$37

Manitowoc Grove GRT655/GRT655L Operator Manual – PDF DOWNLOAD

Manitowoc Grove GRT655/GRT655L Operator Manual – PDF DOWNLOAD

FILE DETAILS:

Manitowoc Grove GRT655/GRT655L Operator Manual – PDF DOWNLOAD

Language : English

Pages : 268

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Manitowoc Grove GRT655/GRT655L Operator Manual – PDF DOWNLOAD

SECTION 1 Introduction

General 1-1

Customer Support 1-1

New Owners 1-1

Noise/vibration Test results 1-1

Noise Level Test Results 1-1

Vibration Level Test Results 1-2

Serial Number Location 1-2

List Of Specifications 1-4

General 1-4

Dimensions 1-4

Capacities 1-4

Torque Converter 1-4

Transmission 1-4

Engine 1-4

Cummins QSB 6 7 – Tier 4F 1-4

Cummins QSB 6 7 – Tier 3 1-4

Axles 1-4

Brakes 1-4

Wheels and Tires 1-4

Swing Gearbox 1-4

Boom 1-4

Swivel Assembly 1-4

Hydraulic Pumps 1-5

Pump #1 1-5

Pump #2 1-5

Pump #3 1-5

Hoists 1-5

SECTION 2 Safety Information

Safety Messages 2-2

General 2-2

Safety Alert Symbol 2-2

Signal Words 2-2

General 2-2

Safety Decals 2-2

Accidents 2-2

Operator Information 2-3

Operator Qualifications 2-3

Operational Aids 2-4

Rated Capacity Limiter (RCL) Systems 2-4

Anti-Two-Blocking Device 2-5

Working Area Limiter (If Equipped) 2-5

Crane Stability/Structural Strength 2-6

Load Charts 2-7

Work Site 2-7

Wind Forces 2-7

Wind Speeds 2-8

Determination of 3-second wind gust speed at boom tip height: 2-10

Size and Shape of the load: 2-10

Determining Wind Drag Coefficient (Cd) 2-11

Maximum Permissible Wind Speed 2-12

Example and Sample Calculations (Non-metric) 2-18

Lifting Operations 2-20

Counterweight 2-21

Outrigger Lift Off 2-21

Multiple Crane Lifts 2-21

Tilt-Up Panel Lifting 2-21

Pile Driving and Extracting 2-22

Crane Equipment 2-22

Crane Inspection 2-22

Electrocution Hazard 2-23

Set-Up and Operation 2-24

Electrocution Hazard Devices 2-24

Electrical Contact 2-25

Special Operating Conditions and Equipment 2-25

Grounding the Crane 2-25

Personnel Handling 2-26

Environmental Protection 2-27

Maintenance 2-27

Service and Repairs 2-27

Lubrication 2-28

Tires 2-29

Hoist Rope 2-29

Synthetic Hoist Rope 2-29

Wire Rope 2-29

Sheaves 2-30

Batteries 2-31

Super Capacitor (If Equipped) 2-31

General Maintenance 2-31

Transporting the Crane 2-32

Travel Operation 2-32

Work Practices 2-33

Personal Considerations 2-33

Crane Access 2-33

Job Preparation 2-33

Working 2-34

Lifting 2-35

Hand Signals 2-36

Boom Extension 2-38

Parking and Securing 2-38

Shut-Down 2-38

Cold Weather Operation 2-38

Temperature Effects on Hook Blocks 2-39

Temperature Effects on Hydraulic Cylinders 2-39

Model Specific Information 2-41

Crane Stability 2-41

Hoist Platform 2-41

Overload Inspection 2-41

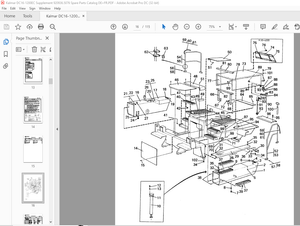

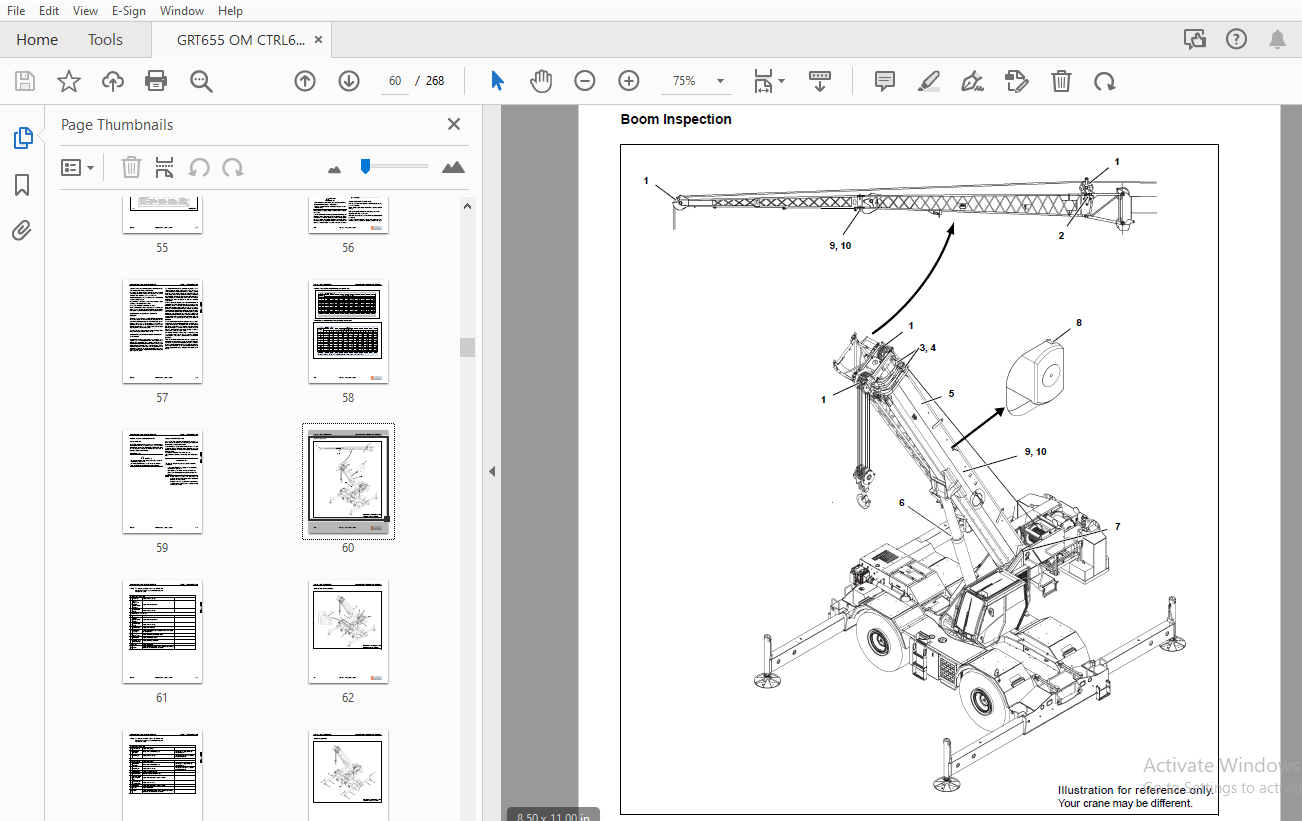

Boom Inspection 2-42

Superstructure Inspection 2-44

Carrier Inspection 2-46

SECTION 3 Operating Controls and Indicators

Controls and Indicators 3-3

Steering Column 3-3

Turn Signal Lever and Windshield Wiper/Washer/Headlight/Horn Controls 3-3

Steering Column Tilt and Telescope Lever 3-4

Park Brake Control Switch 3-4

Headlights Switch 3-4

Drive Axle Selector Switch 3-4

Hazard Lights Switch 3-4

Engine Speed Increment/Decrement Switch 3-4

Ignition Switch 3-4

Transmission Shift Lever 3-5

Cab Overhead Controls 3-5

Skylight Window Latch (Non-CE Certified Cranes) 3-5

Skylight Wiper and Wiper Motor 3-5

Dome Light 3-5

Skylight Sunscreen 3-6

Cab Circulating Fan 3-6

Right Side Window Latch 3-6

Overhead Control Panel 3-6

Skylight Wiper Switch 3-6

Heater/Air Conditioner Fan Speed Switch 3-6

Heater/Air Conditioner Temperature Control Switch 3-6

Heater/Air Conditioner Switch 3-6

Fresh Air/Recirculation Air Switch 3-6

Cab Mounted Work Lights Switch 3-6

Boom Mounted Work Lights Switch (Optional) 3-6

Crane Function Enable/Disable Switch 3-6

Exhaust System Cleaning Switch

(Tier 4 Engine Only) 3-7

Inhibit Exhaust System Cleaning 3-7

Operator Display Module and Rated Capacity Limiter Display Module 3-8

Rated Capacity Limiter Display Module (RDM) 3-8

Operator Display Module (ODM) 3-8

Navigation Control Pad 3-8

USB Connector 3-9

RCL Shutdown Warning Indicator (Non-CE Certified Cranes) 3-9

RCL Shutdown Warning Indicator (CE Certified Cranes) 3-9

RCL Early Warning Indicator 3-10

Anti Two-Block Indicator 3-10

Swing Brake Engaged Indicator 3-10

Brightness Sensor 3-10

Control Seat Assembly 3-11

Boom Lift/Main Hoist Controller (Dual Axis) 3-12

Swing/Telescope or Swing/Auxiliary Hoist Controller (Dual Axis) 3-12

Main Hoist Enable/Disable Switch 3-12

Boom Up Bypass Switch 3-12

Boom Lift Enable/Disable Switch 3-12

Jog Dial 3-12

Outrigger Extend/Retract Switch 3-12

Differential Lock On/Off Switch (Optional) 3-13

Rear Steer Switch 3-13

Auxiliary Hoist Enable/Disable Switch 3-13

Boom Telescope Enable/Disable Switch 3-13

Cab Tilt Switch 3-13

Swing Enable/Disable Switch 3-13

Seat Slide Lever 3-14

Air Conditioner/Heater Climate Unit 3-14

Seat Frame Slide Lever 3-14

Armrest Adjustment Buttons 3-14

Seat Height Adjustment Lever 3-14

Front Limit Bypass Switch (Non-CE Certified Cranes) 3-14

Limit Bypass Set-Up Switch (CE Certified Cranes) 3-15

Emergency Stop Switch 3-15

Level Indicator 3-16

Deadman Switches (Optional) (Dual Axis Controllers only) 3-16

Hoist Speed Toggle Switches 3-16

Horn Button 3-16

Free Swing Button 3-16

Cab Door Release Lever 3-16

Hoist Rotation Indicators (Not Shown) 3-16

Seat Switch (Not Shown) 3-16

Main Hoist Controller (Single Axis Option) 3-16

Boom Lift Controller (Single Axis Option) 3-16

Telescope or Auxiliary Hoist Controller (Single Axis Option) 3-18

Swing Controller (Single Axis Option) 3-18

Hoist Rotation Indicators (Not Shown) 3-18

Foot Pedal Controls 3-18

360° Swing Lock Pedal 3-18

360° Swing Lock Release Lever 3-18

Swing Brake Pedal 3-18

Telescope Control Pedal 3-18

Service Brake Pedal 3-18

Foot Throttle Pedal 3-18

Miscellaneous Controls and Indicators 3-19

Fuse and Relay Panels 3-19

Buzzer 3-19

Rear Limit Bypass Switch (Non-CE Certified Cranes) 3-19

Bridging Switch and Indicator (CE Certified Cranes) 3-20

RCL Internal Light Bar (Optional) 3-20

RCL External Light Tower (Optional) 3-21

Strobe Light or Beacon (Optional) 3-21

Backup Alarm (Not Shown) 3-21

Emergency Exit 3-21

Turntable Swing Pin Lock Control 3-21

120V/220V Engine Block Heater and Outlet 3-22

Birdseye Camera (Optional) 3-22

SECTION 4 Operating Procedures

Pre-Starting Checks 4-3

Fuel Supply 4-3

Engine Oil 4-3

Engine Coolant 4-3

Batteries 4-3

Hydraulic Reservoir and Filter 4-3

Hoist Rope 4-3

Hook Block and Overhaul Ball 4-3

Seats and Mirrors 4-3

Seat Belts 4-3

Seat Belt Maintenance 4-3

Cleaning Seat Belt Webbing 4-3

Signal and Running Lights 4-3

Service and Parking Brakes 4-3

Tires 4-3

Wheels 4-3

Axle Oscillation Lock Outs Operation 4-3

Accessories 4-4

Daily Lubrication 4-4

Boom 4-4

Air Cleaner 4-4

Air Intake Restriction Monitoring (AIRM) Communications System (Tier 4 Only) 4-4

Preload Check 4-4

Using Your Load Chart 4-5

Engine Operation 4-6

Start-Up Procedure 4-6

Idling Engine 4-7

Engine High Idle 4-7

Racing Engine 4-7

Exhaust System Cleaning 4-7

When to Manually Clean the Exhaust System 4-7

Initiating the Manual Exhaust Cleaning Process 4-7

Inhibiting the Exhaust System Cleaning 4-8

Shutdown Procedure 4-8

Battery Disconnect 4-8

Cold Weather Operation 4-8

Component Coolant Heater 4-9

Radiator Shutters 4-9

Auxiliary Cab Heater 4-9

Battery Heater 4-10

Air Diverter 4-10

Super Capacitor 4-10

Diesel Fuel 4-10

Operation Below -40°C (-40°F) 4-11

Crane Warm-up Procedures 4-11

Engine 4-11

Transmission 4-11

Hoist 4-11

Swing Drive and Turntable Bearing 4-12

Axles 4-12

Hydraulic Oil System 4-12

Driving the Crane 4-12

Seat Belts 4-12

Traveling — General 4-13

Traveling — Towing/Pulling 4-13

Traveling — Being Towed/Pulled 4-14

Traveling on Slopes 4-14

General Conditions 4-14

Slope Limitations – Fore/Aft Travel: 4-15

Slope Limitations – Side Slope Travel: 4-15

Traveling with Elevated Boom 4-17

Traveling with Boom Extension Erected 4-17

Extended Travel 4-17

Traveling — Forward 4-18

Traveling — Reverse 4-18

Steering 4-18

Front Wheel Steering 4-18

Rear Wheel Steering 4-18

Four Wheel Steering 4-19

Crab Steering 4-19

Four-Wheel Drive Operation 4-19

Differential Lock Operation (Optional) 4-19

General 4-19

Operation 4-20

Craning Functions 4-20

Controller Operation 4-20

Proper Crane Leveling 4-20

Bubble Level Indicator Adjustment 4-20

TABLE OF CONTENTS GRT655/655L

Using the Outriggers 4-21

Setting the Outriggers 4-21

Outrigger Monitoring System (OMS) (Optional—Standard in North America

and European Union Countries) 4-22

Engaging the Outrigger Mid-Extend Lock Pin 4-22

Stowing the Outriggers 4-22

Stowing the Outrigger Mid-Extend Lock Pin 4-23

Swinging the Boom and Superstructure 4-24

Elevating and Lowering the Boom 4-24

Elevating the Boom 4-24

Lowering the Boom 4-25

Telescoping the Boom 4-25

Extending the Boom 4-25

Retracting the Boom 4-26

Lowering and Raising the Main Hoist Rope 4-26

Lowering the Main Hoist Rope 4-26

Raising the Main Hoist Rope 4-27

Lowering and Raising the Auxiliary Hoist Rope 4-27

Lowering the Auxiliary Hoist Rope 4-27

Raising the Auxiliary Hoist Rope 4-28

Selecting the Hoist Speed Range 4-28

Stowing and Parking 4-29

Leaving Crane Unattended 4-29

Navigating the Operator Display Module and Rated Capacity Limiter Display

Module 4-30

Using the Operator Display Module (ODM) 4-31

Main Screen 4-31

Status Area 4-35

Alerts Area 4-39

Status Bar 4-45

Active Screen Indicator Area 4-48

Menu Screen 4-49

Outrigger Group 4-51

Accessing the Outrigger Extend/Retract Function Screen 4-51

Extending/Retracting the Outrigger Beams 4-52

Extending/Retracting the Outrigger Jacks – Individually 4-53

Extending/Retracting the Outrigger Jacks – x4 4-54

Exiting the Outrigger Extend/Retract Function Screen 4-55

Camera Group (Optional) 4-55

Selecting a Camera View 4-56

Exiting the Camera View Screen 4-57

Working Range Limiter Group 4-57

Introduction 4-57

WRL Limitations Overview 4-58

Accessing a WRL Limitation Screen 4-63

Setting the Boom Height Limitation 4-64

Setting the Boom Angle Limitation 4-67

Setting the Radius Limitation 4-70

Setting the Swing Angle Limitation 4-73

Setting a Virtual Wall Limitation 4-76

Tools Group 4-79

Accessing a Tools Group Function Screen 4-80

Exiting a Tools Group Function Screen 4-80

Setting the Display Screen Brightness 4-80

Setting the Units of Measure 4-80

Setting the Controller Sensitivity 4-81

Setting the Controller Function Speed 4-83

Setting ECO Mode to On/Off 4-84

Information Group 4-85

Accessing an Information Group Function Screen 4-86

Exiting an Information Group Function Screen 4-86

Viewing the Operating Hours 4-87

Viewing the Engine Fault Codes 4-88

Viewing the Crane Fault Codes 4-89

Viewing the Software Revisions 4-89

Viewing the Legal Notice 4-89

Using the Rated Capacity Limiter Display Module (RDM) 4-89

Entering a Code Number Manually 4-92

Using the Setup Wizard 4-94

Overriding the Outrigger Monitoring System (only for Cranes in North America

and European Union Countries) 4-99

Limit Bypass Indicators 4-100

Enabling/Disabling the Rear View Camera 4-101

Using the Birdseye Camera (Optional) 4-103

SECTION 5 Set-Up and Installation

Setup of Crane Before and After Transporting 5-2

Hoist Platform 5-6

Installing Cable on the Hoist 5-6

Anti Two-Block (A2B) Switch 5-6

Locking 5-6

Unlocking 5-7

Checking Before Operation 5-7

Cranes with Main Hoist Only 5-7

Cranes with Main and Auxiliary Hoists 5-7

Hoist Rope Reeving 5-8

Reeving Hoist Rope Over the Boom 5-9

Dead-End Rigging/Wedge Sockets 5-9

Installing Wedge and Socket 5-10

Erecting and Stowing the Boom Extension 5-20

Description 5-20

General Warnings 5-20

Securing the Boom Extension with a Tag Line (Rope) 5-20

Erecting 5-25

Stowing 5-28

Setting the Offset 5-32

Extending and Stowing the Telescoping Boom Extension Fly Section 5-33

Extending 5-33

Retracting 5-33

SECTION 6 Lubrication and Maintenance

General 6-1

Environmental Protection 6-1

Lubricants and Lubrication Intervals 6-1

Standard Lubricants 6-2

Arctic Lubricants and Conditions 6-4

Temperatures Below -9°C (15°F) 6-4

Cold Weather Package and Lubricants 6-4

Cylinder Rod Surface Protection 6-7

Wire Rope Lubrication 6-7

Lubrication Points 6-7

CraneLUBE 6-8

Cummins Oil Registration List 6-8

Safety 6-8

Drive Train 6-10

Drive Train (Continued) 6-11

Drive Train (Continued) 6-14

Drive Train (Continued) 6-15

Steering and Suspension 6-16

Steering and Suspension (Continued) 6-17

Axles 6-18

Turntable 6-19

Turntable (Continued) 6-20

Cab Tilt 6-20

Outriggers 6-21

Boom 6-22

Boom (Continued) 6-23

Boom (Continued) 6-25

Hoist 6-27

Hydraulic 6-29

Rust Protection 6-30

Cleaning Procedures 6-30

Inspection and Repair 6-31

Application 6-31

Areas of Application 6-31

SECTION 7 Alphabetical Index