$38

Maeda CRAWLER CRANE CC985S-1 OPERATION MANUAL 51172 and up – PDF DOWNLOAD

Maeda CRAWLER CRANE CC985S-1 OPERATION MANUAL 51172 and up – PDF DOWNLOAD

FILE DETAILS:

Maeda CRAWLER CRANE CC985S-1 OPERATION MANUAL 51172 and up – PDF DOWNLOAD

Language : English

Pages :356

Downloadable : Yes

File Type : PDF

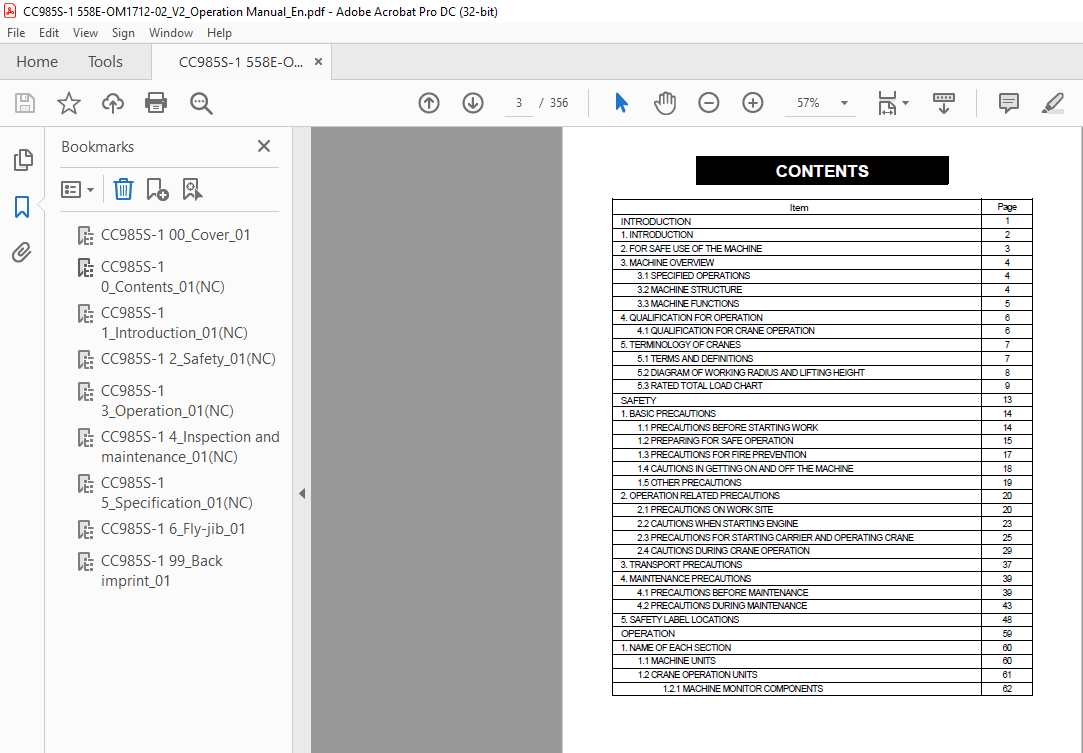

TABLE OF CONTENTS:

Maeda CRAWLER CRANE CC985S-1 OPERATION MANUAL 51172 and up – PDF DOWNLOAD

INTRODUCTION 1

1. INTRODUCTION 2

2. FOR SAFE USE OF THE MACHINE 3

3. MACHINE OVERVIEW 4

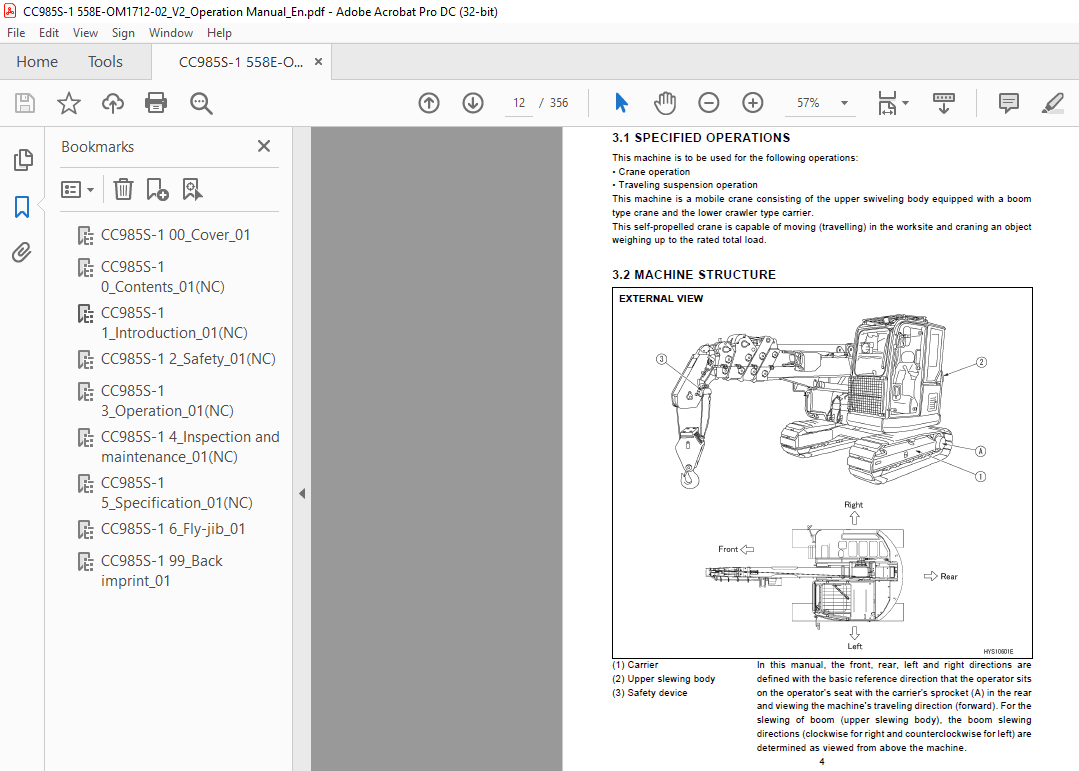

3.1 SPECIFIED OPERATIONS 4

3.2 MACHINE STRUCTURE 4

3.3 MACHINE FUNCTIONS 5

4. QUALIFICATION FOR OPERATION 6

4.1 QUALIFICATION FOR CRANE OPERATION 6

5. TERMINOLOGY OF CRANES 7

5.1 TERMS AND DEFINITIONS 7

5.2 DIAGRAM OF WORKING RADIUS AND LIFTING HEIGHT 8

5.3 RATED TOTAL LOAD CHART 9

SAFETY 13

1. BASIC PRECAUTIONS 14

1.1 PRECAUTIONS BEFORE STARTING WORK 14

1.2 PREPARING FOR SAFE OPERATION 15

1.3 PRECAUTIONS FOR FIRE PREVENTION 17

1.4 CAUTIONS IN GETTING ON AND OFF THE MACHINE 18

1.5 OTHER PRECAUTIONS 19

2. OPERATION RELATED PRECAUTIONS 20

2.1 PRECAUTIONS ON WORK SITE 20

2.2 CAUTIONS WHEN STARTING ENGINE 23

2.3 PRECAUTIONS FOR STARTING CARRIER AND OPERATING CRANE 25

2.4 CAUTIONS DURING CRANE OPERATION 29

3. TRANSPORT PRECAUTIONS 37

4. MAINTENANCE PRECAUTIONS 39

4.1 PRECAUTIONS BEFORE MAINTENANCE 39

4.2 PRECAUTIONS DURING MAINTENANCE 43

5. SAFETY LABEL LOCATIONS 48

OPERATION 59

1. NAME OF EACH SECTION 60

1.1 MACHINE UNITS 60

1.2 CRANE OPERATION UNITS 61

1.2.1 MACHINE MONITOR COMPONENTS 62

ii

Item Page

2. EXPLANATION OF EACH EQUIPMENT 63

2.1 MACHINE MONITOR 63

2.1.1 MONITOR BASIC ACTION AND DISPLAY 65

2.1.2 WARNING DISPLAY 72

2.2 SWITCHES 75

2.3 OPERATION LEVERS AND PEDALS 85

2.4 MOMENT LIMITER (OVERLOAD PREVENTIVE DEVICE) 89

2.4.1 CONFIGURATION OF MOMENT LIMITER 89

2.4.2 FUNCTIONS OF MOMENT LIMITER 90

2.4.3 MOMENT LIMITER OPERATION AND CANCELING (RECOVERY) 91

2.4.4 MOMENT LIMITER FUNCTIONS 94

2.4.5 OVERRIDE SWITCH 102

2.5 OVERWINDING PREVENTION DEVICE 104

2.6 AIR CONDITIONER HANDLING 105

2.6.1 COMPONENTS OF CONTROL PANEL 105

2.6.2 AIR CONDITIONER OPERATION METHOD 109

2.6.3 PRECAUTIONS IN AIR CONDITIONER USE 111

2.6.4 INSPECTION AND MAINTENANCE OF AIR CONDITIONER INSTALLED

MACHINE 111

2.7 CAR RADIO HANDLING 112

2.7.1 EXPLANATION OF EACH EQUIPMENT 112

2.7.2 CAR RADIO OPERATION METHOD 115

2.7.3 PRECAUTIONS IN CAR RADIO USE 117

2.8 FUSE 118

2.9 FUSIBLE LINK 119

2.10 CONTROLLER 120

2.11 CAB FRONT WINDOW 121

2.12 DOOR 123

2.13 HAMMER FOR EMERGENCY ESCAPE 124

2.14 CAP AND COVER WITH LOCK 125

2.15 BATTERY ROOM DOOR 126

2.16 LEFT COVER 126

2.17 RIGHT COVER 127

2.18 MACHINERY COVER 128

2.19 HOLDER FOR OPERATION MANUAL 128

2.20 GREASE PUMP HOLDER 129

2.21 CUP HOLDER 129

2.22 RETRACTABLE SEAT BELT HANDLING 129

3. OPERATION 130

3.1 PRE-OPERATION INSPECTION 130

3.1.1 CHECKING BEFORE STARTING ENGINE 130

3.1.2 CHECKING BEFORE STARTING ENGINE 133

3.1.3 CHECKING AFTER STARTING ENGINE 146

3.2 OPERATIONS AND CHECKS BEFORE STARTING ENGINE 149

3.3 STARTING ENGINE 150

3.4 OPERATIONS AND CHECKS AFTER STARTING ENGINE 152

3.4.1 WARM-UP OPERATIONS FOR ENGINE 152

3.4.2 WARM-UP OPERATIONS FOR HYDRAULIC EQUIPMENT 153

3.5 STOPPING ENGINE 155

3.6 BREAK-IN OPERATION 156

3.7 MACHINE TRAVELLING POSTURE 156

3.8 STARTING (FORWARD AND BACKWARD)/STOPPING THE MACHINE 157

3.9 CHANGING DIRECTION OF THE MACHINE 160

3.10 SLEWING THE MACHINE 161

3.11 PARKING THE MACHINE 162

3.12 INSPECTION AND CHECK AFTER COMPLETING WORK 163

3.12.1 AFTER STOPPING ENGINE 163

3.12.2 LOCKING 163

3.13 PRECAUTIONS IN TRAVELLING 164

3.14 PRECAUTIONS BEFORE CRANE OPERATION 167

3.15 OPERATION BEFORE CRANE WORK 169

3.16 CRANE WORK POSTURE 171

3.17 HOISTING AND LOWERING OPERATION 172

3.17.1 NORMAL HOISTING AND LOWERING OPERATION 172

3.17.2 HOISTING AND LOWERING OPERATION AT HIGH SPEED 173

3.17.3 HOISTING OPERATION WITH HOOK STOWAGE SWITCH 174

3.18 BOOM DERRICKING OPERATION 175

3.19 BOOM TELESCOPING OPERATION 176

3.20 SLEWING OPERATION 178

3.21 ACCELERATOR OPERATION 179

3.22 CRANE STOWAGE OPERATION 181

3.22.1 CRANE STOWAGE OPERATION AT THE TIME OF SIMPLE STOWAGE OF

HOOK BLOCK 181

3.22.2 CRANE STOWAGE OPERATION AT THE TIME OF NORMAL STOWAGE OF

3.23 PROHIBITED OPERATIONS DURING CRANE WORK 186

3.24 OPERATION DURING TRAVELLING HOIST 188

3.24.1 PRECAUTIONS IN OPERATION DURING TRAVELLING HOIST 188

3.24.2 OPERATION POSTURE DURING TRAVELLING HOIST 189

3.24.3 OPERATION OF TRAVELLING HOIST WORK 190

3.24.4 CANCEL OPERATION OF TRAVELLING HOIST OPERATION POSTURE 190

4. HANDLING OF WIRE ROPE 191

4.1 CRITERIA FOR WIRE ROPE REPLACEMENT 191

4.2 WINCH WIRE ROPE REEVING SYSTEM AND GROSS RATED LOAD 193

4.3 MEASURE WHEN WINCH WIRE ROPE IS TWISTED 194

5. TRANSPORTATION 195

5.1 LOADING/UNLOADING 195

5.1.1 LOADING 196

5.1.2 FIXING THE MACHINE 198

5.1.3 UNLOADING 199

5.2 HOISTING MACHINE 200

5.2.1 HOISTING MACHINE WITH BOOM LOWERED 200

5.2.2 HOISTING MACHINE WITH BOOM 202

5.3 CAUTIONS DURING TRANSPORTATION 203

6. HANDLING WHEN COLD 204

6.1 PREPARING FOR LOW TEMPERATURE 204

7. LONG-TERM STORAGE 206

7.1 BEFORE STORING MACHINE 206

7.2 DURING STORAGE 206

7.3 AFTER STORAGE 207

8. TROUBLESHOOTING 208

8.1 WHEN FUEL RUNS OUT 208

8.2 PHENOMENON WHICH IS NOT A FAULT 209

8.3 WHEN BATTERY HAS DISCHARGED 210

8.3.1 BATTERY HANDLING PRECAUTIONS 210

8.3.2 REMOVING/INSTALLING BATTERY 211

8.3.3 CAUTIONS IN CHARGING BATTERY 212

8.3.4 STARTING ENGINE WITH BOOSTER CABLE 213

8.4 WHEN SUCH A PHENOMENON OCCURS 215

8.4.1 ELECTRICAL COMPONENTS 215

8.4.2 MACHINE BODY COMPONENTS 217

8.4.3 ENGINE COMPONENTS 218

8.4.4 MOMENT LIMITER COMPONENTS 220

8.4.5 OVERWINDING PREVENTION DEVICE 221

INSPECTION AND MAINTENANCE 223

1. PRECAUTIONS FOR MAINTENANCE 224

2. BASIC MAINTENANCE 227

3. LEGAL INSPECTION 231

4. PERIODIC REPLACEMENT OF CRITICAL PARTS 232

5. CONSUMABLES 233

6. OTHER REPLACEMENT PARTS 234

7. USE OF FUEL AND LUBRICATING OIL 235

7.1 USE OF FUEL AND LUBRICATING OIL ACCORDING TO TEMPERATURES 235

8. STANDARD TIGHTENING TORQUE 237

8.1 STANDARD TIGHTENING TORQUE LIST 237

9. LIST OF ITEMS FOR INSPECTION AND MAINTENANCE 238

10. MAINTENANCE PROCEDURES 240

10.1 INITIAL 500 HOUR MAINTENANCE 240

10.2 PRE-OPERATION INSPECTION 240

10.3 IRREGULAR MAINTENANCE 241

10.4 MAINTENANCE EVERY 50 HOURS 260

10.5 MAINTENANCE EVERY 250 HOURS 262

10.6 MAINTENANCE EVERY 500 HOURS 266

10.7 MAINTENANCE EVERY 1000 HOURS 276

10.8 MAINTENANCE EVERY 1500 HOURS 282

10.9 MAINTENANCE EVERY 3000 HOURS 282

10.10 MAINTENANCE EVERY 4000 HOURS 283

10.11 MAINTENANCE EVERY 5000 HOURS 284

11. VENTING AIR IN HYDRAULIC CIRCUITS 287

12. RELIEVING INTERNAL PRESSURE OF HYDRAULIC CIRCUIT 291

SPECIFICATIONS 293

1. PRINCIPLE SPECIFICATION LIST 294

2. SPECIFICATION DIMENSIONAL DRAWING 295

3. RATED TOTAL LOAD CHART 296

4. WORKING RADIUS/LIFTING HEIGHT 299

1. CAUTIONS IN USING FLY JIB 302

2. MOUNT POSITION OF FLY JIB SAFETY LABELS 303

3. NAME OF EACH SECTION OF FLY JIB 306

4. MOUNTING AND STOWING THE FLY JIB 307

4.1 MOUNTING FLY JIB 307

4.2 EXTENDING AND RETRACTING NO.2 FLY JIB 313

4.2.1 EXTENDING NO.2 FLY JIB 313

4.2.2 RETRACTING NO.2 FLY JIB 315

4.3 STOWING FLY JIB 316

4.4 REOVING FLY JIB 321

4.5 MOUNTING FLY JIB 324

5. HANDLING MONITOR/MOMENT LIMITTER 330

5.1 NAME OF MONITOR DISPLAY 330

5.1.1 MONITOR DISPLAY IN FLY JIB MODE 330

5.1.2 MONITOR DISPLAY IN FLY JIB STOWAGE MODE 332

5.2 MOMENT LIMITER FUNCTIONS 333

5.3 SETTING WORKING CONDITION 334

6. OPERATION 335

6.1 CAUTION ON FLY JIB OPERATION 335

7. TROUBLESHOOTING 336

7.1 LIST OF ERROR CODE 336

7.2 WHEN THESE PHENOMENON HAPPEN 336

8. INSPECTION AND MAINTENANCE 337

8.1 PRE-OPERATION INSPECTION 337

8.2 MAINTENANCE EVERY 50 HOURS 339

9. SPECIFICATION 340

9.1 SPECIFICATION TABLE 340

9.2 SPECIFICATION DIMENSIONAL DRAWING 341

9.3 RATED TOTAL LOAD CHART 342

9.4 WORKING RADIUS/LIFTING HEIGHT 343

9.4.1 WORKING RADIUS/LIFTING HEIGHT (WITH NUMBER OF BOOM SECTION OF

FLY JIB 1) 343

9.4.2 WORKING RADIUS/LIFTING HEIGHT (WITH NUMBER OF BOOM SECTION OF

FLY JIB 2) 344

INTRODUCTION

1. INTRODUCTION 2

2. FOR SAFE USE OF THE MACHINE 3

3. MACHINE OVERVIEW 4

4. QUALIFICATION FOR OPERATION 6

5. TERMINOLOGY OF CRANES

IMAGES PREVIEW OF THE MANUAL: