$38

Liebherr Wheel loaders L 576-1759 Service manual – PDF DOWNLOAD

Liebherr Wheel loaders L 576-1759 Service manual – PDF DOWNLOAD

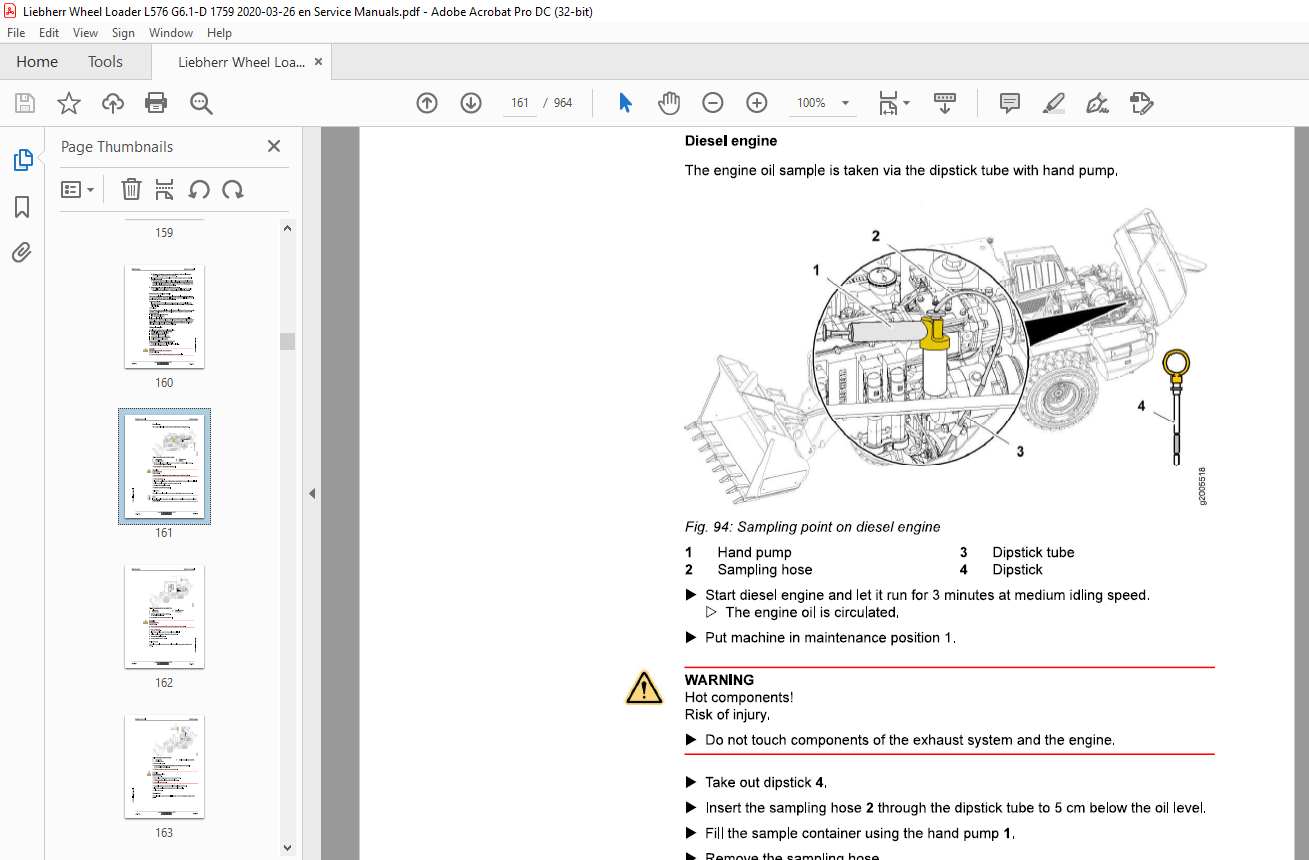

IMAGES PREVIEW OF THE MANUAL:

FILE DETAILS:

Liebherr Wheel loaders L 576-1759 Service manual – PDF DOWNLOAD

Language : English

Pages : 964

Downloadable : Yes

File Type : PDF

Size:213 MB

DESCRIPTION:

Liebherr Wheel loaders L 576-1759 Service manual – PDF DOWNLOAD

PrefaceNotes for users

- This service manual is designed for trained specialist staff of the Liebherr organisation and their dealers.

- This service manual contains specialist knowledge for repairing Liebherr construc- tion machines. Basic specialist knowledge on electronics, hydraulics, mechanics and engine technology is not contained in this service manual. Therefore special- ized training and qualifications are necessary. Liebherr recommends participating in the Liebherr training program for construction machines.

In this service manual you will find information on:

— Special tools— Technical data— Maintenance intervals and maintenance tasks— Adjustment procedures— Structure and function descriptions— Removal and installation tasks— Circuit diagrams, hydraulic plans and technical drawings

- You will find information on controls and operation in the operator’s manual. Information on spare parts are in the spare parts catalogue. Please observe the local accident prevention laws.

- You can find information on repairs of machine parts in the service documentation under “Wheel loader – repair instructions”.

Introduction:

Intended Use:1.1. Laws, Rules, Guidelines and Safety Regulations

To ensure safe operation:

- Consult with the worksite manager about safety regulations at the place of use.

- Adhere to safety regulations at the place of use.

- Follow traffic regulations.

- Adhere to valid guidelines provided by insurers (for example, employers’ professional liability insurance companies, accident insurance, etc.).

- Avoid working methods that can endanger safety.

- Follow all intervals specified for recurrent checks and inspections as outlined in this operator’s manual.

1.2. Intended Use of Wheel Loader

The wheel loader is used to pick up, move, and dump the following materials:

- Soil

- Stones

- Broken rocks

- Bulk materials

This applies to a standard machine under normal operating conditions. Special applications are described in a separate options operator’s manual.

To ensure the intended use:

- Adhere to the operator’s manual.

- Follow maintenance intervals.

- Carry out inspection and maintenance tasks.

- Follow the specifications in the technical data.

- When using the machine on public roads, ensure it complies with applicable national regulations.

- Only lift loads with intended working attachments (fork prongs, crane boom), which must be properly fitted and functioning.

- Ensure that machines used underground (for mining and tunnel construction) are fitted with systems to reduce exhaust emissions (such as diesel particulate filters).

- Adhere to the requirements of each individual country for underground operation.

- For special uses, use special working attachments and, if necessary, special safety equipment.

- Exclusively mount and use special working attachments with approval and as per the stipulations of the manufacturer of the basic machine.

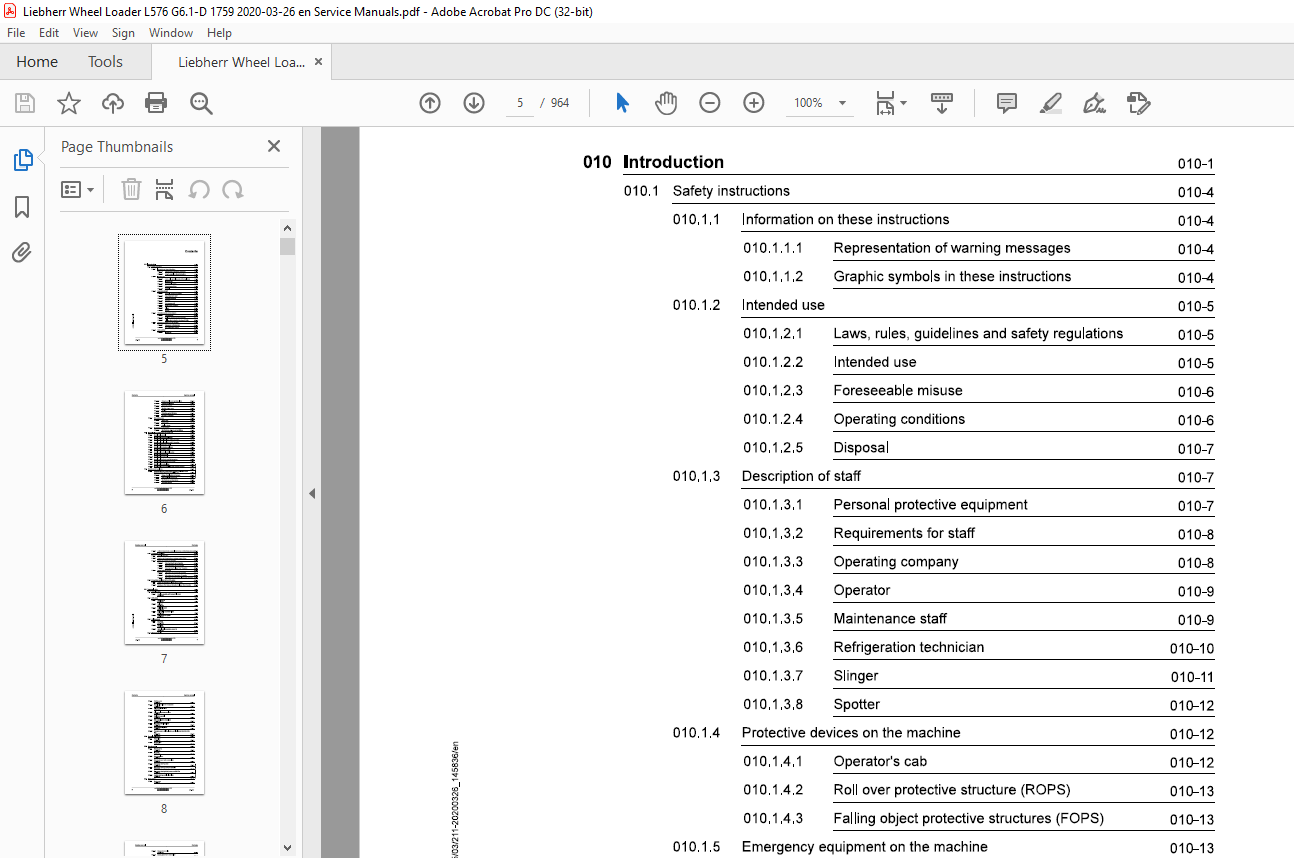

TABLE OF CONTENTS:

Liebherr Wheel loaders L 576-1759 Service manual – PDF DOWNLOAD

010 Introduction 010-1

010.1 Safety instructions 010-4

010.1.1 Information on these instructions 010-4

010.1.1.1 Representation of warning messages 010-4

010.1.1.2 Graphic symbols in these instructions 010-4

010.1.2 Intended use 010-5

010.1.2.1 Laws, rules, guidelines and safety regulations 010-5

010.1.2.2 Intended use 010-5

010.1.2.3 Foreseeable misuse 010-6

010.1.2.4 Operating conditions 010-6

010.1.2.5 Disposal 010-7

010.1.3 Description of staff 010-7

010.1.3.1 Personal protective equipment 010-7

010.1.3.2 Requirements for staff 010-8

010.1.3.3 Operating company 010-8

010.1.3.4 Operator 010-9

010.1.3.5 Maintenance staff 010-9

010.1.3.6 Refrigeration technician 010-10

010.1.3.7 Slinger 010-11

010.1.3.8 Spotter 010-12

010.1.4 Protective devices on the machine 010-12

010.1.4.1 Operator’s cab 010-12 “…’ ;;;, 010.1.4.2 Roll over protective structure (ROPS) 010-13 ~

010.1.4.3 Falling object protective structures (FOPS) 010-13

010.1.5 Emergency equipment on the machine 010-13 iil

010.1.5.1 Emergency exit (standard) 010-13 “‘ I~D 010.1.5.2 Fire extinguisher (option) 010-14

010.1.6 Safe operation 010-14

010.1.6.1 Intoxicants 010-14

010.1.6.2 Dangerous fuels and operating fluids 010-14

010.1.6.3 Transporting machine 010-15

010.1.6.4 Access to machine 010-15

010.1.6.5 Machine danger zone 010-16

010.1.6.6 Visibility 010-16

010.1.6.7 Protection against vibration 010-17

010.1.6.8 Operation of machine 010-18

010.1.7 Safe maintenance 010-21

010.1.7.1 Spare parts 010-21

010.1.7.2 Heavy parts 010-21

010.1.7.3 Regular checks 010-22

010.1.8 Modifications to the machine 010-22

010.1.8.1 Modifications, add-ons and retrofittings 010-22

010.2 Special tools for maintenance and repair work 010-23

010.2.1 Special tools, general 010-23

010.2.2 Special tools for the diesel engine 010-25

010.2.3 Special tools for lift cylinders with Z kinematics 010-29

010.2.4 Special tools for tilt cylinders with Z kinematics 010-29

010.2.5 Special tools for steering wheel 010-30

010.2.6 Special tools for steering cylinders 010-31

010.2.7 Special tools for brake system 010-31

010.2.8 Special tools for the electrical system 010-32

010.2.9 Special tools for front axle 010-33

010.2.10 Special tools for rear axle 010-33

010.2.11 Special tools for the air conditioning system 010-33

010.2.12 Special tools for Grammer driver’s seat 010-35

010.2.13 Special tools for cab glazing 010-35 C: i CD

010.2.14 Special tools for the central lubrication system (Liebherr) 010-35

010.3 Standards and regulations 010-37 ‘

010.3.1 Prestressing forces and tightening torques for bolts with metric ~

standard and fine threads as per DIN ISO 261 010-37 ~ iil

010.3.1.1 Range of application and purpose 010-37

010.3.1.2 Other applicable documents 010-37 ~ ID

010.3.1.3 Modifications and descriptions 010-38

010.3.1.4 Tightening torques 010-38

010.3.2 Liebherr standards for assembly instructions and tightening torqueso10-44

010.4 Preservation guidelines 010-45

010.4.1 General information 010-45

010.4.2 Machine out of service for an unknown period of time 010-45

010.4.3 Putting the machine out of service 010-46

010.4.3.1 Out of service for up to 2 months 010-46

010.4.3.2 Out of service for up to 12 months 010-47

010.4.3.3 Out of service for longer than 12 months 010-48

010.4.4 Putting back into service 010-48

010.4.4.1 After being out of service for 2 months 010-48

010.4.4.2 After being out of service for 12 months 010-49

010.4.4.3 After being out of service for longer than 12 months 010-49

010.5 Preservation guidelines for the SCR system 010-50

010.5.1 Putting out of service for longer than 2 months 010-50

010.5.2 Starting up after being out of service for longer than 2 months 010-50

020 Technical data 020-1

020.1 Overall machine 020-5

020.1.1 Complete machine with bucket (Z lift arms)

020.2 Drive group 020-7

020.2.1 Diesel engine

020.2.2 Fuel tank

020.2.3 Fuel level sensor

020.2.4 Fuel pre-filter (separator filter)

020.2.5 Compressed air system ;;;, L576-1759; 020-9

020.3 Cooling system

020.3.1 Fan pump ~

020.3.2 Fan motor

020.3.3 Hydraulic oil temperature sensor B8

020.4 Working hydraulics 020-11

Working pump

020.4.2 Control valve block for Z kinematics

020.4.3 Pilot control valve block

020.4.4 Pilot control hydro accumulator

020.4.5 Stabilisation module

020.4.6 Ride control hydro accumulator

020.4.7 Z-bar kinematics lift cylinder

020.4.8 Z kinematics tilt cylinder

020.4.9 Pressure sensors for lift cylinders and tilt cylinders B90, B91, B92,

020.5 Hydraulic components 020-14

020.5.1 Return filter

020.5.2 Breather filter

020.6 Steering system 020-15

020.6.1 Steering pump

020.6.2 Servostat

020.6.3 Steering cylinder

020.6.4 Steering damper hydro accumulator

020.6.5 Emergency steering pump C:’

020.6.6 Emergency steering pressure switch B3 ;;;,

020.6.7 Emergency steering check pressure switch B3a ~’

020.6.8 Joystick steering control valve block

020.7 Brake system 020-18

020.7.1 Brake pump

020.7.2 Compact brake valve

L576-1759; 020-18

020.7.3 Service brake hydro accumulator

L576-1759; 020-18

020.7.4 Brake light pressure switch B12

L576-1759; 020-18

020.7.5 Brake accumulator pressure sensor B19

L576-1759; 020-19

020.7.6 Parking brake hydro accumulator

L576-1759; 020-19

020.8 Electrical system 020-20

020.8.1 Central control unit (Master5-Premium)

L576-1759; 020-20

020.8.2 Input module

L576-1759; 020-20

020.8.3 Output module

L576-1759; 020-20

020.8.4 Battery

L576-1759; 020-21

020.8.5 Voltage transformer

L576-1759; 020-21

020.8.6 Reversing camera

L576-1759; 020-21

020.9 Gearbox 020-22

020.9.1 Transmission

L576-1759; 020-22

020.9.2 Filter bypass switch B85

L576-1759; 020-22

020.9.3 Proportional solenoid for gear shifting Y1, Y2, Y3, Y 4, Y5, Y6

L576-1759; 020-22

020.9.4 Pressure sensor for hydrostat B80, B81

L576-1759; 020-23

020.9.5 Speed sensor B82, B83, B84

C: L576-1759; 020-23 i “.C.D.’ 020.9.6 Transmission oil temperature sensor B86 ;;;,

~

L576-1759; 020-23

0

0 “0 ‘ 020.9.7 Proportional solenoid for position control Y7

~ L576-1759; 020-24

~

iil 020.10 Axles and drive shafts 020-25 “”” “”” “‘ 020.10.1 Front axle ~ ID L576-1759; 020-25 …J

020.10.2 Rear axle

L576-1759; 020-25

copylight © Liebherr-Werk Bischofshofen GmbH 2020

L576-1759 llEBHERR 9

Contents

10

020.10.3 Drive shaft between diesel engine and transmission

L576-1759;

020.10.4 Drive shaft between transmission and front axle

L576-1759;

020.10.5 Drive shaft between transmission and rear axle

L576-1759;

020.10.6 Tyres

L576-1759;

020.10.6.2 Tyres for timber work

020.10.6.3 Special tyres

Service manual

020-25

020-26

020-26

020-26

020-27

020-28

——————-

020. 11 Steel parts of the basic machine

020.11.1 Ballast weights

L576-1759;

020.11.1.1 Standard (z-bar kinematics) and industrial lift arms

020.11.1.2 Foam-filled tyres or tracks

020.12 Working attachment

020.12.1 Quick coupler locking hydraulic cylinder

L576-1759;

020.13 Operator’s cab, heating and air conditioning

020.13.1.1 Air conditioning compressor

020.13.2 Air conditioning pressure switch

L576-1759;

020.14 Lubrication system

020.14.1 Central lubrication system (Liebherr)

L576-1759;

020.14.1.1 Central lubrication pump

020.14.1.2 Progressive distributor

020.14.2 Progressive distributor

L576-1759;

020.14.2.1 MX-F

020-29

020-29

020-29

020-29

020-30

020-30

020-31

020-31

020-31

020-32

020-32

020-32

020-32

020-33

020-33 ——————–

020.14. 2. 2 MX-F 25 020-33

——————–

020.14. 2. 3 MX-F 45 020-34

——————–

020.14. 2 .4 MX-F 75 020-34

——————–

020.14. 2. 5 MX-F105

020.14.3 Progressive distributor SXE-2

L576-1759;

020.14.3.1 SXE-2 / MX-F

020-34

020-34

020-34 ——————-

020.14. 3. 2 SXE-2 100 020-34

——————-

020.14. 3. 3 SXE-2 150 020-35

copylight © Liebherr-Werk Bischofshofen GmbH 2020

llEBHERR L576-1759

C: i “.C.D.’ ;;;,

!:j

0

0 “0 ‘

~

~

iil

“”” “”” “‘ ~ ID

…J

C: i “.C.D.’ ;;;,

~

0

0 “0 ‘

~

~

iil

“”” “”” “‘ ~ ID

…J

Service manual Contents

020.14.3.4 SXE-2 220 020-35

——————–

020.14. 3. 5 SXE-2 400 020-35

020.14.3.6 SXE-2 760 020-35

030 Maintenance 030-1

L576-1759

030.1 Maintenance and inspection schedule

030.2 Filling quantities and lubrication chart

030.2.1 Lubricant filling quantity

L576-1759;

030.2.2 Fuel and operating fluid filling quantity

L576-1759;

030.3 Lubricants and fuels

030.3.1 General information on lubricants and fuels

030.3.1.1

030.3.1.2

030.3.1.3

030.3.1.4

General questions

Safety data sheets

Technical data sheets

Specific Liebherr standards

030-11

030-16

030-16

030-16

030-17

030-17

030-17

030-17

030-17

030-17

030.3.2 General information on changing lubricants and fuels 030-17

030.3.3 Converting hydraulic system from mineral oils to biodegradable

hydraulic fluids 030-18

030.3.4 Diesel fuels

L576-1759; 030-18

030.3.4.1

030.3.4.2

030.3.4.3

Minimum quality requirement

Operating temperatures of diesel fuels

Minimum quality requirement

030.3.5 Diesel exhaust fluid

L576-1759;

030.3.5.1 Liebherr recommendation

030.3.5.2 Minimum quality requirement

030.3.6 Engine oils

L576-1759;

030.3.6.1 Liebherr recommendation

030.3.6.2 Minimum quality requirement

030.3.6.3 Changing intervals

030.3.6.4 Complicating factors

030.3.7 Refrigerant

L576-1759;

030.3.8 Coolant

L576-1759;

copylight © Liebherr-Werk Bischofshofen GmbH 2020

llEBHERR

030-18

030-19

030-19

030-19

030-19

030-19

030-20

030-20

030-20

030-20

030-21

030-21

030-22

11

Contents Service manual

030.3.8.1 Requirements for the water used 030-22

030.3.8.2 Antifreeze and corrosion inhibitor 030-22

030.3.8.3 Minimum quality requirement 030-22

030.3.9 Hydraulic oil

L576-1759; 030-22

030.3.9.1 Liebherr recommendation 030-22

030.3.9.2 Minimum quality requirement 030-23

030.3.9.3 Oil analysis 030-23

030.3.9.4 Oil change 030-23

030.3.10 Splitter box oil

L576-1759; 030-24

030.3.10.1 Liebherr recommendation 030-24

030.3.10.2 Minimum quality requirements 030-24

030.3.11 Gear oil

L576-1759; 030-24

030.3.11.1 Liebherr recommendation 030-24

030.3.11.2 Minimum quality requirement 030-24

030.3.12 Axle oil

L576-1759; 030-25

030.3.12.1 Liebherr recommendation 030-25

030.3.12.2 Minimum quality requirement 030-25

030.3.13 Lubrication grease

L576-1759; 030-25

030.3.13.1 Liebherr recommendation 030-25

030.3.13.2 Minimum quality requirement 030-25

030.3.14 Windscreen washer fluid

L576-1759; 030-26

030.3.14.1 Liebherr recommendation 030-26

030.3.14.2 Minimum quality requirement 030-26

C:

030.3.15 Refrigerant oil for air conditioning compressor i

L576-1759; 030-26 “.C.D.’ ;;;,

030.3.15.1 Liebherr recommendation 030-26 !:j

0

0 “0 ‘

030.4 Maintenance tasks 030-27 ~

~

030.4.1 Safety precautions iil

L576-1759; 030-27 “”” “”” “‘

030.4.2 Preparatory tasks for maintenance 030-27 ~ ID

…J

030.4.2.1 Maintenance positions

L576-1759; 030-28

copylight © Liebherr-Werk Bischofshofen GmbH 2020

12 llEBHERR L576-1759

Service manual Contents

030.4.2.2 Opening the service hatches

L576-1759; 030-29

030.4.2.3 Turning off the battery main switch

L576-1759; 030-33

030.4.3 Overall machine 030-34

030.4.3.1 Checking machine is in proper condition

L576-1759; 030-34

030.4.3.2 Removing loose parts, dirt, ice and snow from

machine

L576-1759; 030-36

030.4.3.3 Cleaning machine

L576-1759; 030-36

030.4.3.4 Changing the VCl-capsules

L576-1759; 030-39

030.4.3.5 Oil analyses

L576-1759; 030-42

030.4.4 Drive group 030-49

030.4.4.1 Checking diesel engine oil level

L576-1759; 030-49

030.4.4.2 Diesel engine: changing diesel engine oil

L576-1759; 030-52

030.4.4.3 Diesel engine: changing oil filter

L576-1759; 030-55

030.4.4.4 Checking diesel engine belt drive

L576-1759; 030-56

030.4.4.5 Changing diesel engine belt drive

L576-1759; 030-57

030.4.4.6 Checking fastening of diesel engine control units and

sensor cable connections

L576-1759; 030-58

030.4.4.7 Checking diesel engine valve clearance

L576-1759; 030-59

030.4.4.8 Diesel engine: changing oil separator filter cartridge

L576-1759; 030-61

C: i “.C.D.’ 030.4.4.9 LD5ie7s6e-l1 e7n5g9i;n e: Changing the heating flange 030-62 ;;;,

~ 0 030.4.4.10 Fuel tank: Draining off condensate and sediment

0 “0 ‘ L576-1759; 030-62 ~

~ 030.4.4.11 Fuel pre-filter: Draining off condensate iil

“”” L576-1759; 030-63 “”” “‘ ~ 030.4.4.12 Changing fuel pre-filter cartridge

ID …J L576-1759; 030-64

030.4.4.13 Changing fuel fine filter element

L576-1759; 030-67

copylight © Liebherr-Werk Bischofshofen GmbH 2020

L576-1759 llEBHERR 13

Contents Service manual

030.4.4.14 Diesel exhaust fluid tank: checking ventilation

L576-1759; 030-70

030.4.4.15 Air filter system: Cleaning the service cover and dust

discharge valve

L576-1759; 030-71

030.4.4.16 Cleaning or changing the main element of the air

filter system

L576-1759; 030-72

030.4.4.17 Air filter system: Changing the safety element

L576-1759; 030-75

030.4.4.18 Dust protection for alternator (option): cleaning or

replacing filter element

L576-1759; 030-76

030.4.4.19 Splitter box: Checking the oil level

L576-1759; 030-79

030.4.4.20 Splitter box: Changing the oil

L576-1759; 030-80

030.4.4.21 Checking that the diesel engine intake and exhaust

system is in good condition and not loose or leaking

L576-1759; 030-82

030.4.4.22 Checking the diesel engine for leaks, contamination

and damage

L576-1759; 030-84

030.4.4.23 Diesel engine: checking profile clamps

L576-1759; 030-85

030.4.4.24 Diesel particulate filter: Cleaning filter module

L576-1759; 030-87

030.4.4.25 Changing the compressed air dryer

L576-1759; 030-90

030.4.4.26 Checking compressed air system

L576-1759; 030-91

030.4.5 Cooling system 030-92

030.4.5.1 Cooling system: Checking the coolant level

L576-1759; 030-92

030.4.5.2 Coolant: checking anti-freeze and corrosion protec- C:

tion agent concentration i CD

L576-1759; 030-93 “…’ ;;;,

030.4.5.3 Cleaning the cooling system !:j

0

0

L576-1759; 030-100 “0 ‘

~

030.4.5.4 Changing coolant in cooling system ~

L576-1759; 030-101 iil

“”” “”” 030.4.6 Hydraulic components 030-104 “‘ ~ ID

030.4.6.1 Hydraulic tank: Checking the oil level …J

L576-1759; 030-104

copylight © Liebherr-Werk Bischofshofen GmbH 2020

14 llEBHERR L576-1759

Service manual Contents

030.4.6.2 Draining off condensate and sediment from the

hydraulic tank

L576-1759; 030-106

030.4.6.3 Change the return filter insert in the hydraulic tank.

L576-1759; 030-107

030.4.6.4 Changing the hydraulic tank breather filter

L576-1759; 030-108

030.4.6.5 Hydraulic tank: analysing the oil

L576-1759; 030-109

030.4.6.6 Changing the oil in the hydraulic tank

L576-1759; 030-110

030.4.7 Steering system 030-114

030.4.7.1 Steering: Checking the function

L576-1759; 030-114

030.4.7.2 Steering cylinders: Lubricating the bearings

L576-1759; 030-114

030.4.8 Brake system 030-115

030.4.8.1 Service brake: checking function and effectiveness

L576-1759; 030-115

030.4.8.2 Checking service brake discs for wear

L576-1759; 030-116

030.4.8.3 Checking the gap and wear on the parking brake

linings

L576-1759; 030-120

030.4.8.4 Emergency actuation of parking brake: checking the

seal

L576-1759; 030-126

030.4.8.5 Checking emergency parking brake actuation

L576-1759; 030-126

030.4.9 Electrical system 030-127

030.4.9.1 Checking function of the lighting and horn

L576-1759; 030-127

030.4.9.2 Batteries: Checking the acid level and terminals

C:

L576-1759; 030-128

i “.C.D.’ 030.4.9.3 Control lever: Change the travel direction switch ;;;, rocker and cap.

~ L576-1759; 030-130 0

0 “0 ‘ ~ 030.4.9.4 Personnel detection: cleaning sensor

~ L576-1759; 030-133

iil

“”” 030.4.10 Gearbox 030-133 “”” “‘ ~ 030.4.10.1 Transmission: checking the oil level

ID …J L576-1759; 030-133

030.4.10.2 Changing gear oil and gear oil filter

L576-1759; 030-136

copylight © Liebherr-Werk Bischofshofen GmbH 2020

L576-1759 llEBHERR 15

Contents Service manual

030.4.10.3 Change the transmission hydrostat oil filter.

L576-1759; 030-140

030.4.11 Axles and drive shafts 030-141

030.4.11.1 Axles Changing the oil

L576-1759; 030-141

030.4.11.2 Checking drive shafts

L576-1759; 030-143

030.4.11.3 Checking the tyre pressure

L576-1759; 030-145

030.4.11.4 Checking the wheel tightness

L576-1759; 030-147

030.4.12 Steel parts of the basic machine 030-147

030.4.12.1 Lubricating the articulation bearing and the rear axle

oscillating bearing

L576-1759; 030-147

030.4.12.2 Cooler hood: Lubricating moving parts with penetrating

oil

L576-1759; 030-148

030.4.12.3 Engine hood: Lubricating moving parts with penetrating

oil

L576-1759; 030-149

030.4.12.4 Right cab access: Lubricating moving parts with

penetrating oil

L576-1759; 030-150

030.4.12.5 Service hatches: cleaning and maintaining seals

L576-1759; 030-150

030.4.13 Working attachment 030-151

030.4.13.1 Lubricating the lift arms and working attachment

L576-1759; 030-151

030.4.13.2 Lift arms: Checking the bucket bearing seals

L576-1759; 030-153

030.4.13.3 Lift arms: checking bucket bearing bushings

L576-1759; 030-154

030.4.13.4 Checking the lift arm bucket stops

C: L576-1759; 030-155 i CD 030.4.13.5 Bucket: Check the teeth or undercut blade for wear “‘ … ;;;,

and replace if necessary !:j

0

L576-1759; 030-157 0 “0 ‘

~

030.4.13.6 Lubricate and test the bearings on the quick coupler. ~

L576-1759; 030-160 iil

“”” 030.4.13.7 High dump bucket: Lubricating the bearing “”” “‘ L576-1759; 030-161 ~ ID

…J

030.4.14 Operator’s cab, heating and air conditioning 030-161

copylight © Liebherr-Werk Bischofshofen GmbH 2020

16 llEBHERR L576-1759

Service manual

030.5

030.6

C: i “.C.D.’ ;;;,

~

0

0 “0 ‘

~

~

iil

“”” “”” “‘ ~ ID

…J

L576-1759

Contents

030.4.15

030.4.14.1 Operator’s cab: cleaning the fresh and recirculated

air filters

L576-1759;

030.4.14.2 Operator’s cab: changing fresh air filter and recirculated

air filters

L576-1759;

030.4.14.3 Safety belt: Checking the condition and function

L576-1759;

030.4.14.4 Testing the windscreen washer system

L576-1759;

030.4.14.5 Windscreen washer system: filling windscreen

washer fluid

L576-1759;

030.4.14.6 Cab: Lubricating the lock and cylinder with penetrating

oil

L576-1759;

030.4.14.7 Operator’s cab: cleaning and maintaining seals

L576-1759;

030.4.14.8 Heating and air conditioning: Checking the function

L576-1759;

Lubrication system

030.4.15.1 Checking the level in the grease reservoir of the

central lubrication system

L576-1759;

030.4.15.2 Central lubrication system: Checking the pipes,

hoses and lubrication points for leaks and damage

030-161

030-162

030-164

030-165

030-165

030-166

030-166

030-167

030-168

030-168

L576-1759; 030-169

030.4.15.3 Central lubrication system: Checking the lubrication

of the bearings

L576-1759; 030-170

Testing and adjustment checklist

L576-1759; 030-171

Testing and adjustment tasks 030-177

030.6.1 Safety precautions

L576-1759; 030-177

030.6.2 Overall machine 030-177

030.6.2.1 Preparing for adjustment procedures

L576-1759; 030-177

030.6.2.2 Hydraulic oil: operating temperature

L576-1759; 030-179

030.6.2.3 Gear oil operating temperature

L576-1759; 030-180

030.6.2.4 Service management

L576-1759; 030-180

030.6.3 Drive group 030-181

copylight © Liebherr-Werk Bischofshofen GmbH 2020

llEBHERR 17

Contents Service manual

030.6.3.1 Pedals: calibration

L576-1759; 030-181

030.6.3.2 Reading the diesel engine service files

L576-1759; 030-183

030.6.4 Cooling system 030-184

030.6.4.1 Fan speed proportional solenoid valve

L576-1759; 030-184

030.6.5 Working hydraulics 030-186

030.6.5.1 Multi-lever control (optional): Calibration

L576-1759; 030-186

030.6.5.2 Calibrating working hydraulics angle sensors

L576-1759; 030-188

030.6.5.3 Proportional solenoids in the control valve block: calibration

L576-1759; 030-191

030.6.5.4 Pilot control valve block: pressure reducing valve

L576-1759; 030-195

030.6.5.5 Working pump: flow regulator (standby pressure)

L576-1759; 030-196

030.6.5.6 Working pump flow regulator (differential pressure)

L576-1759; 030-197

030.6.5.7 Working pump: power regulator

L576-1759; 030-199

030.6.5.8 Z-bar kinematics control valve block: secondary pressure

relief valves

L576-1759; 030-201

030.6.5.9 Z-bar kinematics control valve block: primary pressure

relief valve

L576-1759; 030-203

030.6.5.10 Z-bar kinematics control valve block: LS-pressure

cut-off

L576-1759; 030-205

030.6.5.11 Stabilisation module cut-out function

L576-1759; 030-206

030.6.5.12 Ride control hydro accumulator nitrogen filling C: i

L576-1759; 030-207 “.C.D.’

030.6.6 Hydraulic components 030-208

;;;,

!:j

0

0 030.6.6.1 Hydro accumulator: checking and topping up “‘ 0

~

nitrogen filling ~

L576-1759; 030-208 iil

“”” 030.6.6.2 Checking the hydraulic lines for damage “”” “‘ L576-1759; 030-210 ~ ID

…J

030.6.7 Steering system 030-215

030.6.7.1 Joystick for joystick steering (option): calibration

L576-1759; 030-215

copylight © Liebherr-Werk Bischofshofen GmbH 2020

18 llEBHERR L576-1759

Service manual

L576-1759

030.6.7.2

030.6.7.3

030.6.7.4

030.6.7.5

030.6.7.6

030.6.7.7

030.6.7.8

030.6.7.9

030.6.8 Brake system

030.6.8.1

030.6.8.2

030.6.8.3

030.6.8.4

Contents

Angle sensor for articulation angle (option): calibration

(machine with steering wheel steering)

L576-1759; 030-215

Angle sensor for articulation angle (option): calibration

(machine without steering wheel steering)

L576-1759; 030-217

Control block for joystick steering (option): calibration

L576-1759; 030-218

Steering pump: LS pressure cut-off valve

L576-1759; 030-220

Steering pump flow regulator (standby pressure)

L576-1759; 030-221

Steering pump: flow regulator (differential pressure)

L576-1759; 030-223

Steering damper hydro accumulator nitrogen filling

L576-1759; 030-224

Control block for joystick steering: determining installation

position of position sensors

L576-1759; 030-225

030-226

Brake accumulator pressure sensor B19: deviation

L576-1759; 030-226

Compact brake valve hydro accumulator charging

function

L576-1759; 030-227

Service brake pressure

L576-1759; 030-228

Service brake hydro accumulator capacity

L576-1759; 030-229

030.6.9 Electrical system 030-231

030.6.9.1 Central control unit (Master5): creating service file

L576-1759; 030-231

030.6.9.2 Central control unit (Master5): software update

L576-1759; 030-232

030.6.9.3 Central control unit (Master5): resetting to factory

settings

L576-1759; 030-235

030.6.9.4 Central control unit (Master5): connecting Sculi diagnostic

software

L576-1759; 030-237

030.6.9.5 Central control unit (Master5): connecting LiFT function

L576-1759; 030-240

030.6.9.6 Addressing CAN module and checking system information

L576-1759; 030-241

copyright© Liebherr-Werk Bischofshofen GmbH 2020

llEBHERR 19

Contents

030.6.10

030.6.11

030.6.12

Service manual

Gearbox

030.6.10.1 Gearbox: basic calibration

L576-1759;

030.6.10.2 Gearbox: service calibration

L576-1759;

030.6.10.3 Transmission control unit: software update

L576-1759;

Axles and drive shafts

030.6.11.1 Tyres: setting radius

L576-1759;

Working attachment

030.6.12.1 Valve block for quick coupler (option): Pressure

reducing valve

L576-1759;

030.6.12.2 Parameters for lift arm geometry

L576-1759;

030-245

030-245

030-247

030-250

030-251

030-251

030-252

030-252

030-253

030.6.12.3 Working attachment: automatic return of 3rd function

L576-1759; 030-254

030.6.13 Operator’s cab, heating and air conditioning 030-255

030.6.13.1 Checking the pressure and temperature conditions of

the air conditioning unit

L576-1759; 030-255

030.6.14 Options 030-256

030.6.14.1 LiDAT: connecting to LiDAT module

L576-1759;

030.6.14.2 LiDAT: software update for LiDAT module

L576-1759;

030.6.14.3 LiDAT: creating report and snapshot

L576-1759;

030-256

030-258

030-260

030.6.14.4 Liebherr weighing device with Truck Payload Assist:

calibration

L576-1759; 030-264

030.6.14.5

030.6.14.6

Skyview 360°: calibration

L576-1759;

Personnel detection: transmitting configuration files

030-264 I

ill

L576-1759; 030-271

040 Drive group

040.1 Engine

030.6.14.7 Tyre pressure monitoring: changing and programming

pressure sensor

L576-1759; 030-275

040-1

040-3

—————————-

040. 1. 1 Diesel engine overview

L576-1759; 040-3

copylight © Liebherr-Werk Bischofshofen GmbH 2020

… ;;;,

!:j

~

I

I ~

ID

…J

20 llEBHERR L576-1759

Service manual Contents

040.1.2 Electrical components of diesel engine

L576-1759; 040-7

040.1.3 Ambient temperature sensor

L576-1759; 040-10

040.1.5 Fuel system 040-16

040.1.5.2 Fuel level sensor

L576-1759; 040-19

040.1.5.3 Separ fuel pre-filter

L576-1759; 040-21

040.1.6 Air filter system 040-21

040.1.6.1 Air filter

L576-1759; 040-22

040.1.6.2 Vacuum switch

L576-1759; 040-23

040.1.7 Exhaust system 040-23

040.1.7.1 Exhaust gas treatment (stage V): overview

L576-1759; 040-24

040.1.7.2 Exhaust gas treatment (stage IV/ tier 4f): overview

L576-1759

L576-1759;

040.1.7.3 Metering unit

L576-1759;

040.1.7.4 Sampling module

L576-1759;

040.1.7.5 Exhaust treatment sensors

L576-1759;

040.1.8 Compressed air system

040.1.8.1 Overview of the compressed air system

L576-1759;

040.1.8.2 Compressor

L576-1759;

040.1.8.3 Air dryer

L576-1759;

040.1.8.4 SCR system air supply valve

L576-1759;

040.2 Clutch

L576-1759;

040.3 Splitter box

L576-1759;

050 Cooling system

050.1 Cooling system: General overview

L576-1759;

050.2 Cooling system hydraulics

copyright© Liebherr-Werk Bischofshofen GmbH 2020

llEBHERR

040-33

040-38

040-41

040-42

040-43

040-44

040-46

040-47

040-48

040-49

040-51

050-1

050-2

050-3

21

Contents Service manual

050.2.1 Overview of cooling system hydraulics

L576-1759; 050-4

050.2.2 Fan pump

L576-1759; 050-8

050.2.3 Fan motor

L576-1759; 050-9

050.3 Cooling system electronics 050-13

050.3.1 Overview of electrical controls of cooling system

L576-1759; 050-13

050.3.2 Hydraulic oil temperature sensor

L576-1759; 050-16

050.4 Cooler 050-18

050.4.1 Cooler unit

L576-1759; 050-18

050.5 Reversible fan drive 050-19

050.5.1 Overview of reversible fan drive

L576-1759; 050-19

050.5.2 Fan reversal valve block

L576-1759; 050-21

060 Working hydraulics 060-1

060.1 Overview of Z-bar kinematics working hydraulics

L576-1759; 060-2

060.2 Working pump

L576-1759; 060-11

060.3 Control block for Z-bar kinematics

L576-1759; 060-19

060.4 Pilot control 060-28

060.4.1 Pilot control valve block

L576-1759; 060-28

060.5 Ride control 060-30

060.5.1 Overview of ride control system

L576-1759; 060-30 C: i 060.5.2 Stabilisation module “.C.D.’

L576-1759; 060-33

;;;,

!:j

0

0

060.5.3 Electric ride control unit “0 ‘

L576-1759; 060-36 ~

~

060.6 Electronics of the working hydraulics 060-38 iil

“”” “””

060.6.1 Overview of electrical controls the working hydraulics “‘ ~

L576-1759; 060-38 ID

…J

060.6.2 Working hydraulics angle sensors

L576-1759; 060-40

copylight © Liebherr-Werk Bischofshofen GmbH 2020

22 llEBHERR L576-1759

Service manual

L576-1759

060.6.3 Pressure sensors for lift cylinders and tilt cylinders

L576-1759;

060. 7 Pipe break protection

060.7.1 Pipe break protection: overview

L576-1759;

060.7.2 Valve block for pipe break protection

L576-1759;

060.7.3 Ride control release solenoid valve

L576-1759;

080 Hydraulic components

080.1 Hydraulic system: overview

L576-1759;

080.2 Hydraulic tank

080.2.1 Overview of hydraulic tank

L576-1759;

080.2.2 Steel tank

L576-1759;

080.2.3 Return filter

L576-1759;

080.2.4 Leak oil strainer

L576-1759;

080.2.5 Breather filter

L576-1759;

090 Steering system

090.1 Steering system overview

L576-1759;

090.2 Steering pump

L576-1759;

090.3 Servostat

L576-1759;

090.4 Steering cylinder

090.4.1 Steering cylinder

L576-1759;

090.4.2 Steering stabilisation valve block

L576-1759;

090.4.3 Valve block for steering stabilisation (without steering wheel

steering)

L576-1759;

090.5 Emergency steering

090.5.1 Emergency steering overview

L576-1759;

copyright© Liebherr-Werk Bischofshofen GmbH 2020

llEBHERR

Contents

060-42

060-44

060-44

060-47

060-48

080-1

080-2

080-5

080-5

080-7

080-9

080-10

080-10

090-1

090-3

090-8

090-14

090-17

090-17

090-20

090-21

090-23

090-23

23

Contents

24

Service manual

090.5.2 Emergency steering pump

L576-1759;

090.5.3 Emergency steering electronics

090.5.3.1 Overview of electrical controls of emergency steering

system

090-25

090-27

L576-1759; 090-27

090.5.3.2 Emergency steering pressure switch

L576-1759; 090-32

090.5.3.3 Emergency steering check pressure switch

L576-1759; 090-33

090.6 Joystick steering 090-35

090.6.1 Joystick steering: overview (combined with steering wheel steering)

L576-1759; 090-35

090.6.2 Joystick steering: overview (without steering wheel steering)

L576-1759;

090.6.3 Joystick steering control block

L576-1759;

090.6.4 Joystick steering electrical system

090-39

090-42

090-48

090.6.4.1 Electronic control unit for joystick steering: overview

L576-1759; 090-48

090.6.4.2

090.7 2in1 steering

Joystick with position tracking

L576-1759;

090.7.1 2in1 steering: total overview

L576-1759;

090.7.2 Servostat for 2in1 steering

L576-1759;

100 Brake system

100.1 Overview of brake system

L576-1759;

100.2 Service brake and parking brake

100.2.1 Brake pump

L576-1759;

100.2.2 Compact brake valve

L576-1759;

100.3 Parking brake

100.3.1 Parking brake

L576-1759;

11 0 Electrical system

110.1 Overview of electrical system

Service manual Contents

110.2 Lighting

L576-1759; 110-6

110.3 Circuit diagrams

L576-1759; 110-7

110.4 Electronic control unit 110-9

110.4.1 General overview of electronic control system

L576-1759; 110-9

110.4.2 Central control unit (Master5-Premium)

L576-1759; 110-11

110.4.3 Modules 110-14

110.4.3.1 Overview of the input and output modules

110.4.3.2 Input modules

110.4.3.3 Output modules

110.5 Electrical components of the driver’s cab 110-21

110.5.1 Fuse and relay boards

110.5.2 Door contact switch (inductive sensor)

110.6 Electrical components in the rear section 110-27

110.6.1 Battery installation

110.6.2 Electric battery main switch

120.1 Overview of transmission

120.2 Transmission hydraulics 120-16

120.2.1 Overview of transmission hydraulics

120.2.3 Transmission control valve block

120.2.4 Hydrostat module “”” “”” L576-1759; 120-24 “‘ ~ ID 120.3 Transmission electronics 120-29

120.3.1 Overview of electrical control system of transmission

120.3.2 Filter bypass switch

L576-1759; 120-30

120.3.3 Gear shifting proportional solenoid

L576-1759; 120-31

120.3.4 Pressure sensor for hydrostat

L576-1759; 120-32

120.3.5 Engine speed sensor

L576-1759; 120-33

120.3.6 Temperature sensor

L576-1759; 120-34

120.3.7 Proportional solenoid for position control

L576-1759; 120-34

130 Axles and drive shafts 130-1

130.1 Axles 130-2

130.1.1 Front axle

L576-1759; 130-2

130.1.2 Rear axle

L576-1759; 130-7

130.2 Cardan shafts 130-9

130.2.1 Drive shaft between diesel engine and transmission

L576-1759; 130-9

130.2.2 Drive shaft between transmission and front axle

130.2.3 Drive shaft between transmission and rear axle

140 Steel parts of the basic machine 140-1

140.1 Vehicle frame 140-2

140.1.1 Articulation bearing

140.1.2 Articulation lock

140.2 Covering i’

140.2.1 Linear motor for opening the engine hoo

150 Working attachment 150-1 iil

150.1 Lift arms for Z kinematics 150-2 “~’ ID

150.1.1 Z kinematics

150.2 Quick coupler 150-4

150.2.1 Quick coupler

L576-1759;

150.2.2 Quick coupler hydraulics

150.2.2.1

150.2.2.2

Overview of quick coupler hydraulics

L576-1759;

Valve block for quick coupler

L576-1759;

150.2.3 Quick coupler electrics

150.2.3.1 Quick coupler electric control unit

L576-1759;

160 Operator’s cab, heating and air conditioning

L576-1759

160.1 Overview of operator’s cab, heating and air conditioning unit

L576-1759;

160.2 Display and control elements

160.2.1 Control lever

L576-1759;

160.2.2 Accelerator pedal

L576-1759;

160.3 Heating, ventilation, air conditioning

160.3.1 Heating, ventilation, air conditioning: General overview

L576-1759;

160.3.2 Heating and air conditioning unit

Heating and air conditioning unit

Blower

160.3.3 Air conditioning controller

160.4 Air conditioning

160.4.1 Basic function of the air conditioning unit

160.4.2 Air conditioning compressor

160.4.3 Condenser

160.4.4 Dryer

160.4.5 Air conditioning pressure switch

Contents Service manual

170 Lubrication system 170-1

170.1 Liebherr automatic central lubrication system 170-2

170.1.1 Liebherr automatic central lubrication system: overview

L576-1759; 170-2

170.1.2 Liebherr central lubrication pump

L576-1759; 170-6

170.1.3 Progressive distributor MX-F

L576-1759; 170-10

170.1.4 Progressive distributor SXE-2

L576-1759; 170-12

190 Options 190-1

190.1 LiDAT 190-2

190.1.1 Overview of LiDAT

L576-1759; 190-2

190.1.2 LiDAT on machine

L576-1759; 190-4

190.1.3 LiDAT module (LiTU3)

L576-1759; 190-6

190.2 Liebherr weighing device with Truck Payload Assist

L576-1759; 190-10

190.3 Skyview 360° 190-12

190.3.1 Skyview 360°: complete overview

L576-1759; 190-12

190.3.2 Skyview 360° on machine

L576-1759; 190-16

190.4 Remote control for door lock

L576-1759; 190-17

190.5 Personnel detection

L576-1759; 190-20

190.6 Entfall des Lenkstockschalters 190-23

190.6.1 Elimination of steering-column switch: overview

L576-1759; 190-23 C: i CD

190.6.2 Additional controller (HY-TTC-30S) “…’

200.1 Malfunctions 200-2 “”””’ “””

200.1.1 Warning symbols 200-2 ~ ID

200.1.2 SCR system warning symbols 200-3

200.1.3 Service code indicator in display 200-4

copylight © Liebherr-Werk Bischofshofen GmbH 2020

28 llEBHERR L576-1759

Service manual

200.2 Troubleshooting

200.2.1 Replacing fuses

Fuses on fuse board A4 in the operator’s cab 200-6

Fuses on fuse board A4a in the left ballast weight 200-9

Fuses on fuse board A4b in the operator’s cab 200-11