$36

MAEDA MC-104C-2 MINI-CRAWLER CRANE OPERATION MANUAL M01736 and up – PDF DOWNLOAD

MAEDA MC-104C-2 MINI-CRAWLER CRANE OPERATION MANUAL M01736 and up – PDF DOWNLOAD

FILE DETAILS:

MAEDA MC-104C-2 MINI-CRAWLER CRANE OPERATION MANUAL M01736 and up – PDF DOWNLOAD

Language : English

Pages : 192

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

MAEDA MC-104C-2 MINI-CRAWLER CRANE OPERATION MANUAL M01736 and up – PDF DOWNLOAD

INTRODUCTION 1- 1

1. FOREWARD 1- 2

2. SAFETY INFORMATION 1- 3

3. OUTLINE OF THE MACHINE 1- 4

3.1 DESIGNATED TYPE OF WORK 1- 4

3.2 CONFIGURATION OF THE MACHINE 1- 4

3.3 FUNCTIONS THIS MACHINE IS PROVIDED WITH 1- 5

4. QUALIFICATION FOR OPERATING THE MACHINE 1- 5

4.1 QUALIFICATION REQUIRE FOR OPERATING CRANES 1- 5

5. GLOSSARY 1- 6

5.1 DEFINITIONS OF WORDS 1- 6

5.2 HOW TO READ WORKING RADIUS / LIFTING HEIGHT DIAGRAM 1- 7

5.3 HOW TO RATED TOTAL LOAD CHART 1- 8

5.4 HOW TO READ LOAD INDICATOR 1-12

SAFETY 2- 1

1. BASIC RULES 2- 2

2. RULES FOR OPERATION 2- 7

2.1 BEFORE STARTING UP ENGINE 2- 7

2.2 AFTER THE ENGINE HAS STARTED 2- 8

2.3 DURING CRANE OPERATION 2-12

3. RULES FOR TRANSPORTING A CRANE 2-18

4. RULES FOR HANDLING THE BATTERY 2-20

5. RULES TO OBSERVE IN CONNECTION WITH SERVICES 2-22

5.1 PRIOR TO CONDUCTING SERVICE 2-22

5.2 DURING SERVICE WORK 2-24

6. LOCATION FOR AFFIXING CAUTION PLATES 2-29

OPERATION 3- 1

1. NOMENCLATURE OF COMPONENTS 3- 2

1.1 NOMENCLATURE OF MACHINE COMPONENTS 3- 2

1.2 NOMENCLATURE OF TRAVEL CONTROL COMPONENTS 3- 3

1.2.1 CONTROL LEVERS 3- 4

1.2.2 SWITCHES 3- 6

1.2.3 METER, LAMP AND FUSES 3- 7

1.3 NOMENCLATURE OF CRANE CONTROL COMPONENTS 3- 8

1.3.1 CONTROL LEVERS 3- 9

1.3.2 SWITCHES 3-10

1.3.3 METERS AND LAMPS 3-11

1.4 OVER-HOIST PREVENTIVE DEVICE 3-12

1.5 EMO SWITCH (EMERGENCY STOP SWITCH) 3-13

1.6 OVER-LOWERING PREVENTION DEVICE 3-13

1.7 MACHINERY COVER 3-14

2. OPERATION CONTROL 3-15

2.1 INSPECTION PRIOR TO STARTING UP THE ENGINE 3-15

2.1.1 VISUAL CHECK 3-15

2.1.2 INSPECTION BEFORE STARTING YOUR WORK 3-17

2.2 STARTING UP THE ENGINE 3-23

2.2.1 STARTING UP THE ENGINE WITH MAIN STARTER SWITCH 3-23

2.2.2 STARTING UP THE ENGINE WITH AUXILIARY STARTER SWITCH 3-24

3.2.3 STARTING UP THE ENGINE WITH RECOIL STARTER IN USE 3-25

2.3 OPERATION AND CHECKING AFTER ENGINE HAS STARTED 3-26

2.4 BREAK-IN OPERATION 3-28

2.5 TRAVEL POSITION OF THE MACHINE 3-28

2.6 STARTING THE MACHINE 3-29

2.7 CHANGING TRAVEL DIRECTION OF THE MACHINE 3-30

2.8 STOPPING AND PARKING THE MACHINE 3-31

2.9 STOPPING THE ENGINE 3-32

2.10 INSPECTION AND CHECK AFTER STOPPING THE ENGINE 3-32

2.11 RULES FOR TRAVELING 3-33

2.12 SETTING UP THE OUTRIGGER 3-34

2.13 MATTERS TO BE KNOWN BEFORE STARTING CRANE WORK 3-39

2.14 OPERATIONS PRIOR TO STARTING CRANE WORK 3-40

2.15 CRANE WORK POSITION 3-41

2.16 HOISTING AND LOWERING OPERATION 3-42

2.17 BOOM DERRICKING AND LOWERING OPERATION 3-42

2.18 BOOM TELESCOPING OPERATION 3-43

2.19 SWING OPERATION 3-44

2.20 ACCELERATOR LEVER OPERATION 3-44

2.21 HOW TO USE LOAD INDICATOR AND LOAD METER 3-45

2.22 STOWING THE CRANE 3-47

2.23 STOWING THE OUTRIGGER 3-48

2.24 MATTERS PROHIBITED IN CONNECTION WITH CRANE OPERATION 3-51

3. HANDLING OF RUBBER TRACK 3-53

3.1 SMART WAY OF USING IT 3-53

3.2 WARRANTY 3-53

3.3 PROHIBITED TYPES OF WORK 3-54

3.4 RULE FOR USING IT 3-55

4. HANDLING OF WIRE ROPE 3-57

4.1 STANDARD FOR WIRE ROPE REPLACEMENT 3-57

4.2 MEASURES TO TAKE WHEN WINCH WIRE ROPE IS TWISTED 3-58

5. TRANSPORT 3-59

5.1 LOADING AND UNLOADING 3-59

5.2 HOW TO LIFT THE MACHINE 3-60

5.3 RULES FOR LOADING 3-61

5.4 RULE FOR TRANSPORT 3-61

6. HANDLINE IN COLD CLIMATE 3-62

6.1 PREPARATION FOR LOW AMBIENT TEMPERATURE 3-62

7. LONG TERM STARAGE 3-63

7.1 TREATMENT PRIOR TO STORAGE 3-63

7.2 DURING STORAGE 3-63

7.3 AFTER STORAGE 3-63

8. HANDLING OF BATTERY 3-64

8.1 RULES FOR HANDLING THE BATTERY 3-64

8.2 DE-MOUNTING AND MOUNTING THE BATTERY 3-65

8.3 RULES FOR CHARGING THE BATTERY 3-65

8.4 STARTING WITH BOOSTER CABLE IN USE 3-66

9. MEASURES TO BE TAKEN IN CASE OF ABNORMALITY 3-68

9.1 IN CONNECTION WITH ELECTRICAL COMPONENTS 3-68

9.2 IN CONNECTION WITH THE MACHINE 3-68

9.3 IN CONNECTION WITH ENGINE 3-69

INSPECTION AND MAINTENANCE 4- 1

1. RULES FOR CONDUCTING SERVICE 4- 2

2. BASICS OF SERVICE 4- 4

3. LEGALLY REQUIRED INSPECTION 4- 6

3.1 SAFETY REGULATION ON CRANE 4- 6

4. CONSUMABLE PARTS 4- 6

5. LUBRICATION OIL AND GREASE 4- 7

5.1 APPLICABLE LUBRICANTS BY AMBIENT TEMPERATURE 4- 7

6. STANDARD TOOLS AND STANDARD TIGHTENING TORQUE 4- 8

6.1 INQUIRY ON STANDARD TOOLS 4- 8

6.2 LIST OF STANDARD TIGHTENING TORQUE 4- 8

7. LIST OF INSPECTION AND SERVICE 4-11

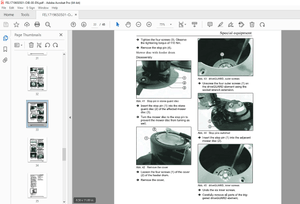

8. WORKING PROCEDURE 4-13

8.1 FIRST 10 HOUR SERVICE 4-13

8.2 FIRST 20 HOUR SERVICE 4-13

8.3 FIRST 200 HOUR SERVICE 4-13

8.4 INSPECTION BEFORE STARTING YOUR WORK 4-13

8.5 IRREGULAR SERVICE 4-14

8.6 SERVICE IN EVERY 50 HOURS 4-29

8.7 SERVICE IN EVERY 100 HOURS 4-31

8.8 SERVICE IN EVERY 200 HOURS 4-32

8.9 SERVICE IN EVERY 500 HOURS 4-35

8.10 SERVICE IN EVERY 1000 HOURS 4-38

SPECIFICATIONS 5- 1

1. SPECIFICATIONS 5- 2

2. OVERALL DIMENSIONS 5- 3

3. TOTAL RATED LOAD CHART 5- 4

4. WORKING RANGE 5- 4