$31

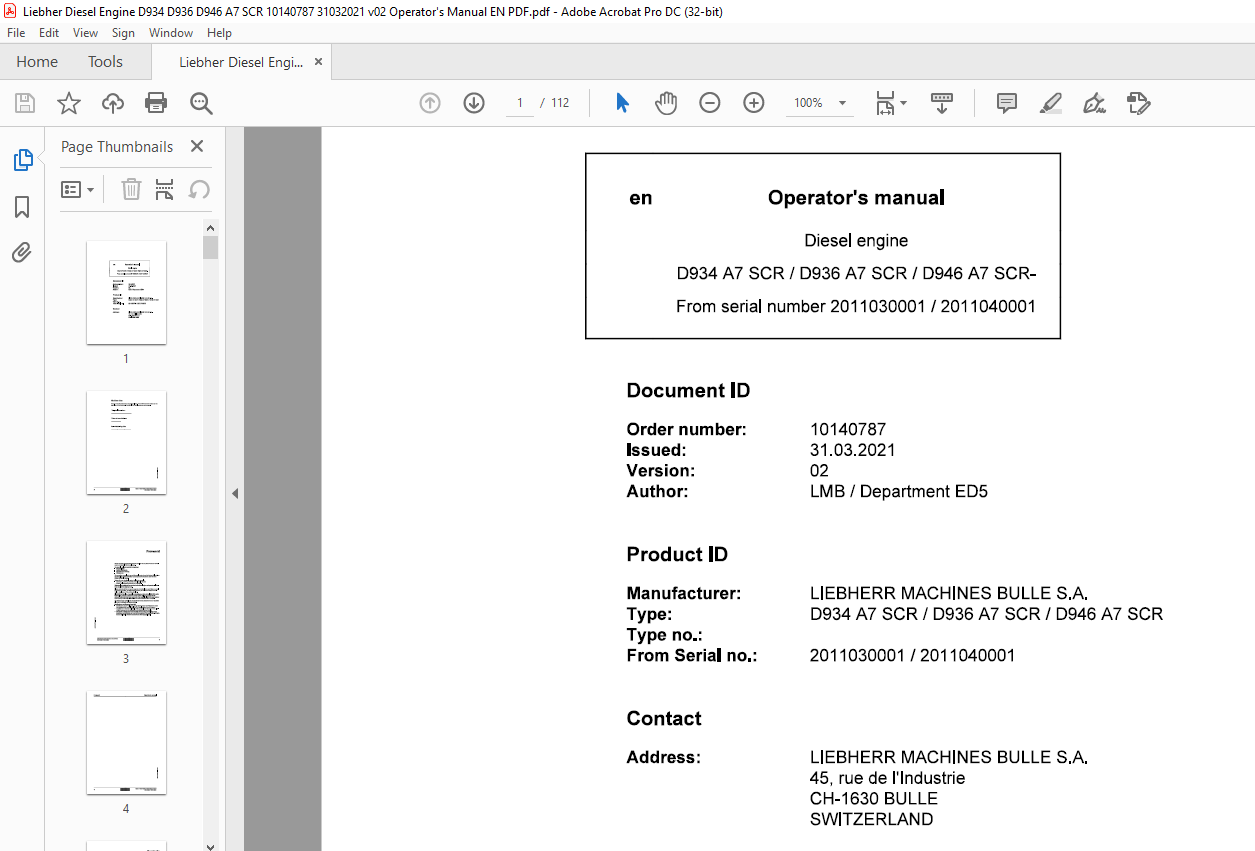

Liebherr D934 A7 SCR D936 A7 SCR D946 A7 SCR Diesel Engine Operator’s Manual 2011030001 – 2011040001

Liebherr D934 A7 SCR D936 A7 SCR D946 A7 SCR Diesel Engine Operator’s Manual 2011030001 – 2011040001 – PDF DOWNLOAD

FILE DETAILS:

Liebherr D934 A7 SCR D936 A7 SCR D946 A7 SCR Diesel Engine Operator’s Manual 2011030001 – 2011040001 – PDF DOWNLOAD

Language : English

Pages : 112

Downloadable : Yes

File Type : PDF

Size: 14.8 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Liebherr D934 A7 SCR D936 A7 SCR D946 A7 SCR Diesel Engine Operator’s Manual 2011030001 – 2011040001 – PDF DOWNLOAD

Product ID

Manufacturer: LIEBHERR MACHINES BULLE S,A,

Type: D934 A7 SCR / D936 A7 SCR / D946 A7 SCR

Type no.:

From Serial no.: 2011030001 – 2011040001

Foreword:

These operating instructions have been compiled for the user and for the maintenance

personnel of the diesel engine.

The manual includes descriptions regarding:

– Technical data

– Safety requirements

– Operation and servicing

– Maintenance

The operating manual is to be read thoroughly and referred to before initial start-up

and at regular periods thereafter by each person contracted to carry out work

with/on the diesel engine.

Tasks with or on the diesel engine include for example:

Operation, servicing, disposing of fuels and lubricants.

Repair, including maintenance and inspection.

- This simplifies training of the operator for his diesel engine and prevents malfunctions

resulted from improper use. - Please understand that we do not recognise warranty claims submitted as a result

of improper operation, insufficient maintenance, the utilisation of impermissible

fuels or negligence of the safety guidelines. - LIEBHERR will declare all possible undertakings carried out by LIEBHERR and/or

their dealers, such as guarantees, service orders, etc. null and void without

advance notice wherever spare parts other than original LIEBHERR spare parts or

spare parts purchased by LIEBHERR are used for maintenance or repair. - The maintenance intervals may be shorter than those prescribed in the inspection

plan when working in extreme conditions.

TABLE OF CONTENTS:

Liebherr D934 A7 SCR D936 A7 SCR D946 A7 SCR Diesel Engine Operator’s Manual 2011030001 – 2011040001 – PDF DOWNLOAD

Product Description

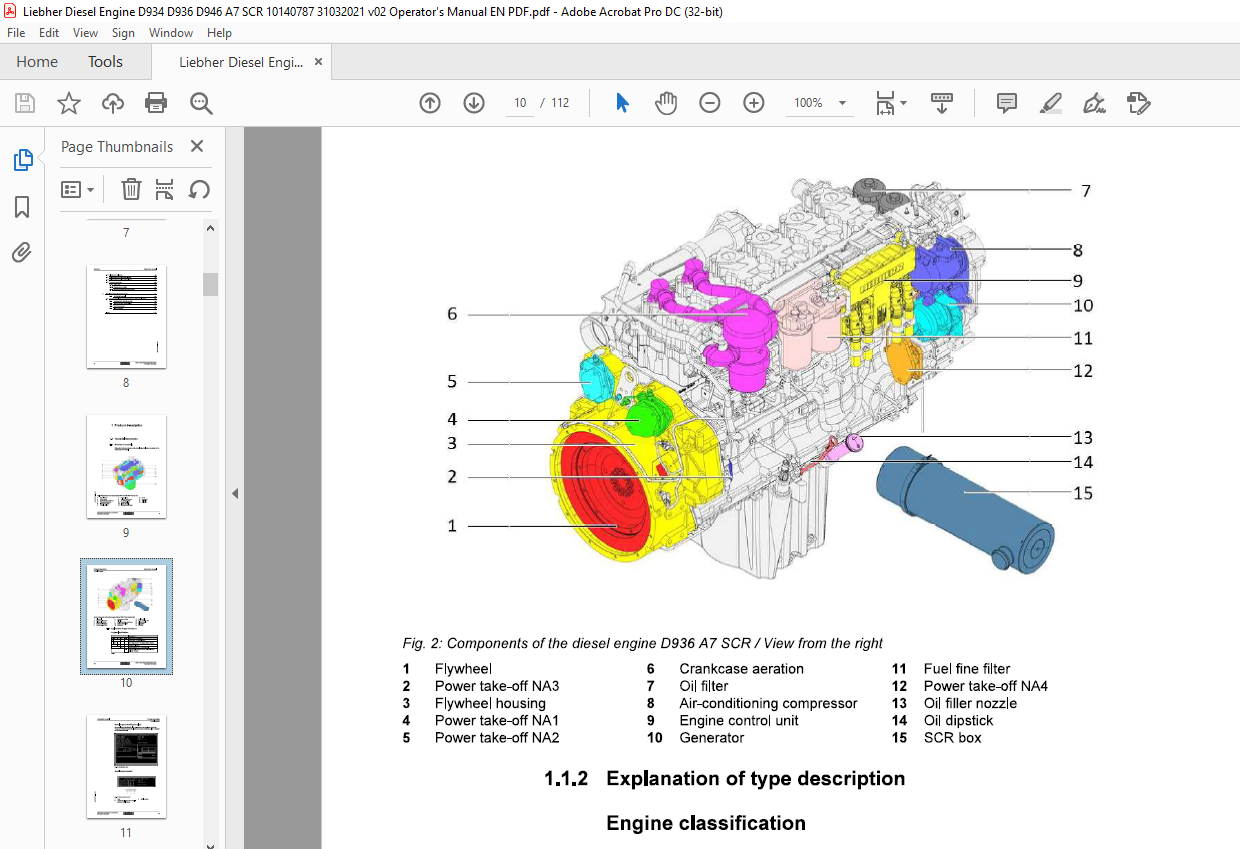

1.1 Technical Description

1.2 Technical data

1.2.1 Diesel engine

1.2.2 Cylinder head, standard

1.2.3 Cylinder head with engine auxiliary brake system (ABS)

1.2.4 Coolant pump D934

1.2.5 Coolant pump D936 / D946

1.2.6 Coolant thermostat

1.2.7 Generator

1.2.8 Starter

1.2.9 Flywheel housing

1.2.10 Air compressor Wabco 293 cm3

1.2.11 Air compressor Wabco 352 cm3

1.2.12 Air compressor Knorr 300 cm3

Notes on Safety

2.1.1 Designation of warning information

2.2 General notes on safety

2.3 Use as directed

2.4 Notes on the prevention of crushing and burns

2.5 Notes on the prevention of fire and explosions

2.6 Observe safety precautions when starting

2.7 Measures for safe maintenance

2.8 Observe the safety precautions for diesel engines featuring electronic control units

2.9 Safety and emergency run program for diesel engines featuring electronic control units

2.10 Special notes regarding tasks on the Common Rail System

2.11 Particularly hazardous

2.12 Disposing of fuels and lubricants

2.13 Exhaust gas after-treatment system (SCR)

Operation, Servicing

3.1 Control and operating elements

3.2 Operation

3.2.1 Preparations prior to initial start-up

3.2.2 Initial start-up / test run

3.2.3 Start the diesel engine

3.2.4 Starting in frosty temperatures

3.2.5 Switching off the diesel engine

3.2.6 Exhaust gas after-treatment system (SCR)

Malfunctions

4.1 Faults – Cause – Remedy

Maintenance

5.1 Maintenance and inspection chart

5.2 Filling amounts

5.2.1 Table for filling amounts

5.3 Fuels and lubricants

5.3.1 Handling fuels and lubricants

5.3.2 Environmental-protection guidelines

5.3.3 Disposal of used materials

5.3.4 Diesel fuels

5.3.5 Lube-oils for the diesel engine

5.3.6 Coolant for diesel engine

5.4 Special tools for maintenance tasks

5.5 Preparatory maintenance tasks

5.6 Maintenance tasks (daily), every 10 operating hours

5.6.1 Checking the engine oil level

5.6.2 Visual inspection (leaks, contamination, damages)

5.6.3 Checking the coolant level

5.6.4 Checking / draining the water separator of the fuel prefilter

5.6.5 Checking low-pressure display of the air filter

5.7 Maintenance tasks (weekly) every 50 operating hours

5.7.1 Drain water and sediment in the fuel tank

5.7.2 Cleaning the dust-discharge valve of the air filter

5.8 Maintenance Tasks, every 500 operating hours

5.8.1 Changing diesel engine oil and replacing the oil filter 71

5.8.2 Replacing the oil separator filter element 74

5.8.3 Checking and replacing the ribbed V-belt 75

5.8.4 Checking induction and exhaust gas system for sound condition and for leaks 77

5.8.5 Checking the cooling and heating systems for sound condition and for leaks 77

5.8.6 Checking lubrication system and fuel system for leaks and for sound condition 78

5.8.7 Checking batteries and cable connections 78

5.8.8 Checking the control unit mounting for sound condition 78

5.8.9 Checking sensors, actuators, cable fittings and plugs for sound condition 79

5.9 Maintenance tasks every 1000 operating hours

5.9.1 Checking the engine mounting and diesel engine bracket for secure fastening 80

5.9.2 Checking and adjusting valve clearance 80

5.9.3 Replacing the fuel prefilter element 85

5.9.4 Replacing the fuel fine-filter 86

5.10 Maintenance tasks every 2000 operating hours

5.10.1 Checking anticorrosive / antifreeze concentration in the coolant 88

5.11 Maintenance tasks every 4500 operating hours

5.11.1 Replacing the foam element and the filter element of the SCR urea pump 91

5.12 Maintenance tasks every 6000 operating hours

5.12.1 Replacing the coolant 93

5.13 Maintenance tasks every 10000 operating hours

5.13.1 Replace the heater flange 95

5.14 Maintenance tasks as required

Check the heater flange 97

5.15 Bleeding the fuel system 98

Replacing the dry air filter main element 101

Replacing the dry air filter safety element 102

Transport and storage 103

5.19.1 Lifting gear 103

5.19.2 Storage up to 6 months 103

5.19.3 Storage for between 6 and 24 months 104

6 Supplemental Information USA 105

6.2.1 EPA/CARB Fuel label 105

6.3 Emission control warranty statement warranty rights and obligations 106

6.3.1 Manufacturer’s warranty coverage 106

6.3.2 Owner’s warranty responsibilities 106

6.3.3 Warranty coverage 107

6.3.4 Warranted parts 107

Index 109