$35

Maeda Crawler Crane LC383M-5 Operation Manual 541E-OM1010-00 – PDF DOWNLOAD

Maeda Crawler Crane LC383M-5 Operation Manual 541E-OM1010-00 – PDF DOWNLOAD

FILE DETAILS:

Maeda Crawler Crane LC383M-5 Operation Manual 541E-OM1010-00 – PDF DOWNLOAD

Language : English

Pages :271

Downloadable : Yes

File Type : PDF

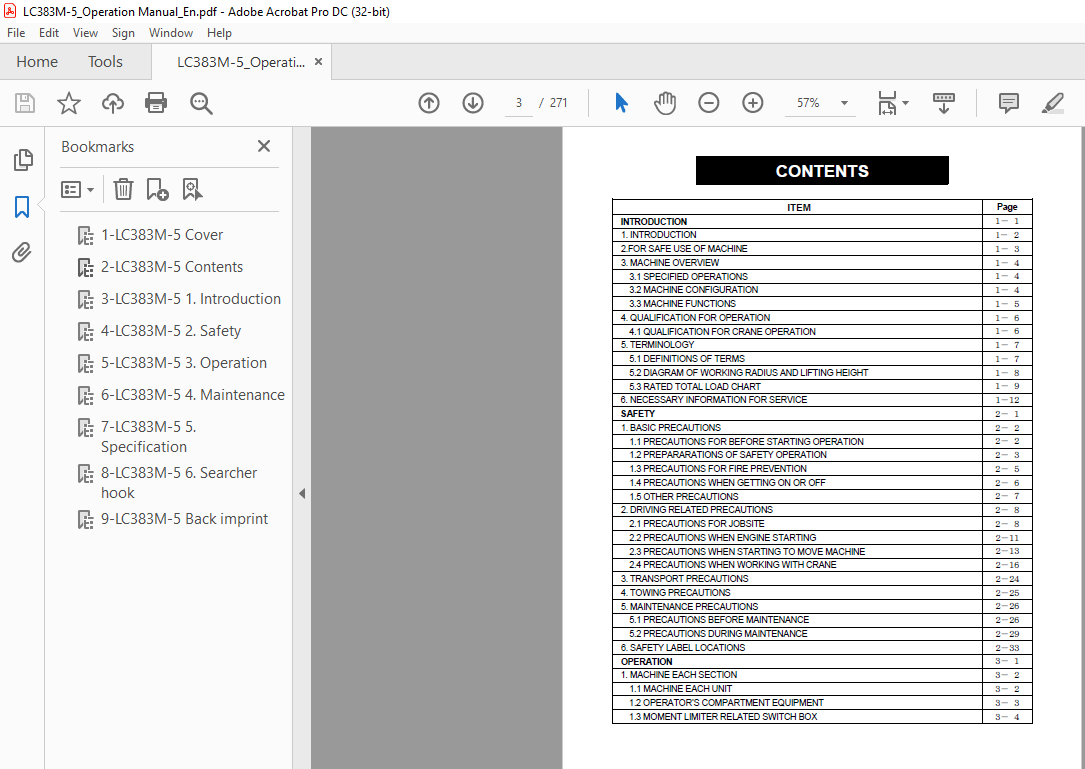

TABLE OF CONTENTS:

Maeda Crawler Crane LC383M-5 Operation Manual 541E-OM1010-00 – PDF DOWNLOAD

INTRODUCTION 1- 1

1. INTRODUCTION 1- 2

2.FOR SAFE USE OF MACHINE 1- 3

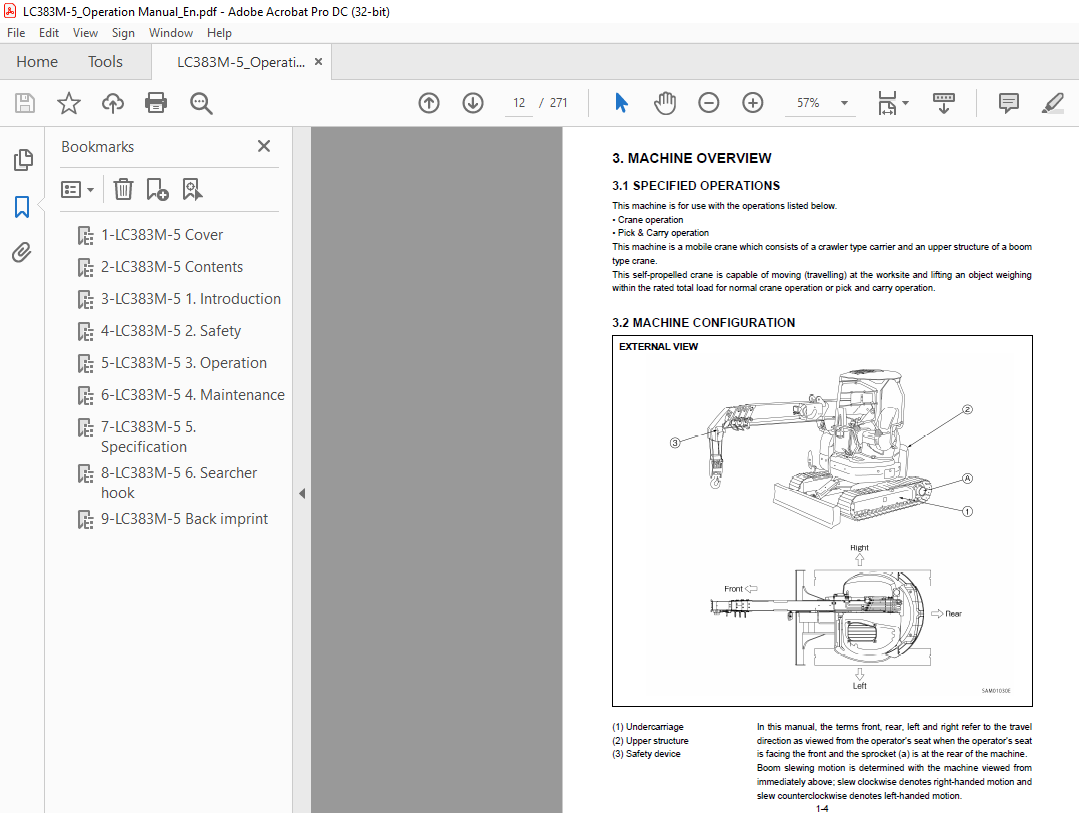

3. MACHINE OVERVIEW 1- 4

3.1 SPECIFIED OPERATIONS 1- 4

3.2 MACHINE CONFIGURATION 1- 4

3.3 MACHINE FUNCTIONS 1- 5

4. QUALIFICATION FOR OPERATION 1- 6

4.1 QUALIFICATION FOR CRANE OPERATION 1- 6

5. TERMINOLOGY 1- 7

5.1 DEFINITIONS OF TERMS 1- 7

5.2 DIAGRAM OF WORKING RADIUS AND LIFTING HEIGHT 1- 8

5.3 RATED TOTAL LOAD CHART 1- 9

6. NECESSARY INFORMATION FOR SERVICE 1-12

SAFETY 2- 1

1. BASIC PRECAUTIONS 2- 2

1.1 PRECAUTIONS FOR BEFORE STARTING OPERATION 2- 2

1.2 PREPARARATIONS OF SAFETY OPERATION 2- 3

1.3 PRECAUTIONS FOR FIRE PREVENTION 2- 5

1.4 PRECAUTIONS WHEN GETTING ON OR OFF 2- 6

1.5 OTHER PRECAUTIONS 2- 7

2. DRIVING RELATED PRECAUTIONS 2- 8

2.1 PRECAUTIONS FOR JOBSITE 2- 8

2.2 PRECAUTIONS WHEN ENGINE STARTING 2-11

2.3 PRECAUTIONS WHEN STARTING TO MOVE MACHINE 2-13

2.4 PRECAUTIONS WHEN WORKING WITH CRANE 2-16

3. TRANSPORT PRECAUTIONS 2-24

4. TOWING PRECAUTIONS 2-25

5. MAINTENANCE PRECAUTIONS 2-26

5.1 PRECAUTIONS BEFORE MAINTENANCE 2-26

5.2 PRECAUTIONS DURING MAINTENANCE 2-29

6. SAFETY LABEL LOCATIONS 2-33

OPERATION 3- 1

1. MACHINE EACH SECTION 3- 2

1.1 MACHINE EACH UNIT 3- 2

1.2 OPERATOR’S COMPARTMENT EQUIPMENT 3- 3

1.3 MOMENT LIMITER RELATED SWITCH BOX 3- 4

0-2

ITEM Page

2. EXPLANATION OF DEVICES 3- 5

2.1 MACHINE MONITOR 3- 5

2.1.1 EMERGENCY STOP ITEMS 3- 6

2.1.2 GAUGE AND METER 3- 8

2.1.3 PILOT DISPLAY 3-10

2.2 SWITCHES 3-11

2.3 MOMENT LIMITER (OVERLOAD DETECTOR ) 3-14

2.3.1 MOMENT LIMITER CONFIGURATION 3-14

2.3.2 FUNCTION OF MOMENT LIMITER 3-15

2.3.3 MOMENT LIMITER OPERATIONS 3-17

2.3.4 NAMES OF MOMENT LIMITER DISPLAY UNIT 3-19

2.3.5 MOMENT LIMITER FUNCTIONS 3-28

2.3.6 MOMENT LIMITER STARTING STATUS 3-30

2.3.7 MOMENT LIMITER WORKING ENVELOPE SETTING 3-30

2.3.8 PICK & CARRY/STAITIONARY MODE SELECT SWITCH 3-31

2.3.9 MOMENT LIMITER EMERGENCY STOP CANCEL SWITCH 3-32

2.3.10 MOMENT LIMITER CAUSES OF ERRORS AND ACTIONS TO BE TAKEN 3-33

2.4 OVER HOIST DETECTOR 3-34

2.5 CONTROL LEVERS AND PEDALS 3-35

2.6 COVERS WITH LOCK 3-40

2.7 ENGINE HOOD 3-41

2.8 FUSES 3-43

2.9 FUSIBLE LINK 3-44

2.10 OPERATION MANUAL STORAGE 3-44

2.11 GREASE GUN HOLDER 3-44

2.12 POWER SUPPLY FOR OPTIONS 3-45

3. MACHINE OPERATIONS AND CONTROLS 3-46

3.1 CHECKING/ADJUSTING BEFORE STARTING ENGINE 3-46

3.1.1 VISIBLE CHECKS 3-46

3.1.2 CHECKING BEFORE STARTING (CHECKING BEFORE OPERATION) 3-49

3.1.3 OPERATIONS/CHECKING BEFORE STARTING ENGINE 3-59

3.1.4 CHECKING AFTER STARTING ENGINE 3-61

3.2 STARTING ENGINE 3-64

3.2.1 NORMAL STARTING ENGINE 3-64

3.2.2 STARTING ENGINE IN COLD WEATHER 3-65

3.3 OPERATIONS AFTER STARTING ENGINE 3-67

3.3.1 ENGINE WARM-UP OPERATION 3-67

3.4 STOPPING ENGINE 3-69

3.5 BREAKING-IN MACHINE 3-70

3.6 MACHINE TRAVELING POSTURE 3-71

0-3

ITEM Page

3.7 STARTING/MOVING/STOPPING MACHINE 3-72

3.8 STEERING MACHINE 3-76

3.9 SWINGING 3-78

3.10 CAUTIONS BEFORE OPERATING THE CRANE 3-79

3.11 OPERATIONS BEFORE OPERATING THE CRANE 3-80

3.12 CRANE OPERATION POSTURE 3-82

3.13 HOOK RAISING/LOWERING OPERATION 3-83

3.13.1 NORMAL HOOK RAISING/LOWERING OPERATION 3-83

3.13.2 HOOK RAISING OPERATION BY HOOK STOWAGE SWITCH 3-84

3.14 BOOM DERRICKING OPERATION 3-85

3.15 BOOM TELESCOPING OPERATION 3-86

3.16 SWING OPERATION 3-87

3.17 STOWAGE OPERATION OF CRANE 3-88

3.17.1 CRANE OPERATION FOR TEMPORARY HOOK BLOCK STOWAGE 3-88

3.17.2 CRANE OPERATION FOR REGULAR HOOK BLOCK STOWAGE 3-91

3.18 DO’S AND DON’TS DURING OPERATION 3-93

3.19 PICK AND CARRY OPERATION 3-95

3.19.1 SAFETY PRECAUTIONS FOR PICK AND CARRY OPERATION 3-95

3.19.2 POSTURE FOR PICK AND CARRY OPERATION 3-96

3.19.3 OPERATIONS DURING PICK AND CARRY OPERATION 3-97

3.19.4 RELEASING PICK AND CARRY OPERATION POSTURE 3-97

3.20 OPERATION OF BLADE 3-98

3.20.1 PRECAUTION OF BLADE OPERATION 3-98

3.20.2 OPERATION OF BLADE 3-99

3.20.3 WORKING WITH A BLADE 3-99

3.21 PARKING MACHINE 3-100

3.22 MACHINE INSPECTION AFTER DAILY WORK 3-101

3.22.1 BEFORE STOPPING ENGINE 3-101

3.22.2 AFTER STOPPING ENGINE 3-101

3.22.3 LOCKING 3-101

3.23 CAUTIONS IN TRAVELING 3-102

4. HANDLING WIRE CABLES 3-104

4.1 BENCHMARK FOR REPLACING WIRE CABLES 3-104

4.2 WINCH WIRE CABLE FALL MODE AND RATED TOTAL LOAD 3-106

4.3 WHAT TO DO WITH TWISTED WINCH WIRE CABLE 3-107

5. TRANSPORTATION 3-110

5.1 LOADING/UNLOADING 3-111

5.1.1 LOADING 3-112

5.1.2 SECURING MACHINE 3-114

5.1.3 UNLOADING 3-115

0-4

ITEM Page

5.2 LIFTING MACHINE 3-116

5.2.1 LIFTING THE MACHINE IN THE BOOM LOWERED POSTURE 3-116

5.2.2 LIFTING THE MACHINE IN THE BOOM RAISED POSTURE 3-118

6. HANDLING IN COLD WEATHER 3-120

6.1 PREPARING FOR LOW TEMPERATURE 3-120

7. LONG TERM STORAGE 3-123

7.1 BEFORE STORING IT MACHINE 3-123

7.2 DURING STORAGE 3-123

7.3 AFTER STORAGE 3-123

8. TROUBLES AND ACTIONS 3-124

8.1 RUNNING OUT FUEL 3-124

8.2 PHENOMENA THAT ARE NOT FAILURES 3-124

8.3 TOWING THE MACHINE 3-125

8.4 DISCHARGED BATTERY 3-125

8.4.1 CAUTIONS IN BATTERY HANDLING 3-125

8.4.2 BATTERY REMOVAL AND INSTALLATION 3-126

8.4.3 CAUTIONS IN BATTERY CHARGING 3-127

8.4.4 STARTING ENGINE WITH BOOSTER CABLE 3-128

8.4.5 STARTING ENGINE 3-129

8.5 OTHER TROUBLE 3-130

8.5.1 ELECTRICAL COMPONENTS 3-130

8.5.2 CHASSIS 3-130

8.5.3 ENGINE 3-131

8.5.4 MOMENT LIMITER 3-132

8.5.5 OVER HOIST DETECTOR 3-132

INSPECTION AND MAINTENANCE 4- 1

1. PRECAUTIONS REGARDING MAINTENANCE 4- 2

2. BASIC MAINTENANCE 4- 4

3. LEGAL INSPECTION 4- 7

4. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS 4- 8

5. CONSUMABLES 4- 9

6. OTHER COMPONENTS 4-10

7. USE OF FUEL, COOLANT AND LUBRICANT 4-11

7.1 USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT

TEMPERATURES 4-11

8. TIGHTENING TORQUE SPECIFICATIONS 4-13

8.1 STANDARD TIGHTENING TORQUE LIST 4-13

9. INSPECTION AND MAINTENANCE LIST 4-14

0-5

ITEM Page

10. MAINTENANCE PROCEDURES 4-16

10.1 INITIAL 500 HOUR MAINTENANCE 4-16

10.2 CHECKING BEFORE OPERATION 4-16

10.3 IRREGULAR MAINTENANCE 4-17

10.4 MAINTENANCE EVERY 50 HOURS 4-36

10.5 MAINTENANCE EVERY 100 HOURS 4-38

10.6 MAINTENANCE EVERY 250 HOURS 4-39

10.7 MAINTENANCE EVERY 500 HOURS 4-41

10.8 MAINTENANCE EVERY 1000 HOURS 4-46

10.9 MAINTENANCE EVERY 1500 HOURS 4-48

10.10 MAINTENANCE EVERY 2000 HOURS 4-49

SPECIFICATIONS 5- 1

1. SPECIFICATION LIST 5- 2

2. SPECIFICATION DIMENSIONAL DRAWING 5- 3

3. RATED TOTAL LOAD CHART 5- 4

4. WORKING RADIUS AND LIFTING HEIGHT 5- 7

SEARCHER HOOK 6- 1

1. SEARCHER HOOK EACH SECTION 6- 2

2. MOMENT LIMITER DISPLAY UNIT 6- 3

3. OPERATION 6- 5

4. INSPECTION AND MAINTENANCE 6- 8

4.1 LEGAL INSPECTION 6- 8

4.2 CONSUMABLES 6- 8

4.3 INSPECTION AND MAINTENANCE LIST 6- 8

4.4 MAINTENANCE PROCEDURES 6- 9

4.4.1 INSPECTION OF BEFORE OPERATION 6- 9

5. WORKING RADIUS AND RATED TOTAL LOAD 6-11

5.1 WORKING RADIUS AND LIFTING HEIGHT FOR SEARCHER HOOK 6-11

5.2 RATED TOTAL LOAD CHART FOR SEARCHER HOOK 6-12

IMAGES PREVIEW OF THE MANUAL: