$38

Manitowoc Grove GHC130 Maintenance Manual - PDF DOWNLOAD

Manitowoc Grove GHC130 Maintenance Manual - PDF DOWNLOAD

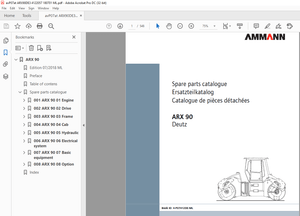

FILE DETAILS:

Manitowoc Grove GHC130 Maintenance Manual - PDF DOWNLOAD

Language : English

Pages :324

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Manitowoc Grove GHC130 Maintenance Manual - PDF DOWNLOAD

Front Cover 1

1 Safety 7

11 Presentation of safety information 7

12 Danger sources 8

13 National and international regulations 8

14 General safety instructions 9

2 Maintenance schedule, lubrication schedule 13

21 Maintenance schedule 13

211 Hydraulic oil analysis 18

22 Lubrication points 23

23 Fill quantities 25

3 General instructions 27

31 Oils and lubricants 30

311 Disposal of lubricants and operating fluids 31

32 Coolant – drive engine 32

321 Coolant – general 32

33 Welding 34

4 Diesel engine 37

41 Engine oil 37

42 Air filter 40

421 Combination cooler 44

422 Diesel prefilter 46

423 Diesel fine filter 49

424 Air intake system 49

425 Belt drives 49

5 Hydraulic system 51

51 Hydraulic hose lines 53

52 Checking the oil level 54

53 Changing the hydraulic oil 55

54 Changing the return filter element 58

55 Replacing the leak oil filter element 59

56 Replacing the aeration filter 61

57 Replacing the HydroClean micro-filter element 62

58 Checking the pre-load of the pressure accumulator 64

59 Checking and cleaning the hydraulic oil cooler 65

6 Crane winch 67

61 General maintenance instructions 67

62 Checking the winch gearbox oil level 69

63 Changing the winch gearbox oil 69

64 Maintaining the brake 70

7 Undercarriage 71

71 Cleaning the frame and track frames 71

72 Maintaining the crawler track 72

721 Spring tensioning fixture - adjusting track tension 73

722 Checking the tightening torque of base plate bolts 75

723 Checking the travel drive oil level 76

724 Changing the travel drive oil 77

8 Rotary connection 79

81 Lubricating the slewing ring raceway manually 80

82 Lubricating the slewing ring gearing 81

821 Gear spray 81

822 Slewing ring lubrication 82

823 Tightening the slewing ring bolts 84

9 Telescopic boom 87

91 Lubricating the telescopic boom 87

92 Inspection of the telescopic boom 88

10 Ballast elements - checking the safety chains 89

11 Automatic climate control 91

111 Cleaning the recirculating air filter 91

112 Cleaning the fresh air filter 93

12 Electrical system 95

121 Servicing battery connections 95

13 Structural steelwork and static load-bearing parts 97

1301 Checking static load-bearing parts and steel components for damage 98

14 Appendix 99

141 Handling, Installation, and Maintenance of Steel Wire Ropes101

142 Driver Seat137

143 Camera System181

144 Radio Remote Control191

145 Cleaning the Cooling System243

146 Winch Life251

147 Install Large Roller Bearings, Slew Gears and Flange Connections261

148 PFEIFER Pouch Socket System269

149 Operating Fluids and Lubricants285

1410 Personnel Basket301

143 Camera Systempdf181

BA-MD3072B_gb181

letzte Seite190

145 Cleaning the Cooling Systempdf243

Cleaning the cooling system244

Safety instructions244

Coolant cooler246

External cleaning246

Internal cleaning247

Tips for preventive maintenance248

Coolant248

Charge-air cooler249

External cleaning249

Oil cooler249

External cleaning249

Internal cleaning249

149 Operating Fluids and Lubricantpdf285

Table of contents288

1 Hydraulic system289

11 Hydraulic oil289

2 Diesel engine290

21 Diesel engine oil290

211 Cummins diesel engine290

2111 Emissions levels Tier 2 and Tier 3290

2112 Emissions levels Tier 4 Interim and Tier 4 Final291

22 Coolant291

23 Fuel291

24 Diesel flow improvers292

25 Diesel exhaust fluid for Tier 4 Final diesel engines292

3 Gearbox293

31 Slewing gear GHC75293

311 Gear oil293

32 Winch gear293

321 Gear oil293

322 Grease lubricating points294

33 Crawler travel drive294

331 Gear oil294

4 Lubrication295

41 Grease - slewing ring roller bearings295

42 Grease - slewing ring, outer gearing295

43 Grease - manual lubricating points296

44 Grease - undercarriage, telescoping296

45 Grease - telescopic boom297

46 Lubricants - wire ropes297

5 Air conditioning system298

51 Refrigerant298

52 Refrigerant oil298

6 Windshield washer system299

61 Antifreeze299

7 Starter batteries300

71 Battery terminal grease300

72 Battery terminal spray300

1410 Personnel Basketpdf301

TABLE OF CONTENTS303

Personnel Basket305

Safety305

General Safety Requirements305

Equipment Operator306

Ground Crew307

Platform Occupants307

Communications308

Lifting Personnel Near Power Lines309

Inspection and Testing310

Inspection310

Lift Testing313

Basket Type and Test Weights314

Yoke Basket318

Safety harnesses318

Basket Installation318

Basket Yoke to Main Boom Installation319

Basket Yoke to Jib Boom Installation319

Yoke Basket Adjustment319

Before Making the Lift320

Yoke Basket Operation320

IMAGES PREVIEW OF THE MANUAL: