$40

Manitowoc Crane GHC130 Operation Manual – PDF DOWNLOAD

Manitowoc Crane GHC130 Operation Manual – PDF DOWNLOAD

FILE DETAILS:

Manitowoc Crane GHC130 Operation Manual – PDF DOWNLOAD

Language : English

Pages :502

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Manitowoc Crane GHC130 Operation Manual – PDF DOWNLOAD

1 Safety 11

11 Presentation of safety information 11

12 Danger sources 12

13 National and international regulations 12

14 Intended use 12

15 Impermissible use 15

16 Crane categorization 16

17 Requirements on personnel 16

18 Work operation 18

181 Boarding or exiting the crane safely 23

182 Emergency exit 23

183 Regulations for applications planning 24

184 Ramming tasks or pulling sheet pile walls 25

185 Deployment on a pontoon 26

186 Start-up 28

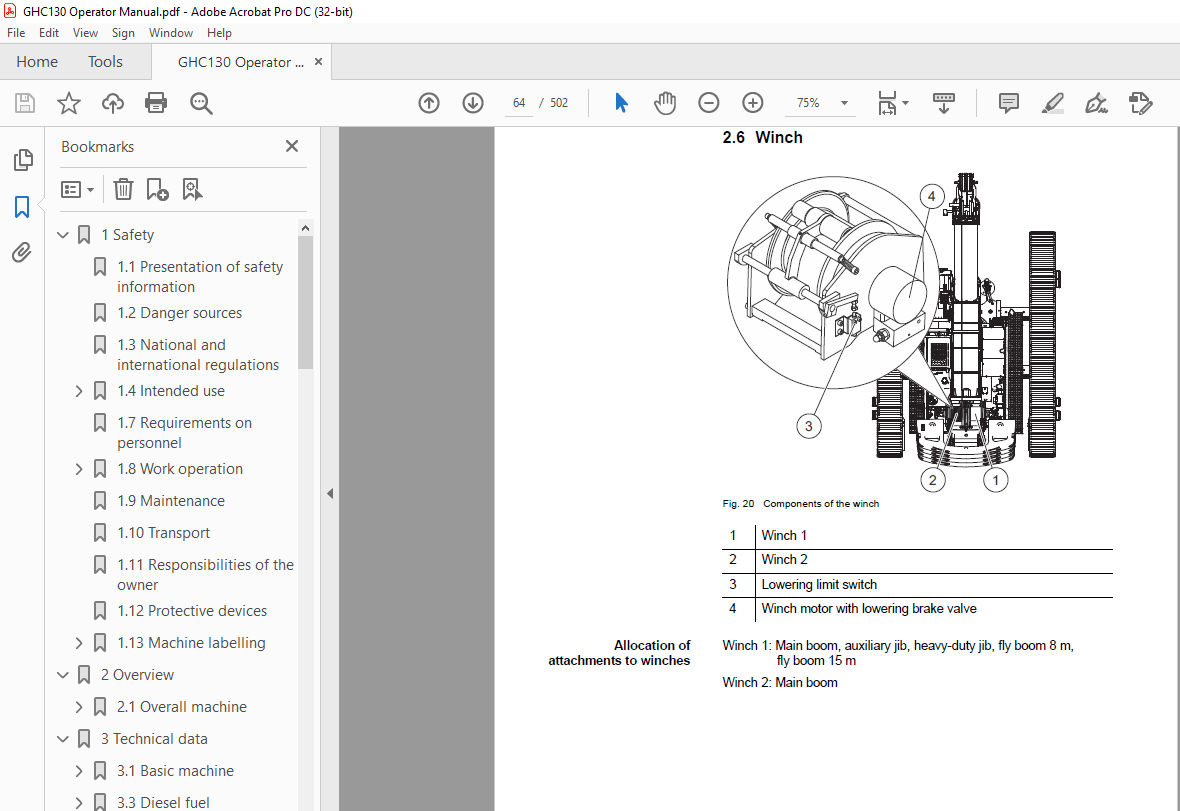

187 Operation 29

188 Travelling 29

189 Decommissioning 30

1810 Setup tasks 30

19 Maintenance 31

110 Transport 32

111 Responsibilities of the owner 33

112 Protective devices 34

113 Machine labelling 35

114 Warnings and information signs 36

2 Overview 57

21 Overall machine 57

22 Undercarriage 58

23 Cab 59

231 Pedals 60

24 Uppercarriage 61

25 Telescopic boom 63

26 Winch 64

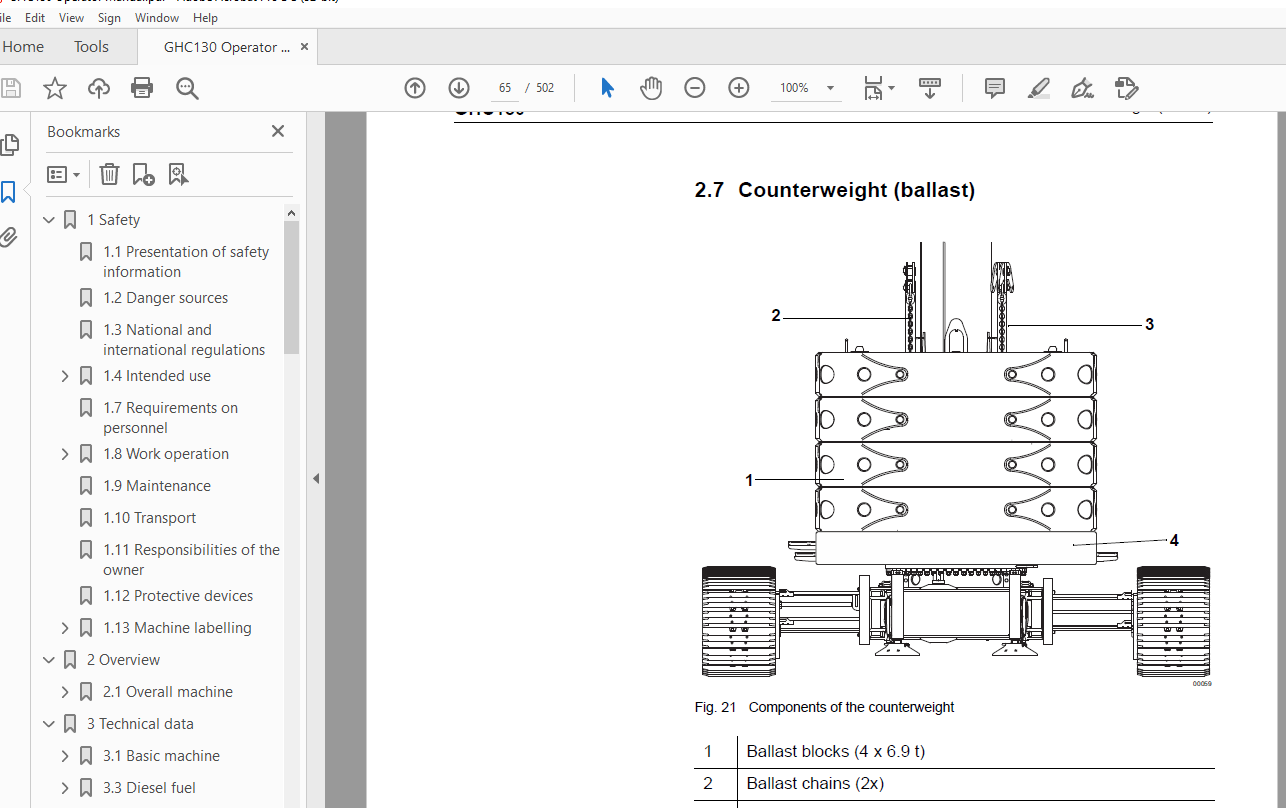

27 Counterweight (ballast) 65

3 Technical data 67

31 Basic machine 67

32 Permissible ground pressure 70

33 Diesel fuel 72

34 Engine oil 73

35 Permissible wind speeds 74

351 Procedure when reaching the limit value “wind – in operation” 75

352 Procedure when reaching the limit value “wind – not in operation” 75

36 Dimensions of the basic machine 76

37 Working loads 77

38 Safe working load reduction due to load-handling devices 79

381 Working diagram – main boom 80

39 Conversion factors 81

310 Hooks 82

4 Start-up 83

41 Initial start-up 84

42 Checks before start-up 84

43 Switching on the battery disconnect switch 86

44 Machine start 87

441 Fastening the seat belt 88

442 Starting the engine 90

443 Selecting setup status 93

444 Bringing the machine to operating temperature 94

445 Jump start 95

45 Switching off engine 96

46 Decommissioning the machine 97

47 Preservation and storage 98

48 Starting up the machine after long-term storage 99

5 SENCON 20101

51 Overview of controls102

511 Quick selection icons103

512 Menu icons104

52 Start screen105

521 Operating status106

522 Telescopic boom and slew uppercarriage notification icons108

523 Diesel engine notification and warning icons110

524 Load moment limitation notification and warning icons112

525 Overall machine notification and warning icons113

526 Working diagram115

527 Winch parameters116

53 Set-up status117

531 Entering uppercarriage inclination119

532 Entering undercarriage ballast120

533 Entering winch reeving121

534 Setting travel speed122

535 Entering track width123

536 Entering attachments and configuring setup program124

537 Entering counterweight127

54 Setup128

55 Setting language131

56 Setting brightness132

57 Setting date and time134

58 Configuring units136

59 USB138

510 Request access138

511 Histogram139

512 Login information140

513 General information141

514 Diagnostics142

5141 Active faults engine143

5142 Active faults machine144

5143 Active faults RCL149

6 Operation151

61 Cab153

611 Driver seat157

62 Uppercarriage locking mechanism159

63 Tilting the cab161

64 Operating elements in the cab162

641 Safety lever163

642 Assignment of the joysticks and pedals165

643 Storage compartment, right of the driver seat166

644 Control panels, right167

645 Control panel, top right169

65 Slewing ring lubrication (option)170

66 Central lubrication system (option)171

67 DEF/system for reducing nitrogen oxide (Tier 4f engines)172

671 Exhaust aftertreatment system regeneration174

68 Control panel – automatic air conditioning178

69 Camera system181

610 Load moment limitation (LML)182

6101 LML function182

6102 Audible and visual warning device statuses183

6103 Operation184

6104 Mode selection184

6105 Bypassing the load moment limitation (LML)185

6106 LML work programs186

6107 Components of the LML189

611 Special equipment193

6111 Remote radio control (option)193

6112 Visual warning device204

612 Work implementation205

6121 Crane operation206

6122 Securing bottom hook block for drive mode207

6123 Moving the machine209

6124 Travel with suspended load212

6125 Moving on inclines and ramps213

6126 Slewing the uppercarriage214

6127 Lifting and lowering loads220

6128 Hook operation with both winches222

6129 Adjusting the boom (luffing)224

61210 Extending/retracting the boom225

61211 Turning on the supplemental hydraulic system (option)226

61212 Operating the clamping tongs (option)227

61213 Operating the soil drill (option)228

61214 Refuel the machine229

61215 Checking the DEF level and refilling (Tier 4f engines)234

7 Setup tasks237

71 Setup operating mode238

72 Remote radio control – setup240

73 Attaching the track wheel carriers241

731 Supporting the machine with outriggers for unloading241

732 Fastening the track wheel carriers246

74 Removing the track wheel carriers254

741 Supporting the machine with outriggers for loading254

742 Removing the track wheel carrier257

743 Loading the machine264

744 Removing tightened retainers267

75 Access ladders268

76 Mounting/removing walkways269

77 Telescoping the undercarriage271

771 Preparatory tasks without counterweight271

772 Preparatory tasks with counterweight271

773 Supporting the machine with outriggers for telescoping272

774 Increasing the track width275

775 Decreasing the track width279

78 Setting up the slewing range safeguard284

79 Connections for clamping tongs and supplemental hydraulic system on the boom head (option)287

710 Attaching clamping tongs (option)288

711 Slewing the soil drill (option) into working position289

712 Slewing the soil drill into transport position (option)290

713 Attaching the counterweight291

7131 Setting up the counterweight291

714 Attaching the fly boom301

7141 Attachment – deflection sheave301

7142 Attaching the fly boom303

715 Folding the fly boom into transport position307

7151 Folding the fly boom into working position317

7152 Folding the fly boom from 0° to 20°326

7153 Folding the fly boom from 0° to 40°327

7154 Folding the fly boom from 20° to 40°329

7155 Folding the fly boom from 40° to 20°331

7156 Folding the fly boom from 20° or 40° to 0°333

7157 Attaching the fly boom extension (7 m)335

716 Attaching the lattice boom extension338

7161 Attaching the lattice boom headpiece to the lattice boom section338

7162 Attaching the lattice boom section339

717 Attaching the auxiliary jib345

718 Emergency control348

7181 Extending outrigger cylinders348

7182 Telescoping the undercarriage out351

7183 Extending the ballasting cylinders and bolting the counterweight354

8 Transport357

81 Controls for unloading the machine359

82 Switching on the battery disconnect switch360

83 Unload machine361

831 Configuring the setup program in the SENCON362

832 Moving the machine off the transport vehicle366

84 Transport dimensions and weights369

841 Overall machine369

842 Attachments371

85 Disconnecting the electrical system from the battery373

86 Lifting the machine374

87 Lashing the machine375

9 Troubleshooting377

91 Diesel engine377

92 Hydraulic system378

93 Heating/air-conditioning system380

931 Heat output380

932 Cooling capacity382

933 System very noisy384

94 Slewing gear385

95 Undercarriage385

96 Cab385

10 Appendix387

101 Handling, Installation, and Maintenance of Steel Wire Ropes387

1011 Rope selection387

1012 How should wire ropes be unloaded?387

1013 How should wire ropes be stored?388

1014 Assembly of wire ropes388

1015 Maintenance of wire ropes393

1016 Inspection of wire ropes396

1017 Concluding remarks404

102 Driver Seat405

1021 General Instructions407

1022 Safety instructions407

1023 Connecting data408

1024 Guarantee and liability409

1025 Seat functions and operation409

1026 Maintenance412

103 Camera system413

1031 Product description413

1032 Safety Instructions414

1033 Operating and Display Elements416

1034 Commissioning417

1035 Operating Modes417

1036 Malfunctions418

1037 Maintenance419

1038 Service Information419

1039 Environmental Protection419

104 Radio Remote Control 0

1041 Introduction 0

1042 Safety precautions 0

1043 Protection devices 0

1044 Installation 0

1045 Checkup before operation 0

1046 Startup procedure 0

1047 Operation of MFS and HL systems 0

1048 Battery charger and rechargeable batteries 0

1049 Battery handling 0

10410 Diagnostics 0

10411 Special Technical Data 0

10412 Maintenance, Guarantee, Disposal 0

10413 Complaint form 0

10414 Abbreviations and definitions 0

10415 Installation and safety test declaration 0

10416 EC Declaration of Conformity 0

10417 HF-Part Conformity Europe 0

10418 Mounting Antennas for Feedback-Systems 0

10419 Mounting instruction for directional antenna on top slewing cranes 0

10420 Guarantee Conditions HETRONIC Germany GmbH 0

105 Cleaning the cooling system436

1051 Safety instructions436

1052 Coolant cooler437

1053 Tips for preventive maintenance438

1054 Coolant438

1055 Charge-air cooler439

1056 Oil cooler439

106 Residual Useful Life of Winches439

1061 General steps required to ensure safe periods of operation439

1062 Periodic inspection of cranes439

1063 Steps required to monitor the winches439

107 Installing Large Roller Bearings, Slewing Gears, and Flange Connections447

1071 General447

1072 Preparatory measures447

1073 Assembly447

1074 Tightening torques for bolts449

108 PFEIFER Pouch Socket System451

1081 Preamble451

1082 Signs and symbols451

1083 Application area and intended use451

1084 General information452

1085 Installation and Assembling454

1086 Important security informations456

1087 Operation456

1088 Accessories and spare parts457

1089 Maintenance and Repair458

10810 Lifting Capacity Table459

109 Operating Fluids and Lubricants460

1091 Hydraulic system461

1092 Diesel engine462

1093 Gearbox464

1094 Lubrication466

1095 Air conditioning system469

1096 Windshield washer system470

1097 Starter batteries470

1010 Personnel Basket471

10101 Safety471

10102 Inspection and testing480

10103 Basket Installation490

11 Reeving diagram496

Index501

Blank Page435

IMAGES PREVIEW OF THE MANUAL: