$38

Maeda MC174 CRM Mini-Crawler Crane Operation Manual – PDF DOWNLOAD

Maeda MC174 CRM Mini-Crawler Crane Operation Manual – PDF DOWNLOAD

FILE DETAILS:

Maeda MC174 CRM Mini-Crawler Crane Operation Manual – PDF DOWNLOAD

Language : English

Pages :357

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Maeda MC174 CRM Mini-Crawler Crane Operation Manual – PDF DOWNLOAD

INTRODUCTION 1- 1

1. INTRODUCTION 1- 2

2.FOR SAFE USE OF MACHINE 1- 3

3. MACHINE OVERVIEW 1- 4

3.1 SPECIFIED OPERATIONS 1- 4

3.2 MACHINE CONFIGURATION 1- 4

3.3 MACHINE FUNCTIONS 1- 5

4. QUALIFICATION FOR OPERATION 1- 6

4.1 QUALIFICATION FOR CRANE OPERATION 1- 6

5. TERMINOLOGY 1- 7

5.1 DEFINITIONS OF TERMS 1- 7

5.2 DIAGRAM OF WORKING RADIUS AND LIFTING HEIGHT 1- 8

5.3 RATED TOTAL LOAD TABLE 1- 9

5.4 LOAD INDICATOR 1-15

SAFETY 2- 1

1. BASIC PRECAUTIONS 2- 2

2. DRIVING RELATED PRECAUTIONS 2- 7

2.1 BEFORE STARTING ENGINE 2- 7

2.2 AFTER STARTING ENGINE 2- 8

2.3 WORKING WITH CRANE 2-12

3. TRANSPORT PRECAUTIONS 2-21

4. BATTERY HANDLING PRECAUTIONS 2-23

5. MAINTENANCE PRECAUTIONS 2-25

5.1 PRECAUTIONS BEFORE MAINTENANCE 2-25

5.2 PRECAUTIONS DURING MAINTENANCE 2-27

6. SAFETY LABEL LOCATIONS 2-32

7. WEEE DIRECTIVE LABEL LOCATIONS 2-42

OPERATION 3- 1

1. MACHINE EACH SECTION 3- 2

1.1 MACHINE EACH UNIT 3- 2

1.2 TRAVELING AND CRANE OPERATION UNITS 3- 3

1.3 INSTRUMENT PANEL SECTIONS 3- 6

1.3.1 DESCRIPTION OF EACH SWITCHES 3- 7

1.3.2 DESCRIPTION OF EACH MONITORS 3-10

1.3.3 DESCRIPTION OF FUSES 3-12

1.4 OUTRIGGER OPERATION PANEL 3-13

1.5 OUTRIGGER SAFETY DEVICES 3-15

1.5.1 FUNCTIONS OF OUTRIGGER SAFETY DEVICES 3-15

1.5.2 NAMES AND DESCRIPTIONS OF OUTRIGGER DISPLAY 3-16

1.5.3 OUTRIGGER UN-SET WARNING LAMP 3-17

1.6 MOMENT LIMITER (OVERLOAD DETECTOR) 3-18

1.6.1 MOMENT LIMITER CONFIGURATION 3-18

1.6.2 FUNCTION OF MOMENT LIMITER 3-19

0-1

ITEM Page

1.6.3 MOMENT LIMITER OPERATIONS 3-20

1.6.4 NAMES OF MOMENT LIMITER DISPLAY UNIT 3-22

1.6.5 MOMENT LIMITER FUNCTIONS 3-29

1.6.6 MOMENT LIMITER STARTING STATUS 3-31

1.6.7 MOMENT LIMITER WORKING ENVELOPE SETTING 3-32

1.6.8 EMERGENCY STOP CANCEL SWITCH 3-33

1.6.9 MOMENT LIMITER ERROR CAUSES AND ACTIONS TO BE TAKEN 3-34

1.7 OVER HOIST DETECTOR 3-35

1.8 OPERATION SEAT 3-36

1.9 ENGINE HOOD 3-37

1.10 MACHINERY COVER 3-38

2. OPERATIONS 3-40

2.1 CHECKING BEFORE OPERATION 3-40

2.1.1 CHECKING BEFORE STARTING ENGINE (VISIBLE CHECKS) 3-40

2.1.2 CHECKING BEFORE STARTING ENGINE 3-43

2.1.3 CHECKING AFTER STARTING ENGINE 3-56

2.2 STARTING ENGINE 3-66

2.2.1 NORMAL ENGINE START 3-66

2.2.2 STARTING ENGINE IN COLD WEATHER 3-67

2.3 OPERATIONS AND CHECKS AFTER STARTING ENGINE 3-68

2.4 BREAKING-IN MACHINE 3-70

2.5 MACHINE TRAVELING POSTURE 3-70

2.6 STARTING MOVING MACHINE 3-71

2.7 CHANGING MACHINE TRAVELING MODE 3-72

2.8 CHANGING PATH OF MACHINE 3-72

2.9 STOPPING/PARKING MACHINE 3-74

2.10 STOPPING ENGINE 3-75

2.11 INSPECTION AFTER STOPPING ENGINE 3-75

2.12 CAUTIONS IN DRIVING 3-76

2.13 DESCRIPTION ON OUTRIGGER AND CRANE SAFETY DEVICES 3-78

2.14 OUTRIGGER SETTING OPERATION 3-82

2.14.1 NAME OF OUTRIGGER COMPONENTS 3-84

2.14.2 OUTRIGGER SETTING OPERATION 3-84

2.15 CAUTIONS BEFORE CRANE OPERATION 3-88

2.16 OPERATIONS BEFORE CRANE OPERATIONS 3-89

2.17 CRANE OPERATION POSTURE 3-90

2.18 HOOK RAISING/LOWERING OPERATION 3-90

2.19 BOOM DERRICKING OPERATION 3-91

2.20 BOOM TELESCOPING OPERATION 3-92

2.21 SLEWING OPERATION 3-93

2.22 ACCELERATION OPERATION 3-93

2.23 CRANE STOWING OPERATION 3-94

2.24 OUTRIGGER STOWING OPERATION 3-96

2.25 DOS AND DON’TS DURING CRANE OPERATIONS 3-100

0-2

ITEM Page

3. HANDLING RUBBER TRACKS 3-102

3.1 GOOD USE 3-102

3.2 WARRANTY 3-102

3.3 DOS AND DON’TS 3-103

3.4 CAUTIONS IN USING RUBBER TRACKS 3-104

4. HANDLING WIRE ROPES 3-106

4.1 BENCH MARK FOR REPLACING WIRE ROPES 3-106

4.2 What TO DO WITH TWISTED WINCH WIRE ROPE 3-107

5. TRANSPORTATION 3-108

5.1 LOADING/UNLOADING 3-108

5.2 HOISTING MACHINE 3-109

5.3 CAUTIONS IN LOADING MACHINE 3-110

5.4 CAUTIONS DURING TRANSPORTATION 3-110

6. HANDLING IN COLD WEATHER 3-111

6.1 PREPARING FOR LOW TEMPERATURE 3-111

7. LONG-TERM STORAGE 3-113

7.1 BEFORE STORING MACHINE 3-113

7.2 DURING STORAGE 3-113

7.3 AFTER STORAGE 3-113

8. HANDLING BATTERY 3-114

8.1 CAUTIONS IN HANDLING BATTERY 3-114

8.2 REMOVING/INSTALLING BATTERY 3-115

8.3 CAUTIONS IN CHARGING BATTERY 3-116

8.4 STARTING ENGINE WITH BOOSTER CABLE 3-117

9. TROUBLESHOOTING 3-119

9.1 ELECTRICAL COMPONENTS 3-119

9.2 MACHINE BODY 3-120

9.3 ENGINE 3-121

INSPECTION AND MAINTENANCE 4- 1

1. PRECAUTIONS FOR MAINTENANCE 4- 2

2. BASIC MAINTENANCE 4- 4

3. LEGAL INSPECTION 4- 6

4. CONSUMABLES 4- 6

5. LUBRICATING OIL 4- 7

5.1 USE OF LUBRICATING OIL ACCORDING TO TEMPERATURES 4- 7

6. ACCESSORY TOOLS AND STANDARD TIGHTENING TORQUE 4- 8

6.1 ACCESSORY TOOLS 4- 8

6.2 STANDARD TIGHTENING TORQUE LIST 4- 8

7. INSPECTION AND MAINTENANCE LIST 4-10

8. MAINTENANCE PROCEDURES 4-12

8.1 INITIAL 10 HOUR MAINTENANCE 4-12

8.2 INITIAL 50 HOUR MAINTENANCE 4-12

8.3 INITIAL 250 HOUR MAINTENANCE 4-12

8.4 CHECKING BEFORE OPERATION 4-12

8.5 IRREGULAR MAINTENANCE 4-13

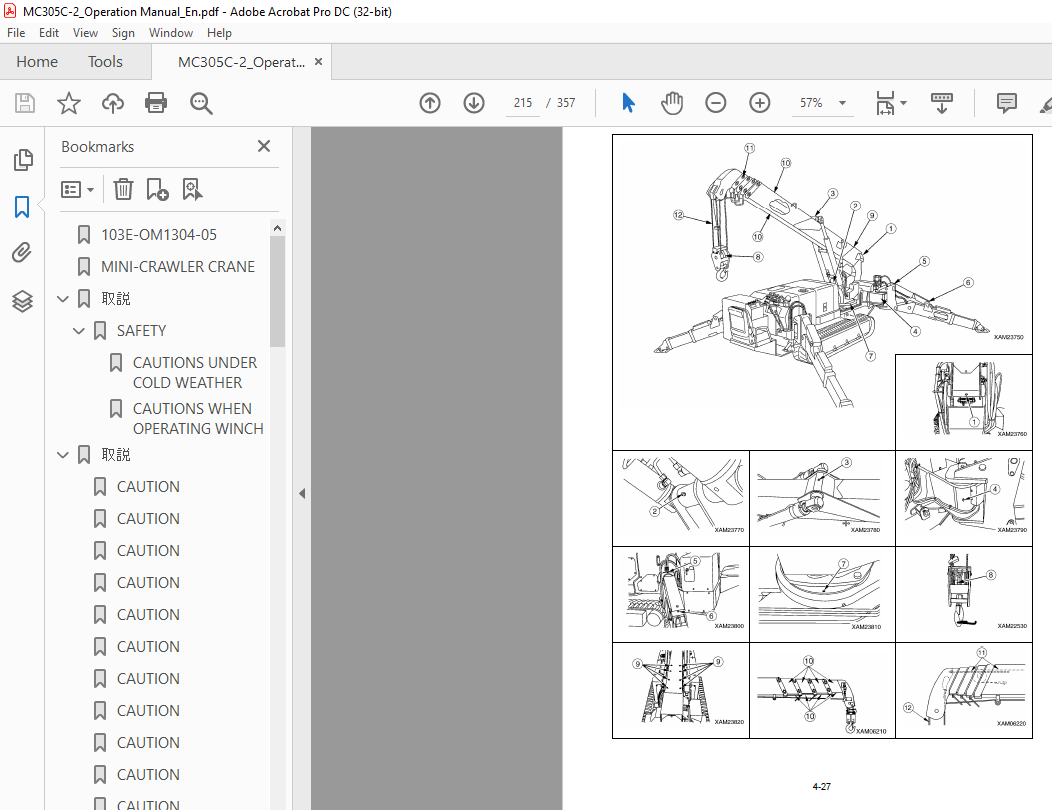

8.6 MAINTENANCE EVERY 30 HOURS 4-22

0-3

ITEM Page

8.7 MAINTENANCE EVERY 50 HOURS 4-24

8.8 MAINTENANCE EVERY 250 HOURS 4-28

8.9 MAINTENANCE EVERY 500 HOURS 4-32

8.10 MAINTENANCE EVERY 1000 HOURS 4-36

8.11 MAINTENANCE EVERY 1500 HOURS 4-45

8.12 MAINTENANCE EVERY 2000 HOURS 4-45

SPECIFICATIONS 5- 1

1. SPECIFICATION LIST 5- 2

2. SPECIFICATION DIMENSIONAL DRAWING 5- 4

3. DIMENSIONAL DRAWING OF OUTRIGGER WIDTH 5- 5

4. RATED TOTAL LOAD TABLE 5- 6

5. WORKING RADIUS AND LIFTING HEIGHT 5- 9

INTERACTIVE REMOTE CONTROL 6- 1

1. OUTLINE OF REMOTE CONTROLLER 6- 2

1.1 FEATURE 6- 2

1.2 CONFIGURATION 6- 2

1.3 FUNCTIONS OF REMOTE CONTROL SYSTEM 6- 3

2. SAFETY PRECAUTIONS 6- 4

2.1 For Safety Operations 6- 4

2.2 PRECAUTIONS FOR CRANE OPERATION 6- 6

2.2.1 PRIOR TO STARTING ENGINE 6- 6

2.2.2 SUBSEQUENT TO STARTING ENGINE 6- 7

2.2.3 TERMINATING THE OPERATION 6- 7

3. LOCATIONS OF SAFETY LABELS 6- 8

4. COMPONENTS OF THE TRANSMITTER 6-10

5. COMPONENTS OF THE RECEIVER 6-16

5.1 COMPONENTS OF THE RECEIVER 6-16

5.2 FUSE IN THE RECEIVER 6-18

6. SETTING UP OPERATION MODES OF TRANSMITTER 6-20

6.1 A MODE 6-20

6.1.1 OPENING A MODE SCREEN 6-20

6.1.2 MESSAGES IN THE A MODE SCREEN 6-20

6.1.3 AN EXAMPLE FOR SETTING IN THE A MODE 6-24

6.2 PROCEDURE IN THE OPERATION MODE 6-25

6.2.1 CALL OUT CRANE MODE 6-25

6.2.2 CALL OUT OUTRIGGER MODE 6-26

7. CHECKING BEFORE OPERATION 6-28

7.1 CHECKING BEFORE STARTING ENGINE 6-28

7.1.1 CHECKING BEFORE TURNING ON THE TRANSMITTER 6-28

7.1.2 CHECKING AFTER TURNING ON THE TRANSMITTER 6-29

7.1.3 CHECKING RECEIVER 6-32

7.2 CHECKING AFTER STARTING ENGINE 6-33

7.2.1 VERIFICATION FOR THE ENGINE START AND STOP 6-33

7.2.2 CHECKING “OUTRIGGER MODE” OPERATION 6-34

7.2.3 CHECKING “CRANE MODE” OPERATION 6-36

0-4

ITEM Page

8. OPERATION 6-39

8.1 CAUTIONS BEFORE OPERATION 6-39

8.2 OPERATION IN OUTRIGGER MODE 6-40

8.2.1 OUTRIGGER SETTING 6-41

8.2.2 OUTRIGGER STOWAGE 6-42

8.3 OPERATION IN CRANE MODE 6-43

8.3.1 SLEWING OPERATION 6-44

8.3.2 BOOM TELESCOPING 6-44

8.3.3 HOOK RAISING AND LOWERING 6-45

8.3.4 BOOM DERRICKING 6-45

8.3.5 AUTOMATIC HOOK STOW FUNCTION 6-46

8.3.6 SET-UP AND CANCEL MICRO SPEED AND ENHANCED SPEED MODE 6-47

8.3.7 ENGINE STOP AND EMERGENCY STOP PROCEDURE 6-49

8.3.8 ENGINE START AND RESET PROCEDURE 6-49

8.4 CHECKING AFTER CRANE OPERATION 6-50

9. TROUBLE SHOOTING 6-51

9.1 BEFORE THE TROUBLE SHOOTING 6-51

9.2 ERRORS IN THE REMOTE CONTROL DEVICES 6-52

10.SYSTEM SPECIFICATIONS 6-54

ENGINE AND ELECTRIC MOTOR SPECIFICATIONS 7- 1

1. PRECAUTIONS (FOR ENGINE AND ELECTRIC MOTOR SPECIFICATION) 7- 2

2. SAFETY LABEL LOCATIONS 7- 3

3. MACHINE EACH SECTION 7- 5

3.1 MACHINE EACH UNIT 7- 5

3.2 TRAVELING AND CRANE OPERATION UNITS 7- 6

3.3 INSTRUMENT PANEL SECTIONS 7- 7

3.4 POWER UNIT 7-10

3.5 POWER SUPPLY BOX 7-10

3.6 INVERTER UNIT 7-11

4. OPERATION 7-14

4.1 CHECKING BEFORE OPERATION 7-14

4.1.1 CHECKING BEFORE STARTING ELECTRIC MOTOR (VISIBLE CHECKS) 7-14

4.1.2 CHECKING BEFORE STARTING ELECTRIC MOTOR 7-14

4.1.3 CHECKING AFTER STARTING ELECTRIC MOTOR 7-14

4.2 POWER SUPPLY CONNECTION 7-15

4.3 OPERATION AND CHECKING AFTER POWER CONNECTION 7-17

4.4 MACHINE OPERATION 7-19

4.5 MACHINE STOP AND CHECKS AFTER STOPPING MACHINE 7-19

4.6 POWER SUPPLY SEPARATION 7-20

5. LONG-TERM STORAGE 7-21

6. ELECTRIC MOTOR TROUBLESHOOTING 7-22

7. PRINCIPLE SPECIFICATION LIST 7-23

8. SPECIFICATION DIMENSINAL DRAWING 7-24

0-5

0-6

ITEM Page

SEARCHER HOOK 8- 1

1. SEARCHER HOOK EACH SECTION 8- 2

2. MOMENT LIMITER DISPLAY UNIT 8- 4

3. OPERATION 8- 6

4. INSPECTION AND MAINTENANCE 8- 8

4.1 LEGAL INSPECTION 8- 8

4.2 CONSUMABLES 8- 8

4.3 INSPECTION AND MAINTENANCE LIST 8- 8

4.4 MAINTENANCE PROCEDURES 8- 9

4.4.1 INSPECTION OF BEFORE OPERATION 8- 9

5. WORKING RADIUS AND RATED TOTAL LOAD 8-11

5.1 WORKING RADIUS AND LIFTING HEIGHT FOR SEARCHER HOOK 8-11

5.2 RATED TOTAL LOAD CHART FOR SEARCHER HOOK 8-12

850kg SEARCHER HOOK 9- 1

1. SAFETY DECAL LOCATIONS 9- 2

2. SEARCHER HOOK EACH SECTION 9- 5

3. MOMENT LIMITER DISPLAY UNIT 9- 6

4. OPERATION 9-10

5. INSPECTION AND MAINTENANCE 9-14

5.1 LEGAL INSPECTION 9-14

5.2 CONSUMABLES 9-14

5.3 INSPECTION AND MAINTENANCE LIST 9-15

5.4 MAINTENANCE PROCEDURES 9-16

5.4.1 INSPECTION OF BEFORE OPERATION 9-16

6. WORKING RADIUS AND RATED TOTAL LOAD 9-18

6.1 WORKING RADIUS AND LIFTING HEIGHT FOR SEARCHER HOOK 9-18

6.2 RATED TOTAL LOAD CHART FOR SEARCHER HOOK 9-20

IMAGES PREVIEW OF THE MANUAL: