$38

Maeda MINI CRANE MC-285 OPERATING MANUAL – PDF DOWNLOAD (English)

Maeda MINI CRANE MC-285 OPERATING MANUAL – PDF DOWNLOAD (English)

FILE DETAILS:

Maeda MINI CRANE MC-285 OPERATING MANUAL – PDF DOWNLOAD (English)

Language : Russian,

Pages :216

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Maeda MINI CRANE MC-285 OPERATING MANUAL – PDF DOWNLOAD (English)

INTRODUCTION

1. Introduction 1-2

2. Safety Precautions 1-3

3. Brief Description of the Machine 1-4

3.1. Intended Use 1-4

3.2. Crane Configuration 1-4

3.3. Features Equipped with the Crane 1-5

4. Operator Qualification Requirements 1-6

4.1. Qualifications of Crane Operators 1-6

5. Glossary 1-7

5.1. Definition of Terms 1-7

5.2. How to Read the Working Range Chart: Working Radius and Lifting Height 1-8

5.3. How to Read the Total Rated Capacity Table 1-9

5.4. How to Read the Load Indicator 1-14

SAFETY PRECAUTIONS

1. General Rules 2-2

2. Operating Rules 2-8

2.1. Before Starting the Engine 2-8

2.2. After Starting the Engine 2-9

2.3. When Working with the Crane 2-13

3. Rules for Transporting the Crane 2-21

4. Handling the Battery 2-23

5. Repairing the Crane 2-25

5.1. Before Repairing 2-25

5.2. During Repairs and Maintenance 2-25

6. Hanging Up Warning Signs 2-37

OPERATION 3-2

1 List of Main Crane Components 3-2

1.2. Main Travel Control Devices 3-3

1.2.1. Control Levers 3-4

1.2.2. Switches 3-6

1.2.3. Instrumentation and Switches 3-7

1.3. Elements of the Crane Control System 3-9

1.3.1. Control Levers 3-10

1.3.2. Switches 3-11

1.3.3. Instrumentation and Lamps 3-13

1.4. Overload Warning System 3-14

1.5. Machine Hood 3-15

1-16

2. Operation and Controls 3-16

2.1. Before Starting the Engine 3-16

2.1.1. Roundabout Inspection 3-16

2.1.2. Prestart Checks 3-18

2.2. Starting the Engine 3-37

2.2.1. Starting the Engine with the Main Starter Switch 3-37

2.2.2. Starting the Engine with the Main Starter Switch in

Cold Weather

3-38

2.2.3. Starting the Engine with the Auxiliary Starter Switch 3-39

2.3. Operation and Checks After Starting the Engine 3-40

2.4. Running-in Run. 3-42

2.5. “Travel” Position. 3-42

2.6. Starting the Machine. 3-43

2.7. Changing the Travel Direction. 3-44

2.8. Stopping and Parking the Crane. 3-45

2.9. Stopping the Engine. 3-46

2.10. Inspection and Checks after Stopping the Engine. 3-46

2.11. Crane Movement Rules. 3-47

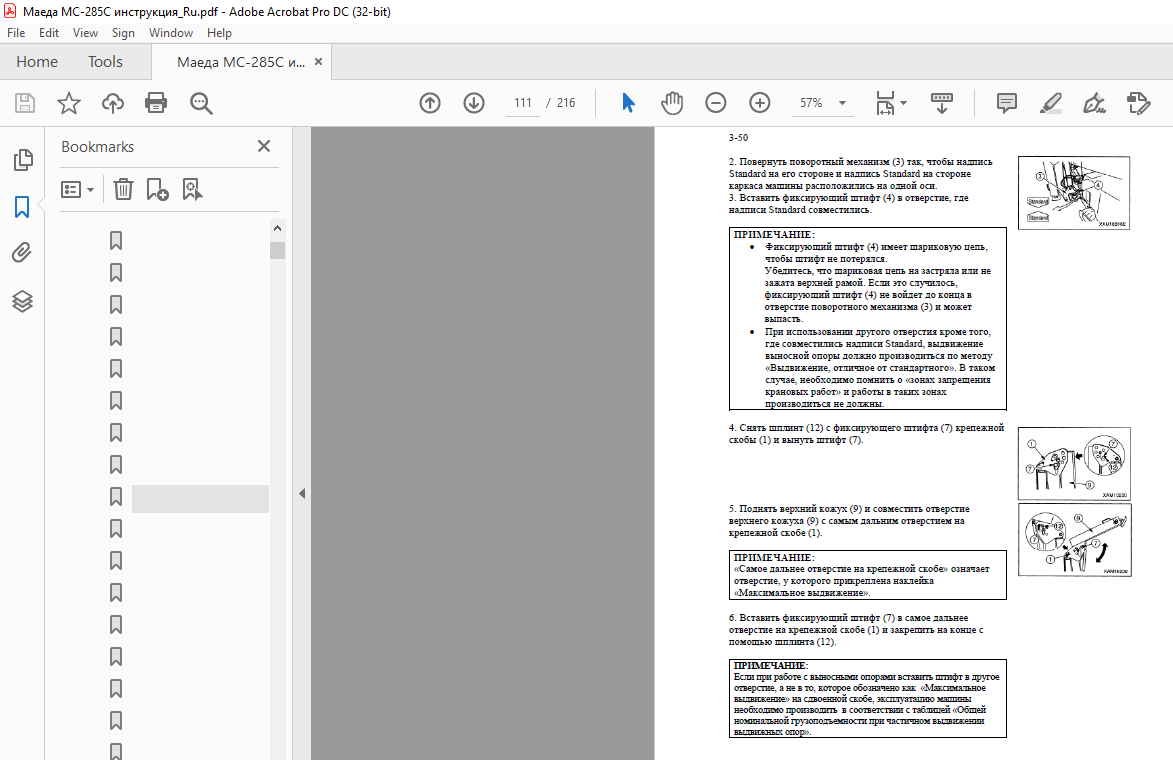

2.12. Installing the Extendable Outriggers. 3-48

2.13. What You Need to Know Before Operating the Crane 3-53

2.14. Pre-Operation Procedures 3-54

2.15. Crane Operating Position 3-55

2.16. Load Raising and Lowering Operations 3-56

2.17. Raising and Lowering the Boom 3-56

2.18. Boom Extension (Telescoping) Operations 3-57

2.18. Boom Extension (Telescoping) Operations 3-57

2.19. Swing Operations 3-58

2.20. Accelerator Pedal Operations 3-59

2.21. How to Use the Load Indicator and Load Cell 3-60

2.22. Laying Down the Crane 3-63

2.23. Folding the Outriggers 3-64

2.24. Prohibited Actions When Working on the Crane 3-67

3. Handling Rubber Tracks 3-69

3.1. Proper Handling of Rubber Tracks 3-69

3.2. Warranty 3-69

3.3. Prohibited Work 3-70

3.4. Operating Rules 3-71

4. Using the Rope 3-73

4.1. Rope Replacement Standards 3-73

4.2. Actions in Case of Rope Twisting 3-74

5. Transportation 3-75

5.1. Loading and Unloading 3-75

5.2. How to Lift the Machine 3-76

5.3. Loading Rules 3-77

5.4. Transport Rules 3-77

6. Handling the Crane in Cold Climates 3-78

6.1. Preparing for Low Ambient Temperatures 3-78

1-17

7. Long-Term Storage 3-80

7.1. Preparing for Long-Term Storage 3-80

7.2. During Storage 3-80

7.3. After Storage 3-80

8. Handling the Battery 3-81

8.1. Handling the Battery 3-81

8.2. Removing and Installing the Battery 3-82

8.3. Replacing the Battery 3-82

8.4. Starting with Jumper Cables 3-83

9. Action to Take in the Event of a Malfunction 3-85

9.1. When Connecting to Electrical Components 3-85

9.2. In Connection with the Machine 3-85

9.3. In Connection with the Engine 3-86

MAINTENANCE

1. Carrying Out Repairs 4-2

2. Basics of Repair and Maintenance 4-4

3. Inspection Required by Law 4-6

3.1 Rules for Safe Inspection of the Crane 4-6

4. Consumables 4-7

5. Lubricating Oil and Grease 4-8

5.1 Lubricants Used at Different Temperatures 4-8

6. Standard Tools and Standard Tightening Torque 4-9

6.1 Summary of Standard Tools 4-9

6.2 Standard Tightening Torque Table 4-9

7. Scheduled Maintenance 4-12

8. Repair Procedure 4-14

8.1 After the First 10 Hours of Operation 4-14

8.2 After the First 50 Hours of Operation 4-14

8.3 After the First 250 Hours of Operation 4-14

8.4 If Necessary 4-15

8.5 Checking Before Starting 4-21

8.6. After every 30 operating hours 4-40

8.7. After every 50 operating hours 4-42

8.8. After every 100 operating hours 4-45 8.9

. After every 250 operating hours 4-46

8.10. After every 500 operating hours 4-48

8.11. After every 1,000 operating hours 4-55

8.12. After every 2,000 operating hours 4-63

1-18

SPECIFICATIONS

1. Main Technical Data and Specifications 5-2

1.1. Specification Table 5-2

1.2. Overall Dimensions 5-3

1.3. Total Rated Load Table 5-4

1.4. Working Radius/Lifting Height Diagram

IMAGES PREVIEW OF THE MANUAL: