$45

Kymco Dink Classic 200 Service Manual - PDF DOWNLOAD

Kymco Dink Classic 200 Service Manual - PDF DOWNLOAD

FILE DETAILS:

Kymco Dink Classic 200 Service Manual - PDF DOWNLOAD

Language : English

Pages : 225

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

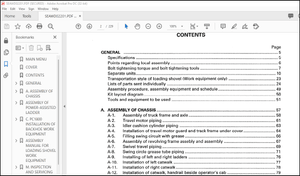

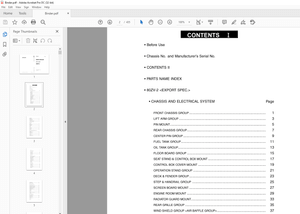

TABLE OF CONTENTS:

Kymco Dink Classic 200 Service Manual - PDF DOWNLOAD

GENERAL INFORMATION 1EXHAUST MUFFLER/FRAME COVERS 2INSPECTION/ADJUSTMENT 3LUBRICATION SYSTEM 4ENGINE REMOVAL/INSTALLATION 5CYLINDER HEAD/VALVES 6CYLINDER/PISTON 7DRIVE AND DRIVEN PULLEYS/KICK STARTER 8FINAL REDUCTION 9A.C. GENERATOR/STARTER CLUTCH 10CRANKCASE/CRANKSHAFT 11COOLING SYSTEM 12FUEL SYSTEM/CARBURETOR/FUEL PUMP 13STEERING HANDLEBAR/FRONT WHEEL/FRONT BRAKE/FRONT SHOCK ABSORBER/FRONT FORK 14REAR BRAKE/REAR FORK/REAR WHEEL/REAR SHOCK ABSORBER` 15BATTERY/CHARGING SYSTEM 16IGNITION SYSTEM 17STARTING SYSTEM 18SWITCHES/HORN/FUEL UNIT/ THERMO-STATIC SWITCH/TEMPERATURE GAUGE/INSTRUMENTS/ LIGHTS 19E/M EXHAUST EMISSION CONTROL SYSTEM 20

DESCRIPTION:

Kymco Dink Classic 200 Service Manual - PDF DOWNLOAD

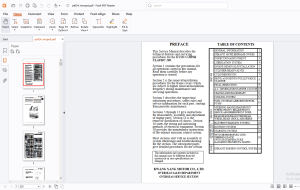

PREFACE;

- This Service Manual describes the technical features and servicing procedures for the KYMCO DINK CLASSIC 200.

- Section 1 contains the precautions for all operations stated in this manual. Read them carefully before any operation is started.

- Section 2 is the removal/installation procedures for the frame covers which are subject to higher removal/installation frequency during maintenance and servicing operations.

- Section 3 describes the inspection/ adjustment procedures, safety rules and service information for each part, starting from periodic maintenance.

- Sections 5 through 13 give instructions for disassembly, assembly and adjustment of engine parts. Section 14 is the removal/ installation of chassis. Section 16 states the testing and measuring methods of electrical equipment. Section 20 provides the maintenance instructions of the exhaust emission control system.

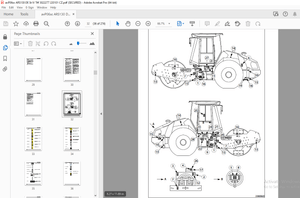

- Most sections start with an assembly or system illustration and troubleshooting for the section. The subsequent pages give detailed procedures for the section

GENERAL INFORMATION:

- DINK 200 Apply or add designated greases and lubricants to the specified lubrication points.

- After reassembly, check all parts for proper tightening and operation.

- When two persons work together, pay attention to the mutual working safety.

- Disconnect the battery negative (-) terminal before operation.

- When using a spanner or other tools, make sure not to damage the motorcycle surface.

- After operation, check all connecting points, fasteners, and lines for proper connection and installation.

- When connecting the battery, the positive (+) terminal must be connected first.

- After connection, apply grease to the battery terminals.

- Terminal caps shall be installed securely.

G.B 15/03/25