$45

LEEBOY 8515D CONVEYOR PAVER Operations, Service & Parts Manual SN 33074 PDF DOWNLOAD

LEEBOY 8515D CONVEYOR PAVER Operations, Service & Parts Manual SN 33074 PDF DOWNLOAD

FILE DETAILS:

LEEBOY 8515D CONVEYOR PAVER Operations, Service & Parts Manual SN 33074 PDF DOWNLOAD

Language : English

Pages : 398

Downloadable :Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

LEEBOY 8515D CONVEYOR PAVER Operations, Service & Parts Manual SN 33074 PDF DOWNLOAD

Manual No. 1015239-01

This manual applies to Serial Number 133074 and above.

Safety Precautions 1-4

Machine Precautions 1-7

Hot Material Precautions 1-7

Hydraulic Systems Precautions 1-7

Refueling Precautions 1-8

Battery Precautions 1-8

Starting and Stopping Precautions 1-8

Parking Precautions 1-8

Operating Precautions 1-8

Poor Visibility 1-9

Storage Precautions 1-9

Maintenance Precautions 1-9

Safety Decals 1-10

Safety Decals Care 1-11

Decal Installation (Sticker Type) 1-11

Decal Installation (Top Protected) 1-11

Limited Warranty Policy 2-2

Contact Information 2-3

Specification Charts 2-4

Torque Specifications 2-7

Standard Inch Fasteners 2-7

Metric Fasteners 2-8

Hydraulic Fittings 2-8

Determining Proper Torque 2-9

Component Location

LeeBoy 8515D Conveyor Paver

Components Overview 3-3

Hydraulic System 3-3

Hopper and Conveyors 3-3

Augers 3-4

Operator Platform 3-4

Screed 3-4

Electrical System 3-4

Standard Equipment/Options 3-4

Machine Overview 3-5

Left Control Panel 3-6

Right Control Panel 3-8

Center Control Panel 3-10

Steering and Speed Control Box 3-11

Screed Controls 3-12

Burner Controls 3-13

Propane Tank Controls 3-13

Steering Wheel (Option) 3-14

Electric Heat (Option) 3-14

Operation 4-1

General Information 4-3

Receiving the Machine 4-3

Initial and Daily Inspection 4-3

Start-Up Procedure 4-4

Stopping the Engine 4-4

DPF Regeneration (REGEN) 4-4

PV480 Powerview Display 4-5

Gauge Screen 4-5

Set Points and Throttle Speed 4-5

Soft Keys (Buttons) 4-6

Status Icons 4-7

Main Menu 4-8

Gauges 4-8

Diagnostics 4-9

System Info 4-10

User Settings 4-12

Regeneration Messages 4-14

LeeBoy 8515D Conveyor Paver

Messages, Cautions, Warnings 4-17

Driving the Paver 4-18

Operator Control Station 4-18

Steering and Speed Control 4-18

Paver Operation 4-19

Spray Down 4-19

Heating the Screed 4-20

Hopper Wings 4-22

Conveyors 4-23

Hydraulic Cut-Off Gates 4-23

Electric Flight Screw 4-24

Set the Screed Extension, Flight Screw and Endgate 4-24

Sonic Auger Sensor 4-26

Starting to Pave 4-27

Basic Paving 4-27

Setting the Crown 4-28

Mat Texture Adjustment 4-29

815HD Screed Extension Double Adjustment (Option) 4-30

Unloading and Loading 4-30

Unloading 4-30

Loading 4-31

Tie-Down Procedure 4-31

Optional Components 4-32

Auger Extensions Option 4-32

Umbrella Option 4-32

Screed Sloping Extensions 4-32

Steering Wheel Option 4-32

Roll-Up Curb Attachments 4-32

Truck Hitch Attachment Option 4-33

Electric Screed Options 4-33

Topcon® Sonic and Dual Grade Control 4-34

Rubber or Steel Track Options 4-34

815HD (Heavy Duty) Electric Screed 4-34

LeeBoy 8515D Conveyor Paver

Maintenance 5-1

Maintenance Schedule 5-3

Routine Maintenance 5-5

Preparing Paver for Maintenance 5-5

Every 10 Hours or Daily Routine Maintenance 5-5

Every 50 Hours or Weekly Routine Maintenance 5-5

Every 100 Hour or Monthly Maintenance 5-6

Every 250 Hours or Quarterly Routine Maintenance 5-6

Every 500 Hours or Semi-Annual Routine Maintenance 5-6

Every 1000 Hours or Annual Routine Maintenance 5-6

Torque Hub Lubrication 5-6

Lubrication Points 5-7

Maintenance Adjustments 5-8

Conveyor Flight Chain 5-8

Conveyor Drive Chain 5-8

Auger Drive Chain Adjustment 5-9

Screed Extension Top Guide Adjustment 5-9

Track Tension Pressure Relief 5-10

Conveyor Switch Adjustment 5-10

Torque Hub Hydraulic Motor Gear Adjustments 5-11

Engine Maintenance 5-12

Check Engine Lubrication Oil 5-12

Change Engine Oil and Filter 5-13

Change Air Filter 5-13

Fuel System 5-14

Fuel Tank 5-14

Change Fuel Filter 5-14

Water Separator 5-15

Hydraulic System 5-16

Check Hydraulic Oil 5-16

Change Hydraulic Oil and Filter 5-16

Electrical System 5-17

Battery Servicing 5-18

Alternator 5-18

Screed Electric Heat (Option) 5-19

Screed Electric Heat Elements 5-19

LeeBoy 8515D Conveyor Paver

Element Resistance Testing 5-20

Heating Elements 5-20

Generator Voltage Testing 5-21

Generator Capacitor 5-22

Replacement Procedures 5-22

Front Idler 5-22

Track Tension Cylinder 5-23

Track Rollers 5-23

Track Sprocket (Steel or Poly) 5-23

Rubber Track (Option) 5-24

Rear Conveyor Shaft, Bearings and Sprockets 5-24

Conveyor Drive Motors 5-25

Auger and Inner Bearings 5-25

Auger Motors 5-26

Main Screed Wear Plate 5-27

Screed Extension Wear Plate 5-28

Torque Hub 5-29

Two-Speed Hydraulic Motors 5-30

Conveyor Switch Replacement 5-31

Weldment 5-31

Troubleshooting 5-32

Plus One 5-32

Test Ports 5-33

Troubleshooting Chart 5-34

PV480 Diagnostic Trouble Code (DTC) Chart 5-37

Electrical System (1 of 11) 6-3

Electrical System (2 of 11) 6-5

Electrical System (3 of 11) 6-7

Electrical System (4 of 11) 6-9

Electrical System (5 of 11) 6-11

Electrical System (6 of 11) 6-13

Electrical System (7 of 11) 6-15

Electrical System (8 of 11) 6-17

Electrical System (9 of 11) 6-19

Electrical System (10 of 11) 6-21

Electrical System (11 of 11) 6-23

LeeBoy 8515D Conveyor Paver

Lower Control, Sloping (Left) 6-25

Lower Control, Sloping (Right) 6-27

Lower Control, Non-Sloping (Left) 6-29

Lower Control, Non-Sloping (Right) 6-31

Auxilliary Harness 6-33

Generator Control to Bulkhead Harness 6-35

Bulkhead to Generator Harness 6-37

Electric Steering Cord, 4 Feet 6-39

Dash Assembly (1 of 5) 6-41

Dash Assembly (2 of 5) 6-43

Dash Assembly (3 of 5) 6-45

Dash Assembly (4 of 5) 6-47

Dash Assembly (5 of 5) 6-49

Gauge Panel (1 of 2) 6-51

Gauge Panel (2 of 2) 6-53

Plus One Harness (1 of 2) 6-55

Plus One Harness (2 of 2) 6-57

Ultrasonic Power Harness 6-59

Steering Wheel Box (Option) 6-61

Dual joystick control Box (Option) 6-63

Electric Heat Control (Option) 6-65

Electric Heat Control – Heated Endgates (Option) 6-67

Hydraulic Schematic (1 of 4) 6-69

Hydraulic Schematic (2 of 4) 6-71

Hydraulic Schematic (3 of 4) 6-73

Hydraulic Schematic (4 of 4) 6-75

Illustrated Parts List 7-1

Quick Reference 7-5

Sprocket Drive Track System – 4 Roller Undercarriage 7-6

Sprocket Drive Track System – 4 Roller Undercarriage 7-8

Rubber Track Undercarriage – 5 Roller Undercarriage 7-10

Conveyor Drive Assembly (1 of 2) 7-12

Conveyor Drive Assembly (2 of 2) 7-14

Hopper Components (1 of 2) 7-16

Hopper Components (2 of 2) 7-18

Auger Assembly 7-20

LeeBoy 8515D Conveyor Paver

Conveyor Drive Cutoff / Screed Lift Cylinders 7-22

Hydraulic Components / (Left) Side Fuel Tank 7-24

Hydraulic Test Port Assembly 7-26

H1 Pump & Controls 7-28

Kubota T4F Engine Assembly (1 of 3) 7-30

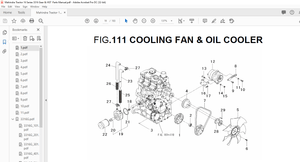

Kubota T4F Engine Assembly (2 of 3) 7-32

Kubota T4F Engine Assembly (3 of 3) 7-34

Kubota Sheet Metal Covers 7-36

Spray Down 7-38

Screed Arm Assembly With Toe Point 7-40

Propane Heater And Automatic Ignitors 7-42

Control Valve Assembly 7-44

Lower Hydraulic Manifold – 6 Valve 7-46

Dash Assembly 7-48

Screed Sloping Overview 7-50

Screed Non-Sloping Overview 7-52

Screed Frame Sloping – Propane 7-54

Screed Frame Non-Sloping – Propane 7-56

Extension Single Adjust Assembly – Propane (Left) 7-58

Extension Single Adjust Assembly – Propane (Right) 7-60

Extension Double Adjust Assembly – Propane (Left) 7-62

Extension Double Adjust Assembly – Propane (Right) 7-64

Screed Frame Sloping – Electric 7-66

Screed Frame Non-Sloping – Electric 7-68

Extension Single Adjust Assembly – Electric (Left) 7-70

Extension Single Adjust Assembly – Electric (Right) 7-72

Extension Double Adjust Assembly – Electric (Left) 7-74

Extension Double Adjust Assembly – Electric (Right) 7-76

Endgate Assembly (Left) 7-78

Endgate Assembly (Right) 7-80

Screed Pull Arm Assembly (Left) 7-82

Screed Pull Arm Assembly (Right) 7-84

Citrus Tank & Heat Control Box 7-86

Vibrator Assembly (Left) 7-88

Walk Board Assembly 7-90

Slide Plate Assembly 7-92

LeeBoy 8515D Conveyor Paver

Screed Miscellaneous Components 7-94

Generator 7-96

Power Crown (Option) 7-98

Strike Offs And Extensions (Option ) 7-100

Paver Leveling Control TOPCON System 4 (Option) 7-102

Paver Leveling Control TOPCON System P-32 (Option) 7-104

Truck Hitch Assembly (Option) 7-106

815HD Series Screed 8515 Sloping Overview 7-108

815HD Series Screed 8515 Non-Sloping Overview 7-110

815HD Series Screed Frame Sloping 7-112

815HD Series Screed Frame Non-Sloping 7-114

815HD Series Vibrator Assembly 7-116

815HD Series Walk Board Assembly 7-118

815HD Series Slide Plate Assembly 7-120

815HD Series Extension Assembly (Left) 7-122

815HD Series Extension Assembly (Right) 7-124

815HD Series Endgate Assembly (Left) 7-126

815HD Series Endgate Assembly (Right) 7-128

815HD Series Screed Pull Arm Assembly (Left) 7-130

815HD Series Screed Pull Arm Assembly (Right) 7-132

815HD Series Citrus Tank & Heat Control Box 7-134

815HD Series Screed Optional Components 7-136

HD Heated Endgate Assembly – Option (1 of 3) 7-138

HD Heated Endgate Assembly – Option (2 of 3) 7-140

HD Heated Endgate Assembly – Option (3 of 3) 7-142

HD Heated LeeBoy Edge Endgate Assembly – Option (1 of 3) 7-144

HD Heated LeeBoy Edge Endgate Assembly – Option (2 of 3) 7-146

HD Heated LeeBoy Edge Endgate Assembly – Option (3 of 3) 7-148

HD Heated Endgate Assembly – Option 7-150

VIDEO PREVIEW:

DESCRIPTION:

LEEBOY 8515D CONVEYOR PAVER Operations, Service & Parts Manual SN 33074 PDF DOWNLOAD

SAFETY PRECAUTIONS :

Refueling Precautions

• Do NOT overfill the fuel tank as overflow creates a fire hazard when spilled on hot components • DO NOT smoke when refueling and never refuel when the engine is running. Fuel is highly flammable and should be handled with care. Death or serious injury can occur due to explosion and/or fire.• DO NOT fill tank to capacity. Allow room for expansion to reduce the risk of fuel expanding and spilling from the tank.• Tighten fuel cap securely. Should fuel cap be lost, replace it with an original manufacturer’s approved cap. Pressurization of the tank may result from use of non-approved cap.• Prevent fires by keeping the machine clean of accumulated debris, grease, and spilled fuel.• Use ultra-low sulfur diesel fuel (ULSD) only.Battery Precautions• Keep all sparks and flames away from batteries, as gas given off by electrolytes is explosive.• Acid propelled by an explosion can cause blindness if it comes in contact with eyes. Always wear safety glasses when working near batteries.• If you come in contact with battery electrolyte solution, wash off immediately. Chemicals can cause burns.• Always disconnect the battery ground cable before working on the electrical system to avoid injury from spark or short circuit. Electrical shock and burns can occur.• To avoid electrolyte loss, DO NOT tip batteries more than 45 degrees.Starting and Stopping Precautions• Check all around the paver to make sure there are no people working on the machine or in the path of the machine before starting. DO NOT start until area is clear. Death or serious injury can occur to bystanders from being crushed under a moving machine.• Check brakes, steering and other control devices in accordance with instructions before starting. Be sure both steering levers (joysticks) are in neutral with the neutral lock engagedParking Precautions• Park paver on level ground whenever possible, set steering levers in neutral and lock. Apply the parking brake. Park the paver with wheels securely blocked on grades.• Remove ignition key when leaving paver parked or unattended.