$41

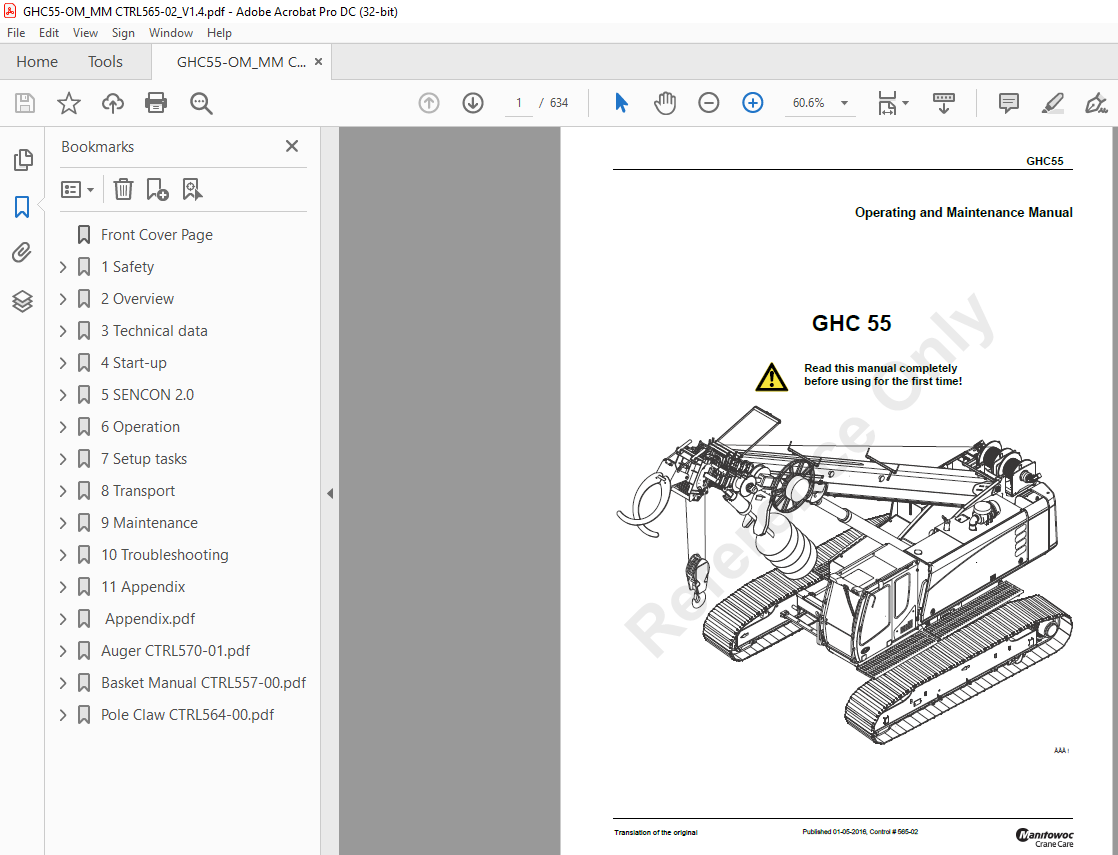

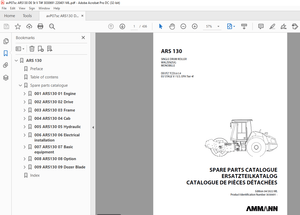

Manitowoc Grove GHC 55 Operating & Maintenance Manual – PDF DOWNLOAD

Manitowoc Grove GHC 55 Operating & Maintenance Manual – PDF DOWNLOAD

FILE DETAILS:

Manitowoc Grove GHC 55 Operating & Maintenance Manual – PDF DOWNLOAD

Language : English

Pages :634

Downloadable : Yes

File Type : PDF

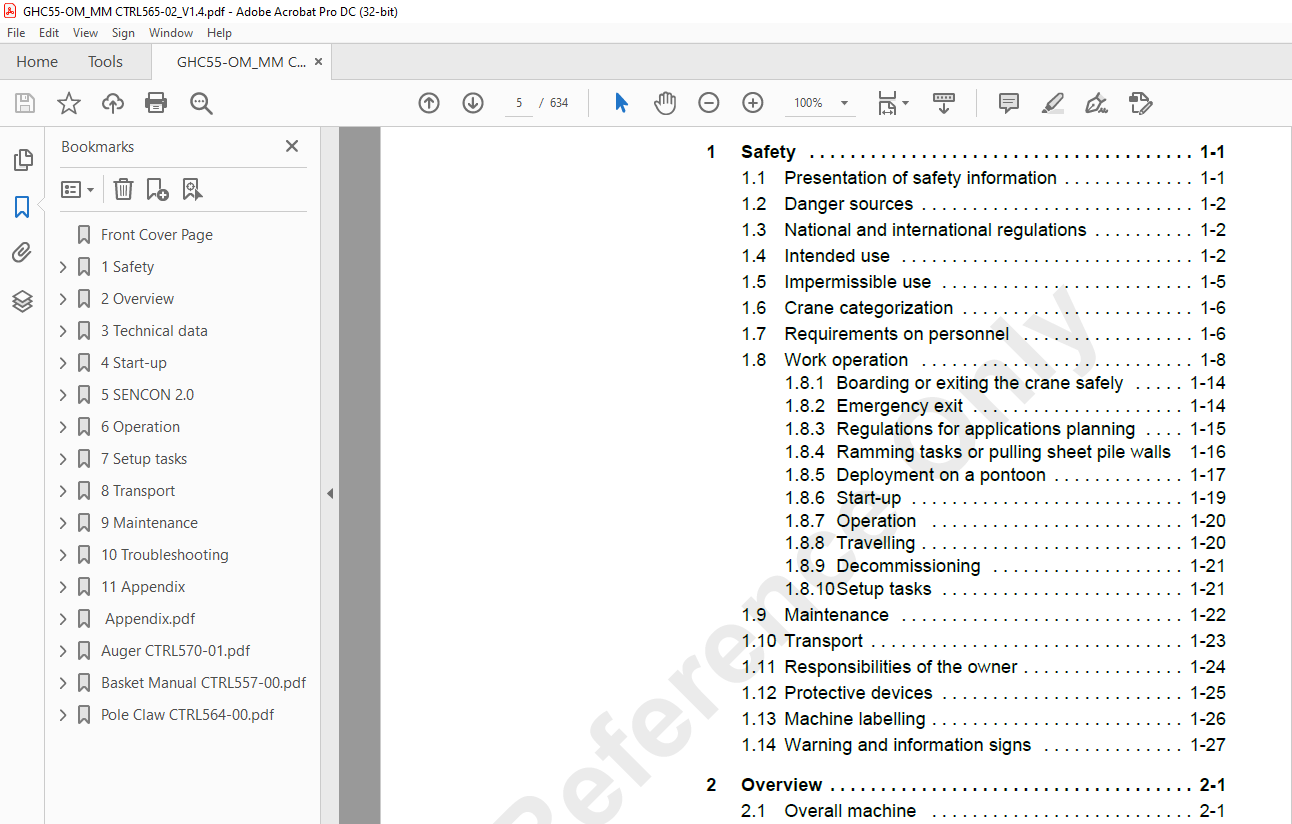

TABLE OF CONTENTS:

Manitowoc Grove GHC 55 Operating & Maintenance Manual – PDF DOWNLOAD

Front Cover Page 1

1 Safety 13

11 Presentation of safety information 13

12 Danger sources 14

13 National and international regulations 14

14 Intended use 14

15 Impermissible use 17

16 Crane categorization 18

17 Requirements on personnel 18

18 Work operation 20

181 Boarding or exiting the crane safely 26

182 Emergency exit 26

183 Regulations for applications planning 27

184 Ramming tasks or pulling sheet pile walls 28

185 Deployment on a pontoon 29

186 Start-up 31

187 Operation 32

188 Travelling 32

189 Decommissioning 33

1810 Setup tasks 33

19 Maintenance 34

110 Transport 35

111 Responsibilities of the owner 36

112 Protective devices 37

113 Machine labelling 38

114 Warning and information signs 39

2 Overview 41

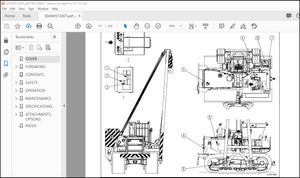

21 Overall machine 41

22 Undercarriage 42

23 Cab 43

24 Uppercarriage 44

25 Winch 46

3 Technical data 49

31 Basic machine 49

32 Permissible ground pressure 52

33 Diesel fuel 54

34 Engine oil 55

35 Permissible wind speeds 56

351 Procedure when reaching the limit value “wind in operation” 56

352 Procedure when reaching the limit value “wind not in operation” 56

36 Hooks 57

37 Dimensions of the basic machine 58

38 Working diagram – main boom 60

39 Weights 61

310 Working loads 61

311 Conversion factors 63

4 Start-up 65

41 Initial start-up 66

42 Checks before start-up 66

43 Switching on the battery disconnect switch 68

44 Machine start 69

441 Fastening the seat belt 70

442 Starting the engine 72

443 Selecting setup status 75

444 Bringing the machine to operating temperature 76

445 Jump start 77

45 Switching off engine 78

46 Decommissioning the machine 79

47 Preservation and storage 80

48 Starting up the machine after long-term storage 81

5 SENCON 20 83

51 Overview of controls 84

511 Quick selection icons 85

512 Menu icons 86

52 Start screen 87

521 Operating status 88

522 Telescopic boom and slew uppercarriage notification icons 90

523 Diesel engine notification and warning icons 92

524 Load moment limitation notification and warning icons 94

525 Overall machine notification and warning icons 95

526 Working diagram 97

527 Winch parameters 98

53 Load moment limitation 99

531 Entering uppercarriage inclination101

532 Entering undercarriage ballast102

533 Entering winch reeving103

534 Setting travel speed104

535 Entering track width105

536 Entering attachments and configuring setup program106

537 Entering counterweight108

54 Setting language109

55 Setting brightness110

56 Setting date and time112

57 Configuring units114

58 USB116

59 Request access116

510 Histogram117

511 Login information118

512 General information119

513 Diagnostics120

5131 Active faults engine121

5132 Active faults machine122

5133 Active faults RCL126

6 Operation127

61 Safety instructions127

62 Cab129

621 Driver seat133

622 Tilting the cab135

63 Operating elements in the cab136

631 Emergency stop switch137

632 Safety lever137

633 Assignment of the joysticks and pedals139

634 Storage compartment, right of the driver seat140

635 Control panels, right142

636 Control panel, top right144

64 Slewing ring lubrication (option)145

65 Central lubrication system (option)146

651 DEF/system for reducing nitrogen oxide (Tier 4f engines)147

652 Exhaust aftertreatment system regeneration (Tier 4f engines)149

653 Control panel – automatic air conditioning152

654 Camera system155

66 Load moment limitation (LML)156

661 LML function156

662 Audible and visual warning device statuses157

663 Operation158

664 Mode selection158

665 Bypassing the load moment limitation (LML)159

666 Operating modes table160

667 Safety components162

67 Special equipment166

671 Remote radio control (option)166

672 Diesel filter heater (option)177

673 Beacon178

68 Work implementation179

681 Crane operation180

682 Securing bottom hook block for drive mode181

683 Moving the machine183

684 Travel with suspended load186

685 Moving on inclines and ramps187

686 Slewing the uppercarriage188

687 Lifting and lowering loads194

688 Hook operation with both winches196

689 Adjusting the boom (luffing)198

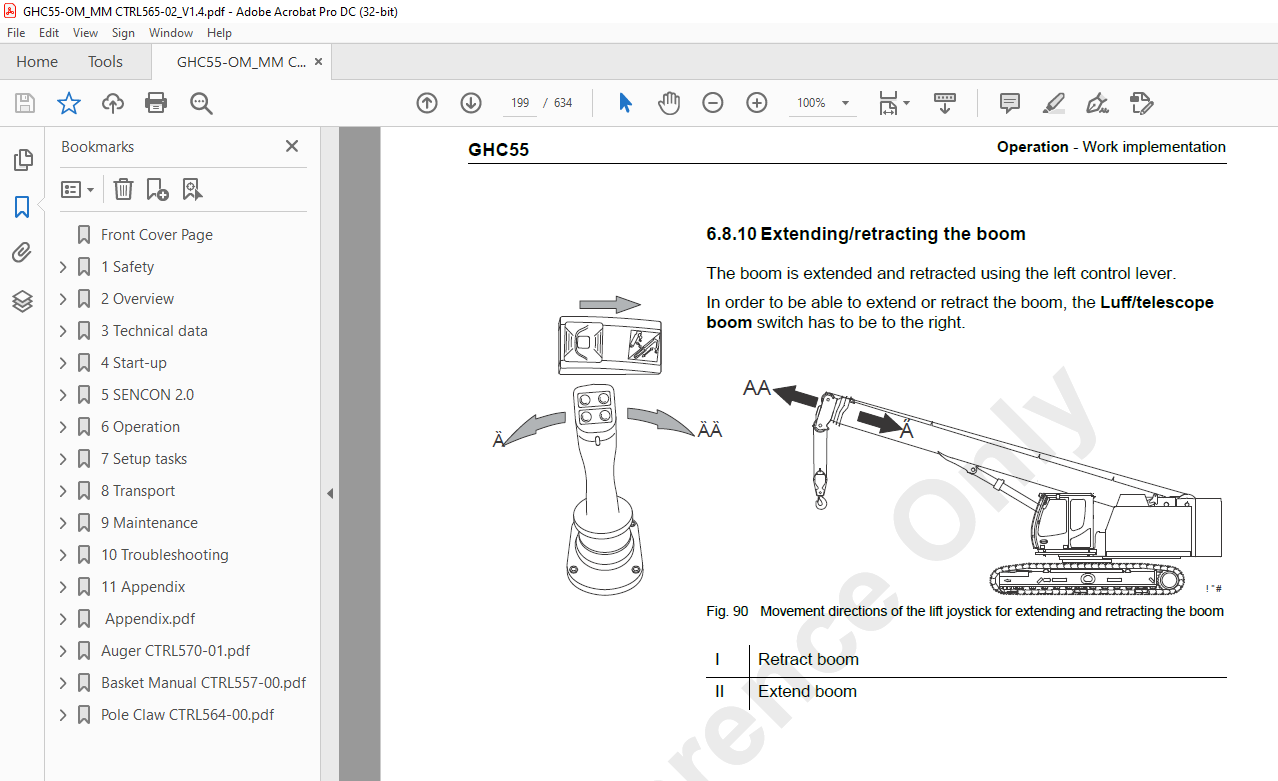

6810 Extending/retracting the boom199

6811 Turning on the supplemental hydraulic system (option)200

6812 Operating the clamping tongs (option)201

6813 Operating the soil drill (option)203

6814 Refuel the machine204

6815 Checking the DEF level and refilling (Tier 4f engines)208

7 Setup tasks211

71 Walkways212

711 Mounting/Removing212

712 Stowing214

72 Setup operating mode215

73 Changing the track width217

731 Track width markings217

732 Extending the running gear218

733 Retracting the running gear220

74 Access ladders222

75 Setting up the slewing range safeguard223

76 Connections for clamping tongs and supplemental hydraulic system on the boom head (option)225

77 Attaching clamping tongs (option)226

78 Slewing the soil drill (option) into working position227

79 Slewing the soil drill into transport position (option)228

710 Attaching the fly boom (65 m)229

711 Folding the fly boom (65 m) into working position235

712 Folding the fly boom (65 m) into transport position246

713 Folding the fly boom from 0° to 40°256

714 Folding the fly boom from 40° to 0°258

715 Attaching the fly boom extension (65 m) (option)260

716 Folding the fly boom extension (65 m) into transport position263

717 Folding the fly boom extension to working position266

718 Attaching the auxiliary jib271

8 Transport275

81 Controls for unloading the machine276

82 Switching on the battery disconnect switch277

83 Unload machine277

831 Configuring the setup program in the SENCON278

832 Moving the machine off the transport vehicle282

84 Lashing points285

85 Transport dimensions and weights286

86 Locking the uppercarriage287

87 Lifting the machine288

9 Maintenance291

91 Cleaning tasks293

92 Oils and lubricants296

921 Disposing of lubricants and operating fluids297

93 Coolant298

94 Welding303

95 Diesel engine304

951 Cummins diesel engine QSB45, Tier 4f305

952 Cummins diesel engine QSB45, Tier IIIa311

96 Combination cooler320

97 Water separator322

98 Belt drives325

99 Hydraulic system326

991 Hydraulic hose lines328

992 Depressurizing the hydraulic system329

993 Checking the oil level331

994 Changing the hydraulic oil333

995 Return filter – changing filter element336

996 Leak oil filter – changing the filter element338

997 Replacing the aeration filter339

998 Checking the pre-load of the pressure accumulator340

999 Replacing the HydroClean micro-filter element341

910 Winch343

9101 Maintaining the brake345

9102 Checking the winch gearbox oil level345

9103 Changing the winch gearbox oil346

911 Undercarriage347

9111 Cleaning and lubricating347

9112 Checking the travel drive oil level348

9113 Changing the travel drive oil349

9114 Crawler track351

9115 Spring tensioning fixture – adjusting track tension354

9116 Track rollers356

9117 Sprocket356

9118 Base plates357

912 Rotary connection358

9121 Lubricating the slewing ring bearing race359

9122 Lubricating the slewing ring gearing361

9123 Tightening the slewing ring bolts365

913 Telescopic boom367

9131 Lubricating the telescopic boom367

9132 Inspect the telescoping boom368

9133 Rope mechanism in the telescopic boom – holding lines and haulback lines369

914 Electrical system372

9141 Batteries372

9142 Fuses374

915 Automatic climate control375

9151 Cleaning the recirculating air filter375

9152 Cleaning the fresh air filter376

916 Ropes378

917 Maintenance schedule379

9171 Hydraulic oil analysis384

9172 Lubrication point overview389

9173 Fill quantities390

9174 Tightening torques for screws391

10 Troubleshooting395

101 Drive engine395

102 Hydraulic system396

103 Heating/air-conditioning system398

1031 Heat output398

1032 Cooling capacity400

1033 System very noisy402

104 Slewing gear402

105 Undercarriage403

106 Cab403

11 Appendix405

111 Reeving Diagram406

112 Handling, Installation, and Maintenance of Steel Wire Ropes409

113 Driver Seat427

114 Camera System435

115 Radio Remote Control442

116 Cleaning the Cooling System474

117 Residual Useful Life of Winches477

118 Installing Large Roller Bearings, Slewing Gears and Flange Connections485

119 PFEIFER Pouch Lock System489

1110 List of Operating Fluids and Lubricants498

1111 Operating Console509

1112 Decal Scheme537

1113 Auger585

1114 Personnel Basket601

1115 Pole Claw625

Appendixpdf405

10 Appendix409

101 Handling, Installation, and Maintenance of Steel Wire Ropes409

1011 Rope selection409

1012 How should wire ropes be unloaded?409

1013 How should wire ropes be stored?410

1014 Assembly of wire ropes410

1015 Maintenance of wire ropes415

1016 Inspection of wire ropes418

1017 Concluding remarks426

102 Driver Seat427

1021 General Instructions429

1022 Safety instructions429

1023 Connecting data430

1024 Guarantee and liability431

1025 Seat functions and operation431

1026 Maintenance434

103 Camera system435

1031 Product description435

1032 Safety Instructions436

1033 Operating and Display Elements438

1034 Commissioning439

1035 Operating Modes439

1036 Malfunctions440

1037 Maintenance441

1038 Service Information441

1039 Environmental Protection441

104 Radio Remote Control442

1041 Introduction442

1042 Safety precautions443

1043 Protection devices444

1044 Installation445

1045 Checkup before operation446

1046 Startup procedure448

1047 Operation of MFS and HL systems449

1048 Battery charger and rechargeable batteries451

1049 Battery handling453

10410 Diagnostics455

10411 Special Technical Data456

10412 Maintenance, Guarantee, Disposal457

10413 Complaint form459

10414 Abbreviations and definitions460

10415 Installation and safety test declaration460

10416 EC Declaration of Conformity462

10417 HF-Part Conformity Europe463

10418 Mounting Antennas for Feedback-Systems471

10419 Mounting instruction for directional antenna on top slewing cranes472

10420 Guarantee Conditions HETRONIC Germany GmbH472

105 Cleaning the cooling system474

1051 Safety instructions474

1052 Coolant cooler475

1053 Tips for preventive maintenance476

1054 Coolant476

1055 Charge-air cooler477

1056 Oil cooler477

106 Residual Useful Life of Winches477

1061 General steps required to ensure safe periods of operation477

1062 Periodic inspection of cranes477

1063 Steps required to monitor the winches477

107 Installing Large Roller Bearings, Slewing Gears, and Flange Connections485

1071 General485

1072 Preparatory measures485

1073 Assembly485

1074 Tightening torques for bolts487

108 PFEIFER Pouch Socket System489

1081 Preamble489

1082 Signs and symbols489

1083 Application area and intended use489

1084 General information490

1085 Installation and Assembling492

1086 Important security informations494

1087 Operation494

1088 Accessories and spare parts495

1089 Maintenance and Repair496

10810 Lifting Capacity Table497

109 Operating Fluids and Lubricants498

1091 Hydraulic system499

1092 Diesel engine500

1093 Gearbox502

1094 Lubrication504

1095 Air conditioning system507

1096 Windshield washer system508

1097 Starter batteries508

1010 Personnel Basket 0

Decal Scheme537

Table of contents541

1 ANSI signage for the Maxcab cab543

11 Overview graphics of Maxcab cab543

12 ANSI warning and safety signage for Maxcab cab544

2 ANSI signage for GHC55 undercarriage557

21 Overview graphics of GHC55 undercarriage557

22 Warning and safety signs on GHC55 undercarriage557

3 ANSI signage for GHC55 uppercarriage561

31 Overview graphics of GHC55 uppercarriage561

32 Warning and safety signs on GHC55 uppercarriage563

4 Index583

Auger CTRL570-01pdf585

TABLE OF CONTENTS587

AUGER589

Safety589

Safety Tips – Auger Equipped Cranes589

Auger system description589

Speed Shift Circuit589

Latch Circuit589

Auger System590

Auger Controls590

Auger Power Switch590

Auger Control590

Auger Latch Switch591

Auger Stow Control591

Auger Operation592

Unstow Auger592

Operating Auger593

Digging Depth593

Stowing Auger593

Machine Usage with Auger Stowed595

Travel with Auger595

Auger Specifications595

Performance595

Hydraulic System595

Inspection595

Daily595

Weekly595

Monthly595

Periodic595

Lubrication – Digger Drive Gear595

Changing the Gear Oil596

Troubleshooting596

Basket Manual CTRL557-00pdf601

TABLE OF CONTENTS603

Personnel Basket605

Safety605

General Safety Requirements605

Equipment Operator606

Ground Crew607

Platform Occupants607

Communications608

Lifting Personnel Near Power Lines609

Inspection and Testing610

Inspection610

Lift Testing613

Basket Type and Test Weights614

Yoke Basket618

Safety harnesses618

Basket Installation618

Basket Yoke to Main Boom Installation619

Basket Yoke to Jib Boom Installation619

Yoke Basket Adjustment619

Before Making the Lift620

Yoke Basket Operation620

Pole Claw CTRL564-00pdf625

TABLE OF CONTENTS627

Pole Claw629

Safety629

Description630

Pole Claw System630

Attaching the Pole Claw630

Switching on the Supplemental Hydraulic System631

Joystick Control631

Operating the Clamping Tongs631Front Cover Page 1

1 Safety 13

11 Presentation of safety information 13

12 Danger sources 14

13 National and international regulations 14

14 Intended use 14

15 Impermissible use 17

16 Crane categorization 18

17 Requirements on personnel 18

18 Work operation 20

181 Boarding or exiting the crane safely 26

182 Emergency exit 26

183 Regulations for applications planning 27

184 Ramming tasks or pulling sheet pile walls 28

185 Deployment on a pontoon 29

186 Start-up 31

187 Operation 32

188 Travelling 32

189 Decommissioning 33

1810 Setup tasks 33

19 Maintenance 34

110 Transport 35

111 Responsibilities of the owner 36

112 Protective devices 37

113 Machine labelling 38

114 Warning and information signs 39

2 Overview 41

21 Overall machine 41

22 Undercarriage 42

23 Cab 43

24 Uppercarriage 44

25 Winch 46

3 Technical data 49

31 Basic machine 49

32 Permissible ground pressure 52

33 Diesel fuel 54

34 Engine oil 55

35 Permissible wind speeds 56

351 Procedure when reaching the limit value “wind in operation” 56

352 Procedure when reaching the limit value “wind not in operation” 56

36 Hooks 57

37 Dimensions of the basic machine 58

38 Working diagram – main boom 60

39 Weights 61

310 Working loads 61

311 Conversion factors 63

4 Start-up 65

41 Initial start-up 66

42 Checks before start-up 66

43 Switching on the battery disconnect switch 68

44 Machine start 69

441 Fastening the seat belt 70

442 Starting the engine 72

443 Selecting setup status 75

444 Bringing the machine to operating temperature 76

445 Jump start 77

45 Switching off engine 78

46 Decommissioning the machine 79

47 Preservation and storage 80

48 Starting up the machine after long-term storage 81

5 SENCON 20 83

51 Overview of controls 84

511 Quick selection icons 85

512 Menu icons 86

52 Start screen 87

521 Operating status 88

522 Telescopic boom and slew uppercarriage notification icons 90

523 Diesel engine notification and warning icons 92

524 Load moment limitation notification and warning icons 94

525 Overall machine notification and warning icons 95

526 Working diagram 97

527 Winch parameters 98

53 Load moment limitation 99

531 Entering uppercarriage inclination101

532 Entering undercarriage ballast102

533 Entering winch reeving103

534 Setting travel speed104

535 Entering track width105

536 Entering attachments and configuring setup program106

537 Entering counterweight108

54 Setting language109

55 Setting brightness110

56 Setting date and time112

57 Configuring units114

58 USB116

59 Request access116

510 Histogram117

511 Login information118

512 General information119

513 Diagnostics120

5131 Active faults engine121

5132 Active faults machine122

5133 Active faults RCL126

6 Operation127

61 Safety instructions127

62 Cab129

621 Driver seat133

622 Tilting the cab135

63 Operating elements in the cab136

631 Emergency stop switch137

632 Safety lever137

633 Assignment of the joysticks and pedals139

634 Storage compartment, right of the driver seat140

635 Control panels, right142

636 Control panel, top right144

64 Slewing ring lubrication (option)145

65 Central lubrication system (option)146

651 DEF/system for reducing nitrogen oxide (Tier 4f engines)147

652 Exhaust aftertreatment system regeneration (Tier 4f engines)149

653 Control panel – automatic air conditioning152

654 Camera system155

66 Load moment limitation (LML)156

661 LML function156

662 Audible and visual warning device statuses157

663 Operation158

664 Mode selection158

665 Bypassing the load moment limitation (LML)159

666 Operating modes table160

667 Safety components162

67 Special equipment166

671 Remote radio control (option)166

672 Diesel filter heater (option)177

673 Beacon178

68 Work implementation179

681 Crane operation180

682 Securing bottom hook block for drive mode181

683 Moving the machine183

684 Travel with suspended load186

685 Moving on inclines and ramps187

686 Slewing the uppercarriage188

687 Lifting and lowering loads194

688 Hook operation with both winches196

689 Adjusting the boom (luffing)198

6810 Extending/retracting the boom199

6811 Turning on the supplemental hydraulic system (option)200

6812 Operating the clamping tongs (option)201

6813 Operating the soil drill (option)203

6814 Refuel the machine204

6815 Checking the DEF level and refilling (Tier 4f engines)208

7 Setup tasks211

71 Walkways212

711 Mounting/Removing212

712 Stowing214

72 Setup operating mode215

73 Changing the track width217

731 Track width markings217

732 Extending the running gear218

733 Retracting the running gear220

74 Access ladders222

75 Setting up the slewing range safeguard223

76 Connections for clamping tongs and supplemental hydraulic system on the boom head (option)225

77 Attaching clamping tongs (option)226

78 Slewing the soil drill (option) into working position227

79 Slewing the soil drill into transport position (option)228

710 Attaching the fly boom (65 m)229

711 Folding the fly boom (65 m) into working position235

712 Folding the fly boom (65 m) into transport position246

713 Folding the fly boom from 0° to 40°256

714 Folding the fly boom from 40° to 0°258

715 Attaching the fly boom extension (65 m) (option)260

716 Folding the fly boom extension (65 m) into transport position263

717 Folding the fly boom extension to working position266

718 Attaching the auxiliary jib271

8 Transport275

81 Controls for unloading the machine276

82 Switching on the battery disconnect switch277

83 Unload machine277

831 Configuring the setup program in the SENCON278

832 Moving the machine off the transport vehicle282

84 Lashing points285

85 Transport dimensions and weights286

86 Locking the uppercarriage287

87 Lifting the machine288

9 Maintenance291

91 Cleaning tasks293

92 Oils and lubricants296

921 Disposing of lubricants and operating fluids297

93 Coolant298

94 Welding303

95 Diesel engine304

951 Cummins diesel engine QSB45, Tier 4f305

952 Cummins diesel engine QSB45, Tier IIIa311

96 Combination cooler320

97 Water separator322

98 Belt drives325

99 Hydraulic system326

991 Hydraulic hose lines328

992 Depressurizing the hydraulic system329

993 Checking the oil level331

994 Changing the hydraulic oil333

995 Return filter – changing filter element336

996 Leak oil filter – changing the filter element338

997 Replacing the aeration filter339

998 Checking the pre-load of the pressure accumulator340

999 Replacing the HydroClean micro-filter element341

910 Winch343

9101 Maintaining the brake345

9102 Checking the winch gearbox oil level345

9103 Changing the winch gearbox oil346

911 Undercarriage347

9111 Cleaning and lubricating347

9112 Checking the travel drive oil level348

9113 Changing the travel drive oil349

9114 Crawler track351

9115 Spring tensioning fixture – adjusting track tension354

9116 Track rollers356

9117 Sprocket356

9118 Base plates357

912 Rotary connection358

9121 Lubricating the slewing ring bearing race359

9122 Lubricating the slewing ring gearing361

9123 Tightening the slewing ring bolts365

913 Telescopic boom367

9131 Lubricating the telescopic boom367

9132 Inspect the telescoping boom368

9133 Rope mechanism in the telescopic boom – holding lines and haulback lines369

914 Electrical system372

9141 Batteries372

9142 Fuses374

915 Automatic climate control375

9151 Cleaning the recirculating air filter375

9152 Cleaning the fresh air filter376

916 Ropes378

917 Maintenance schedule379

9171 Hydraulic oil analysis384

9172 Lubrication point overview389

9173 Fill quantities390

9174 Tightening torques for screws391

10 Troubleshooting395

101 Drive engine395

102 Hydraulic system396

103 Heating/air-conditioning system398

1031 Heat output398

1032 Cooling capacity400

1033 System very noisy402

104 Slewing gear402

105 Undercarriage403

106 Cab403

11 Appendix405

111 Reeving Diagram406

112 Handling, Installation, and Maintenance of Steel Wire Ropes409

113 Driver Seat427

114 Camera System435

115 Radio Remote Control442

116 Cleaning the Cooling System474

117 Residual Useful Life of Winches477

118 Installing Large Roller Bearings, Slewing Gears and Flange Connections485

119 PFEIFER Pouch Lock System489

1110 List of Operating Fluids and Lubricants498

1111 Operating Console509

1112 Decal Scheme537

1113 Auger585

1114 Personnel Basket601

1115 Pole Claw625

Appendixpdf405

10 Appendix409

101 Handling, Installation, and Maintenance of Steel Wire Ropes409

1011 Rope selection409

1012 How should wire ropes be unloaded?409

1013 How should wire ropes be stored?410

1014 Assembly of wire ropes410

1015 Maintenance of wire ropes415

1016 Inspection of wire ropes418

1017 Concluding remarks426

102 Driver Seat427

1021 General Instructions429

1022 Safety instructions429

1023 Connecting data430

1024 Guarantee and liability431

1025 Seat functions and operation431

1026 Maintenance434

103 Camera system435

1031 Product description435

1032 Safety Instructions436

1033 Operating and Display Elements438

1034 Commissioning439

1035 Operating Modes439

1036 Malfunctions440

1037 Maintenance441

1038 Service Information441

1039 Environmental Protection441

104 Radio Remote Control442

1041 Introduction442

1042 Safety precautions443

1043 Protection devices444

1044 Installation445

1045 Checkup before operation446

1046 Startup procedure448

1047 Operation of MFS and HL systems449

1048 Battery charger and rechargeable batteries451

1049 Battery handling453

10410 Diagnostics455

10411 Special Technical Data456

10412 Maintenance, Guarantee, Disposal457

10413 Complaint form459

10414 Abbreviations and definitions460

10415 Installation and safety test declaration460

10416 EC Declaration of Conformity462

10417 HF-Part Conformity Europe463

10418 Mounting Antennas for Feedback-Systems471

10419 Mounting instruction for directional antenna on top slewing cranes472

10420 Guarantee Conditions HETRONIC Germany GmbH472

105 Cleaning the cooling system474

1051 Safety instructions474

1052 Coolant cooler475

1053 Tips for preventive maintenance476

1054 Coolant476

1055 Charge-air cooler477

1056 Oil cooler477

106 Residual Useful Life of Winches477

1061 General steps required to ensure safe periods of operation477

1062 Periodic inspection of cranes477

1063 Steps required to monitor the winches477

107 Installing Large Roller Bearings, Slewing Gears, and Flange Connections485

1071 General485

1072 Preparatory measures485

1073 Assembly485

1074 Tightening torques for bolts487

108 PFEIFER Pouch Socket System489

1081 Preamble489

1082 Signs and symbols489

1083 Application area and intended use489

1084 General information490

1085 Installation and Assembling492

1086 Important security informations494

1087 Operation494

1088 Accessories and spare parts495

1089 Maintenance and Repair496

10810 Lifting Capacity Table497

109 Operating Fluids and Lubricants498

1091 Hydraulic system499

1092 Diesel engine500

1093 Gearbox502

1094 Lubrication504

1095 Air conditioning system507

1096 Windshield washer system508

1097 Starter batteries508

1010 Personnel Basket 0

Decal Scheme537

Table of contents541

1 ANSI signage for the Maxcab cab543

11 Overview graphics of Maxcab cab543

12 ANSI warning and safety signage for Maxcab cab544

2 ANSI signage for GHC55 undercarriage557

21 Overview graphics of GHC55 undercarriage557

22 Warning and safety signs on GHC55 undercarriage557

3 ANSI signage for GHC55 uppercarriage561

31 Overview graphics of GHC55 uppercarriage561

32 Warning and safety signs on GHC55 uppercarriage563

4 Index583

Auger CTRL570-01pdf585

TABLE OF CONTENTS587

AUGER589

Safety589

Safety Tips – Auger Equipped Cranes589

Auger system description589

Speed Shift Circuit589

Latch Circuit589

Auger System590

Auger Controls590

Auger Power Switch590

Auger Control590

Auger Latch Switch591

Auger Stow Control591

Auger Operation592

Unstow Auger592

Operating Auger593

Digging Depth593

Stowing Auger593

Machine Usage with Auger Stowed595

Travel with Auger595

Auger Specifications595

Performance595

Hydraulic System595

Inspection595

Daily595

Weekly595

Monthly595

Periodic595

Lubrication – Digger Drive Gear595

Changing the Gear Oil596

Troubleshooting596

Basket Manual CTRL557-00pdf601

TABLE OF CONTENTS603

Personnel Basket605

Safety605

General Safety Requirements605

Equipment Operator606

Ground Crew607

Platform Occupants607

Communications608

Lifting Personnel Near Power Lines609

Inspection and Testing610

Inspection610

Lift Testing613

Basket Type and Test Weights614

Yoke Basket618

Safety harnesses618

Basket Installation618

Basket Yoke to Main Boom Installation619

Basket Yoke to Jib Boom Installation619

Yoke Basket Adjustment619

Before Making the Lift620

Yoke Basket Operation620

Pole Claw CTRL564-00pdf625

TABLE OF CONTENTS627

Pole Claw629

Safety629

Description630

Pole Claw System630

Attaching the Pole Claw630

Switching on the Supplemental Hydraulic System631

Joystick Control631

Operating the Clamping Tongs631

IMAGES PREVIEW OF THE MANUAL: