$33

Mahindra Tractor 35 Series 3535 4035 Gear ML 120 Operator’s & Parts Manual – PDF DOWNLOAD

Mahindra Tractor 35 Series 3535 4035 Gear ML 120 Operator’s & Parts Manual – PDF DOWNLOAD

FILE DETAILS

Mahindra Tractor 35 Series 3535 4035 Gear ML 120 Operator’s & Parts Manual – PDF DOWNLOAD

Language : English

Pages : 104

Downloadable : Yes

File Type : PDF

Size: 10.2 MB

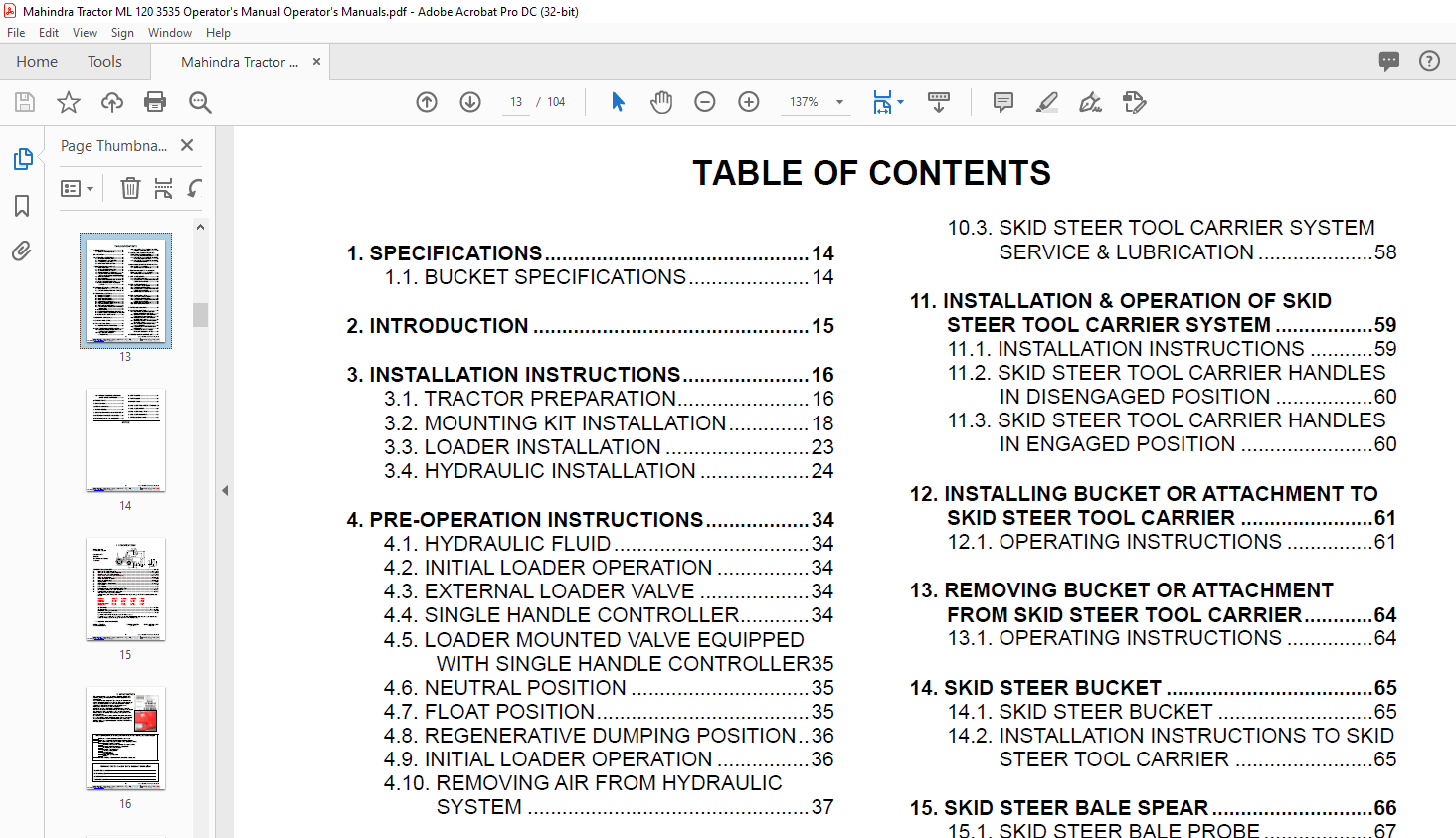

TABLE OF CONTENTS:

Mahindra Tractor 35 Series 3535 4035 Gear ML 120 Operator’s & Parts Manual – PDF DOWNLOAD

1 SPECIFICATIONS 14

1 1 BUCKET SPECIFICATIONS 14

2 INTRODUCTION 15

3 INSTALLATION INSTRUCTIONS 16

3 1 TRACTOR PREPARATION 16

3 2 MOUNTING KIT INSTALLATION 18

3 3 LOADER INSTALLATION 23

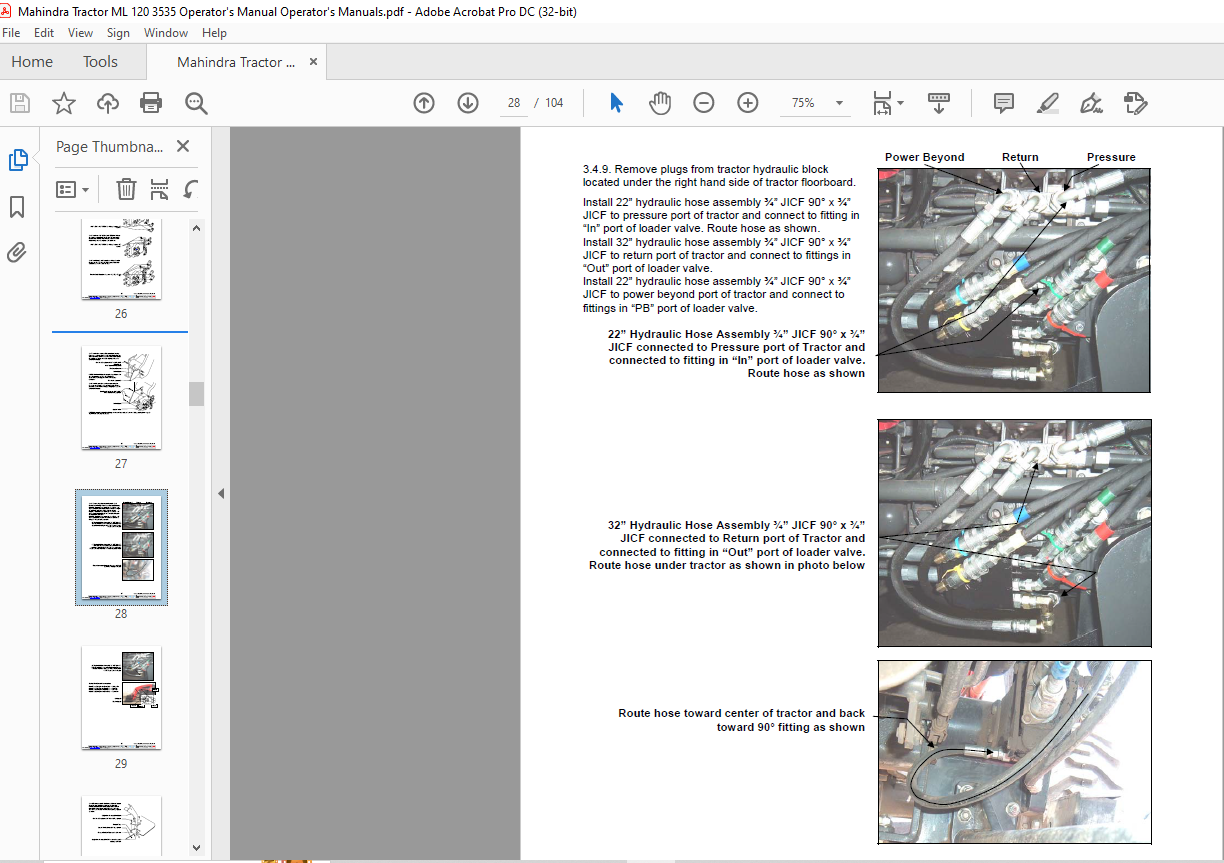

3 4 HYDRAULIC INSTALLATION 24

4 PRE-OPERATION INSTRUCTIONS 34

4 1 HYDRAULIC FLUID 34

4 2 INITIAL LOADER OPERATION 34

4 3 EXTERNAL LOADER VALVE 34

4 4 SINGLE HANDLE CONTROLLER 34

4 5 LOADER MOUNTED VALVE EQUIPPED

WITH SINGLE HANDLE CONTROLLER35

4 6 NEUTRAL POSITION 35

4 7 FLOAT POSITION 35

4 8 REGENERATIVE DUMPING POSITION 36

4 9 INITIAL LOADER OPERATION 36

4 10 REMOVING AIR FROM HYDRAULIC

SYSTEM 37

5 DAILY MAINTENANCE & LUBRICATION 38

5 1 DAILY CHECKS 38

5 2 LOADER LUBRICATION AND SERVICE 39

6 OPERATING INSTRUCTIONS 41

6 1 FILLING THE BUCKET 41

6 2 LIFTING THE LOAD 41

6 3 CARRYING THE LOAD 41

6 4 DUMPING THE BUCKET 42

6 5 LOWERING THE BUCKET 42

6 6 OPERATING WITH FLOAT CONTROL 42

6 7 LOADING FROM A BANK 42

6 8 PEELING AND SCRAPING 43

6 9 LOADING LOW TRUCKS OR SPREADERS

FROM A PILE 43

6 10 BACKFILLING 43

6 11 HANDLING LARGE HEAVY OBJECTS 44

6 12 BACK GRADING OR DOZING MATERIAL45

6 13 PROHIBITED OPERATIONS 46

7 DISMOUNTING THE LOADER 47

8 MOUNTING THE LOADER 52

9 OPTIONAL GRILL GUARD 56

9 1 INSTALLATION INSTRUCTIONS 56

10 SKID STEER TOOL CARRIER SYSTEM 57

10 1 RECOMMENDED LOADER FACTORY

APPROVED ATTACHMENTS 57

10 2 NON-LOADER FACTORY

ATTACHMENTS 57

10 3 SKID STEER TOOL CARRIER SYSTEM

SERVICE & LUBRICATION 58

11 INSTALLATION & OPERATION OF SKID

STEER TOOL CARRIER SYSTEM 59

11 1 INSTALLATION INSTRUCTIONS 59

11 2 SKID STEER TOOL CARRIER HANDLES

IN DISENGAGED POSITION 60

11 3 SKID STEER TOOL CARRIER HANDLES

IN ENGAGED POSITION 60

12 INSTALLING BUCKET OR ATTACHMENT TO

SKID STEER TOOL CARRIER 61

12 1 OPERATING INSTRUCTIONS 61

13 REMOVING BUCKET OR ATTACHMENT

FROM SKID STEER TOOL CARRIER 64

13 1 OPERATING INSTRUCTIONS 64

14 SKID STEER BUCKET 65

14 1 SKID STEER BUCKET 65

14 2 INSTALLATION INSTRUCTIONS TO SKID

STEER TOOL CARRIER 65

15 SKID STEER BALE SPEAR 66

15 1 SKID STEER BALE PROBE 67

15 2 ASSEMBLY INSTRUCTIONS 67

15 3 INSTALLATION INSTRUCTIONS TO SKID

STEER TOOL CARRIER 67

15 4 OPERATING INSTRUCTIONS 67

16 SKID STEER PALLET FORK 68

16 1 SKID STEER PALLET FORK 69

16 2 ASSEMBLY INSTRUCTIONS 69

16 3 INSTALLATION INSTRUCTIONS TO SKID

STEER TOOL CARRIER 69

16 4 OPERATING INSTRUCTIONS 69

16 5 PARKING INSTRUCTIONS 69

17 OPTIONAL BALLAST BOX 70

18 LEAK DOWN INSPECTION 71

18 1 FRONT END LOADER FIELD LEAK

DOWN INSPECTION AND TEST 71

18 2 LEAKAGE TEST FOR LIFT CYLINDER

SEALS (Open Center Systems) 72

18 3 LEAKAGE TEST FOR LIFT CIRCUIT

LOADER VALVE SPOOL 74

18 4 LEAKAGE TEST FOR TILT OR BUCKET

CYLINDER, SEALS 74

18 5 TILT OR BUCKET CYLINDER VALVE

SPOOL LEAKAGE 75

18 6 ACCEPTABLE LIFT CYLINDER LEAK

DOWN RATES 76

18 7 ACCEPTABLE TILT OR BUCKET

CYLINDER LEAK DOWN RATES 76

19 TROUBLE SHOOTING PROCEDURES 77

35 Series 4WD, Model – 3535 & 4035 Loader June’08

Downloaded from www Manualslib com manuals search engine

13

19 1 TROUBLE SHOOTING CABLES AND

SINGLE LEVER CONTROLLER 81

20 TORQUE CHART 82

21 PARTS MANUAL 83

22 DECALS & MANUALS 84

23 BOOM ASSEMBLY 86

24 MOUNTING BRACKETS AND HARDWARE 88

25 HYDRAULIC CYLINDERS AND HOSES 90

26 HYDRAULIC VALVE AND HARDWARE 92

27 LIFT CYLINDER 94

28 TILT CYLINDER 95

29 LOADER VALVE 96

30 SKID STEER TOOL CARRIER ATTACHMENT98

31 SKID STEER BUCKET 100

32 SKID STEER PALLET FORK 101

33 SKID STEER BALE SPEAR 102

34 OPTIONAL GRILL GUARD 103

DESCRIPTION:

Mahindra Tractor 35 Series 3535 4035 Gear ML 120 Operator’s & Parts Manual – PDF DOWNLOAD

SAFETY PRECAUTIONS

READ MANUALS AND DECALS

1. Read and understand both the tractor and the loader Operator Manuals and all decals before using the

loader.

2. Lack of knowledge can lead to accidents.

3. It is the loader owner’s responsibility to make sure anyone operating the loader reads and understands

this manual first before operating the machine.

4. Follow all safety, operating, and service instructions.

5. Replace damaged or illegible safety labels. See following pages for required labels.

ROPS AND SEAT BELT

6. Equip your tractor with an approved rollover-protective structure (ROPS) or ROPS Cab and seat belt for

your protection.

7. ROPS (Roll-Over Protective Structures) and seat belt equipped tractors are recommended for operator

use in all loader operations.

8. Operator should wear safety hard hat, safety glasses, safety shoes, and other PPE. Avoid wearing loose

clothing or jewelry that may catch in moving parts.

9. Use seat belt as specified by tractor/ROPS manufacturer.

YOURSELF

10. Do not stand, walk, or work under a raised loader bucket or attachment unless it is securely blocked and

held in position.

11. Operate controls only when properly seated in the operator’s seat.

12. Only one person, the operator, should be on the machine when it is in operation.

13. Accidental movement of valve handle/handles or leak in the hydraulic system could cause the loader to

drop, or attachment to dump, causing severe injury.

OTHERS

14. Do not allow anyone in loader work area, under raised loader, or to reach through the loader boom when

the bucket or attachment is raised.

15. A frequent cause of personal injury or death is persons falling off and being run over. Inadvertent

movement of the loader or attachment could result in serious injury or death.

16. Do not permit others to ride on your tractor, loader, bucket, or any attachment.

17. Do not lift or carry anyone on buckets, forks, probes, or any other portion of the loader or loader

attachments.

18. Do not allow children or unqualified persons to operate equipment.

PREPARATION

19. Move the wheels to the tractor manufacturer’s widest recommended settings to increase stability.

20. For better stability, always use a tractor equipped with a wide front axle, never use a tractor equipped with

a tricycle type front axle.

21. Add rear ballast or rear weight to the tractor to compensate for the load and increase stability.

22. Add recommended rear tire liquid weight or rear wheel weights for increased stability.

23. Do not modify, alter, or permit anyone else to modify or alter the loader, any of its components, or any

loader function without first consulting a Mahindra dealer.

24. Assemble, remove, and reinstall the loader only as directed in this manual. Failure to do this could result

in serious personal injury or death.

25. The loader may shift during shipping and handling, making it unstable on the pallet. Support loader with

an overhead hoist or other suitable means prior to removing bands or attaching straps securing loader to

pallet. Failure to do so could result in accidental tip-over of the loader that could cause serious injury to

you and/or bystanders

IMAGES PREVIEW OF THE MANUAL: