$31

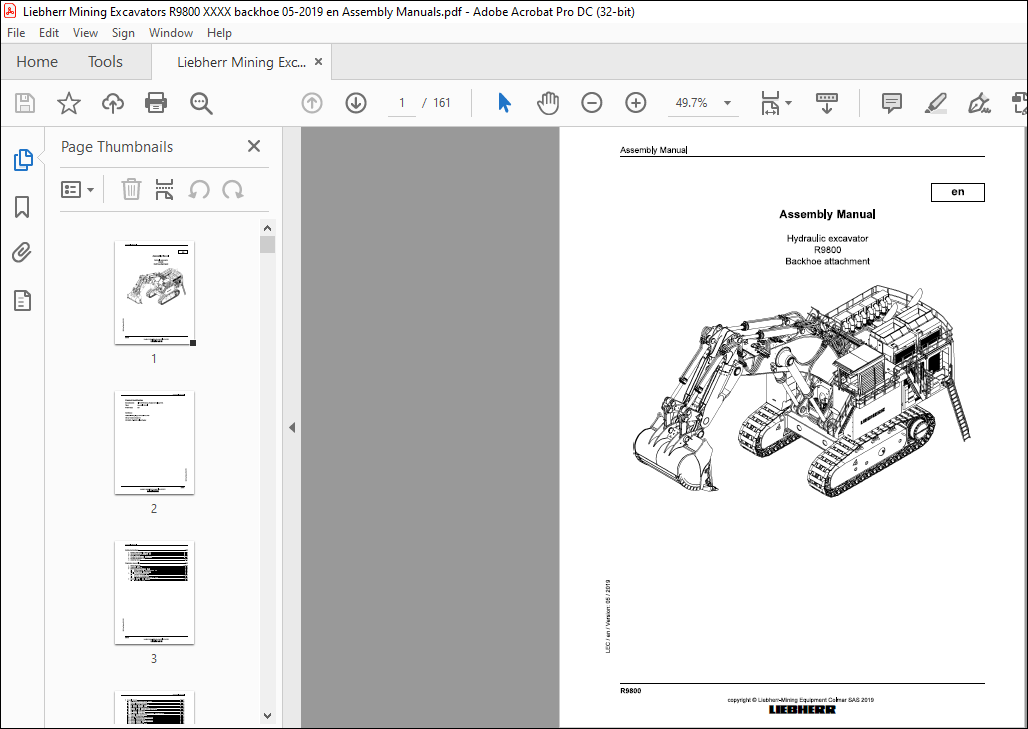

Liebherr Hydraulic excavator R9800 Backhoe attachment Assembly Manual – PDF DOWNLOAD

Liebherr Hydraulic excavator R9800 Backhoe attachment Assembly Manual – PDF DOWNLOAD

IMAGES PREVIEW OF THE MANUAL:

FILE DETAILS:

Liebherr Hydraulic excavator R9800 Backhoe attachment Assembly Manual – PDF DOWNLOAD

Language : English

Pages :161

Downloadable : Yes

File Type : PDF

Size: 25.9 MB

DESCRIPTION:

Liebherr Hydraulic excavator R9800 Backhoe attachment Assembly Manual – PDF DOWNLOAD

Safety instructions

- Working with the machine holds dangers to which you as the owner, machine operator or maintenance expert could be exposed. lf you regularly read and note the safety information, however, you can preveni danger and accidents. This is particularly true for those who are only occasionally in contact with the machine, eg. for maintenance work.

- The following information comprises safety regulations which, iffollowed conscientiously, will contribute to your safety and that of other persons, as well as avoiding damage to the machine.

- Following these precautions does not release you from the responsibility to take note of safety regulations which apply on site or of guidelines given by legal bodies or professional associations. For EU countries, guideline 2009 / 104 / EC contains the minimum required safety information applicable to the owner.

Safety InstructionsGeneral Safety Instructions

- Familiarize yourself with the operating instructions before starting up the machine.

- Ensure that you have obtained, read, and understood any additional instructions relating to special accessories for the machine.

- Only specifically authorized persons may operate, maintain, or repair the machine. The legal minimum age is to be adhered to.

- Only employ trained or appropriately instructed personnel. Clearly establish which personnel are responsible for operating, setting up, maintaining, and repairing the machine. Give personnel the power to refuse to carry out unsafe instructions. This also applies in relation to traffic regulations.

- Only permit apprentices and personnel who are in training or who have only general training to operate the machine under the constant supervision of an experienced member of staff.

- As far as possible, monitor personnel to ensure that they are adhering to safe working practices, are aware of risks, and are observing the operating instructions.

- Always wear safe work clothes when you are working on or with the machine. Avoid wearing rings, wrist watches, ties, scarves, open jackets, baggy clothing, etc. There is a risk of injury from, for example, getting caught up or being drawn in.

- Wear individual protective equipment (protective goggles, safety helmets, safety shoes and gloves, reflective vests, and ear protection, etc.).

- Ensure that you obtain information on any special safety regulations for the job site from the site foreman.

R9800 Assembly Manual Safety Instructions:

- Always tilt up the safety lever before leaving the operator’s seat.

- When getting in and out, do not hold onto the steering column, control panel, or joystick. Doing this could cause unintentional movement, which could result in an accident.

- Never jump from the machine; use the steps, ladders, gangplanks, and supporting straps provided for this purpose.

- Face the machine when getting in or out and always use three-point support, i.e., two hands and one foot or two feet and one hand must always be in contact with the access system at the same time.

- Familiarize yourself with the location of the emergency exit.

- In the absence of any other instructions, proceed as follows for all maintenance and repair work:

- park the machine on firm, level ground

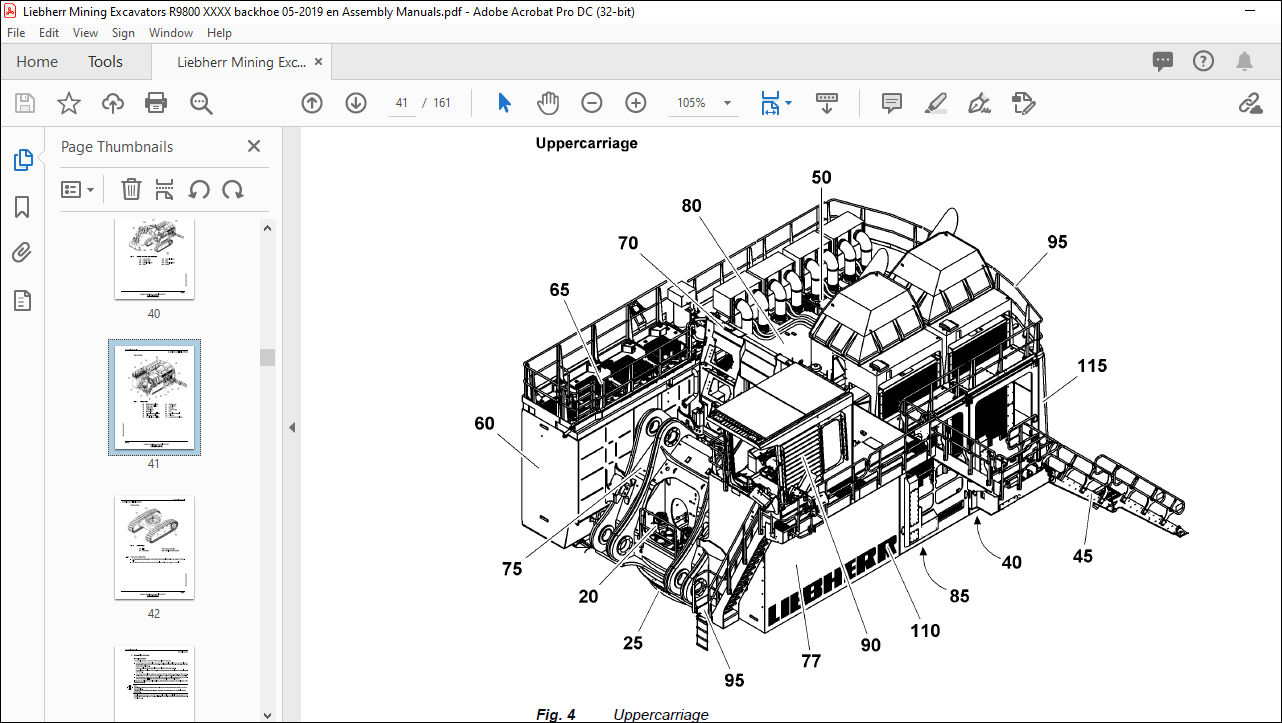

- align the uppercarriage with the undercarriage so that the sprockets locate at the back-end

- anchor the bucket in the ground.

- place all operating levers into neutral and tilt the safety lever up.

- switch off the engine and remove the start key.

- Before touching any parts of the hydraulic circuits, you must also operate all pilot control devices (joystick and pedals) in all directions with the start key in contact position and with the security lever lowered, in order to reduce the actuating and dynamic pressures in the work circuits. You must then reduce the internal tank pressure as described in these operating instructions.

- Secure all loose parts on the machine.

- Never operate a machine before carrying out a careful inspection tour and checking whether any warning signs are missing or illegible.

- Respect all danger and safety instructions.

- For special applications, the machine must be equipped with specific safety equipment. Work only if they are mounted and functional.

- Do not carry out any modifications, alterations, or conversions to the machine which may affect safety without the express permission of the manufacturer. This also applies to the installation of safety devices and valves and for welding work on load-bearing parts.

- It is forbidden to repair or alter any operator protective structure (for example, structure of the cab, FOPS, ROPS, TOPS).

- Ensure that any damaged operator protective structure is immediately replaced.

- Non-original equipment and component parts or such kind, which have generally not been

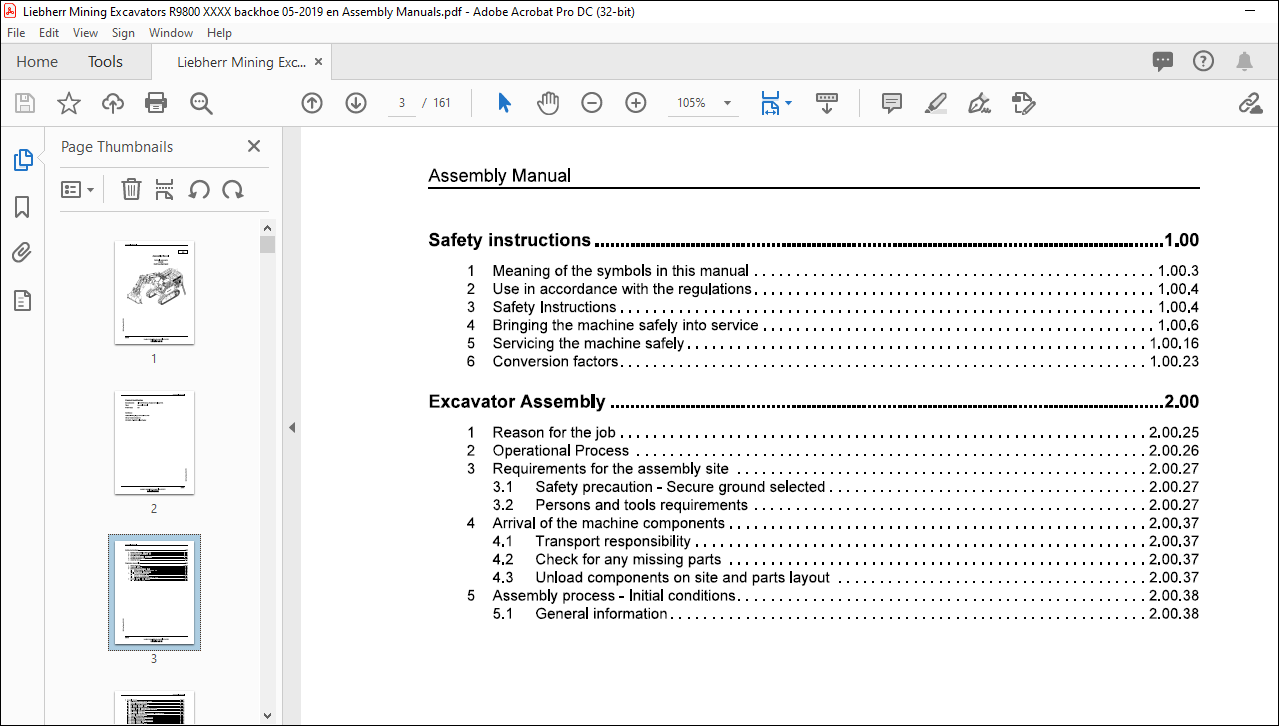

TABLE OF CONTENTS:

Liebherr Hydraulic excavator R9800 Backhoe attachment Assembly Manual – PDF DOWNLOAD

Safety instructions 1 00

1 Meaning of the symbols in this manual 1 00 3

2 Use in accordance with the regulations 1 00 4

3 Safety lnstructions 1 00 4

4 Bringing the machine safely into service 1 00 6

5 Servicing the machine safely 1 00 16

6 Conversion factors 1 00 23

Excavator Assembly 2 00

1 Reason for the job 2 00 25

2 Operational Process 2 00 26

3 Requirements for the assembly site 2 00 27

3 1 Safety precaution – Secure ground selected 2 00 27

3 2 Persons and toais requirements 2 00 27

4 Arrival of the machine components 2 00 37

4 1 Transport responsibility 2 00 37

4 2 Check for any missing parts 2 00 37

4 3 Unload components on site and parts layout 2 00 37

5 Assembly process – lnitial conditions 2 00 38

5 1 General information 2 00 38

R9800

copyright© Liebherr-Mining Equipment Colmar SAS 2019

MJFCIFSS

Assembly Manual

6 Assembly process 2 00 41

6 1 Unloading trucks / Positioning elements 2 00 48

6 2 Opening boxes and containers 2 00 51

6 3 Assembly of the chain / track pads 2 00 53

6 4 Pre-assembly of the fuel tank 2 00 54

6 5 Pre-assembly of the counterweight 2 00 58

6 6 Assembly of the valve bank on the uppercarriage 2 00 60

6 7 Pre-assembly ofthe cabin 2 00 62

6 8 Pre-assembly of the boom 2 00 64

6 9 Pre-assembly of the High Temperatura Cooler and Powerpack 2 00 69

6 1 O Assembly of the undercarriage 2 00 73

6 11 Torque of undercarriage 2 00 81

6 12 Hydraulic connection of the undercarriage 2 00 82

6 13 Assembly of the track chain 2 00 83

6 14 Assembly and torque of the uppercarriage 2 00 87

6 15 Assembly of the fuel tank 2 00 94

6 16 Assembly of the hydraulic tank 2 00 98

6 17 Assembly of the powerpack 1 2 00 102

6 18 Assembly of the powerpack 2 2 00 107

6 19 Electrical connections 2 00 113

6 20 Hydraulic connections 2 00 114

6 21 Assembly of the counterweight 2 00 115

6 22 Assembly of the guard railing 2 00 120

6 23 Assembly of the cabin 2 00 122

6 24 Assembly of the boom 2 00 125

6 25 Assembly ofthe stick 2 00 131

6 26 Assembly of the greasing system 2 00 140

6 27 Oil filling 2 00 140

6 28 Assembly of the Fire Fighting System 2 00 141

6 29 Assembly of the air filter / Exhaust pipes 2 00 143

6 30 Electrical tests 2 00 145

6 31 First start check procedures 2 00 146

6 32 Troubleshooting 2 00 147

6 33 Assembly of the boom and stick cylinders 2 00 148

6 34 Assembly of the bucket 2 00 152

6 35 Adjustments 2 00 156

6 36 Commissioning 2 00 157