$42

Kubota Tractor M7001 Workshop Manual – PDF DOWNLOAD

Kubota Tractor M7001 Workshop Manual – PDF DOWNLOAD

FILE DETAILS:

Kubota Tractor M7001 Workshop Manual – PDF DOWNLOAD

Language : English

Pages : 1661

Downloadable : Yes

File Type : PDF

Size: 329 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Kubota Tractor M7001 Workshop Manual – PDF DOWNLOAD

TO THE READER:

This Workshop Manual tells the servicing personnel about the mechanism, servicing and maintenance of the Ml-131,

Ml-151 and Ml-171 . It contains 4 parts: “Information”, “General”, “Mechanism” and “Servicing”.

Information

This section primarily contains information below.

• Safety first

• Safety decal

• Specifications

• Dimensions

General

This section primarily contains information below.

• Engine identification

• Model identification

• General precautions

• Maintenance check list

• Check and maintenance

• Special tools

Mechanism

This section contains information on the structure and the function of the unit. Before you continue with the

subsequent sections, make sure that you read this section.

Servicing

This section primarily contains information below.

• Troubleshooting

• Servicing specifications

• Tightening torques

• Checking, disassembling and servicing

All illustrations, photographs and specifications contained in this manual are of the newest information available at the

time of publication.

Kubota reserves the right to change all information at any time without notice.

Since this manual includes many models, information or illustrations and photographs can show more than one

model.

<Related document>

• DIESEL ENGINE MECHANISM (PDF file in Kubota web site: 9Y011-01870)

• TRACTOR MECHANISM (PDF file in Kubota web site: 9Y011-18200)

• DIAGNOSIS MANUAL V6108-CR-TIEF4 (PDF file in Kubota web site: 9Y110-03160)

• DIESEL PARTICULATE FILTER HANDLING MANUAL (PDF file in Kubota web site: 9Y111-08130)

• K-OBD Quick Reference Manual (PDF file in Kubota web site: 9Y110-03800)

The Kubota Tractor M7001 is a high-performance tractor designed for the modern farmer who demands efficiency, reliability, and versatility. Here is a closer look at this model:

- Engine and Transmission: The M7001 is powered by a Kubota 6-cylinder diesel engine that delivers up to 170 horsepower. It features a common rail system that delivers fuel at high pressure, improving combustion efficiency and reducing emissions. It also has a Powershift transmission with 24 forward and 24 reverse gears, allowing the operator to select the appropriate speed for the task at hand.

- Hydraulics and Hitch: The M7001 comes with a hydraulic system that delivers a maximum flow rate of 29 gallons per minute, making it capable of handling a range of implements. It also features a Category III/IIIN 3-point hitch that can lift up to 12,787 pounds, allowing the operator to easily attach and use a wide range of implements.

- Operator Platform: The M7001 is designed with a comfortable and spacious operator platform, featuring an adjustable deluxe seat, air conditioning, and a panoramic roof for maximum visibility. The tractors also feature an easy-to-read instrument panel, making it easy for the operator to monitor key functions such as engine speed, fuel level, and hydraulic pressure.

- Versatility: The M7001 is a versatile machine, capable of handling a range of tasks on the farm or ranch. It is compatible with a range of implements, including plows, cultivators, and mowers, making it an ideal choice for large-scale farming operations.

- Intelligent Functions: The M7001 also features several intelligent functions to enhance its performance and efficiency. This includes a programmable headland management system that allows the operator to program the tractor to automatically lift and lower implements at specific points in the field. It also has an auto-guidance system that uses GPS technology to provide accurate and efficient tractor steering.

- Safety: The M7001 is designed with safety in mind, featuring a roll bar, seat belts, and a parking brake. It also has a rearview camera and a blind-spot monitor, providing better visibility and helping to prevent accidents.

- Maintenance: The M7001 is designed to be easy to maintain, with features such as a full-opening hood and easy-to-reach service points. The tractors also come with a Kubota dealer network that provides comprehensive service and support to owners.

Overall, the Kubota Tractor M7001 is a reliable, high-performance tractor that is designed to meet the needs of modern farmers and other professionals in the agriculture industry. Its intelligent functions, comfortable operator platform, and easy maintenance make it an ideal choice for large-scale farming operations.

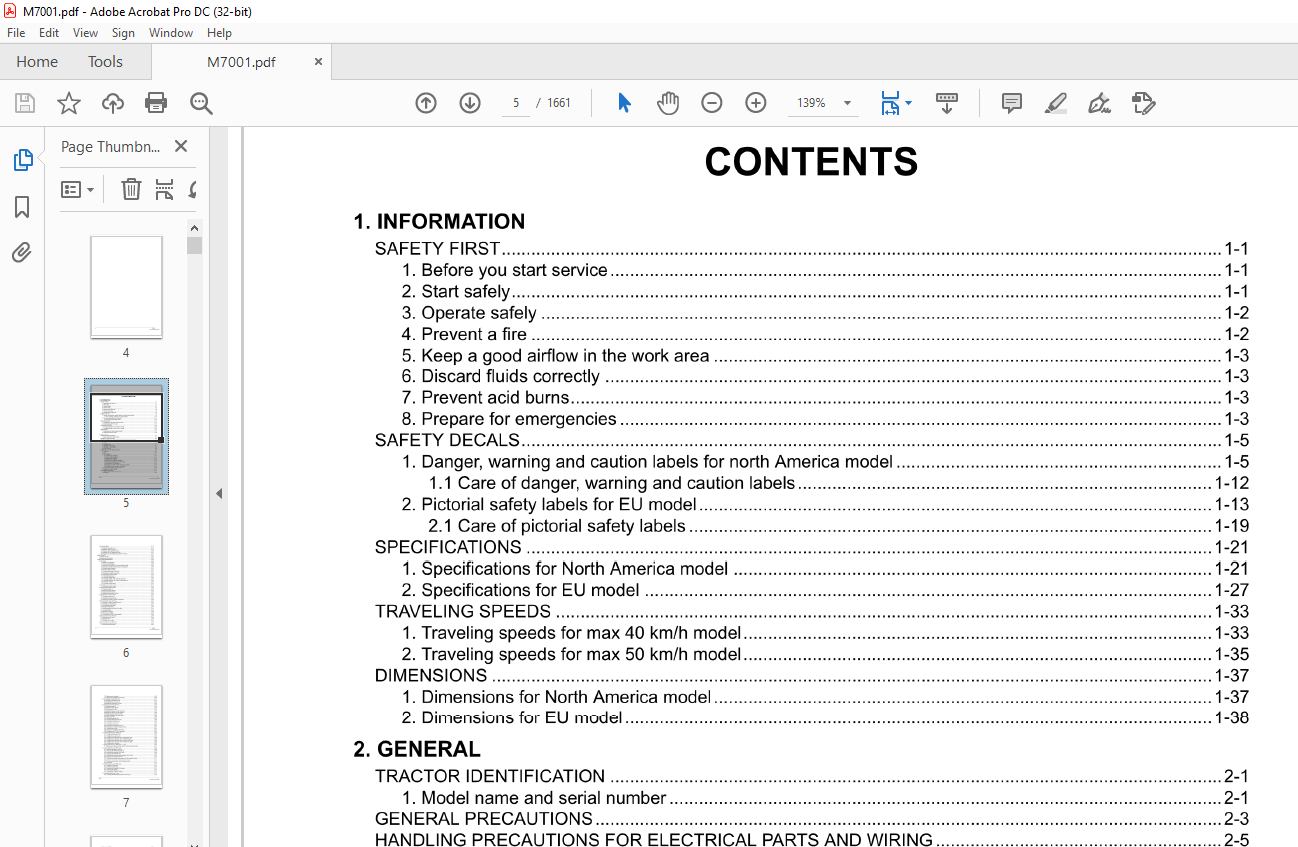

TABLE OF CONTENTS:

Kubota Tractor M7001 Workshop Manual – PDF DOWNLOAD

1 INFORMATION

SAFETY FIRST 1-1

1 Before you start service 1-1

2 Start safely 1-1

3 Operate safely 1-2

4 Prevent a fire 1-2

5 Keep a good airflow in the work area 1-3

6 Discard fluids correctly 1-3

7 Prevent acid burns 1-3

8 Prepare for emergencies 1-3

SAFETY DECALS 1-5

1 Danger, warning and caution labels for north America model 1-5

1 1 Care of danger, warning and caution labels 1-12

2 Pictorial safety labels for EU model 1-13

2 1 Care of pictorial safety labels 1-19

SPECIFICATIONS 1-21

1 Specifications for North America model 1-21

2 Specifications for EU model 1-27

TRAVELING SPEEDS 1-33

1 Traveling speeds for max 40 km/h model 1-33

2 Traveling speeds for max 50 km/h model 1-35

DIMENSIONS 1-37

1 Dimensions for North America model 1-37

2 Dimensions for EU model 1-38

2 GENERAL

TRACTOR IDENTIFICATION 2-1

1 Model name and serial number 2-1

GENERAL PRECAUTIONS 2-3

HANDLING PRECAUTIONS FOR ELECTRICAL PARTS AND WIRING 2-5

1 Handling of wiring 2-5

2 Battery 2-6

3 Handling fuse 2-7

4 Handling of connector 2-7

5 Handling of circuit tester 2-8

6 Coler of wiring 2-8

LUBRICANTS, FUEL AND COOLANT 2-9

1 Engine oil 2-11

2 Fuel 2-11

3 DEF (AdBlue) 2-11

3 1 Handling DEF (AdBlue) 2-11

3 2 Quality of DEF (Ad Blue) 2-11

3 3 Adding DEF (AdBlue) 2-12

3 4 Draining DEF (AdBlue) 2-12

3 5 Storing purchased DEF (Ad Blue) 2-13

3 6 Storing DEF (AdBlue) in the DEF tank 2-13

3 7 Disposing of DEF (AdBlue) 2-14

3 8 Handling precautions after stopping the engine 2-14

3 9 Precautions when using in cold regions 2-14

4 Transmission oil and rear axle case oil 2-15

5 Biodiesel fuel (BDF) B0-B5 2-16

TIGHTENING TORQUES 2-17

M7001

1 General use screws, bolts and nuts 2-17

2 Stud bolts 2-18

iii

KiSC issued 09, 2020 A

3 Hydraulic fittings 2-19

3 1 Hydraulic hose tightening torque 2-19

3 2 Hydraulic pipe cap nuts 2-19

3 3 Adaptors, elbows and nuts 2-19

3 4 Hydraulic pipes tightening torque 2-20

3 5 Hydraulic joint nut tightening torque 2-21

3 6 Hydraulic pipe joint tightening torque (PT thread) 2-21

MAINTENANCE 2-23

1 Service intervals 2-23

2 Maintenance items chart 2-26

CHECK AND MAINTENANCE 2-29

1 Daily check 2-29

1 1 Walk around inspection 2-29

1 2 Checking and refueling 2-29

1 3 Inspecting DEF/AdBlue® level and adding the fluid 2-30

1 4 Checking pneumatic brake pressure (If equipped) 2-30

1 5 Checking water separator 2-31

1 6 Checking engine oil level 2-31

1 7 Checking transmission fluid level 2-32

1 8 Checking coolant level 2-32

1 9 Cleaning grill, radiator and cooler 2-32

1 10 Checking DPF/SCR muffler 2-33

1 11 Checking brake pedal 2-34

1 12 Checking parking brake 2-34

1 13 Checking gauges, meter and Easy Checker™ 2-34

1 14 Checking head light, turn signal / hazard light etc 2-34

1 15 Checking seat belt 2-34

1 16 Checking movable parts 2-34

2 Check points of initial 5, 10, 25 and 50 hours 2-34

2 1 Tightening bar axle torque 2-34

3 Check points of initial 50 hours 2-35

3 1 Changing engine oil 2-35

3 2 Replacing engine oil filter 2-35

3 3 Checking fan belt tension 2-35

3 4 Replacing transmission oil filter 2-36

4 Check points of every 50 hours 2-37

4 1 Checking neutral circuit 2-37

4 2 Checking wheel bolt torque 2-39

4 3 Checking tie-rod dust cover 2-40

4 4 Checking air brake for trailer (If equipped) 2-40

5 Check points of every 100 hours 2-40

5 1 Cleaning air cleaner primary element 2-40

5 2 Cleaning pre-cleaner tubes 2-41

5 3 Lubricating grease fittings 2-42

5 4 Adjusting brake pedal 2-43

5 5 Adjusting parking brake lever free play 2-44

5 6 Checking battery condition 2-45

5 7 Charging battery 2-45

5 8 Direction for storage 2-46

5 9 How to detach battery 2-46

5 10 Checking front PTO oil (If equipped) 2-46

6 Check points of every 200 hours 2-46

6 1 Draining fuel tank water 2-46

6 2 Adjusting toe-in 2-47

6 3 Cleaning inner air filter 2-48

6 4 Cleaning fresh air filter 2-48

7 Check points of every 400 hours 2-49

7 1 Checking fan belt tension 2-49

iv M7001

KiSC issued 09, 2020 A

M7001

7 2 Cleaning water separator 2-50

7 3 Cleaning fuel solenoid pump element 2-50

8 Check points of initial 500 hours 2-51

8 1 Changing transmission fluid 2-51

8 2 Changing rear axle case oil 2-52

8 3 Replacing transmission oil filter 2-53

9 Check point of every 500 hours 2-54

9 1 Changing engine oil 2-54

9 2 Replacing engine oil filter 2-54

9 3 Cleaning pre-fuel filter 2-55

9 4 Replacing fuel filter 2-55

9 5 Replacing hydraulic oil filter (Suction) 2-55

9 6 Replacing hydraulic oil filter (Return) 2-56

9 7 Replacing power steering oil filter 2-57

9 8 Checking radiator hose and clamp 2-58

9 9 Checking fuel line 2-59

9 10 Checking intake air line 2-59

9 11 Checking differential lock hose 2-60

9 12 Checking lift cylinder hose 2-60

9 13 Checking power steering line 2-60

9 14 Checking oil cooler line 2-60

9 15 Checking front suspension hose 2-61

9 16 Checking air conditioner pipe and hose 2-61

9 17 Checking brake hose 2-61

9 18 Checking air conditioner drive belt 2-61

9 19 Changing front PTO oil (If equipped) 2-62

10 Check points of every 1000 hours 2-62

10 1 Changing transmission fluid 2-62

10 2 Replacing transmission oil filter 2-63

10 3 Changing rear axle case oil 2-64

10 4 Changing front differential case oil (Standard type) 2-65

10 5 Changing front axle gear case oil (Standard type) 2-65

10 6 Changing front differential case oil (Heavy duty type) 2-66

10 7 Changing front axle gear case oil (Heavy duty type) 2-66

10 8 Checking valve clearance 2-66

11 Check points of every 1000 hours or 1 year 2-67

11 1 Replacing air cleaner primary element and secondary element 2-67

11 2 Checking exhaust manifold 2-68

12 Check points of every 1500 hours 2-68

12 1 Cleaning fuel injector nozzle tip 2-68

12 2 Checking DEF/AdBlue® injector tip 2-68

12 3 Checking and cleaning EGR cooler 2-69

12 4 Checking DEF/AdBlue® line 2-70

12 5 Checking positive crankcase ventilation (PCV) valve 2-70

12 6 Replacing oil separator element 2-70

12 7 Checking accumulator gas pressure (Front suspension type) 2-71

13 Check points of every 2000 hours or 2 years 2-71

13 1 Flushing cooling system and changing coolant 2-71

13 2 Anti-freeze 2-72

14 Check points of every 3000 hours 2-73

14 1 Checking turbocharger 2-73

14 2 Checking supply pump 2-73

14 3 Checking and cleaning EGR system 2-73

14 4 Cleaning DPF muffler 2-73

14 5 Checking DEF/AdBlue® injector 2-73

14 6 Replacing DEF/AdBlue® pump filter 2-74

15 Check points of every 1 year 2-75

15 1 Checking DPF differential pressure sensor pipe 2-75

V

KiSC issued 09, 2020 A

15 2 Checking EGR pipe 2-75

15 3 Checking CAB isolation cushion 2-76

15 4 Checking oil separator hose 2-76

16 Check points of every 2 years 2-76

16 1 Replacing DPF differential pressure sensor hose 2-76

16 2 Replacing boost sensor hose 2-76

17 Check point of every 3 years 2-77

17 1 Replacing parking brake cable 2-77

18 Check points of every 4 years 2-77

18 1 Replacing radiator hose (Water pipes) 2-77

18 2 Replacing fuel lines 2-77

18 3 Replacing intake air line 2-78

18 4 Replacing oil separator hose 2-78

18 5 Replacing oil cooler line 2-78

18 6 Replacing power steering hose 2-78

18 7 Replacing lift cylinder hose 2-78

18 8 Replacing differential lock hose 2-78

18 9 Replacing front suspension hose (Front suspension type) 2-79

18 10 Replacing brake hose 2-80

18 11 Replacing air conditioner hose 2-80

19 Service as required 2-80

19 1 Bleeding fuel system 2-80

19 2 Bleeding brake system 2-81

19 3 Replacing fuse 2-83

19 4 Replacing light bulb 2-88

19 5 Replacing head lamp 2-88

19 6 Lubricating points 2-88

19 7 Adding washer liquid 2-88

19 8 Checking amount of refrigerant (Gas) 2-88

SPECIAL TOOLS 2-91

1 General 2-91

1 1 Diagnosis tool kit (K-OBD) 2-91

1 2 CAN BUS interface 2-91

1 3 CAN BUS extension 2-91

1 4 Cable IMT to AFS600 F-F SP 2-91

1 5 Flash program cable RS232 2-92

1 6 KV diagnostic (Implements) 2-92

1 7 Tractor CAN BUS connector 2-92

1 8 Flash program adapter RS232 2-92

1 9 Mini gender changer 2-93

2 Engine 2-93

2 1 Diesel engine compression tester 2-93

2 2 Oil pressure tester 2-93

2 3 Diagnosis tool kit 2-93

2 4 Valve seat cutter 2-94

2 5 Connecting rod alignment tool 2-94

2 6 Plastigauge 2-94

2 7 Radiator tester 2-94

2 8 Compression tester adapter (Glow plug adapter) 2-95

2 9 Valve guide replacing tool 2-96

2 10 Idle gear bushing replacing tool 2-96

2 11 Small end bushing replacing tool 2-97

2 12 Balancer shaft bearing replacing tool 2-98

2 13 Balancer shaft 2 bearing C replacing tool B 2-100

2 14 Balancer shaft bearing replacing tool C 2-103

2 15 Balancer shaft bearing replacing tool D 2-105

2 16 Oil seal installing tool A 2-107

2 17 Oil seal installing tool B 2-108

vi M7001

KiSC issued 09, 2020 A

M7001

2 18 DEF header unit replacing tool 2-109

3 Front axle 2-110

3 1 Standard front axle 2-110

3 2 Heavy duty front axle 2-117

4 Transmission 2-138

4 1 Powershift transmission 2-138

4 1 1 Striker 2-138

4 1 2 Grab sleeve 2-138

4 1 3 Basic tool 2-138

4 1 4 Press bush 2-138

4 1 5 Grab sleeve 2-138

4 1 6 Grab sleeve 2-139

4 1 7 Grab sleeve 2-139

4 1 8 Basic tool 2-139

4 1 9 Puller 2-139

4 1 10 Basic tool 2-139

4 1 11 Grab sleeve 2-140

4 1 12 Basic tool 2-140

4 1 13 Cut-off device 2-140

4 1 14 Bush 2-140

4 1 15 Sleeve 2-140

4 1 16 Lever riveting tongues 2-141

4 1 17 Locating pin (M10) 2-141

4 1 18 Fixture 2-141

4 1 19 Extractor 2-141

4 1 20 Pressure bush 2-141

4 1 21 Plug insert 2-142

4 1 22 Clamping device 2-142

4 1 23 Assembly lever 2-142

4 1 24 Slotted nut wrench 2-142

4 1 25 Clamping bar 2-142

4 1 26 Grab sleeve 2-143

4 1 27 Grab sleeve 2-143

4 1 28 Assembly bars 2-143

4 1 29 Adjusting screws (M8) 2-143

4 1 30 Adjusting screws (M14) 2-143

4 1 31 Measuring lever 2-144

4 1 32 Drivertool 2-144

4 1 33 Driver tool 2-144

4 1 34 Drivertool 2-144

4 1 35 Grab sleeve 2-144

4 1 36 Assembly fixture 2-145

4 1 37 Pressure pin 2-145

4 1 38 Straightedge 2-145

4 1 39 Spring scale 2-145

4 1 40 Driver tool 4 2-145

4 1 41 Drivertool 5 2-146

4 1 42 Drivertool 6 2-146

4 1 43 Handle 2-146

4 1 44 Assembly fixture 2-146

4 1 45 lnsert 2-146

4 1 46 Pressure ring 2-14 7

4 1 47 Press-fit mandrel 2-147

4 1 48 Grab sleeve 9 2-147

4 1 49 Socket wrench 2-147

4 1 50 Clamping device 2-147

4 1 51 Slotted nut wrench 3 2-148

4 1 52 Adjusting screws 2-148

vii

KiSC issued 09, 2020 A

4 1 53 Load carrying fixture 2-148

4 1 54 Assembly aid 2-148

4 1 55 Locating pin 2-148

4 1 56 Transmission stand with tilting device 2-149

4 1 57 Fixture (Bracket) 2-149

4 1 58 Clamping device 2-149

4 1 59 Clamping plate 2-149

4 1 60 Support stand 2-149

4 1 61 Striker 2-150

4 1 62 Striker··· ·· ··· ···· ··· ···· ·· ·········· ··· ··· ······· ·· ····· ·· ······ •················· ··········•· ·· ···•······•· ··· ··· ··· ·· ·· ··· ·· ·· ······ 2-150

4 1 63 Eyebolt 2-150

4 1 64 Counter support 2-150

4 1 65 Reduction 2-150

4 1 66 Inner extractor 2-151

4 1 67 Locating pin 2-151

4 2 CVT 2-151

4 2 1 Adjusting screws 2-151

4 2 2 Striker 2-151

4 2 3 Load carrying fixture 2-151

4 2 4 Assembly aid 2-152

4 2 5 Locating pin 2-152

4 2 6 Locating pin 2-152

4 3 Rear axle 2-152

4 3 1 Slotted nut wrench 2-152

4 3 2 Grab sleeve 2-152

4 3 3 Socket wrench 2-153

4 3 4 Clamping device 2-153

4 3 5 Slotted nut wrench 2-153

4 3 6 Grab sleeve 2-153

4 3 7 Basic tool 2-153

4 3 8 Assembly fixture 2-154

4 3 9 Pressure pin 2-154

4 3 10 Locating pins (M12) 2-154

4 3 11 Straightedge 2-154

4 3 12 Spring scale 2-154

4 3 13 Driver tool 2-155

4 3 14 Drivertool 2-155

4 3 15 Drivertool 2-155

4 3 16 Handle 2-155

4 3 17 Assembly fixture 2-155

4 3 18 Insert (M22 x 1 5) 2-156

4 3 19 Pressure ring 2-156

4 3 20 Press-fit mandrel 2-156

4 3 21 Locating pins (M14) 2-156

5 Hydraulic 2-156

5 1 Complete suitcase with component 2-156

5 2 Empty case 2-157

5 3 Adaptor of PST main clutch 2-157

5 4 Adaptor of PST system 2-157

5 5 Adaptor of PST clutch/4WD clutch 2-157

5 6 Adaptor of CVT 2-158

5 7 T-joint for differential lock 2-158

5 8 Adaptor of PTO 2-158

5 9 Adaptor of auxiliary valve 2-158

5 10 Kit for pump flow 2-159

5 11 Kit for pump flow 2-159

5 12 T-joint of steering valve 2-159

5 13 Adaptor of front PTO 2-159

viii M7001

KiSC issued 09, 2020 A

5 14 Pressure gauge 2-160

5 15 Hydraulic cable 2-160

5 16 Cylinder safety valve setting pressure adaptor 2-160

5 17 Hydraulic cylinder block tool 2-163

5 18 Adapter for flow meter 2-165

6 Cabin 2-165

6 1 General 2-165

6 1 1 Toe-in gauge 2-165

6 1 2 Cabin lifting tool 2-166

6 2 Air conditioner 2-173

6 2 1 Air conditioner service tool 2-174

6 2 2 Electric gas leak tester 2-175

6 2 3 Vacuum pump 2-175

6 2 4 Adaptor (for R134a) 2-175

6 2 5 Stopper magnet clutch (for A/C compressor) 2-176

6 2 6 Stopper bolt (for A/C compressor) 2-177

7 Front suspension 2-177

7 1 Accumulator gas charge kit 2-177

7 1 1 Pressure reducer 2-178

7 1 2 Charging hose 2-179

7 1 3 Adaptor 2-179

3 ENGINE

MECHANISM 3-1

M7001

1 Feature of engine 3-1

2 Engine body 3-1

2 1 Structure of cylinder block 3-1

2 2 Function of center direct injection system (E-CDIS) 3-2

2 3 Function of piston 3-2

2 4 Function of balancer 3-2

3 Lubricating system 3-3

3 1 Function of oil cooler 3-3

3 2 Function of oil separator 3-3

4 Cooling system 3-4

4 1 Thermostat 3-4

4 1 1 Structure of thermostat 3-4

4 1 2 Operation of thermostat 3-5

4 1 3 Flow characteristic of thermostat 3-6

4 2 Function of bottom bypass system 3-6

5 Common rail system (CRS) 3-6

5 1 Structure of common rail system 3-6

5 2 Outline of fuel system 3-8

5 3 Structure of supply pump 3-9

5 3 1 Function of feed pump 3-9

5 3 2 Function of regulating valve 3-9

5 3 3 Function of suction control valve (SCV) 3-10

5 3 4 Function of pump unit 3-11

5 3 5 Function of delivery valve 3-11

5 3 6 Function of fuel temperature sensor 3-11

5 4 Function of rail 3-11

5 5 Function of injector 3-12

5 5 1 Operation of injector 3-14

5 5 2 Electrical circuit of injector drive 3-16

5 5 3 Function of injector QR/ID codes 3-16

5 5 4 Handling injectors with QR codes (Reference) 3-16

5 6 Engine control system 3-17

5 6 1 Diagram of engine control system 3-17

5 6 2 Function of engine electronic control unit (ECU) 3-20

ix

KiSC issued 09, 2020 A

5 6 3 Sensors 3-20

6 Exhaust gas recirculation (EGR) system 3-24

6 1 General structure of EGR system 3-24

6 1 1 Structure of high pressure EGR system 3-26

6 1 2 Structure of low pressure EGR system 3-26

6 2 Function of EGR valve 3-27

6 2 1 Function of EGR valve lift sensor 3-28

6 3 Function of reed valve 3-28

7 After treatment system 3-29

7 1 Schematic diagram of after treatment devices 3-29

7 2 Components 3-30

7 2 1 Function of diesel oxidation catalyst (DOC) 3-30

7 2 2 Function of diesel particulate filter (DPF) 3-30

7 2 3 Function of intake throttle valve 3-30

7 2 4 Function of air flow sensor 3-30

7 2 5 Function of temperature sensor 3-31

7 2 6 Function of differential pressure sensor 3-31

7 2 7 Function of selective catalytic reduction (SCR) 3-31

7 2 8 Function of diesel exhaust fluid (DEF) pump 3-32

7 2 9 Function of DEF injector 3-32

7 2 10 Function of DEF tank 3-33

7 2 11 Function of coolant valve 3-33

7 2 12 Function of after treatment control unit (ACU) 3-33

7 3 SCR system 3-35

7 3 1 Outline of the SCR system 3-35

7 3 2 Flow of coolant and DEF in SCR system 3-36

7 3 3 Process of thaw control 3-36

7 3 4 SCR trouble indication in instrument panel 3-37

7 4 DPF regeneration system 3-40

7 4 1 Outline of regeneration mode 3-40

7 4 2 Indicator and switch lamp 3-41

SERVICING 3-45

1 Troubleshooting for engine 3-45

2 Servicing specifications for engine 3-49

3 Tightening torques for engine 3-53

4 Checking, disassembling, and servicing 3-55

4 1 Checking and adjusting 3-55

4 1 1 Engine body 3-55

4 1 2 Lubricating system 3-56

4 1 3 Cooling system 3-56

4 1 4 Turbocharger 3-59

4 2 Preparation 3-59

4 2 1 Separating cabin from tractor 3-59

4 2 2 Removing SCR 3-73

4 2 3 Removing DPF muffler 3-74

4 2 4 Oil cooler pipe, wire harness, fuel hose 3-75

4 2 5 Main frame 3-75

4 3 Disassembling and assembling 3-76

4 3 1 DPF muffler 3-76

4 3 2 External components 3-79

4 3 3 Exhaust gas recirculation (EGR) (Low pressure side) 3-80

4 3 4 Turbocharger 3-80

4 3 5 Exhaust gas recirculation (EGR) (High pressure side) 3-81

4 3 6 Common rail system (CRS) 3-82

4 3 7 Cylinder head and valve 3-84

4 3 8 Thermostat 3-91

4 3 9 Water pump and oil cooler 3-91

4 3 10 Front cover 3-92

X M7001

KiSC issued 09, 2020 A

4 3 11 Flywheel and flywheel housing 3-93

4 3 12 Piston and connecting rod 3-98

4 3 13 Crankshaft and crankcase 3-102

4 3 14 Timing gears 3-103

4 4 Servicing 3-104

4 4 1 Cylinder head and valve 3-104

4 4 2 Timing gears 3-112

4 4 3 Piston and connecting rod 3-116

4 4 4 Crankshaft 3-119

4 4 5 Cylinder 3-122

4 4 6 Oil pump 3-123

4 5 Replacing 3-124

4 5 1 Replacing supply pump 3-124

4 5 2 Replacing injector 3-126

4 5 3 Replacing engine ECU 3-128

4 5 4 Replacing DPF 3-131

4 5 5 Replacing SCR 3-138

4 5 6 Replacing ACU 3-138

4 5 7 Replacing DEF injector 3-142

4 5 8 Replacing header unit of DEF tank 3-144

4 TRANSMISSION

MECHANISM 4-1

1 Powershift 4-1

1 1 Structure 4-1

1 1 1 Structure of power shift traveling system 4-1

1 1 2 Structure of PTO (Power shift) 4-4

1 2 Operation of power train 4-5

1 2 1 Operation of power shift section 4-5

1 2 2 Operation or range and creep shift section 4-7

1 2 3 Operation of PTO shift section 4-7

1 3 Hydraulic control of power shift 4-8

1 3 1 Hydraulic circuit 4-8

1 3 2 Component parts of power shift hydraulic control system 4-11

1 4 Electric control system 4-16

1 4 1 Electrical control system of power shift 4-16

1 4 2 Power shift transmission – switch and sensor location 4-17

1 4 3 Component parts 4-18

2 CVT 4-25

2 1 Structure 4-25

2 1 1 Traveling system ofCVT 4-25

2 1 2 Structure of PTO (CVT) 4-27

2 2 Operation of power train 4-28

2 2 1 Operation principle of CVT 4-28

2 2 2 Driving chart and gear shift pattern of CVT 4-29

2 3 Hydraulic system 4-32

2 3 1 Hydraulic circuit 4-32

2 3 2 Component parts of CVT hydraulic control system 4-33

2 4 Electric control system 4-35

2 4 1 Electric control system of CVT 4-35

2 4 2 CVT – switch and sensor location 4-36

2 4 3 Component parts 4-36

3 Front PTO 4-37

3 1 Structure of front PTO 4-37

3 2 Hydraulic circuit of front PTO 4-38

3 3 System component of front PTO 4-39

3 3 1 Front PTO soft start control 4-40

SERVICING 4-41

M7001 xi

KiSC issued 09, 2020 A

1 Power shift 4-41

1 1 Troubleshooting for transmission (Power shift) 4-41

1 2 Servicing specifications for transmission (Power shift) 4-4 7

1 3 Tightening torques for transmission (Power shift) 4-48

1 4 Checking and adjusting 4-50

1 4 1 System pressure 4-50

1 4 2 Hydraulic control for power shift 4-50

1 4 3 Main clutch 4-51

1 4 4 PTO clutch 4-51

1 4 5 Differential lock 4-51

1 4 6 4 wheel drive 4-52

1 5 Preparation 4-52

1 5 1 Separating power shift transmission from tractor 4-52

1 5 2 Separating power shift component from transmission 4-76

1 5 3 Separating main transmission from differential case 4-77

1 6 Disassembling 4-77

1 6 1 Removing damper disc 4-77

1 6 2 Power shift components 4-77

1 6 3 Pump drive 4-86

1 6 4 Front wheel drive 4-89

1 6 5 Crawler gear shifting and main clutch 4-91

1 6 6 Main transmission 4-96

1 6 7 Hydraulic shift control 4-101

1 6 8 Removing differential 4-104

1 6 9 PTO 4-106

1 6 10 Oil supply and power lift 4-111

1 7 Assembling 4-114

1 7 1 Power shift component 4-114

1 7 2 Clutch housing 4-135

1 7 3 Main transmission 4-139

1 7 4 Main clutch and crawler gear shifting 4-158

1 7 5 Front wheel drive 4-169

1 7 6 Pump drive 4-173

1 7 7 Hydraulicshiftcontrol 4-180

1 7 8 Power lift and oil supply 4-185

1 7 9 PTO 4-194

1 7 10 Differential 4-204

1 7 11 Mounting power shift transmission to the main transmission 4-209

1 7 12 Mount main transmission to rear axle 4-212

2 CVT 4-214

2 1 Troubleshooting for transmission (CVT) 4-214

2 2 Servicing specifications for transmission 4-217

2 3 Tightening torques for transmission (CVT) 4-218

2 4 Checking and adjusting 4-220

2 4 1 Checking system pressure 4-220

2 4 2 Checking lubrication pressure 4-220

2 4 3 Checking 4 wheel drive operating pressure 4-220

2 4 4 Checking differential lock operating pressure 4-221

2 4 5 CF, CR, C1, C2, C3, C4 and BG clutch 4-221

2 4 6 Diagnostic protocol of KVT model 4-222

2 5 Preparation 4-226

2 5 1 Separating CVT from tractor 4-226

2 6 Disassembling 4-248

2 6 1 Removing speed sensor, pressure sensor, solenoid valve and inductive sensor 4-248

2 6 2 Removing clutch control 4-249

2 6 3 Removing oil supply 4-251

2 6 4 Removing system control 4-252

2 6 5 Removing hydraulic unit 4-254

xii M7001

KiSC issued 09, 2020 A

2 7 Assembling 4-258

2 7 1 Assembling hydraulic unit 4-258

2 7 2 Assembling system control 4-263

2 7 3 Assembling oil supply 4-266

2 7 4 Assembling clutch control 4-268

2 7 5 Assembling inductive sensor, solenoid valve, pressure sensor, speed sensor and speed

transmitter 4-272

3 Front PTO 4-276

3 1 Troubleshooting for transmission (Front PTO) 4-276

3 2 Servicing specifications for transmission (Front PTO) 4-277

3 3 Checking and adjusting 4-278

3 3 1 Clutch pressure 4-278

3 3 2 Pump pressure 4-278

3 4 Preparation 4-278

3 4 1 Separating front PTO from tractor 4-278

3 5 Disassembling 4-281

3 5 1 Oil pump 4-281

3 5 2 PTO unit 4-282

3 5 3 Clutch 4-282

3 5 4 Piston 4-285

3 6 Assembling 4-286

3 6 1 Clutch 4-286

3 6 2 PTO unit 4-287

3 6 3 Oil pump 4-288

5 REAR AXLE

MECHANISM 5-1

1 Structure 5-1

1 1 Structure of rear axle 5-1

1 2 Structure of bar axle 5-2

1 2 1 Structure of classical type 5-2

1 2 2 Structure of plug on type 5-2

SERVICING 5-3

1 Troubleshooting for rear axle 5-3

2 Servicing specifications for rear axle 5-4

3 Tightening torques for rear axle 5-5

4 Checking, disassembling, and servicing 5-6

4 1 Preparation 5-6

4 1 1 Separating rear axle from tractor 5-6

4 2 Disassembling 5-8

4 2 1 Disassembling planetary gear 5-8

4 2 2 Disassembling rear axle shaft 5-9

4 3 Assembling 5-10

4 3 1 Assembling rear axle shaft 5-10

4 3 2 Assembling rear axle shaft into rear axle end drive 5-11

4 3 3 Assembling planetary gear 5-12

4 3 4 Assembling planetary carrier into rear axle shaft 5-1 3

4 3 5 Assembling rear axle end drive installation into rear axle housing 5-14

6 BRAKES

MECHANISM 6-1

M7001

1 Traveling brake 6-1

1 1 Structure of traveling brake 6-1

1 2 Component parts 6-3

1 2 1 Master cylinder 6-3

1 2 2 Brake pressure switch 6-3

1 2 3 Service brake switch 6-3

1 2 4 Parking brake switch 6-3

xiii

KiSC issued 09, 2020 A

1 2 5 Emergency brake accumulator 6-4

2 Hydraulic trailer brake 6-5

2 1 Structure of hydraulic trailer brake 6-5

2 2 Component parts 6-6

2 2 1 Hydraulic trailer brake valve 6-6

3 Air trailer brake 6-9

3 1 Structure of air trailer brake 6-9

3 2 Air pressure circuit 6-10

3 3 Component parts 6-11

3 3 1 Air compressor 6-11

3 3 2 Regulator valve 6-11

3 3 3 Pneumatic pressure switch 6-11

3 3 4 Trailer air brake control valve (Dual line) 6-12

3 3 5 Trailer air brake control valve (Single line) 6-13

SERVICING 6-15

1 Troubleshooting for brakes 6-15

2 Servicing specifications for brakes 6-16

3 Tightening torques for brakes 6-17

4 Checking, disassembling, and servicing 6-18

4 1 Checking and adjusting 6-18

4 1 1 Adjusting brake pedal free travel 6-18

4 1 2 Checking brake pedal stroke 6-18

4 1 3 Checking brake hose 6-19

4 1 4 Adjusting brake 6-19

4 1 5 Adjusting parking brake lever free play 6-19

4 1 6 Testing hydraulic trailer brake (If equipped) 6-20

4 1 7 Checking air trailer brake (If equipped) 6-20

4 1 8 Bleeding brake system 6-21

4 2 Disassembling and assembling 6-22

4 2 1 Brake pedal 6-22

4 2 2 Master cylinder 6-22

4 2 3 Hydraulic trailer brake valve (If equipped) 6-37

4 2 4 Air trailer brake control valve (If equipped) 6-37

4 2 5 Brake 6-37

7 FRONT AXLE

MECHANISM 7-1

1 Structure 7-1

1 1 Structure of standard front axle 7-1

1 2 Structure of heavy duty front axle 7-3

1 3 Structure of front suspension 7-7

2 Front suspension system 7-8

2 1 Outline of front suspension 7-8

2 2 Control of front suspension 7-9

2 2 1 Function of suspension mode 7-9

2 2 2 Front suspension mode change conditions 7-9

2 3 Hydraulic system of front suspension 7-10

2 3 1 Hydraulic system outline of front suspension 7-10

2 3 2 Hydraulic circuit of front suspension 7-11

2 3 3 Hydraulic system operation of front suspension 7-12

2 3 4 Component parts 7-12

2 4 Electrical system of front suspension 7-13

2 4 1 Electrical system outline of front suspension 7-13

2 4 2 Component parts 7-13

SERVICING 7-15

1 Troubleshooting for front axle 7-15

2 Servicing specifications for front axle 7-19

3 Tightening torques for front axle 7-20

xiv M7001

KiSC issued 09, 2020 A

4 Checking and adjusting 7-22

4 1 All type 7-22

4 1 1 Checking toe-in 7-22

4 1 2 Checking tie-rod dust cover 7-22

4 1 3 Checking axial sway of front wheel 7-22

4 2 Front suspension type 7-23

4 2 1 Suspension control valve 7-23

4 2 2 Accumulator gas pressure 7-24

5 Preparation 7-24

5 1 Draining lubricants 7-24

5 1 1 Standard front axle 7-24

5 1 2 Heavy duty front axle 7-25

5 2 Separating front axle 7-26

5 2 1 Rigid type 7-26

5 2 2 Front axle suspension type 7-27

6 Disassembling 7-30

6 1 Standard front axle 7-30

6 1 1 Disassembling final planetary reduction 7-30

6 1 2 Disassembling steering case 7-34

6 1 3 Disassembling front differential 7-38

6 2 Heavy duty front axle 7-47

6 2 1 Disassembling swinging support 7-4 7

6 2 2 Disassembling planetary reduction gear 7-48

6 2 3 Disassembling steering knuckle and steering sensor 7-51

6 2 4 Disassembling steering cylinder 7-55

6 2 5 Disassembling differential unit 7-57

6 2 6 Disassembling bevel pinion 7-60

6 3 Front suspension component parts 7-63

6 3 1 Removing front suspension control valve 7-63

6 3 2 Removing accumulator 7-64

7 Assembling 7-65

7 1 Standard front axle 7-65

7 1 1 Assembling final planetary reduction 7-65

7 1 2 Assembling steering case 7-69

7 1 3 Assembling front differential 7-77

7 1 4 Assembling crown wheel and pinion 7-84

7 1 5 Installing differential unit 7-87

7 2 Heavy duty front axle 7-90

7 2 1 Assembling swinging support 7-90

7 2 2 Assembling planetary reduction gear 7-91

7 2 3 Assembling steering knuckle and steering sensor 7-95

7 2 4 Assembling steering cylinder 7-100

7 2 5 Assembling differential unit 7-103

7 2 6 Assembling bevel pinion 7-107

8 Servicing 7-113

8 1 Adjusting king pin preload 7-113

8 2 Adjusting backlash between differential pinion and differential side gear 7-114

8 3 Adjusting turning torque of pinion shaft 7-114

8 STEERING

MECHANISM 8-1

M7001

1 Power steering type 8-1

1 1 Structure of power steering 8-1

1 2 Hydraulic system 8-2

1 2 1 Hydraulic circuit of power steering 8-2

1 2 2 Component parts 8-3

2 Auto steering 8-4

2 1 Structure of auto steering 8-4

xv

KiSC issued 09, 2020 A

2 2 Hydraulic system 8-5

2 2 1 Hydraulic circuit of auto steering 8-5

2 2 2 Operation 8-6

2 2 3 Component parts 8-7

2 3 Electrical system 8-8

2 3 1 Outline of auto steering electric system 8-8

2 3 2 Component parts (Factory-installed) 8-9

SERVICING 8-11

1 Troubleshooting for steering 8-11

2 Servicing specifications for steering 8-13

3 Tightening torques for steering 8-14

4 Checking, disassembling, and servicing 8-15

4 1 Checking and adjusting 8-15

4 1 1 Checking power steering relief valve pressure 8-15

4 2 Preparation 8-15

4 2 1 Separating steering cylinder from tractor 8-15

4 3 Disassembling and assembling 8-16

4 3 1 Steering cylinder 8-16

4 3 2 Steering controller 8-23

9 HYDRAULIC SYSTEM

MECHANISM 9-1

1 Hydraulic circuit 9-1

1 1 Hydraulic circuit of standard model 9-1

1 2 Hydraulic circuit of premium model and premium KVT model 9-2

2 Structure 9-3

2 1 Structure of standard model 9-3

2 2 Structure of premium model 9-4

2 3 Structure of premium KVT model 9-5

3 Outline of hydraulic system 9-6

3 1 Outline of hydraulic system (Standard model) 9-6

3 2 Outline of hydraulic system (premium model and premium KVT model) 9-6

4 Axial piston variable pump 9-8

4 1 Premium model and premium KVT model 9-8

4 1 1 Structure of axial piston variable pump 9-8

4 1 2 Operation of axial piston variable pump 9-9

5 Auxiliary control valve 9-13

5 1 Standard model 9-13

5 1 1 Function of pressure compensator valve 9-13

5 1 2 Function of SB23-M valve (Type A) 9-14

5 2 Premium model and premium KVT model 9-15

5 2 1 Function of SB23-EHS1 9-15

5 2 2 Function of pilot valve 9-15

6 3 point hydraulic system 9-16

6 1 Hydraulic circuit 9-16

6 1 1 Hydraulic circuit of 3-point hitch hydraulic system (Standard model) 9-16

6 1 2 Hydraulic circuit of 3-point hitch hydraulic system (Premium model and premium KVT

model) 9-17

7 3-point hitch control system 9-18

7 1 Outline of 3-point hitch control system (Standard model) 9-18

7 2 Outline of 3-point hitch control system (Premium model and premium KVT model) 9-20

7 3 Electric component 9-24

7 3 1 Control panel (Standard model) 9-24

7 3 2 Control panel and terminal monitor (Premium and premium KVT model) 9-24

7 3 3 3-point hitch control unit (VCU2) 9-24

7 3 4 Lift arm sensor 9-24

7 3 5 Draft sensor 9-25

7 4 Hydraulic components 9-25

xvi M7001

KiSC issued 09, 2020 A

7 4 1 Hydraulic pump 9-25

7 4 2 Auxiliary control valve 9-25

7 4 3 High pressure selecting valve 9-25

7 5 Ride control system 9-26

7 5 1 Function of ride control system 9-26

7 6 Slip control system 9-27

7 6 1 Premium model and premium KVT model 9-27

SERVICING 9-29

1 Standard model 9-29

1 1 Troubleshooting for hydraulic system (Standard model) 9-29

1 2 Servicing specifications for hydraulic system 9-31

1 3 Tightening torques for hydraulic system (Standard model) 9-32

1 4 Checking and adjusting 9-33

1 4 1 Hydraulic pump for three-point hitch 9-33

1 4 2 Three point hitch system 9-33

1 4 3 Auxiliary control valve linkage 9-34

1 5 Disassembling and assembling 9-35

1 5 1 Preparation 9-35

1 5 2 Hydraulic pump for three-point hitch 9-4 7

1 5 3 Hydraulic pump (for transmission) 9-49

1 5 4 Hydraulic control valve assembly 9-51

1 5 5 Power lift 9-53

1 5 6 Hydraulic cylinder 9-55

1 5 7 Draft pin 9-55

1 5 8 Front 3-point hitch 9-56

2 Premium model and premium KVT model 9-58

2 1 Troubleshooting for hydraulic system (Premium and premium-KVT model) 9-58

2 2 Servicing specifications for hydraulic system 9-60

2 3 Tightening torques for hydraulic system (Premium model and premium KVT model) 9-61

2 4 Checking and adjusting 9-62

2 4 1 Hydraulic pump for three-point hitch 9-62

2 4 2 Three point hitch system 9-62

2 5 Disassembling and assembling 9-63

2 5 1 Preparation 9-63

2 5 2 Hydraulic pump for three-point hitch 9-75

2 5 3 Hydraulic pump (for transmission) 9-77

2 5 4 Auxiliary control valve assembly 9-79

2 5 5 Power lift 9-81

2 5 6 Hydraulic cylinder 9-83

2 5 7 Draft pin 9-84

2 5 8 Front 3-point hitch 9-85

10 ELECTRICAL SYSTEM

MECHANISM 10-1

M7001

1 Relay and fuse 10-1

1 1 Rei ay 1 0-1

1 1 1 Component of relay box 10-1

1 1 2 Outline of battery cut relay 10-1

1 2 Fuse 10-1

1 2 1 Structure of fuse box 10-1

1 2 2 Slow blow fuse 1 10-2

1 2 3 Slow blow fuse 2 10-2

1 2 4 CEU 10-2

2 Starting system 10-3

2 1 System outline and electrical circuit 10-3

3 Instrument panel 10-5

4 K-Monitor (Terminal Monitor) 10-6

4 1 Specification of terminal monitor 10-6

xvii

KiSC issued 09, 2020 A

4 2 ISOBUS 10-7

4 3 Outline of K-monitor 10-8

4 4 Outline of K-monitor pro 10-8

4 5 Outline of terminal display 10-9

5 Armrest 10-10

5 1 Outline of standard model armrest 10-10

5 2 Outline of premium model armrest 10-10

5 3 Outline of premium-KVT armrest 10-10

5 4 Outline of joystick model armrest 10-10

6 Controller area network (CAN) communication 10-11

7 ISOBUS 10-13

7 1 Outline of ISOBUS socket 10-13

7 2 Outline of ISOBUS monitor socket 10-14

8 Headland management system 10-15

8 1 Outline 10-15

8 1 1 Outline of headland management system 10-15

8 1 2 Programming headland management system 10-15

8 1 3 Handling headland management system 10-15

8 1 4 Program list 10-17

8 2 Structure of headland management system 10-21

8 3 Components 10-22

8 3 1 Outline of ARU 10-22

8 3 2 Outline of terminal monitor 10-22

8 3 3 Outline of VCU2 10-22

SERVICING 10-23

1 Troubleshooting for electrical system 10-23

2 Servicing specifications for electrical system 10-28

3 Tightening torques for electrical system 10-30

4 Checking and adjusting 10-31

4 1 Diagnosis trouble code (ACU) 10-31

4 2 Diagnosis trouble code (VDC) 10-35

4 3 Diagnosis trouble code (ARU) 10-53

4 4 Diagnosis trouble code (CEU) 10-65

4 5 Diagnosis trouble code (ECU) 10-71

4 6 Diagnosis trouble code (NAC) 10-85

4 7 Diagnosis trouble code (SCM) 10-89

4 8 Diagnosis trouble code (SWP) 10-95

4 9 Diagnosis trouble code (TCU-CVT) 10-99

4 10 Diagnosis trouble code (TCU-PST) 10-110

4 11 Diagnosis trouble code (TECU) 10-127

4 12 Diagnosis trouble code (VCU1 ) 10-142

4 13 Diagnosis trouble code (VCU2) 10-143

4 14 Checking and adjusting by instrument panel 10-228

4 14 1 Diagnostic trouble code (DTC) 10-228

4 14 2 SCR trouble 10-231

4 14 3 DPF trouble indication in instrument panel 10-234

4 14 4 Can communication trouble indication in instrument panel 10-236

4 14 5 Mode and item selection 10-236

4 15 Checking and adjusting by terminal monitor 10-238

4 15 1 Warning / error message on terminal monitor 10-238

4 15 2 OTC message on terminal monitor 10-238

4 15 3 DM1 /2 on terminal monitor 10-239

4 15 4 OTC (SPN, FMI) on terminal monitor 10-240

4 15 5 ECU/ACU trouble on terminal monitor 10-240

4 15 6 TCUNDCNCU1NCU2/ARU/SWP trouble on terminal monitor 10-240

4 15 7 DTC search application 10-240

4 16 Battery 10-241

4 16 1 Checking battery voltage 10-241

xvi ii M7001

KiSC issued 09, 2020 A

M7001

4 16 2 Checking battery terminal connection 10-241

4 16 3 Checking battery condition indicator 10-241

4 16 4 Recharging battery 10-242

4 16 5 Directions for storage 10-242

4 17 Fuse, grounding and connector 10-243

4 17 1 Checking fuse 10-243

4 17 2 Checking grounding wire 10-250

4 17 3 Checking joint connector 10-251

4 17 4 CAN termination 10-259

4 18 ECU 10-267

4 18 1 Calibration of ECU 10-267

4 18 2 Vehicle control unit1 (VCU1) 10-275

4 18 3 Vehicle control unit2 (VCU2) 10-279

4 18 4 Transmission control unit (TCU) 10-286

4 18 5 Engine control unit (ECU) 10-293

4 18 6 After treatment control (ACU) 10-300

4 18 7 TECU, central electric control unit (CEU) 10-303

4 18 8 Dash board monitor (DBM) 10-312

4 18 9 K-Monitor (Terminal Monitor) 10-313

4 18 10 Armrest unit (ARU) 10-321

4 18 11 VDC (for CVT model) 10-323

4 19 Starting system 10-326

4 19 1 Main key switch 10-326

4 19 2 Battery cut switch 10-327

4 19 3 Battery cut relay 10-328

4 19 4 Starter 10-329

4 19 5 Relay (ECU / starter) 10-330

4 19 6 Glow plug 10-331

4 19 7 Glow relay 10-332

4 19 8 Diode (TCU) 10-334

4 19 9 Relay (ACU heater) 10-334

4 20 Engine control system 10-335

4 20 1 Fuel injector 10-335

4 20 2 Suction control valve (SCV) 10-336

4 20 3 Rail pressure sensor 10-336

4 20 4 Fuel temperature sensor 10-337

4 20 5 Fuel pump 10-337

4 20 6 Boost sensor 10-338

4 20 7 Intake air temperature sensor 10-339

4 20 8 EGR valve 10-340

4 20 9 Crankshaft position sensor (NE sensor) 10-340

4 20 10 Camshaft position sensor (G sensor) 10-341

4 20 11 Intake air flow sensor 10-341

4 20 12 Intake throttle valve 10-342

4 20 13 Exhaust temperature sensor 10-343

4 20 14 Differential pressure sensor 10-344

4 20 15 Parked regeneration switch 10-344

4 20 16 DPF inhibit switch 10-345

4 20 17 Fuel tank sensor 10-345

4 20 18 DEF tank sensor (Header unit) 10-346

4 20 19 DEF pump sensor 10-346

4 20 20 DEF injector 10-347

4 20 21 NOx sensor pre/post (1/2) 10-350

4 20 22 SCR inlet temperature sensor 10-350

4 21 Charging system 10-351

4 21 1 Alternator 10-351

4 22 Powershift system 10-352

4 22 1 Clutch pedal sensor 10-352

xix

KiSC issued 09, 2020 A

4 22 2 Clutch switch 10-355

4 22 3 Powershift input / output speed sensor 10-357

4 22 4 Main clutch speed sensor 10-359

4 22 5 Traveling speed sensor 10-361

4 22 6 PTO rotation speed/shaft detection sensor 10-363

4 22 7 Oil temperature sensor 10-365

4 22 8 System pressure switch 10-369

4 22 9 Transmission filter pressure switch 10-371

4 22 10 Solenoid valve (Powershift clutch A-F) 10-371

4 22 11 Solenoid valve (Main clutch) 10-373

4 22 12 Solenoid valve (Range gear shift) 10-375

4 22 13 Solenoid valve (Differential) 10-377

4 22 14 Solenoid valve (Brake cooler cutoff) 10-379

4 22 15 Solenoid valve (PTO clutch) 10-381

4 22 16 Solenoid valve (4WD) 10-383

4 22 17 Neutral switch 10-386

4 22 18 Position sensor 10-387

4 23 CVT system 10-389

4 23 1 Clutch pedal sensor 10-389

4 23 2 Clutch switch 10-391

4 23 3 Engine input speed sensor 10-393

4 23 4 Oil temperature sensor 10-394

4 23 5 System pressure switch 10-396

4 23 6 Filter bypass switch 10-397

4 23 7 Lubrication pressure sensor 10-399

4 23 8 Thermal related filter bypass pressure switch 10-400

4 23 9 Hydrostatic unit output speed sensor 10-401

4 23 10 Redundant speed sensor 10-404

4 23 11 Speed/direction of rotation sensor 10-406

4 23 12 PTO rotation speed sensor 10-408

4 23 13 PTO shaft detection sensor 10-409

4 23 14 Solenoid valve (Clutch 1 to 4, BG, forward and reverse) 10-411

4 23 15 Solenoid valve (Hydrostatic control) 10-413

4 23 16 Solenoid valve (4WD, Differential lock) 10-414

4 23 17 Solenoid valve (Brake cooling) 10-417

4 23 18 Solenoid valve (PTO clutch) 10-418

4 24 Hydraulic control system 10-419

4 24 1 Hydraulic transmission 10-419

4 24 2 Checking external switch for 3-point hitch / remote control valve (2nd) 10-420

4 24 3 Checking external switch for rear PTO 10-421

4 24 4 Checking connector voltage of rear hitch position sensor 10-422

4 24 5 Checking connector voltage of rear hitch draft sensor 10-423

4 24 6 Checking radar sensor (If equipped) 10-424

4 24 7 Checking hydraulic return filter pressure sensor resistance 10-424

4 24 8 Checking steering filter sensor supply voltage 10-425

4 25 Steering control system 10-426

4 25 1 Checking steering wheel angle sensor 10-426

4 25 2 Checking steering controller (Auto steering ready model) 10-427

4 25 3 Checking steering sensor (SASA) (Auto steering ready model) 10-428

4 26 Front suspension system (Front suspension model) 10-429

4 26 1 Checking front suspension position sensor 10-429

4 26 2 Checking front suspension pressure sensor 10-430

4 26 3 Checking front suspension solenoid valve 10-431

4 27 Front PTO 10-431

4 27 1 Checking front PTO solenoid valve 10-432

4 28 Lighting system 10-433

4 28 1 Combination switch 10-433

4 28 2 Flasher unit (North America model) 10-442

XX M7001

KiSC issued 09, 2020 A

4 29 Cabin control system 10-442

4 29 1 Shuttle lever 10-442

4 30 Warning lamp, indicator lamp and gauge 10-445

4 30 1 Engine oil pressure switch 10-445

4 30 2 Coolant temperature sensor 10-446

4 30 3 Air cleaner switch 10-446

4 31 Others 10-448

4 31 1 Checking radio (If equipped) 10-448

4 31 2 Checking cigar socket 10-448

4 31 3 Checking trailer socket (EU model) 10-449

4 31 4 Checking trailer socket (NA model) 10-449

4 31 5 Checking loader electrical outlet 10-449

4 31 6 Electrical outlet 10-450

4 31 7 Terminal information for electrical outlet (NA model) 10-450

5 Disassembling and assembling 10-450

5 1 Starter motor 10-450

5 1 1 Disassembling motor 10-450

5 2 Alternator 10-451

5 2 1 Disassembling front bracket 10-451

5 2 2 Removing pulley 10-451

5 2 3 Removing rotor 10-452

5 2 4 Removing brush 10-452

5 2 5 Reassembling brush 10-452

5 2 6 Removing bearing at slip ring side 10-453

6 Servicing 10-453

6 1 Starter 10-453

6 1 1 Checking commutator and mica 10-453

6 1 2 Checking brush wear 10-453

6 1 3 Checking armature coil 10-454

6 1 4 Checking overrunning clutch 10-454

6 1 5 Checking brush holder 10-454

6 1 6 Checking field coil 10-455

6 2 Alternator 10-455

6 2 1 Checking bearing 10-455

6 2 2 Checking stator 10-455

6 2 3 Checking rotor 10-456

6 2 4 Checking slip ring 10-456

6 2 5 Checking brush wear 10-456

6 2 6 Checking rectifier 10-456

11 CABIN

MECHANISM 11-1

M7001

1 Air conditioning system 11-1

1 1 Structure of air conditioning system 11-1

1 2 Function of compressor 11-2

1 2 1 Operation of compressor 11-2

1 2 2 Function of compressor oil 11-2

1 3 Structure of air conditioner unit 11-2

1 3 1 Function of A/C blower 11-3

1 4 Outline of air conditioning system control 11-4

1 5 Air flow of air conditioning system 11-5

1 6 Location of air control vent 11-5

1 7 Electrical system 11-6

1 7 1 Electrical circuit 11-6

1 7 2 Function of blower relay and compressor relay 11-7

1 7 3 Blowerswitch 11-10

2 Pneumatic cabin suspension system 11-11

2 1 Structure of pneumatic cabin suspension system 11-11

xxi

KiSC issued 09, 2020 A

2 2 Components 11-15

2 2 1 Function of pneumatic suspension 11-15

2 2 2 Function of compressed air tank 11-15

2 2 3 Function of cab suspension feed valve 11-15

2 2 4 Function of pipe sensor 11-15

2 2 5 Function of compressor 11-15

3 Seat 11 -16

3 1 Dimensions ofseat 11-16

3 2 Structure of seat 11-18

3 3 Height level control of seat 11-19

3 4 Electrical system of seat 11-21

3 5 Components 11-22

3 5 1 Function of horizontal spring unit 11-22

3 5 2 Function of compressor 11 -23

SERVICING 11-25

1 Troubleshooting for cabin 11-25

2 Servicing specifications for cabin 11-32

3 Tightening torques for cabin 11 -33

4 Precautions at repairing refrigerant cycle 11-34

4 1 Handling of service tools 11-36

4 1 1 Service tools 11-36

4 1 2 Operation of manifold gauge set 11-36

4 1 3 Setting refrigerant charging hose 11-37

4 1 4 Vacuum pump adapter 11-38

4 1 5 Function of electric gas leak tester 11-39

4 1 6 Setting can tap valve 11-39

4 1 7 Setting T-joint 11-40

4 1 8 Objective of R134a refrigerant recovery and recycling machine 11-40

5 Checking and charging refrigerant cycle 11-40

5 1 Checking with manifold gauge 11-40

5 1 1 Connecting manifold gauge and preparing test 11-40

5 1 2 Gauge indication when operating normally 11-41

5 1 3 Gauge indication when insufficient refrigerant 11-41

5 1 4 Gauge indication when excessive refrigerant or insufficient condenser cooling 11-41

5 1 5 Gauge indication when air entered in the cycle 11-42

5 1 6 Gauge indication when moisture entered in the cycle 11-42

5 1 7 Gauge indication when refrigerant fails to circulate 11-43

5 1 8 Gauge indication when expansion valve opens too far or improper installation of heat

sensitizing tube 11-43

5 1 9 Gauge indication when damaged compression of compressor 11-44

5 2 Discharging, evacuating and charging 11-44

5 2 1 Discharging the refrigerant 11-44

5 2 2 Evacuating system 11-45

5 2 3 Charging refrigerant 11-46

5 2 4 Checking charge refrigerant amount 11-47

6 Checking and adjusting 11-49

6 1 Air conditioning system 11-49

6 1 1 Air conditioning system operating condition 11-49

6 1 2 Compressor 11-51

6 1 3 Compressor relay and blower relay 11-52

6 1 4 Control panel (Blower switch, A/C switch, mode control dial, temperature control dial,

and recirculation / fresh air selection switch) 11-53

6 1 5 Blower resistor 11-56

6 1 6 Blower motor 11-56

6 1 7 Temperature motor 11-57

6 1 8 Mode motor 11-57

6 1 9 Recirculation / fresh air motor 11-58

6 1 10 Pressure switch 11-58

xxii M7001

KiSC issued 09, 2020 A

6 2 Wiper and wiper motor 11-59

6 2 1 Front wiper switch 11-59

6 2 2 Rear wiper switch 11-60

6 2 3 Wiper motor 11-61

6 3 Cabin air suspension system 11-62

6 3 1 Checking proper assembly of cabin air suspension 11-62

6 4 Air suspension seat 11-63

6 4 1 Compressor 11 -63

6 4 2 Cam switch 11-64

6 4 3 Outlet valve 11-64

6 4 4 Bowden pull wire 11-65

7 Preparation 11-66

7 1 Separating cabin from tractor 11-66

7 1 1 Preparation 11-66

7 1 2 Air conditioner, wiring harness, heater hose and hydraulic hose 11-70

7 1 3 Steering hose and brake hose 11-72

7 1 4 Wiring harness and cables 11-73

7 2 Removing cabin roof 11-79

7 2 1 Removing cabin outer roof 11-79

7 3 Air conditioning system 11-80

7 3 1 Compressor 11-80

7 3 2 Removing air conditioner unit 11-81

7 3 3 Removing air conditioner pipes 11-86

7 3 4 Removing heater hoses 11-88

7 4 Cabin 11-89

7 4 1 Cabin windshields 11-89

7 4 2 Wiper motor 11-91

7 4 3 Suspension seat 11-92

7 4 4 Disassembling seat 11-92

7 4 5 Shock absorbers 11-93

7 4 6 Pneumatic spring 11-94

7 4 7 Height level control unit 11-95

7 4 8 Passenger seat 11-96

8 Servicing 11-97

8 1 Air conditioning system 11-97

8 1 1 Compressor 11-97

12 K-OBD

GENERAL INFORMATION 12-1

M7001

1 K-08D kit 12-1

1 1 K-08D kit box inside 12-1

1 2 License key of K-08D 12-1

2 Connector 12-1

2 1 K-08D dongle 12-1

2 2 CAN connection cable 12-2

2 3 Y cable 12-2

3 CANBUS 12-2

4 Connecting port 12-3

4 1 Connecting port 12-3

4 2 Connecting port for Y cable 12-3

5 Launching K-OBD 12-3

5 1 Launching K-08D 12-3

5 2 Configuration for launching 12-4

6 User interface 12-5

6 1 User interface 12-5

7 K-08D news (OTC search application) 12-6

7 1 Checking K-08D news (OTC search) 12-6

8 Selecting model 12-6

xxiii

KiSC issued 09, 2020 A

8 1 Selecting tractor model 12-6

9 Changing of security level 12-6

9 1 Log in level 12-6

10 Menu bar 12-7

10 1 Settings 12-7

10 1 1 Settings 12-7

10 2 Software update of K-OBD 12-7

10 2 1 Updating of K-O8D 12-7

OPERATION 12-9

1 Updating xCU 12-9

1 1 VCU2 12-9

1 1 1 Update VCU2 12-9

1 2 TCU (PST/KVT), VDC 12-10

1 2 1 Update TCU (PST/KVT) and VDC 12-10

1 3 VCU 1 /ARU/DBM/SWP/TECU/CEU/NAC/SC 12-12

1 3 1 Update VCU1 /ARU/DBM/SWP/TECU/CEU/NAC/SC 12-12

2 Calibrations 12-14

2 1 VCU1 foot pedal 12-14

2 2 VCU2 Front axle suspension 12-16

2 3 VCU2 Rear hitch 12-18

2 4 VCU2 Wheel angle 12-20

2 5 TCU-PST clutch pedal 12-22

2 6 TCU-PST main clutch 12-24

2 7 TCU-PST power shift clutch 12-27

2 8 TCU-PST PTO clutch 12-29

2 9 ARU potention meter 12-30

2 10 ARU fronUrear PTO switch 12-33

2 11 ARU fingertip 1-6 12-35

2 12 VDC clutch pedal 12-38

2 13 VDC PTO clutch 12-40

2 14 TCU-KVT TCU calibration 12-41

2 15 Steering controller 12-43

2 15 1 Wheel angle sensor 12-43

2 15 2 Spool calibration 12-46

2 16 Calibration value table 12-49

3 Parameter 12-50

3 1 VCU1 table 12-50

3 2 VCU2 table 12-51

3 3 ARU table 12-52

3 4 TCU-PST table 12-53

3 5 VDC table 12-54

4 1/0 testing 12-55

4 1 ACU table 12-55

4 2 ECU table 12-56

4 3 VCU1 table 12-57

4 4 VCU2 table 12-59

4 5 TCU-PST table 12-61

4 6 TCU-KVT table 12-62

4 7 VDC table 12-64

4 8 ARU/CEU/SWP table 12-68

xxiv M7001

KiSC issued 09, 2020