$33

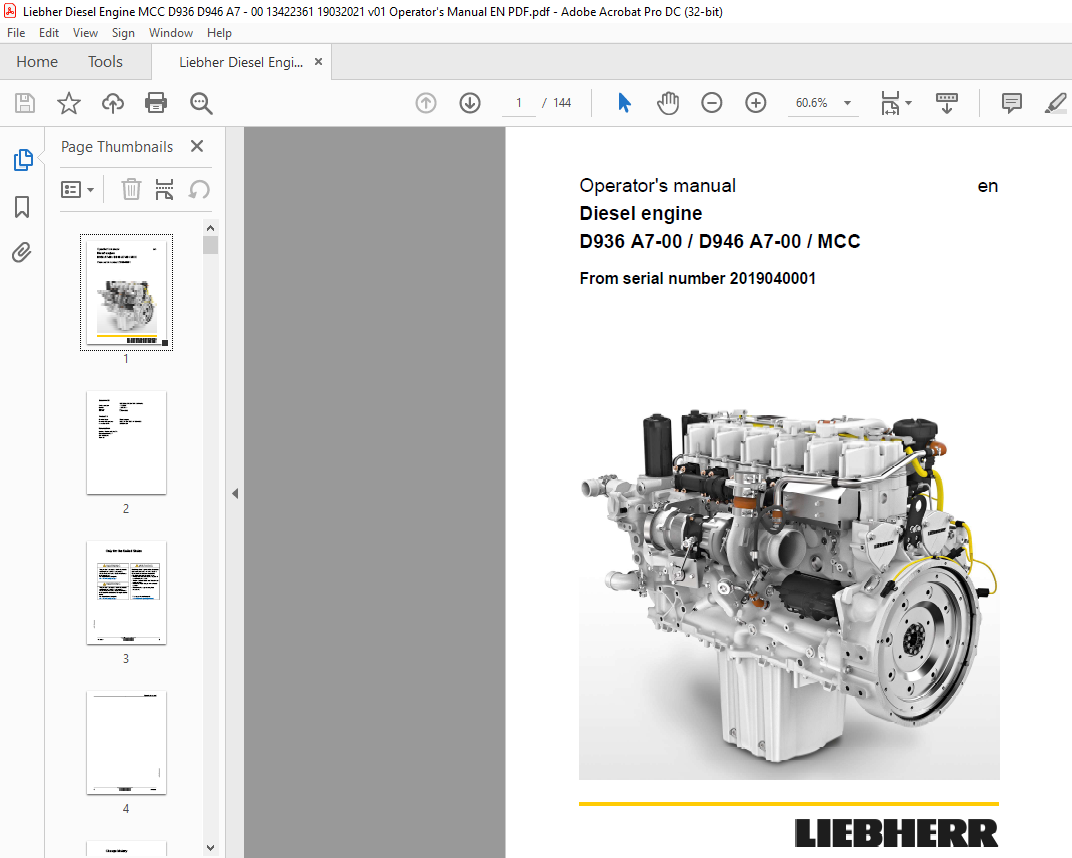

Liebherr D936 A7-00 D946 A7-00 MCC Diesel Engine Operator’s Manual 2019040001 – PDF DOWNLOAD

Liebherr D936 A7-00 D946 A7-00 MCC Diesel Engine Operator’s Manual 2019040001 – PDF DOWNLOAD

FILE DETAILS:

Liebherr D936 A7-00 D946 A7-00 MCC Diesel Engine Operator’s Manual 2019040001 – PDF DOWNLOAD

Language : English

Pages : 144

Downloadable : Yes

File Type : PDF

Size: 6.57 MB

IMAGES PREVIEW OF THE MANUAL:

VIDEO PREVIEW OF THE MANUAL:

DESCRIPTION:

Liebherr D936 A7-00 D946 A7-00 MCC Diesel Engine Operator’s Manual 2019040001 – PDF DOWNLOAD

Product IDManufacturer: LIEBHERR MACHINES BULLE S.A.

Type: D9508 A7-03

Type no.:From Serial no.: 2014140001

About the document:

Contents:

The descriptions for maintenance and care of the engine can be found in these operating instructions.

Work instructions:

A prerequisite for proper maintenance is a flawless and complete basic set of tools and the

necessary devices and special tools.

Only use clean and undamaged tools. Replace damaged tools in a timely manner. Cleanliness and

order contribute to safety at the workplace.

Clean the diesel engine, in particular connections and screw fittings, of oil, fuel and care products

at the start of the repair. Do not use any aggressive cleaning agents. Use lint-free cleaning cloths.

Do not use any flammable liquids to clean the diesel engine.

Sealing material (e.g. o-rings, seals, etc.) must always be replaced.

Removed parts should always be checked for their reusability and replaced, if necessary.

If no specific torques or tightening instructions are specified, screwed assemblies are to be tightened

according to the standard torques; these are included in the “Appendix” section.

Spare parts:

Only original LIEBHERR parts or spare parts purchased from LIEBHERR may be used for maintenance

of LIEBHERR diesel engines.

LIEBHERR will cancel all possible obligations undertaken by LIEBHERR and/or its dealers, such

as guarantee commitments, service agreements etc., without prior notice if parts other than original

LIEBHERR parts or spare parts purchased from LIEBHERR are used for maintenance.

All part information in this operator’s manual, e.g. identification numbers, thread sizes, dimensions,

etc., are only informational. Spare part orders may only be carried out by means of the spare parts

catalog pertaining to the scope of delivery.

TABLE OF CONTENTS:

Liebherr D936 A7-00 D946 A7-00 MCC Diesel Engine Operator’s Manual 2019040001 – PDF DOWNLOAD

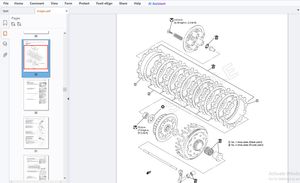

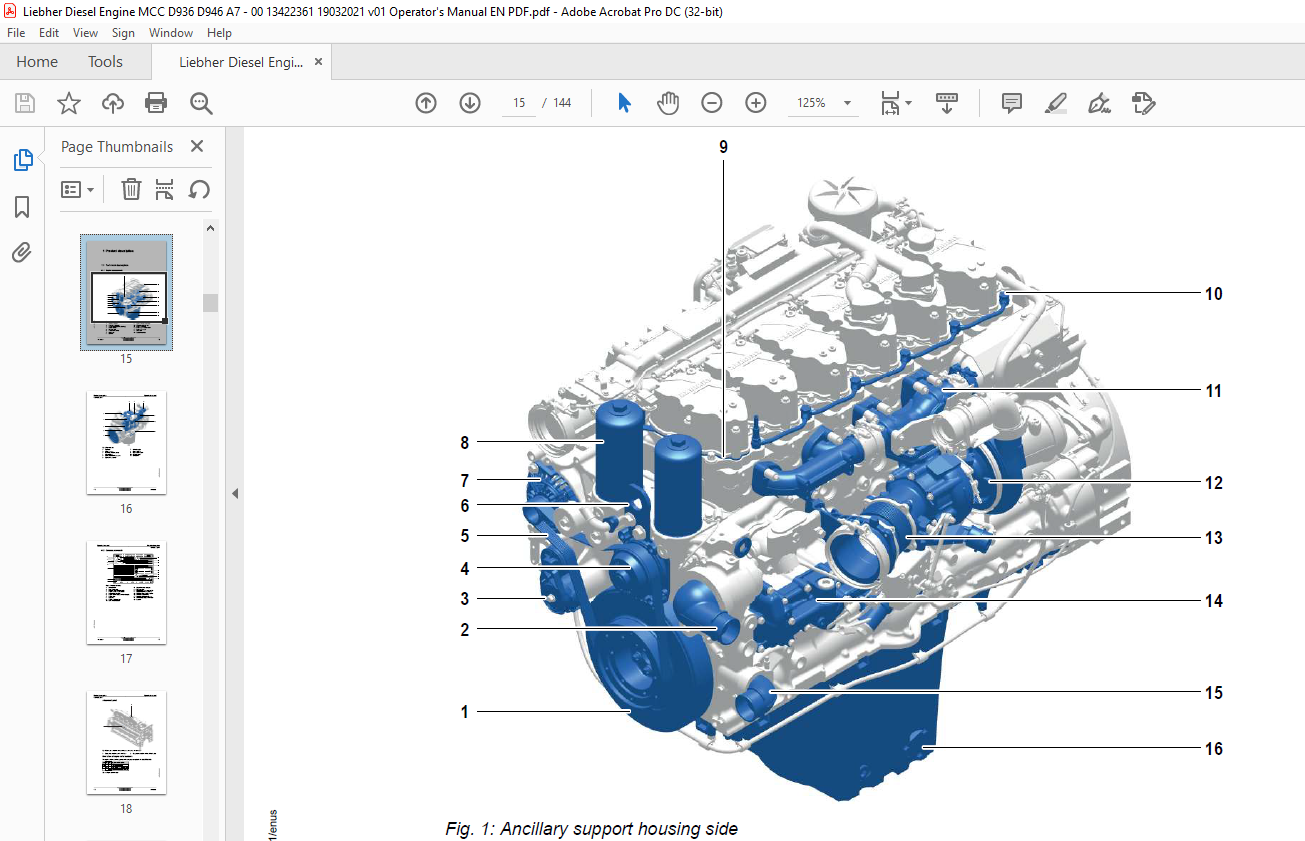

1 Product description 15

1.1 Technical description 15

1.1.1 Engine components 15

1.1.2 Company nameplate 17

1.1.3 Firing order, cylinder designation and engine serial number 19

1.1.4 Direction of rotation 19

1.1.5 Engine control unit type plate (ECU2) 20

1.2 Technical data 21

1.2.1 Diesel engine 21

1.2.2 Valve clearance 21

1.2.3 Valve clearance, auxiliary braking system (ABS) 21

1.2.4 Coolant thermostat 22

2 Safety 23

2.1 Labeling of warnings 23

2.1.1 Additional labels 23

2.2 Target group 24

2.3 Intended use 24

2.4 Foreseeable misuse 24

2.5 General safety instructions 25

2.6 Preventing personal injuries 27

2.6.1 Bruises 27

2.6.2 Burns and scalds 27

2.6.3 Fires and explosions 27

2.6.4 Poisoning 27

2.6.5 High-pressure injection (liquids at high pressure can squirt out) 28

2.6.6 Electrical energy 28

2.6.7 Danger due to noise 28

2.7 Personal protective equipment 28

/ 2019040001

copyright © Liebherr Machines Bulle SA 2021

11

Contents Operator’s manual

LMB/01/19.03.2021/enus

2.8 Operating areas and maintenance areas 29

2.8.1 Safety instructions 29

2.8.2 Operating areas 30

2.8.3 Maintenance areas 30

2.8.4 Securing and releasing the diesel engine against accidental start-up 31

2.8.5 Emergency stop 32

2.9 Signage 32

2.10 Preventing property damage 33

3 Transport and storage 35

3.1 Dimensions and weights 35

3.2 Lifting the engine 36

3.3 Transport 38

3.3.1 Transport attachment 38

3.3.2 Transport device 39

3.4 Storage 41

3.4.1 Storage 41

3.4.2 Storage time 45

4 Operation 47

4.1 Preliminary work for the initial commissioning of the engine 47

4.2 Starting the engine 48

4.3 Turning off the engine 50

5 Maintenance 51

5.1 Maintenance schedule 51

5.2 Preliminary work 54

5.2.1 Bringing the engine into maintenance position 54

5.2.2 As needed 54

5.3 Diesel engine 56

5.3.1 Checking the V-ribbed belt for damage 56

5.3.2 Checking the V-ribbed belt for tension 56

5.3.3 Checking the belt drive 57

5.3.4 Replacing the belt drive 60

5.3.5 Checking the engine mount 63

12

copyright © Liebherr Machines Bulle SA 2021

/ 2019040001

Operator’s manual Contents

LMB/01/19.03.2021/enus

5.3.6 Checking the intake system for leaks and damage 64

5.3.7 Checking the exhaust system 65

5.4 Engine oil system 66

5.4.1 Checking the engine oil system for leaks and damage 66

5.4.2 Checking the engine oil level 69

5.4.3 Changing the engine oil 70

5.4.4 Replacing the oil separator filter insert 76

5.5 Cylinder head 79

5.5.1 Checking and setting the valve clearance 79

5.6 Cooling system 96

5.6.1 Checking the cooling system and heating system for leaks and damage 96

5.6.2 Checking the coolant level 97

5.6.3 Checking the concentration of the antifreeze agent in the coolant 97

5.6.4 Replacing the coolant 98

5.7 Fuel system 102

5.7.1 Checking the fuel system for leaks and damage 102

5.7.2 Replacing the fuel prefilter 103

5.7.3 Reducing the pressure in the fuel system 103

5.7.4 Replacing the fuel fine filter 103

5.7.5 Ventilating the fuel system 106

5.8 Air filter 108

5.8.1 Checking the air filter low pressure indicator 108

5.8.2 Cleaning the air filter dust discharge valve 108

5.8.3 Replacing the dry air filter main element 108

5.8.4 Replacing the dry air filter safety element 108

5.9 Electrical system 109

5.9.1 Checking the batteries 109

5.9.2 Checking the cable connections 109

5.9.3 Checking the engine control unit bearings for damage 109

5.9.4 Checking sensors, actuators, cable holders and plugs 110

5.9.5 Checking the heating flange 111

5.9.6 Replacing the heating flange 114

5.10 Lubricants and operating fluids 116

5.10.1 Fill quantities 116

5.10.2 Engine oil for diesel engines without emission type approval 116

/ 2019040001

copyright © Liebherr Machines Bulle SA 2021

13

Contents Operator’s manual

LMB/01/19.03.2021/enus

5.10.3 Coolant 117

5.10.4 Fuel for diesel engines without emission type approval 118

6 Malfunctions 119

6.1 Faults – Cause – Remedy 119

7 Tools and devices 125

7.1 Tools 125

7.1.1 Special tool 125

7.1.2 Assembly agents 125

7.1.3 Diagnostic tools 126

7.2 Devices 127

7.2.1 Lifting traverse with two-point-raising (basic version) 127

7.2.2 Lifting traverse with two-point-raising 128

7.2.3 Engine assembly stand 129

7.2.4 Transport device 130

8 Appendix 133

8.1 Tightening torques 133

8.1.1 For hex bolts / cylinder screws / external hex bolts 133

8.1.2 For locking screws and banjo bolts 135

8.1.3 Standard torques for metric flange connections 136

8.1.4 Metric screw connection series L (light) (up to 500 bar/7252 Psi) 137

8.1.5 Metric screw connection series S (heavy) (up to 800 bar/11603 Psi) 138

8.1.6 Inch screw connection series L (light) (up to 500 bar/7252 Psi) 138

8.1.7 Inch screw connection series S (heavy) (up to 800 bar/11603 Psi) 139

8.1.8 Metric thread unit series L (light) (up to 500 bar/7252 Psi) for aluminum 140