$45

LEEBOY 8515C CONVEYOR PAVER Operations, Service & Parts Manual 1003095-04 PDF DOWNLOAD

LEEBOY 8515C CONVEYOR PAVER Operations, Service & Parts Manual 1003095-04 PDF DOWNLOAD

FILE DETAILS:

LEEBOY 8515C CONVEYOR PAVER Operations, Service & Parts Manual 1003095-04 PDF DOWNLOAD

Language : English

Pages : 390

Downloadable :Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

LEEBOY 8515C CONVEYOR PAVER Operations, Service & Parts Manual 1003095-04 PDF DOWNLOAD

Manual No. 1003095-04

This manual applies to serial number and above: 101133

Safety 1-1

Safety Precautions 1-3

Safety Label Locations 1-6

Information and Specifications 2-1

Limited Warranty Policy 2-3

Warranty 2-3

Limitations 2-3

Items Not Covered 2-4

Other Limitations 2-4

Contact Information 2-5

Record of Ownership 2-5

Nameplate 2-5

Screed Serial Number Location 2-6

General Information 2-7

Major Components 2-7

Engine 2-7

Hydraulic System 2-7

Torque Hubs 2-7

Hopper 2-7

Operator Platform 2-7

Screed 2-8

Electrical System 2-8

Optional Components 2-9

Screed Generator 2-9

LeeBoy Model 8515C Conveyor Paver

Screed Heating Controls 2-9

Screed Heating Elements 2-9

Specification charts 2-10

Dimensions 2-12

Torque Specs 2-13

Inch Fasteners 2-13

Metric Fasteners 2-14

Hydraulic Fittings 2-15

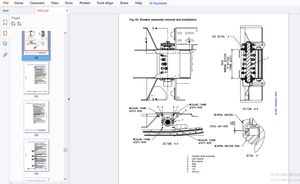

Full Torque Nut Coupling Installation 2-15

Component Location 3-1

Operation Controls Location 3-2

Right Instrument Panel (Dash) 3-4

Center Instrument Panel (Dash) and Powerview™ Display 3-8

Left Instrument Panel (Dash) 3-10

Left Instrument Panel (Dash) — Continued 3-12

Steering and Speed Control Module — Dual Joysticks 3-14

Steering and Speed Control Module — Steering Wheel (Option) 3-16

Right Side Controls 3-18

Left Side Controls 3-20

Legend Electric Screed Operation Controls (Option) 3-22

815HD Screed Operation Controls (Option) 3-24

Electric Heat Control Box (Option) 3-26

Operation 4-1

General Information 4-3

Safety 4-3

Pre-Start Inspection and Preparation 4-4

Tier 4 Engine Overview 4-4

Tampering: 4-5

Starting the Engine 4-5

Preliminary 4-5

Engine Start-up 4-5

Stopping the Engine 4-6

General Operation 4-6

Controls 4-7

E-Stop Function 4-7

Powerview™ Display 4-8

LeeBoy Model 8515C Conveyor Paver

Gauge Screens 4-8

Soft Keys (Buttons) 4-9

Status Icons 4-10

Main Menu 4-11

Gauges 4-11

System Info 4-13

User Settings 4-15

Regen (FOR KUBOTA ENGINES ONLY) 4-18

Messages, Cautions, Warnings 4-21

Paver Driving Instructions 4-22

Electronic Control Steering Box 4-22

Paver Operation 4-23

Conveyor Operation 4-24

Hydraulic Cutoff Gates Operation 4-24

Sonic Augers Operation 4-25

Auger Extensions 4-25

Electric Flight Screws Operation 4-26

Spray Down 4-26

Burner Ignition Procedure 4-27

Electric Heating Controls 4-28

Starting To Pave 4-29

Setting Screed To Pave 4-30

Setting Screed Endgates 4-31

Mat Texture Adjustment 4-32

Unloading And Loading 4-33

Unloading 4-34

Loading 4-34

Tie Down Procedure 4-34

Electric Screed Heating System (Option) 4-35

Generator 4-35

Control Box 4-36

Cycle Timer 4-37

Element Relay 4-37

Element Breaker 4-38

Element Connections 4-38

LeeBoy Model 8515C Conveyor Paver

Truck Hitch Attachment (Option) 4-39

Umbrella (Option) 4-40

Maintenance 5-1

Lubrication Chart 5-3

General Information 5-6

Maintenance Schedule 5-6

General Information 5-6

Preparing Paver for Maintenance 5-6

Paver Lubrication 5-6

10-Hour or Daily Routine Maintenance 5-7

50-Hour (Initial) or Weekly Routine Maintenance 5-7

100-Hour or Monthly Routine Maintenance 5-8

250-Hour or Quarterly Routine Maintenance 5-8

500-Hour or Semi-Annual Routine Maintenance 5-8

1000-Hour or Annual Routine Maintenance 5-8

Maintenance Adjustments 5-9

Screed Extension Top Guide Adjustment 5-9

Electric Screed Extension Top Guide Adjustment (Option) 5-9

Replacing Screed Extension Wear Plates 5-9

Replacing Electric Screed Extension Wear Plates (Option) 5-10

Replacing Screed Main Wear Plates 5-11

Raising Conveyor 5-11

Lowering Conveyor 5-12

Conveyor Flight Chain Adjustment 5-13

Automatic Track Adjustment 5-13

Conveyor Drive Chain Adjustment 5-14

Torque Hub Hydraulic Motor Adjustment 5-14

Auger Drive Chain Adjustment 5-15

Track Tension Pressure Relief 5-15

Track Tension Release 5-15

Conveyor Limit Switch Adjustment 5-16

Electrical System 5-17

Generator Voltage Testing 5-17

Generator Speed Tuning 5-18

Generator Capacitor Replacement 5-19

Element Relay Testing 5-19

LeeBoy Model 8515C Conveyor Paver

Element Resistance Testing 5-20

Battery Servicing 5-21

Engine Maintenance 5-22

General Information 5-22

Engine Lubrication Oil – Kubota 5-22

Changing Engine Lubrication Oil Filter 5-23

Fuel system 5-23

Fuel Tank 5-23

Engine Fuel Filters 5-24

Engine Air Filter 5-24

Hydraulic System 5-25

General Information 5-25

Checking Hydraulic Oil Level 5-25

Adding Hydraulic Oil To Hydraulic Oil Reservoir 5-25

Changing Hydraulic Oil 5-25

Removal & Installation Procedures 5-26

Track Component Replacement 5-26

Rubber Track Replacement 5-28

Torque Hub Replacement 5-29

Rear Conveyor Shaft Replacement 5-30

Auger And Inner Bearing Replacement 5-31

Screed Extensions, Slides Or Bushing Replacement 5-31

Screed Wear Plate Replacement 5-32

Extension Wear Plate Replacement 5-33

Tandem Servo Pump Replacement 5-33

2-Speed Hydraulic Motor Replacement 5-34

Safety Label Installation 5-35

Troubleshooting Charts 5-36

Electric Screed 5-36

Conveyor Paver 5-37

Schematics 6-1

Electrical 1 of 14 6-3

Electrical 2 of 14 6-5

Electrical 3 of 14 6-7

Electrical 4 of 14 6-9

Electrical 5 of 14 6-11

LeeBoy Model 8515C Conveyor Paver

Electrical 6 of 14 6-13

Electrical 7 of 14 6-15

Electrical 8 of 14 6-17

Electrical 9 of 14 6-19

Electrical 10 of 14 6-21

Electrical 11 of 14 6-23

Electrical 12 of 14 6-25

Electrical 13 of 14 6-27

Electrical 14 of 14 6-29

Hydraulic Hosing 1 of 6 6-31

Hydraulic Hosing 2 of 6 6-33

Hydraulic Hosing 3 of 6 6-35

Hydraulic Hosing 4 of 6 6-37

Hydraulic Hosing 5 of 6 6-39

Hydraulic Hosing 6 of 6 6-41

Hydraulic 1 of 4 6-43

Hydraulic 2 of 4 6-45

Hydraulic 3 of 4 6-47

Hydraulic 4 of 4 6-49

Illustrated Parts List (IPL) 7-1

Quick Reference Guide – Filters 7-5

Sprocket Drive Track System (4 Roller Undercarriage) 7-6

Rubber Track Undercarriage (5 Roller Undercarriage) 7-10

Conveyor Drive Assembly 7-12

Hopper Components 7-16

Auger Assembly 7-20

Conveyor Drive Cutoff, Screed Lift Cylinders 7-24

Hydraulic Components LH Side Fuel Tank 7-26

H1 Pump & Controls 7-28

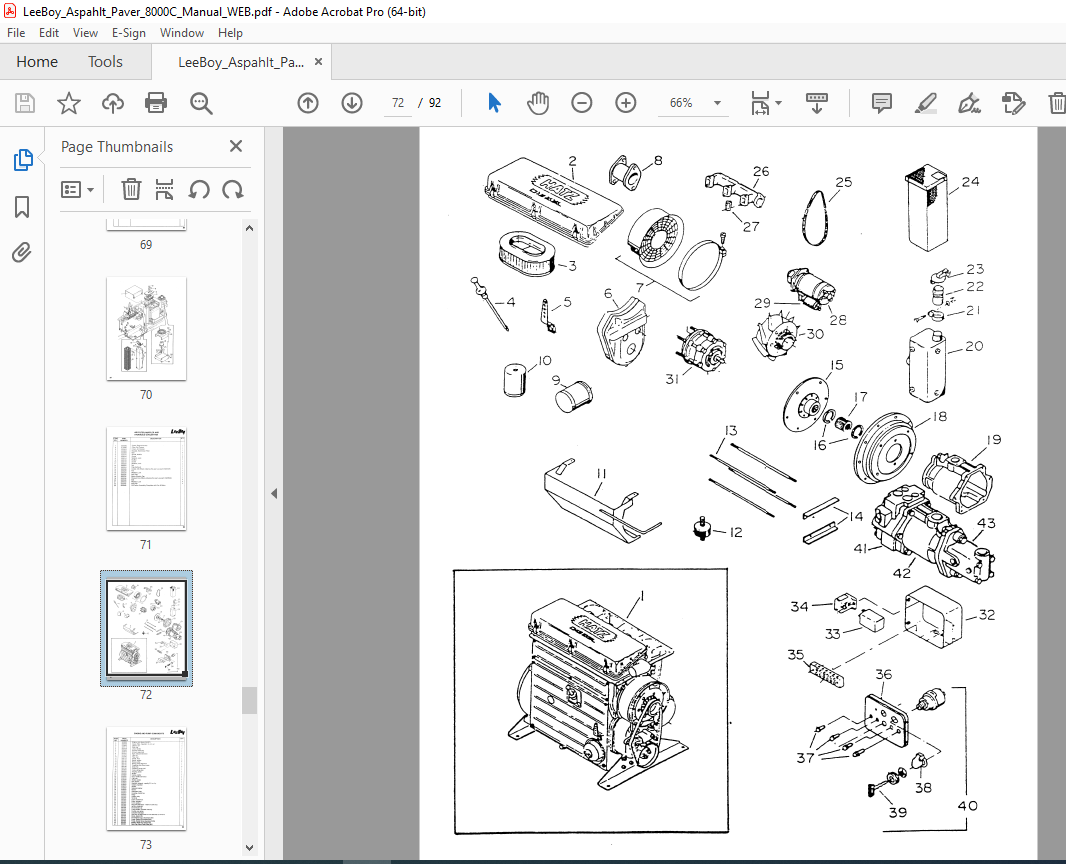

Kubota Engine 7-30

Cummins Engine Assembly 7-34

Cummins Pump Assembly 7-36

Cummins Engine 7-38

Spray Down 7-42

Screed Arm Assembly With Toe Point 7-44

Propane Heater And Automatic Ignitors 7-46

LeeBoy Model 8515C Conveyor Paver

Paver Leveling Control (TOPCON) System 4 7-48

Paver Leveling Control (TOPCON) System 5 7-50

Truck Hitch Assembly 7-52

Kubota Sheet Metal Cover 7-54

Kubota Sheet Metal Cover (Cont ) 7-56

Cummins Sheet Metal Cover 7-58

Strike Offs And Extensions 7-60

Control Valve 7-62

Lower Manifold 7-64

Instrument Panel Dash 7-66

Power Crown (Option) 7-68

Screed Non-sloping Overview 7-70

Screed Sloping Overview 7-72

Screed Frame Non-Sloping – Propane 7-74

Screed Frame Sloping – Propane 7-76

Extension Single Adjust LH Assembly – Propane 7-78

Extension Single Adjust RH Assembly – Propane 7-80

Extension Double Adjust LH Assembly – Propane 7-82

Extension Double Adjust RH Assembly – Propane 7-84

Screed Frame Non-Sloping – Electric 7-86

Screed Frame Sloping – Electric 7-88

Vibrator Assembly LH 7-90

Vibrator Assembly RH 7-92

Walk Board Assembly 7-94

Slide Plate Assembly 7-96

Extension Single Adjust LH Assembly – Electric 7-98

Extension Single Adjust RH Assembly – Electric 7-100

Extension Double Adjust LH Assembly – Electric 7-102

Extension Double Adjust RH Assembly – Electric 7-104

Endgate LH Assembly 7-106

Endgate RH Assembly 7-108

Screed Pull Arms LH Assembly 7-110

Screed Pull Arms RH Assembly 7-112

Citrus Tank & Heat Control Box 7-114

Screed Miscellaneous Components 7-116

Generator 7-118

LeeBoy Model 8515C Conveyor Paver

815HD Series Screed 8515 Non-sloping Overview 7-120

815HD Series Screed 8510 Non-sloping Overview 7-122

815HD Series Screed 8515 Sloping Overview 7-124

815HD Series Screed Frame Sloping 7-126

815HD Series Screed Frame Non-Sloping 7-128

815HD Series Vibrator Assembly 7-130

815HD Series Walk Board Assembly 7-132

815HD Series Slide Plate Assembly 7-134

815HD SERIES Extension LH Assembly 7-136

815HD Series Extension RH Assembly 7-138

815HD Series Endgate LH Assembly 7-140

815HD Series Endgate RH Assembly 7-142

815HD Series Screed Pull Arms LH Assembly 7-144

815HD Series Screed Pull Arms RH Assembly 7-146

815HD Series Citrus Tank & Heat Control Box 7-148

815HD Series Screed OPtional Components 7-150

Alphabetical Parts Index 7-152

DESCRIPTION:

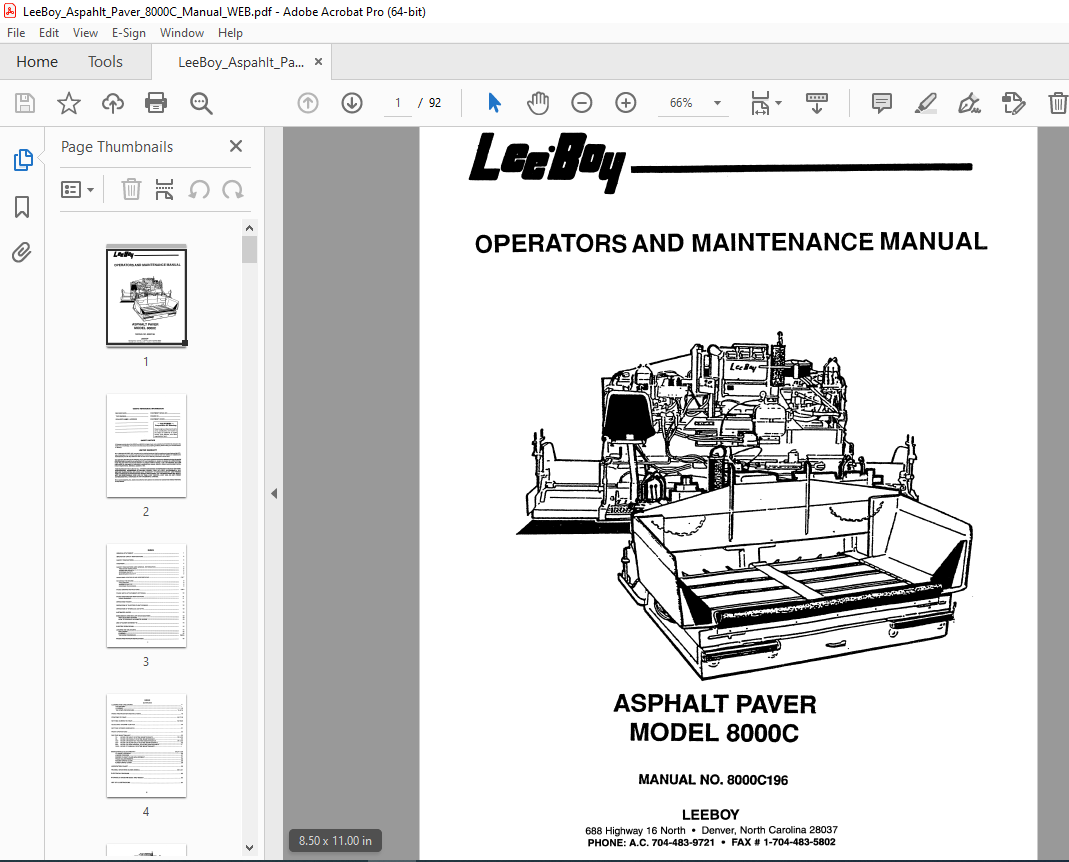

LEEBOY 8515C CONVEYOR PAVER Operations, Service & Parts Manual 1003095-04 PDF DOWNLOAD

INTRODUCTION

Thank you for purchasing the LeeBoy Model 8515C Conveyor Paver. We wish you many years of safe and efficient operation of your paver. READ THIS MANUAL PRIOR TO OPERATING the paver.

- This manual is an important part of the paver and should be kept with the paver at all times in the dedicated storage container on the paver. Even though you may be familiar with similar equipment, you MUST read and understand this manual before operating this paver

- . Reading the manual will help you and others avoid injury and help prevent any damage to the paver. If this manual becomes lost or damaged, contact your authorized LeeBoy Dealer immediately to order a replacement (see “Contact Information” in Section 2).

- This manual is intended as a guide for the safe and efficient use of the paver. This manual covers the procedures for proper operation and maintenance of the paver. This manual contains information that was available at the time of printing and are subject to change without notice.

- This manual should be used with all related supplemental books, engine and transmission manuals, and parts books. Related Service Bulletins should be reviewed to provide information regarding some of the recent changes.

- If any questions arise concerning this publication or others, contact your local LeeBoy Dealer for the latest available information.

This manual provides information for use by the equipment operator under the following headings:Section 1: Safety— Contains general and specific safety guidelines for product and safety label locations.Section 2: Information— Contains warranty, contact information, product identification nameplate, overview of product functions, specification tables, and product dimensions.Section 3: Component Location— Contains graphic and table overview combinations of major component locations and functions.Section 4: Operation— Contains all needed safe operation procedures and guidelines for product, including optional equipment.Section 5: Maintenance— Contains all needed information for safe maintenance procedures (i.e., changing filters, mechanical lubrication, adjustments, removal and installation, etc.) and troubleshooting charts for common problems and corrections. For specific engine maintenance procedures, refer to the engine manufacturer manual. Section 6: Schematics— Contains electrical and hydraulic schematics for product functionality.Section 7: Illustrated Parts List (IPL)— Contains exploded assemblies’/parts’ illustrations and corresponding identification tables for all serviceable components including fasteners.Also contains alphabetical parts index