$38

Landoll Bendi B3-30AC/DS Articulated Counterbalance Forklift Maintenance Manual – PDF DOWNLOAD

Landoll Bendi B3-30AC/DS Articulated Counterbalance Forklift Maintenance Manual – PDF DOWNLOAD

FILE DETAILS:

Landoll Bendi B3-30AC/DS Articulated Counterbalance Forklift Maintenance Manual – PDF DOWNLOAD

Language : English

Pages :252

Downloadable : Yes

File Type : PDF

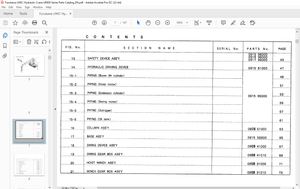

TABLE OF CONTENTS:

Landoll Bendi B3-30AC/DS Articulated Counterbalance Forklift Maintenance Manual – PDF DOWNLOAD

1 Introduction, Safety, and Specifications

Before You Begin 1-1

Introduction 1-1

Operating Instructions 1-1

Service Training 1-1

Required Tools 1-1

Decal Identification 1-2

General Maintenance Instructions 1-5

Safety Guidelines 1-6

Specifications 1-11

General Torque Specifications (rev 4/97) 1-13

Metric Torque Specifications: 1-14

Hydraulic Fitting Torque Specifications 1-15

2 Inspection and Maintenance

Inspection Introduction 2-1

Inspections and Scheduled Maintenance Requirements 2-2

Tools and Equipment Required 2-2

Cleaning and Inspecting the Forklift 2-3

Preparing or Inspection and/or Maintenance 2-3

Performance Testing 2-3

Daily Inspections 2-4

Safety Warning and Operator’s Manual 2-4

Data Plate 2-4

Wheels and Tires 2-4

ESD Straps 2-4

Service Brakes 2-5

Forks 2-5

Mast Racking 2-5

Hydraulic Oil 2-5

Hydraulic Cylinders, Hoses, and Fittings 2-6

Battery 2-6

Specific Gravity Correction 2-6

Battery Restraint System and Rollout Option 2-9

Operator Controls 2-9

Seat 2-11

Maintenance Introduction 2-12

Daily Inspection Checklist 2-12

Inspection Sheets 2-12

Operator’s Daily Checklist 2-13

ii F-874-R0 Edition

3 Troubleshooting

General Bendi B3/30 Troubleshooting Charts 3-1

4 Tires, Brakes and Drivetrain

Floor Plate 4-1

Floor Plate Removal and Assembly 4-1

Tire Inspection 4-2

Visual Inspection 4-2

Brake System 4-4

Brake System Service 4-5

Hydraulic Brake Drums 4-8

Parking Brake Assembly 4-8

Brake Pedal Assembly 4-11

Master Cylinder 4-12

Drivetrain 4-15

Traction Motor, and Gear Box 4-15

Accelerator Pedal 4-17

5 Hydraulic Oil, Motors, Pumps and Cylinders

Hydraulic Components 5-1

Hydraulic System Maintenance 5-1

Steering Motor Service 5-4

Hydraulic Pump Service 5-4

Front Rotation Assembly 5-5

Hydraulic Control Valve Assembly 5-7

6 Electrical System

Steering Column/Dash Assembly 6-1

Remove the Display Panel 6-1

Key Switch 6-2

Rocker (On/Off) Switches 6-2

Steering Wheel Removal 6-3

Steering Column (Console) Removal 6-3

Steering Orbital Control Unit 6-4

Electrical Contactors 6-4

Inspecting the Contacts 6-4

Batteries – Care and Replacement 6-4

Battery Safety – Duplicate of Chapter 1 6-4

Battery Safety 6-4

Checking Batteries 6-5

Battery Care 6-5

Charging the Battery 6-5

iii

Electrical Systems 6-6

Electrical Static Discharge 6-6

Electrical Controls and Levers 6-6

Replacing a Complete Control Panel 6-7

Horn Service 6-8

Truck Lighting 6-9

Headlights 6-9

Brake and Tail Lights 6-9

Back Up Alarms 6-9

Overhead Guard, Lighting and Alarms 6-9

Seat Assembly 6-9

Seat Switch 6-9

Check Driver’s Seat Switch 6-9

Side Shift Circuit Maintenance 6-10

Check Side Shift Circuit Performance 6-10

Fuses 6-10

ESD Strap 6-11

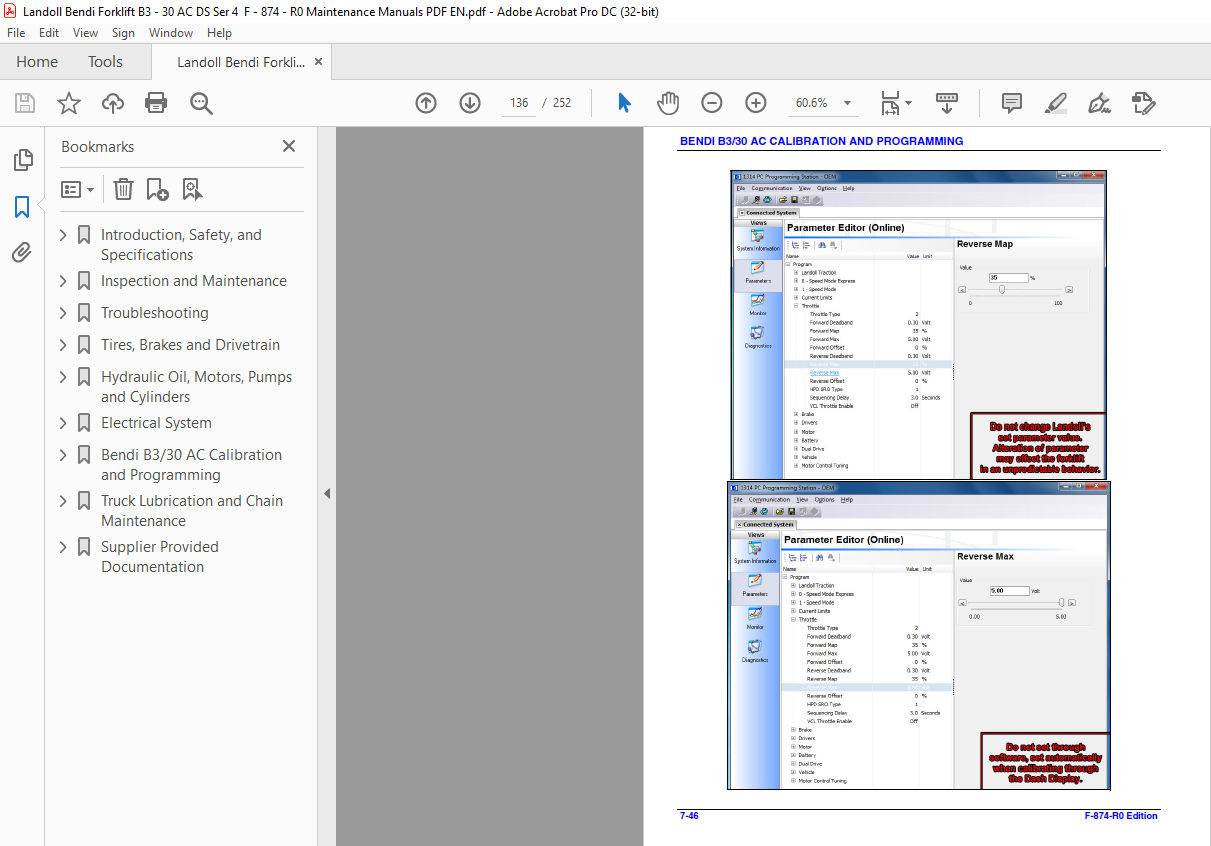

7 Bendi B3/30 AC Calibration and Programming

Controller Theory of Operation 7-1

1314 Bendi B3/30 Controller Software Program Installation and Operation 7-3

USB to Serial Port Adapter Cable 7-3

1314 Installation Procedure 7-4

1314 Update Procedure 7-5

Communicating with Bendi B3/30 Controllers 7-6

Controller Fault History 7-9

Traction Controller Parameters 7-10

Pump Controller Parameters 7-96

Curtis Controller Troubleshooting 7-101

Program Troubleshooting Chart 7-102

Controller Maintenance 7-108

Controller Cleaning 7-108

8 Truck Lubrication and Chain Maintenance

Lubricating the Truck 8-1

Tilt Cylinder Clevis 8-1

Chain Lubrication 8-1

Check Lift Operation 8-2

Removing the Mast From Truck 8-4

9 Supplier Provided Documentation

Lift Technologies Mast Service Manual 9-1

Table of contents – page 5 9-1

IMAGES PREVIEW OF THE MANUAL: