$26

Liebherr Diesel engine D9512 A7-00 (Tier0) – D9512 A7-04 (Tier4) Operator’s Manual – PDF DOWNLOAD

Liebherr Diesel engine D9512 A7-00 (Tier0) – D9512 A7-04 (Tier4) Operator’s Manual – PDF DOWNLOAD

FILE DETAILS:

Liebherr Diesel engine D9512 A7-00 (Tier0) – D9512 A7-04 (Tier4) Operator’s Manual – PDF DOWNLOAD

Language : English

Pages :100

Downloadable : Yes

File Type : PDF

Size:20.4 MB

DESCRIPTION:

Liebherr Diesel engine D9512 A7-00 (Tier0) – D9512 A7-04 (Tier4) Operator’s Manual – PDF DOWNLOAD

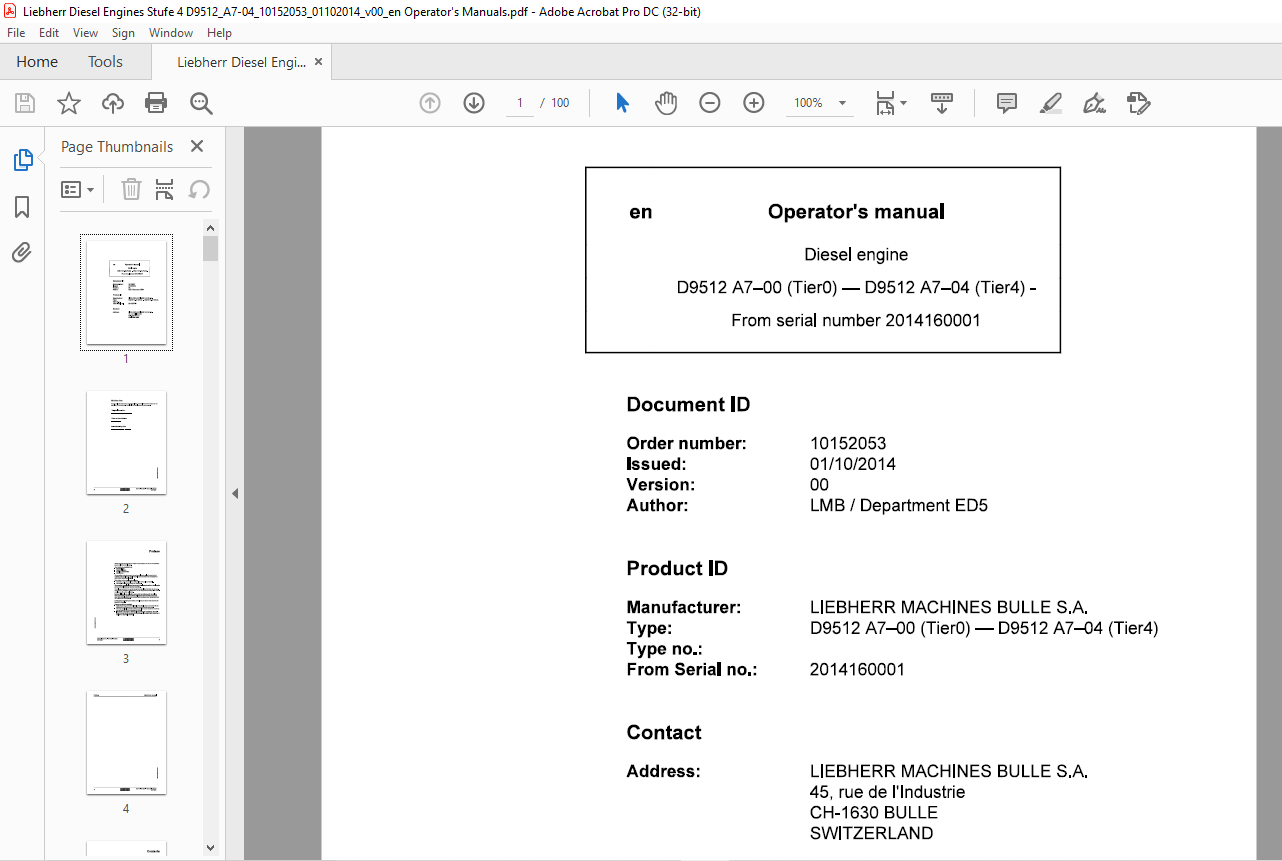

Product ID

Manufacturer: LIEBHERR MACHINES BULLE S.A.

Type: D9512 A7-00 (Tier0)- D9512 A7-04 (Tier4)

Type no:

From Serial no:2014160001

Preface

These operating instructions have been written for the operator and for the maintenance personnel of the diesel engine. They contain descriptions of:

- Technical data

- Safety regulations

- Handling and operation

- Maintenance

The operating instructions are to be read carefully and applied before the first commissioning and later at regular intervals by each person who is assigned to work with or on the diesel engine. Work with or on the diesel engine is, for example:

- Handling, care, disposal of operating fluids and auxiliary materials.

- Servicing, including maintenance, inspection.

The operating manual facilitates the operator’s familiarization with the diesel engine and prevents faults through incorrect operation.

You will understand that we cannot allow any warranty claims that arise due to incorrect operation, insufficient maintenance, use of unapproved operating fluids or non-compliance with safety regulations. Liebherr will cancel all possible obligations received by Liebherr and/or its dealers, such as guarantees, service contracts etc., without advance notice if any parts other than original Liebherr parts or spare parts purchased from Liebherr are used for maintenance and repairs.

In extreme conditions, more frequent maintenance than scheduled in the inspection plan can be required.

Changes, conditions, copyright:

- Subject to changes to technical details of the diesel engine compared with the information and figures of the documents at hand without prior notice.

- Warranty and liability conditions of the general terms and conditions of Liebherr are not extended by the preceding information.

- Information and images in this manual may neither be reproduced or disseminated nor used for competition purposes. All copyright rights according to the law are expressly reserved.

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Liebherr Diesel engine D9512 A7-00 (Tier0) – D9512 A7-04 (Tier4) Operator’s Manual – PDF DOWNLOAD

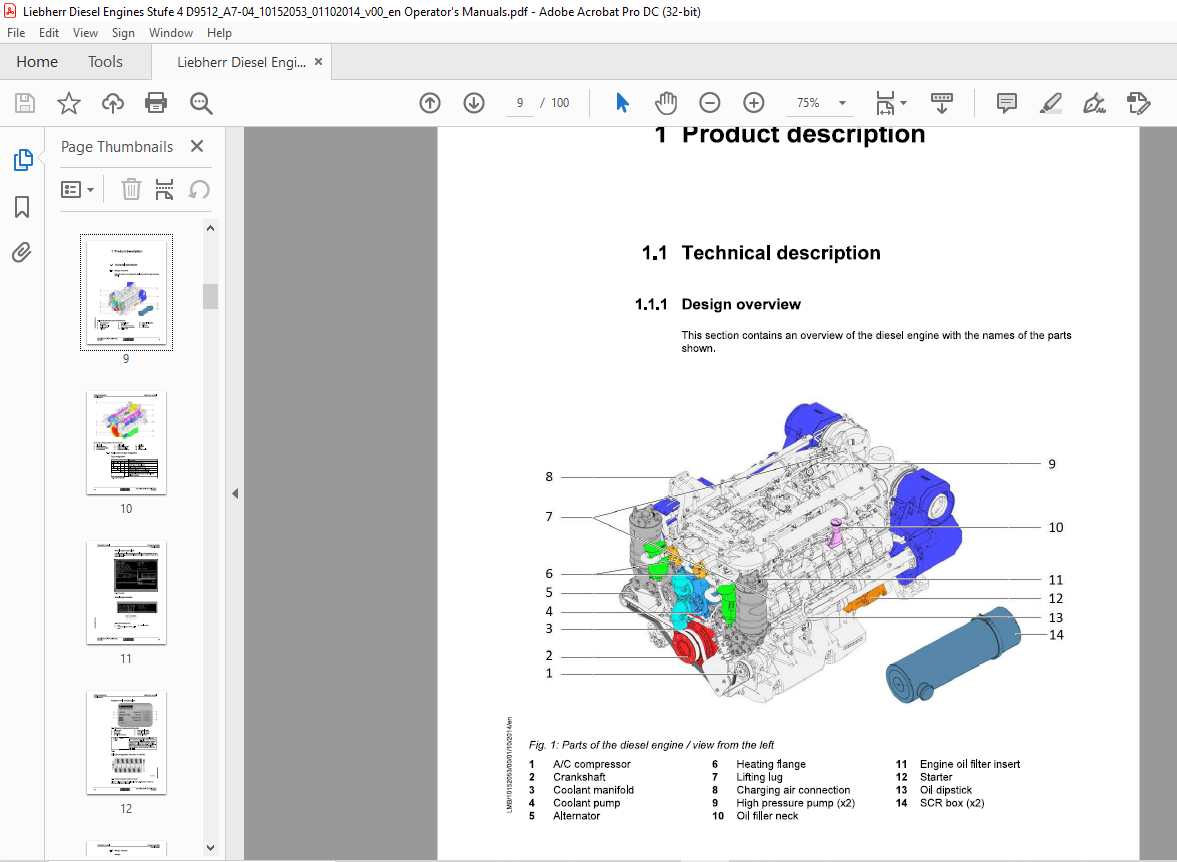

1 Product description

1.1 Technical description

1.1.1 Design overview

1.1.2 Explanation of type designation

1.1.3 Design features

1.1.4 Diesel engine accessory equipment

1.2 Technical data

1.2.1 Diesel engine

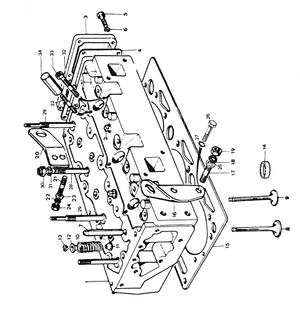

1.2.2 Cylinder head standard

1.2.3 Coolant pump

1.2.4 Coolant thermostat

1.2.5 Alternator

1.2.6 Starter

1.2.7 Flywheel housing1 Product description

1.1 Technical description

1.1.1 Design overview

1.1.2 Explanation of type designation

1.1.3 Design features

1.1.4 Diesel engine accessory equipment

1.2 Technical data

1.2.1 Diesel engine

1.2.2 Cylinder head standard

1.2.3 Coolant pump

1.2.4 Coolant thermostat

1.2.5 Alternator

1.2.6 Starter

1.2.7 Flywheel housing

2 Safety instructions2.1.1 Identification Of the warnings2.2 General safety instructions2.3 Intended use2.4 Instructions for preventing crushing and burns2.5 Instructions for preventing fires and explosion hazards2.6 Safety precautions when starting2.7 Measures for safe maintenance2.8 Safety precautions for diesel engines with electronic control units2.9 Safety and emergency running program for diesel engines with electronic

control units2.10 Special instructions for working on the common rail system2.11 Particular hazards2.12 Disposal of operating fluids2.13 Exhaust after-treatment system (SCR)

Handling, operation3.1 Control and Operating elements3.2 Operation

3.2.1 Preparing for initial commissioning

3.2.2 Initial commissioning I test run

3.2.3 Starting the diesel engine

3.2.4 Starting in freezing temperatures

3.2.5 Shutting down the diesel engine

3.2.6 Exhaust after-treatment system (SCR)

4 Operating faults

4.1 Faults – Cause – Remedy

5 Maintenance5.1 Maintenance and inspection schedule5.2 FIII quantities

5.2.1 FIII quantity table5.3 Lubricants and operating fluids

5.3.1 Handling lubricants and operating fluids

5.3.2 Environmental protedlon measures

5.3.3 Disposal of used consumables

5.3.4 Diesel fuels

5.3.5 Lubricating oils for the diesel engine

5.3.6 Diesel engine coolant5.4 Special tools for maintenance activities5.5 Preparatory maintenance activities5.6 Dally maintenance activities (every 10 operating hours)

5.6.1 Checking the engine oil level

5.6.2 Visual Inspection (leaks. contaminations, damage)

5.6.3 Check coolant level

5.6.4 Checking [draining water trap on the fuel prefllter

5.6.5 Checking underpressure display at the air filter5.7 Weekly maintenance activities (every 50 operating hours)

5.7.1 Draining off water and sediments from the fuel tank

5.7.2 Cleaning the dust extraction valve of the air filter

5.8 Maintenance activities every 500 operating hours

5.8.1 Checking state Of belt drive and replacing, if necessary

5.8.2 Checking the intake and exhaust system for condition and leaks

5.8.3 Check cooling and heating system for condition and leaks

5.8.4 Checking the lubricant and fuel system for condition and leaks

5.8.5 Checking batteries and cable connections

5.8.6 Checking the condition Of the control unit mounting

5.8.7 Checking condition of sensors. actuators. cable holders and plugs

5.9 Maintenance activities every 1000 operating hours

5.9.1 Changing diesel engine oil and Oil filter insert

5.9.2 Replace crankcase ventilation. Oil separator filter insert

5.9.3 Checking that engine bearing and diesel engine console are securely

seated

5.9.4 Changing the fuel prefilter insert

5.9.5 Changing the fuel fine filter

5.10 Maintenance activities every 2000 Operating hours

5.10.1 Changing V-ribbed belt and tensioning device

5.11 Maintenance activities every 4500 operating hours

5.11.1 Replace the foam and filter element of the SCR urea pump

5.12 Maintenance activities every 6000 operating hours

5.12.1 Changing the coolant

5.13 Maintenance activities every 7500 operating hours

5.13.1 Replacing Visco dampers (vibration dampers)

5.14 Maintenance activities every 10000 operating hours

5.14.1 Replacing the heating flange

5.15 Occasional maintenance activities

5.15.1 Checking the heating flange

5.15.2 Venting fuel system

5.15.3 Replacing the dry air filter main element

5.15.4 Replacing the dry air filter safety element

5.15 Occasional maintenance activities5.15.1 Checking the heating flange5.15.2 Venting fuel system5.15.3 Replacing the dry air filter main element5.15.4 Replacing the dry air filter safety element

5.16 Transport and storage5.16.1 Suspension device5.16.2 Storage up to 6 months

5.16.3 Storage over 6 months up to 24 months

6 Supplemental information for the USA

6.2.1 EPA/CARE fuel label

Index