$34

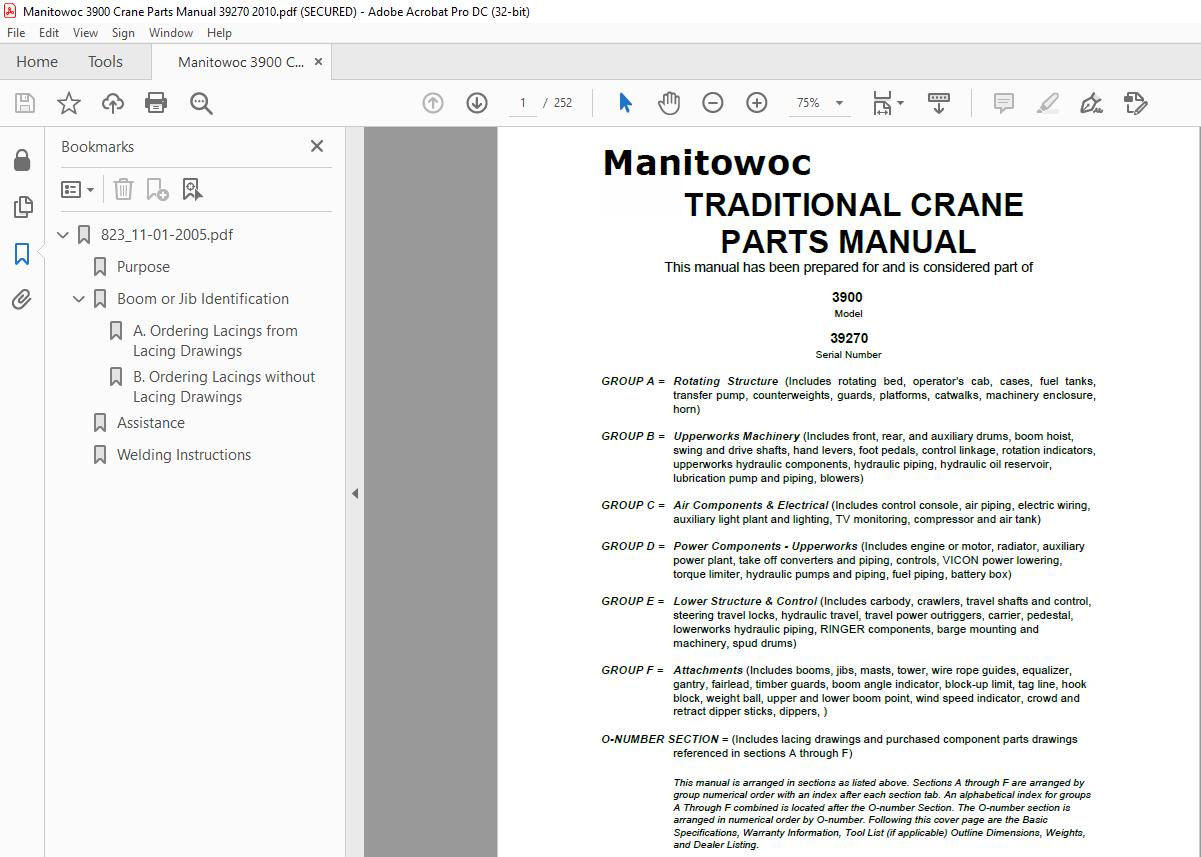

Manitowoc Crane 3900 Parts Manual SN 39270 PDF

Manitowoc Traditional Crane 3900 Parts Manual SN 39270 – PDF DOWNLOAD

FILE DETAILS:

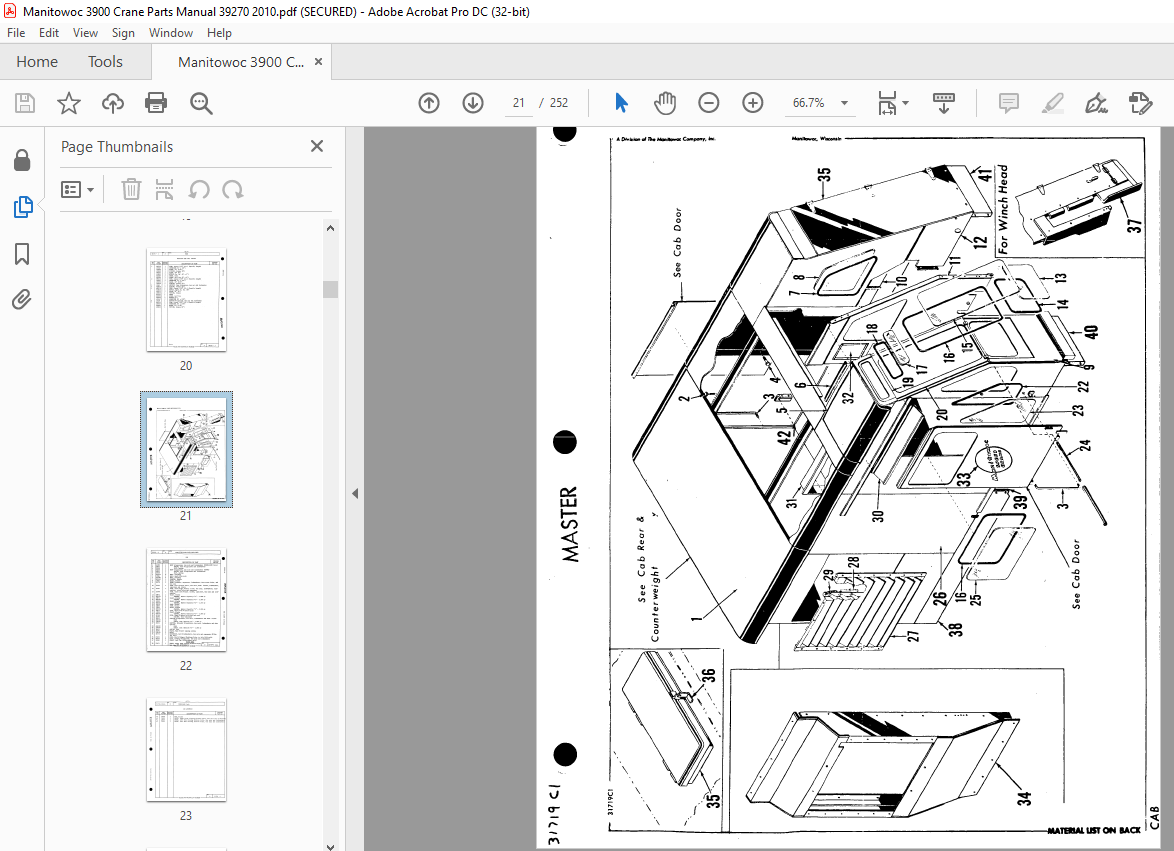

The Manitowoc Traditional Crane 3900 Parts Manual (SN 39270) in PDF format is an essential resource for maintenance. It includes detailed diagrams and authentic part information, facilitating efficient repairs and servicing for the Manitowoc Traditional Crane 3900 with serial number 39270.

Manitowoc Traditional Crane 3900 Parts Manual SN 39270 – PDF DOWNLOAD

Language : English

Pages :252

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Manitowoc Traditional Crane 3900 Parts Manual SN 39270 – PDF DOWNLOAD

WRENCH, Thin (1-I/2″) (All) .5#

WRENCH, Drum Brake (1-7/8″) (Towers) 4.0#

WRENCH, Drum Brake (I-7/8″) (All) 4.0#

WRENCH, Tension Rod (2-I/4″) (Models 3900, 3900T, 3900W,

4100W) 8.0#

WRENCH, Hook Roller Pin Locking Plate (5-3/4″ Hole Centers)

(Models 3900, 3900T, 3900W, 4000W) 5.2#

WRENCH, Hook Roller Pin (4-1/2″) (Model 4100W) 6.8#

WRENCH, 12 Point Socket Type (2-13/16″)

(Models 3900, 3900W, 4000W, 4100W) 15.0#

WRENCH, 12 Point Socket Type (3″) (Model 4000W) 15.0#

WRENCH, 12 Point Socket Type (3-5/32″)

(Models 3900, 3900T, 3900W) 15.0#

WRENCH, Clutch Shaft (2-1/4″) (Model 3900T) 10.0#

WRENCH, Crawler Tread (3-3/16″)(Models 3900, 3900W) 17.0#

ENCH, Travel Shaft (3-13/16″)(Models 3900, 3900T, 3900W) 15.0#

WRENCH, 1-3/4″ Nut (All) 10.0#

TOOLS NOT SHOWN

WRENCH, Crescent (12″)

HANDLE, Socket (3/4″)

EXTENSION, Handle

SOCKET (1-1/16″)

SOCKET (1-1/8″)

SOCKET (1-3/16″)

SOCKET (1-1/4″)

SOCKET (1-5/16″)

SOCKET (1-7/16″)

SOCKET (1-1/2″)

SOCKET (1-5/8″)

SOCKET (1-3/4″)

SOCKET (1-7/8″)

SOCKET (2″)

SOCKET (2-1/4″) (Model 3900)

WRENCH, Combination (7/16″)

WRENCH, Combination (1/2″)

WRENCH, Combination (9/16″)

WRENCH, Combination (5/8″)

WRENCH, Combination (11/16″)

WRENCH, Combination (3/4″)

WRENCH, Combination (13/16″)

WRENCH, Combination (7/8″)

WRENCH, Combination (15/16″)

WRENCH, Combination (I”)

GROUP A = Rotating Structure (Includes rotating bed, operator’s cab, cases, fuel tanks,

transfer pump, counterweights, guards, platforms, catwalks, machinery enclosure,

horn)

GROUP B = Upperworks Machinery (Includes front, rear, and auxiliary drums, boom hoist,

swing and drive shafts, hand levers, foot pedals, control linkage, rotation indicators,

upperworks hydraulic components, hydraulic piping, hydraulic oil reservoir,

lubrication pump and piping, blowers)

GROUP C = Air Components & Electrical (Includes control console, air piping, electric wiring,

auxiliary light plant and lighting, TV monitoring, compressor and air tank)

GROUP D = Power Components – Upperworks (Includes engine or motor, radiator, auxiliary

power plant, take off converters and piping, controls, VICON power lowering,

torque limiter, hydraulic pumps and piping, fuel piping, battery box)

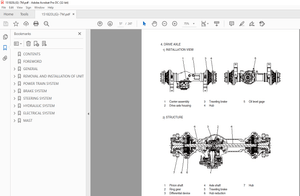

GROUP E = Lower Structure & Control (Includes carbody, crawlers, travel shafts and control,

steering travel locks, hydraulic travel, travel power outriggers, carrier, pedestal,

lowerworks hydraulic piping, RINGER components, barge mounting and

machinery, spud drums)

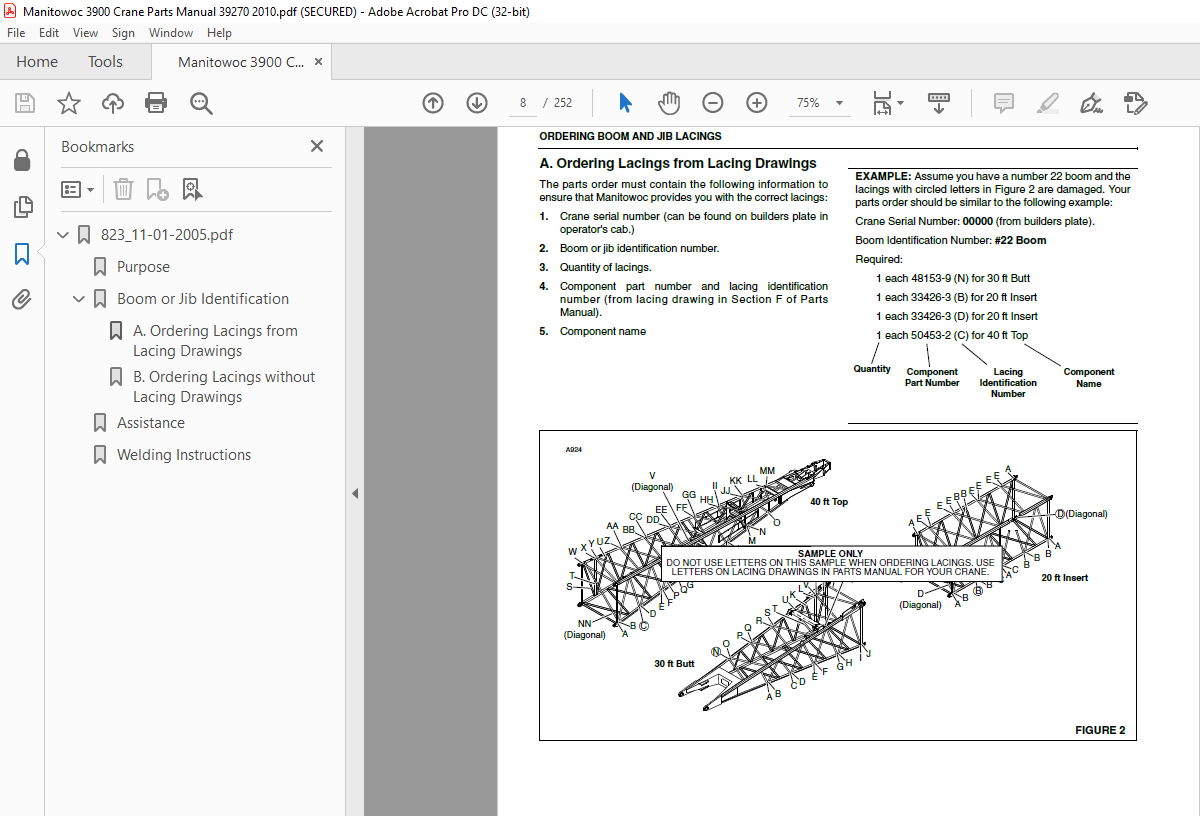

GROUP F = Attachments (Includes booms, jibs, masts, tower, wire rope guides, equalizer,

gantry, fairlead, timber guards, boom angle indicator, block-up limit, tag line, hook

block, weight ball, upper and lower boom point, wind speed indicator, crowd and

retract dipper sticks, dippers, )

O-NUMBER SECTION = (Includes lacing drawings and purchased component parts drawings

referenced in sections A through F)

This manual is arranged in sections as listed above. Sections A through F are arranged by

group numerical order with an index after each section tab. An alphabetical index for groups

A Through F combined is located after the O-number Section. The O-number section is

arranged in numerical order by O-number. Following this cover page are the Basic

Specifications, Warranty Information, Tool List (if applicable) Outline Dimensions, Weights,

and Dealer Listing