errors (diagram) 5-40

5 36 Checking high pressure (HP valves) 5-41

5 37 Checking pump engine droop, driving direction identification, differential pressure measurement 5-42

6 Axles

6 1 Differential lock diagrams 6-2

6 2 Axle type label 6-3

6 3 Front axle screw connections 6-4

6 4 Rear axle screw connections 6-5

6 5 Drain, fill and check plug – front axle 6-6

6 6 Drain, fill and check plug – rear axle 6-7

6 7 Front axle tightening torques (Nm) 6-8

6 8 Rear axle tightening torques (Nm) 6-9

6 9 Sealing work 6-10

Serv-HB 40702 – Ausgabe 2 0 * 407-02s_20_enIVZ fm I-5

Inhaltverzeichnis

7 Brakes

7 1 Brake diagrams 7-2

7 2 Brakes (hydraulic diagram) 7-4

7 3 Brake circuit 7-5

7 4 Trailer brake valve circuit 7-6

7 5 Service brake function 7-7

7 6 Parking brake circuit 7-8

7 7 Service brake 7-9

7 8 Sealing the brake calliper 7-10

7 9 Bleeding the brake system with bleed equipment 7-12

7 10 Setting the brake pedal with the inching potentiometer 7-13

8 Steering system

8 1 Steering system (hydraulic diagram) 8-2

8 2 Steering circuit with final-position synchronisation 8-3

8 3 Steering circuit with front, 4 wheel and crab steering 8-4

8 4 Steering system adjustment 8-5

8 5 Hydraulic ports on servostat 8-5

8 6 Pressure relief valve: adjustment 8-5

8 7 Sealing steering rams 8-6

8 8 Sealing steering rams 8-7

8 9 Checking the steering mode valve 8-8

8 10 Checking a steering ram 8-9

8 11 Overview of steering ram setting 8-9

8 12 How to check and set the steering rams 8-10

8 13 Checking the track setting (1) 8-11

8 14 Correcting the track setting (2) 8-11

8 15 Steering misalignment during final-position synchronisation (3) 8-12

8 16 Adjustment work 8-13

8 17 Checking steering synchronisation (4) 8-14

I-6 Serv-HB 40702 – Ausgabe 2 0 * 407-02s_20_enIVZ fm

Inhaltverzeichnis

9 Work hydraulics

9 1 20 kph 4-fold control valve (hydraulic diagram) 9-2

9 2 30 kph 5-fold control valve (hydraulic diagram) 9-4

9 3 Hydraulics legend 9-5

9 4 Raising/lowering (diagrams) 9-8

9 5 Raising/lowering the telescopic boom (hydraulic diagram) 9-10

9 6 Raising/lowering the telescopic boom, load stabiliser (hydraulic diagram) 9-12

9 7 Dumping in/out, tilt ram lock (electrical diagrams) 9-14

9 8 Dumping out (hydraulic diagram) 9-16

9 9 Tilt ram lock (hydraulic diagram) 9-18

9 10 Extending/retracting the telescopic boom (black/white) (electrical diagrams) 9-20

9 11 Extending/retracting the telescopic boom/proportional (electrical diagrams) 9-22

9 12 Retracting/extending the telescopic boom (hydraulic diagram) 9-24

9 13 Locking/unlocking the quickhitch (black/white) (electrical diagrams) 9-26

9 14 Quickhitch diagram designations (black/white, lock/unlock) 9-27

9 15 Locking/unlocking the quickhitch proportionally (electrical diagrams) 9-30

9 16 Quickhitch diagram designations (proportional, lock/unlock) 9-31

9 17 Locking (hydraulic diagram) 9-34

9 18 Locking/additional control circuit (hydraulic diagram) 9-36

9 19 Locking/return without pressure (hydraulic diagram) 9-38

9 20 Safe load indicator (electrical diagrams) 9-40

9 21 Overload cutoff (hydraulic diagram) 9-42

9 22 Load stabiliser (electrical diagrams) 9-44

9 23 Additional control circuit/tipping trailer (hydraulic diagram) 9-46

9 24 Tipping trailer (hydraulic diagram) 9-48

9 25 Autohitch (hydraulic diagram) 9-50

9 26 Autohitch/tipping trailer (hydraulic diagram) 9-52

9 27 Additional function (electrical diagrams) 9-54

9 28 Autohitch/additional control circuit/tipping trailer (hydraulic diagram) 9-56

9 29 Test report for hydraulics 407-02 (2506) 9-57

9 30 Work hydraulics oil supply 9-58

9 31 Pump pressure/work hydraulics test port 9-59

9 32 Control valve (overview) 9-60

9 33 Control valve design 9-61

9 34 Checking and setting the work hydraulics 9-62

9 35 7-fold pilot valve (overview) 9-63

9 36 4-fold pilot valve (overview) 9-64

9 37 Pilot control circuit 9-65

9 38 Load stabiliser circuit 9-66

9 39 Lift ram circuit 9-67

9 40 Tilt ram circuit 9-68

9 41 3rd control circuit 9-69

9 42 Circuit: additional control circuít and rear tipping trailer 9-70

9 43 Tilt ram lock circuit 9-71

9 44 Circuit: Autohitch and tipping trailer ports 9-72

9 45 Overload cutoff circuit 9-73

9 46 Load stabiliser 9-74

9 47 Valve for tilt ram lock 9-76

9 48 Tipping trailer and additional control circuit valve 9-76

9 49 Work hydraulics/steering system priority valve 9-77

9 50 Valves (general overview) 9-77

9 51 Lift ram (sealing work) 9-78

9 52 Tilt ram (sealing work) 9-79

9 53 Push-out ram 9-80

9 54 Compensating ram 9-81

9 55 Control ram (quickhitch frame) (sealing work) 9-82

9 56 Lift, tilt and push-out rams: velocity 9-83

Serv-HB 40702 – Ausgabe 2 0 * 407-02s_20_enIVZ fm I-7

Inhaltverzeichnis

9 57 Usable consumer pressure at additional control circuit (option) 9-83

9 58 Overload control (“Smart Handling”) 9-84

9 59 Overview of safe load indicator 9-90

9 60 Setting the safe load indicator (0 % point) 9-90

9 61 Setting the safe load indicator (100 % point stability) 9-91

9 62 Inspection plan for overload control (model 407 telehandler) 9-93

9 63 Testing without any load 9-93

9 64 Testing with load 9-95

9 65 Functional description of overload control (Smart Handling) 9-97

9 66 Electric components 9-98

9 67 Circuit diagram: overload control enabled 9-99

9 68 Circuit diagram: automatic retraction OFF 9-100

9 69 Overview of valves 9-101

9 70 Overview of valve connections and ports 9-101

9 71 Circuit diagram: overload control 9-102

9 72 Circuit diagram legend 9-103

9 73 Extend (solenoid valve Y102) (circuit diagram) 9-104

9 74 Pallet forks mode (circuit diagram) 9-105

9 75 Tip switch S084 pressed (circuit diagram) 9-106

9 76 Electric components 9-107

9 77 Overload control relay 9-108

9 78 Installation position: overload control relay 9-109

I-8 Serv-HB 40702 – Ausgabe 2 0 * 407-02s_20_enIVZ fm

Inhaltverzeichnis

10 Electrical system

10 1 Lights (diagrams) 10-2

10 2 Working lights (diagrams) 10-4

10 3 Turn indicators/horn/rotating beacon (diagrams) 10-6

10 4 Window heating/front socket (electrical diagrams) 10-8

10 5 Wipe/wash system (electrical diagrams) 10-10

10 6 Seat/air conditioning system (diagrams) 10-12

10 7 Multimedia/monitoring/cigarette lighter (electrical diagrams) 10-14

10 8 Cab wiring harness 1000256306-01 10-16

10 9 Cab wiring harness legend 10-17

10 10 Engine wiring harness 1000245802 10-22

10 11 Engine wiring harness legend 10-23

10 12 Frame wiring harness 1000256307 10-26

10 13 Frame wiring harness (legend) 10-27

10 14 Cab wiring harness (overload control) 10-30

10 15 Cab wiring harness legend 10-31

10 15 Frame wiring harness (overload control) 10-34

10 16 Frame wiring harness (overload control) (legend) 10-35

10 17 Ohm’s Law (current, voltage, resistance); power 10-36

10 18 Measuring equipment, measuring methods 10-36

10 19 Terminal description 10-37

10 20 Colour coding of electric lines 10-41

10 21 Switching relay function 10-43

10 22 Fuse assignment 10-44

10 23 Switching relay assignment on board 10-45

10 24 Switching relay assignment on bracket 10-45

10 25 Main fuse box with relays in the engine compartment 10-46

10 26 Electric units 10-46

10 27 Connector description (overview) 10-46

10 28 Switch assignment on board (overview) 10-47

10 29 Switch assignment on instrument panel (overview) 10-48

10 30 Control lever (black/white control) 10-49

10 31 Joystick (black/white function) 10-50

10 32 Joystick: retracting/extending the telescopic boom (black/white) 10-51

10 33 Joystick: unlocking/locking the telescopic boom (black/white) 10-52

10 34 Control lever (proportional control) 10-53

10 35 Joystick (proportional function) 10-54

10 36 Joystick: retracting/extending the telescopic boom (proportional) 10-55

10 37 Joystick: unlocking/locking the telescopic boom (proportional) 10-56

10 38 Additional control circuit with potentiometer (proportional) 10-57

10 39 Proportional controls connector assignment (overview) 10-58

10 40 Proportional controls (overview and connections) 10-58

10 41 Retrofitting a rotating beacon 10-59

10 42 Retrofitting the backup warning system 10-59

10 43 Retrofitting 2 front working lights 10-59

10 44 Retrofitting 2 rear working lights 10-60

10 45 Retrofitting a rear 7-pole socket 10-60

10 46 Retrofitting a front 4-pole socket 10-60

10 47 Retrofitting 2 working lights on the telescopic boom (from mid 2011) 10-61

IMAGES PREVIEW OF THE MANUAL: