$45

LEEBOY 8000 BH Operations, Maintenance & Parts Manual 8000295 PDF DOWNLOAD

LEEBOY 8000 BH Operations, Maintenance & Parts Manual 8000295 PDF DOWNLOAD

FILE DETAILS:

LEEBOY 8000 BH Operations, Maintenance & Parts Manual 8000295 PDF DOWNLOAD

Language : English

Pages : 97

Downloadable :Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

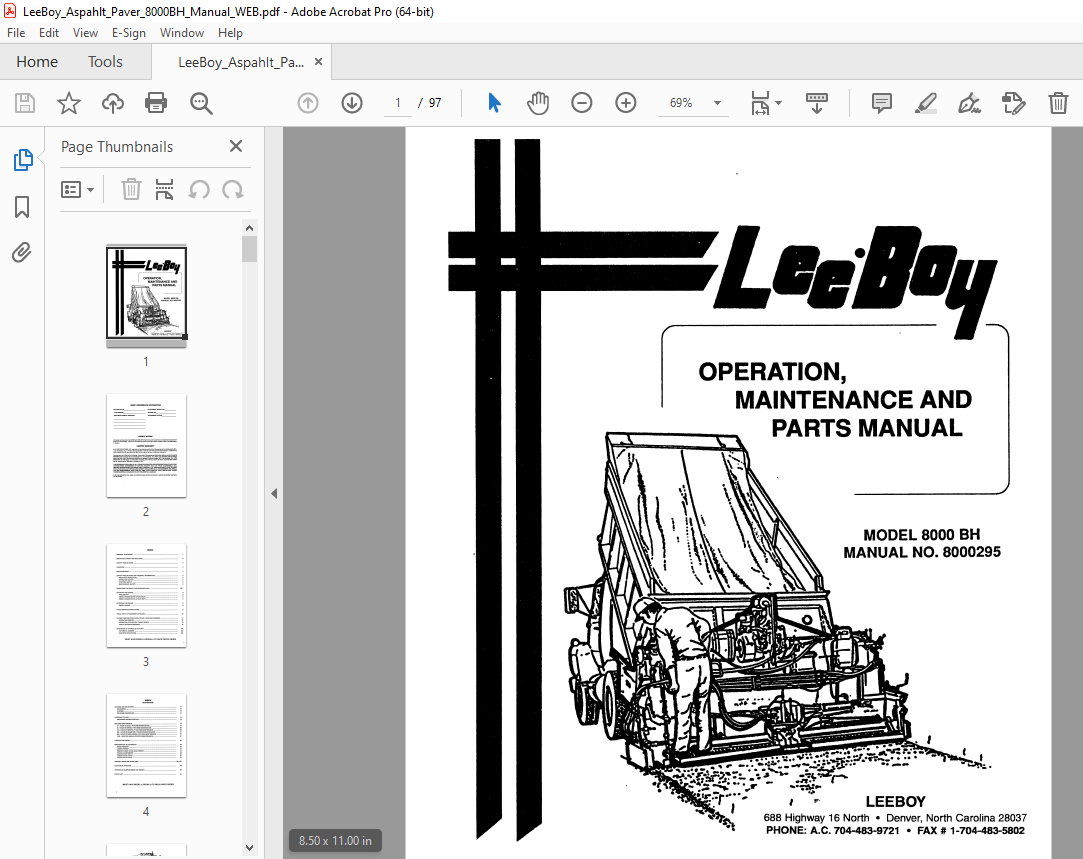

TABLE OF CONTENTS:

LEEBOY 8000 BH Operations, Maintenance & Parts Manual 8000295 PDF DOWNLOAD

GENERAL STATEMENT 1

IMPORTANT SAFETY INSTRUCTIONS 2

SAFETY PRECAUTIONS 3

OVERVIEW 4

SPECIFICATIONS 4

SAFETY PRECAUTIONS AND GENERAL INFORMATION 5

PRE ,START INSPECTION 5

OPERATING SAFETY 5

STOPPING SAFETY 5

MAINTENANCE SAFETY 5

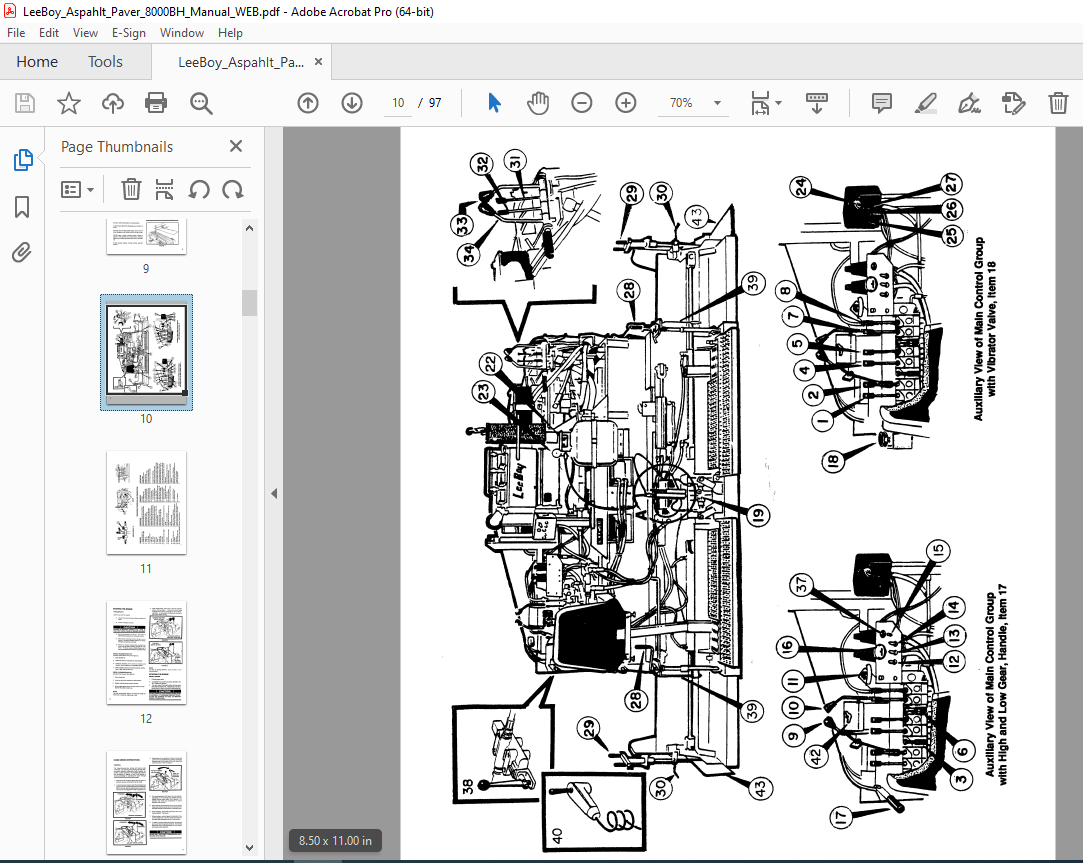

OPERATING CONTROLS AND DESCRIPTIONS 6

STARTING THE ENGINE 8

PRELIMINARY 8

DIESEL ENGINE/START-UP (QUADCO) 8

DIESEL ENGINE/START-UP (LEE-BOY) 8

STOPPING THE ENGINE 8

DIESEL ENGINE 8

PAVER DRIVING INSTRUCTIONS 9 10

TRUCK HITCH ATTACHMENT (OPTIONAL)

PAVING PREPARATION INSTRUCTIONS (LIGHTING BURNERS) 11

OPERATING FEEDER 12

OPERATION OF ELECTRIC FLIGHT SCREW 12

USE OF AUGER EXTENSIONS 12

OPERATION OF HYDRAULIC CUTOFFS 12A

AUTOMATIC AUGERS

ELECTRIC SPRA YDOWN `2A

LOADING AND UNLOADING 13

UNLOADING 13

LOADING 13

TIE DOWN PROCEDURE 14

STARTING TO PAVE 15

ADJUSTING CROWN CONTROL 18

ROUTINE MAINTENANCE 19

10 HOUR OR DAILY ROUTINE MAINTENANCE 19

50 HOUR OR WEEKLY ROUTINE MAINTENANCE 20

100- HOUR OR MONTHLY ROUTINE MAINTENANCE 20

250 HOUR OR QUARTERLY ROUTINE MAINTENANCE 21

500 HOUR OR SEMI-ANNUAL ROUTINE MAINTENANCE 21

1000 – HOUR OR ANNUAL ROUTINE MAINTENANCE 21

LUBRICATION CHART 22

MAINTENANCE ADJUSTMENTS 23

RAISE FEEDERS 23

LOWER FEEDER 24

FEEDER FLIGHT CHAIN ADJUSTMENT 24

TRACK ADJUSTMENTS 25

FEEDER DRIVE CHAIN 25

AUGER DRIVE CHAIN 25

TROUBLE SHOOTING GUIDE 8000 26 & 27

ELECTRICAL DIAGRAM 28

HYDRAULIC DIAGRAM 80008 AND 80008H 29

PARTS LIST 30

DESCRIPTION:

LEEBOY 8000 BH Operations, Maintenance & Parts Manual 8000295 PDF DOWNLOAD

SAFETY PRECAUTIONS

If your paver has been repainted. it is extremely important that all the decals referring to cautions. warnings and danger be replaced in their proper locations. The illustrations on this page will aid you in determining the proper locations. however for additional help, you should refer to the part listing in the parts section of this manual and note the description column. Under this column a description on location is provided for each decal. If you still need more explicit instructions contact your dealer

PRE-START INSPECTION INSPECT

- Have any malfunctioning, broken or missing parts corrected or replaced before using. Hydralic hoses should be checked daily for wear and leaks. Replace if damaged.

- CHECK that all the instruction and safety labels are in place and readable. These are as impo~nt as any other equipment on the machine. READ and FOLLOW all instruction decals.

- WEAR OSHA required safety equipment when running the paver. FILL the fuel tank with the engine off. Never fill near an open flame, when smoking or when screed heat is on.

- CLEAR auger & feeders before starting engine. And make sure all covers and guards are in place.

OPERATING SAFETY

- ALWAYS make sure no person or object is in your line of travel BEFORE starting. WORK slowly in tight areas. DO NOT run engine in a closed building for long periods of time.

- NEVER spray fuel oil on or near screed while it is being heated.

- AVOID steep hills if possible

- DO NOT shift transmissions on steep grades. ALWAYS look BEFORE changing your direction of travel. DO NOT pave in high speed range, use it only for travel. Qa.m.t counter rotate machine in high range.

- NEVER open a valve to burner unless a flame is present. Heat screed for no more than 5 minutes. Make sure all valves are closed after burner is turned off.

- AVOID leaving engine running without operator present.