$38

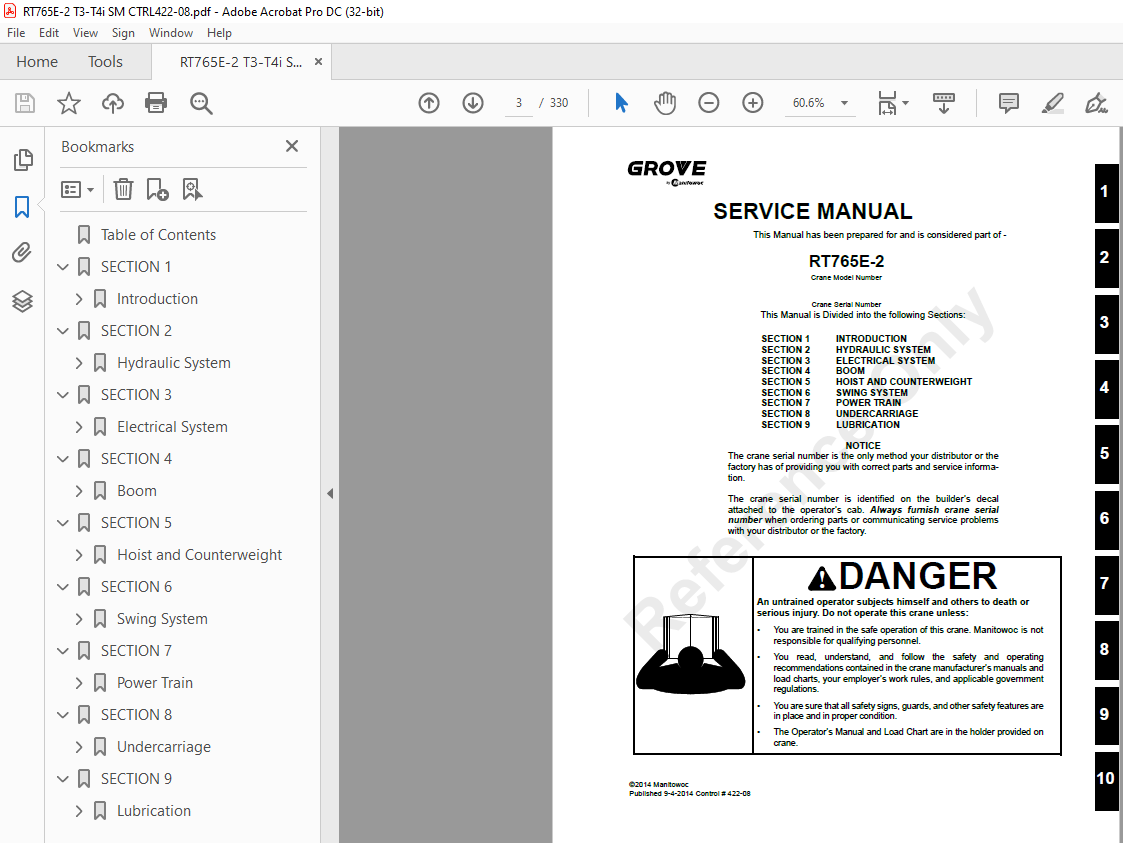

Manitowoc Grove RT765E-2 Service Manual – PDF DOWNLOAD

Manitowoc Grove RT765E-2 Service Manual – PDF DOWNLOAD

FILE DETAILS:

Manitowoc Grove RT765E-2 Service Manual – PDF DOWNLOAD

Language : English

Pages :330

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Manitowoc Grove RT765E-2 Service Manual – PDF DOWNLOAD

Table of Contents 5

SECTION 1 13

Introduction 13

General 13

Overview of Manuals 13

Customer Support 14

General Crane Design 14

Specific Crane Description 14

Lifting Capacities (Load Chart) 14

Basic Components 14

Axle Weight Distribution 14

Serial Number Location 14

Transportation and Lifting Data 14

List Of Specifications 15

General 15

Dimensions 15

Capacities 15

Torque Converter 15

Transmission 15

Engine 15

Cummins QSB 67 15

Axles 15

Brakes 15

Wheels and Tires 15

Swing Gearbox 15

Boom 15

Swivel Assembly 15

Hydraulic Pumps 15

Pump #1 15

Pump #2 15

Pump #3 15

Hoists 16

Crane Nomenclature 19

General Maintenance 21

Cleanliness 21

After Cleaning 21

Removal and Installation 21

Disassembly and Assembly 21

Pressing Parts 22

Locking Devices 22

Wires and Cables 22

Shims 22

Hoses and Tubes 22

Inspection 22

Installation 23

Bearings 23

Antifriction Bearings 23

Double Row, Tapered Roller 23

Heating Bearings 23

Installation 23

Preload 23

Sleeve Bearings 23

Gaskets 23

Batteries 23

Hydraulic Systems 24

Cleanliness 24

Keep the System Clean 24

Sealing Elements 24

Hydraulic Lines 24

Visual Inspection of Hoses and Fittings 24

Hydraulic Fittings 25

Flats from Finger Tight (FFFT) Method 25

37° Flared Steel Fitting: Tube or Hose to Fitting 25

Adjustable Straight Thread O-ring Fittings 25

Nonadjustable Straight Thread O-ring Fitting: Fitting to Port 26

Electrical System 26

Harnesses, Wires, and Connectors 26

Fatigue of Welded Structures 27

Loctite® 27

Application of Medium Strength Loctite® 27

Primer Application 27

Adhesive/Sealant Application 27

Fasteners and Torque Values 28

Torque Wrenches 28

Torque Values 28

Weld Studs 31

Wire Rope 32

General 32

Environmental Conditions 32

Dynamic Shock Loads 32

Lubrication 32

Precautions and Recommendations During Inspection or Replacement 32

Wire Rope Inspection (Running Ropes and Pendant Cables) 33

Keeping Records 33

Frequent Inspection 33

Periodic Inspection 34

Wire Rope Inspection (Boom Extension and Retraction Cables) 34

Periodic Inspection 34

Wire Rope Inspection/Replacement (All Wire Rope) 34

Seizing Wire Rope 35

Method 1 35

Method 2 35

Installing 35×7 Class Wire Rope 36

Procedures for Cutting and Preparing 35×7 Class Wire Rope 36

SECTION 2 39

Hydraulic System 39

Description 40

Hydraulic Symbols 41

Maintenance 43

Preparation 43

Hydraulic System Maintenance Precautions 43

Label Parts When Disassembling 43

Hydraulic Oil Recommendations 43

Draining And Flushing 43

Removing Air From The Hydraulic System 44

Parts Replacement 45

Directional Control Valves 45

Inspection 45

Valve Leakage 45

Binding Spools 45

Visual Inspection of Hoses and Fittings 46

Supply Pressure And Return Circuit 47

Description 47

Hydraulic Reservoir And Filter 47

Pump Distribution 48

No 1 Pump 48

No 2 Pump 48

No 3 Pump 48

Troubleshooting 48

Symptoms and Solutions 48

Troubleshooting Aids 50

Troubleshooting Procedures 50

Hydraulic Oil Return Filter Assembly 51

Element Removal 51

Element Installation 51

Fill Cap/Breather 51

Removal and Replacement 51

Oil Cooler 53

Description 53

Oil Temperature Switches 53

Hydraulic Pumps 55

Description 55

Pump No 1 55

Pump No 2 55

Pump No 3 55

Maintenance 55

No 1 Pump Removal 55

No 1 Pump Installation 55

No 1 Pump and Pump Disconnect Assembly Removal (Optional) 55

No 1 Pump and Pump Disconnect Assembly Installation (Optional) 56

No 2 Pump Removal 56

No 2 Pump Installation 56

No 3 Pump Removal 57

No 3 Pump Installation 57

Testing After Repair or Replacement 57

Pump Disconnect Assembly 59

Disassembly 59

Assembly 59

Pressure Setting Procedures 61

Procedure A – Main Control Valve Reliefs 62

Procedure B – Main Directional Control Valve Pilot Supply Pressure 63

Procedure C – Swing Brake Pilot Supply Pressure 63

Procedure D – Brake Charge Supply Valve Relief Pressure 63

Procedure E – Charge Air Cooler Valve Relief Pressure 64

Procedure F – Brake Dual Accumulator Charge Valve Pressure Limits 64

Procedure G – Accumulator Pre-Charge Pressure 64

Procedure H – PreCharging The Accumulator 65

Procedure I – Swing Valve Work Port Reliefs Pressure 65

Procedure J – Front Steer Relief Valve Pressure 66

Procedure K – Outrigger/Rear Steer Valve Relief 66

Procedure L – Hydraulic Oil Cooler Fan Motor Control Valve 66

Procedure M – Counterweight Removal Valve 67

Valves 68

General 68

Directional Control Valves 71

Description 71

Lift/Telescope/Hoist Directional Valve 71

Swing/Steer Directional Valve 71

Counterweight Removal Directional Valve (Optional) 71

Maintenance 71

Swing/Steer Directional Valve Removal 71

Swing/Steer Directional Valve Installation 71

Hoist/Lift/Telescope Directional Valve Removal 71

Hoist/Lift/Telescope Directional Valve Installation 71

Counterweight Removal Directional Valve Removal 71

Counterweight Removal Directional Valve Installation 71

Functional Check (All Directional Valves) 71

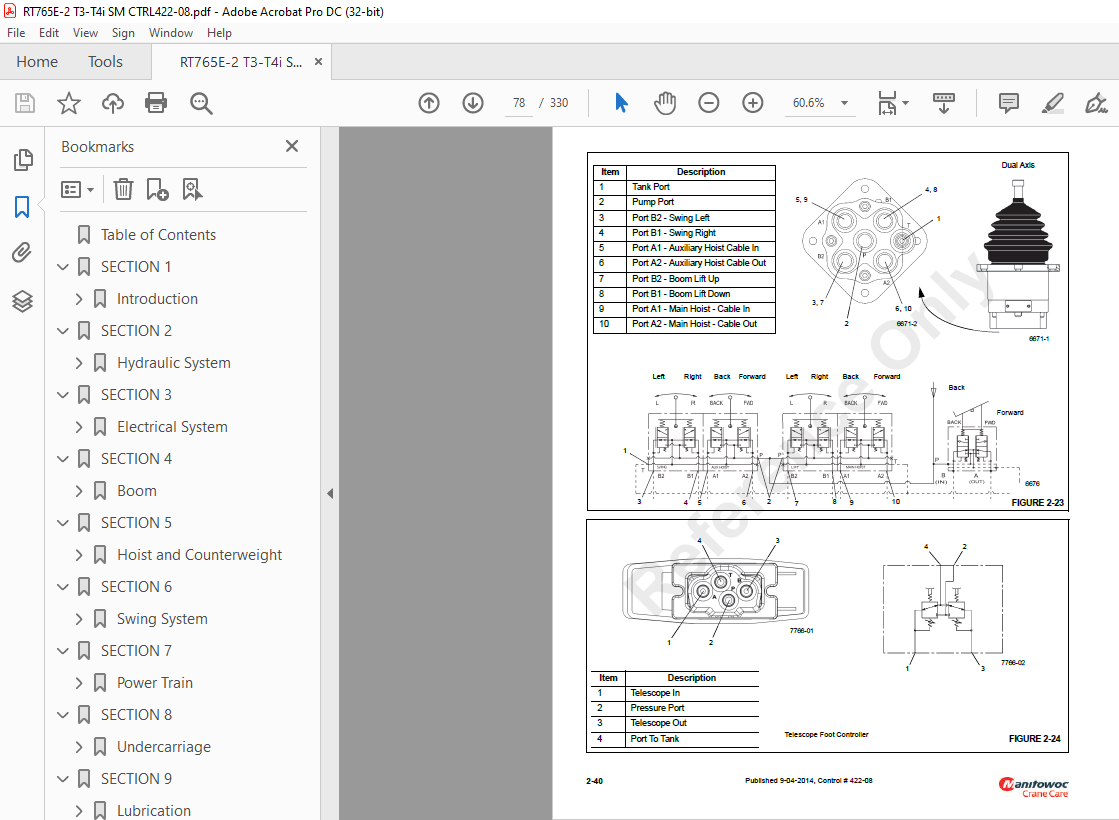

Hydraulic Remote Control Valve 76

Description 76

Dual Axis Controllers (CE Units) 76

Maintenance 76

Armrest Control Valve Removal 76

Armrest Control Valve Installation 76

Armrest Control Valve Functional Check 76

Telescope Pedal Control Valve Removal (With Auxiliary Hoist Option) 76

Telescope Pedal Control Valve Installation (With Auxiliary Hoist Option) 76

Telescope Pedal Control Valve Functional Check (With Auxiliary Hoist Option) 76

Dual Accumulator Charge Valve 79

Description 79

Maintenance 79

Removal 79

Installation 79

Swing Brake And Armrest Lockout Valve Manifold 81

Description 81

Maintenance 81

Removal 81

Installation 81

Function Check – Swing Brake Release Valve 81

Function Check – Crane Function Valve 81

Inlet Filter Screen Replacement 81

Holding Valve 83

Description 83

Maintenance 83

Removal 83

Installation 83

Test the holding valve and port block or manifold by operating the lift cylinder and/or the telescope cylinder, as applicable Verify lift cylinder and/or telescope cylinder works without problems; verify there is no leaking Make repairs as needed 83

Boom Lock Valve 83

Description 83

Outrigger/Rear Steer Valve 85

Description 85

Maintenance 86

Removal 86

Installation 86

Functional Check 86

Outrigger Control Manifold 87

Description 87

Maintenance 88

Removal 88

Inspection 88

Installation 88

Functional Check 88

Parking Brake/Range Shift Valve 89

Description 89

Maintenance 89

Removal 89

Installation 89

Functional Tests 89

Axle Oscillation Lockout Valve 91

Description 91

Maintenance 91

Removal 91

Installation 91

High Speed Boost Selector Valve 92

Description 92

Maintenance 92

Removal 92

Installation 92

Hydraulic Accumulator 93

Description 93

Maintenance 93

Removal 93

Installation 93

Servicing 93

Service Brake and CAC Fan Motor Priority Flow Control Valve 94

Description 94

Maintenance 94

Removal 94

Installation 94

Oil Cooler Fan Motor Priority Flow Control Valve 95

Description 95

Maintenance 95

Removal 95

Installation 95

Telescope Cylinder Charge Valve Manifold (If Equipped) 96

Description 96

Maintenance 96

Removal 96

Installation 96

Cylinders 99

General 99

Maintenance 99

General 99

Surface Protection For Cylinder Rods 99

Leakage Check 99

Temperature Effects On Hydraulic Cylinders100

Lift Cylinder102

Description102

Maintenance102

Disassembly102

Inspection102

Assembly104

Lower Telescope Cylinder106

Description106

Maintenance106

Disassembly106

Inspection106

Assembly106

Upper Telescope Cylinder110

Description110

Maintenance110

Disassembly110

Inspection110

Assembly110

Axle Oscillation Lockout Cylinder113

Description113

Maintenance113

Disassembly113

Inspection113

Assembly115

Steer Cylinder116

Description116

Maintenance116

Disassembly116

Inspection116

Assembly118

Outrigger Extension Cylinder119

Description119

Maintenance119

Disassembly119

Inspection119

Assembly121

Outrigger Jack Cylinder122

Description122

Maintenance122

Disassembly122

Inspection122

Assembly124

Test124

Counterweight Removal Cylinder125

Description125

Maintenance125

Disassembly125

Inspection125

Assembly125

SECTION 3129

Electrical System129

Description129

General129

Alternator131

Batteries131

Cab Electrical Panel131

Carrier Electrical Panel133

Maintenance135

General135

Visual Inspection and Replacement of Electrical Harnesses and Cables135

General Troubleshooting136

Troubleshooting Swivel-Caused Electrical Problems136

Connector Troubleshooting136

Alternator/Charging System Troubleshooting137

Required Tools137

Visual Check137

Engine Off Tests138

Batteries138

Voltage at Alternator138

Battery Drain138

Engine On Tests138

Output Voltage Test138

Maximum Amperage Test138

Voltage Drop Test138

Alternator Replacement139

Removal139

Installation139

Check139

Starter Replacement139

Removal139

Installation139

Check139

Battery Replacement140

Removal140

Installation140

Relay Panel Component Replacement140

Accessory Relay140

Buzzer Replacement140

Gauge Cluster Replacement141

Removal141

Installation141

Check141

Rocker Switch Replacement141

Removal141

Inspection142

Installation142

Check142

Ignition Switch Replacement142

Removal142

Inspection142

Installation143

Check143

Turn Signal Lever and Transmission Shift Lever Replacement143

Removal143

Installation143

Check144

Windshield Wiper Assembly Replacement145

Removal145

Inspection145

Installation145

Check146

Windshield Washer Assembly Replacement146

Removal146

Inspection146

Installation146

Check146

Skylight Wiper Assembly Replacement146

Removal146

Inspection146

Installation146

Check147

Telescope Cylinder Charge System – Electrical Schematic (If Equipped)148

Tools for Troubleshooting149

Optional Equipment149

Beacon Light149

Boom Mounted Floodlights149

Rear View Mirror149

Air Conditioner149

Cold Weather Operation149

Component Coolant Heater149

Troubleshooting150

Maintenance Instructions150

SECTION 4151

Boom151

Description151

Theory of Operation151

Boom Extension151

Boom Retraction152

Maintenance152

Removal152

Disassembly157

Boom Nose Sheaves159

Removal159

Installation160

Assembly160

Installation163

Functional Check164

Inspection164

Boom Alignment and Servicing164

Cam Operated Check Valve Adjustment165

Guide Block Adjustment165

Boom Extension and Retraction Cable166

Maintenance166

Inspection166

Adjustment166

Telescope Circuit167

Description167

Theory Of Operation167

Maintenance168

Troubleshooting168

Removal And Installation170

Disassembly And Assembly170

Description170

Theory of Operation170

Maintenance170

Lift Cylinder Removal172

Disassembly and Assembly172

Lift Cylinder Installation172

Swingaway Boom Extension174

Description174

Maintenance174

Removal174

Installation180

Boom Extension Alignment Device Adjustment181

Swingaway Mounting Adjustment182

Description182

Maintenance182

Periodic Maintenance182

SECTION 5183

Hoist and Counterweight183

Description183

Theory of Operation183

Maintenance184

Warm-up Procedure184

Hoist Area Access184

Removal186

Installation186

Functional Check186

Fluid Level186

Usage and Inspection187

Preventative Maintenance187

Oil Sampling189

Oil Change189

Gear Oil Sampling and Analysis189

General Guidelines for Iron Contaminant Level189

Brake Test Procedure189

Hoist to Boom Alignment190

Preparation190

Tools Required190

Procedure190

Motor and Brake192

Description192

Maintenance192

Removal192

Installation192

Idler Drum and Cable Follower193

Description193

Maintenance193

Idler Drum193

Removal and Disassembly193

Cleaning and Inspection193

Assembly and Installation193

Cable Follower193

Removal and Disassembly193

Cleaning and Inspection193

Assembly and Installation193

Complete Assembly195

Removal195

Installation195

Third Wrap Indicator (Optional— Standard on CE)196

Description196

Maintenance196

Hoist Drum Rotation Indicator System197

Description197

Maintenance197

General197

Troubleshooting197

Removal197

Installation197

Hoist Control Valves199

Description199

Hydraulic Hoist Motor Control Valve199

Hoist Directional Control Valve199

Fixed Counterweight200

Description200

Maintenance200

Removal200

Installation200

Counterweight Plate200

Removable Counterweight (Optional)202

Removal202

Installation202

SECTION 6205

Swing System205

Description205

Theory of Operation205

Swing Drive205

Swing Brake205

Maintenance207

Swing Motor211

Description211

Maintenance211

Removal211

Installation211

Test211

Swing Gearbox And Brake212

Description212

Maintenance212

Swing Brake212

Removal212

Installation212

Testing212

Gearbox212

Removal212

Installation212

Servicing213

Checking The Oil Level213

Testing213

Swing Bearing214

Description214

Maintenance214

General214

Torquing Turntable Bolts214

General214

Tools Required215

Inner Race Torquing215

Outer Race Torquing215

Removal215

Inspection217

Installation217

Testing218

Swivels219

Description219

Hydraulic Swivel221

Description221

Theory Of Operation221

Maintenance221

Removal221

Installation222

Two Port Water Swivel223

Description223

Maintenance223

Removal223

Disassembly223

Cleaning And Inspection223

Assembly223

Installation223

Electrical Swivel224

Description224

Theory of Operation224

Maintenance224

Removal224

Installation224

Preventive Maintenance225

Slew Angle Zero Adjustment Procedure225

Slew Angle Verification225

Swing Lock Pin226

Description226

Maintenance226

360° Swing Lock Control (Positive Lock Type) (Optional)226

Description226

Maintenance226

SECTION 7227

Power Train227

Engine227

Description227

Maintenance228

Engine Removal228

Engine Installation228

Engine Drive Belts229

Electronic Control System230

Description230

Engine Control System Switches And Indicator Lights230

Engine Diagnostic/Speed Control Switch230

Increment/Decrement Switch230

Engine Stop Light230

Engine Warning Light230

Diesel Particulate Filter Indicator (Tier 4 Engines Only)230

Diesel Particulate Filter Regeneration Switch (Tier 4 Engines Only)231

Inhibit Regeneration Indicator232

High Exhaust System Temperature232

Fuel System233

Description233

Fuel Tank233

Injection Fuel Pump233

Fuel Filter-water Separator233

Maintenance233

Fuel Tank233

Removal233

Installation233

Fuel Filter-Water Separator233

Draining233

Air Intake and Exhaust System235

Description235

Air Intake235

Air Cleaner Checks235

Check For Filter Restriction235

Filter Element Replacement237

Element Cleaning237

Air Cleaner Body237

Precleaner237

Vacuator Valve237

Duct Work238

Charge-Air Cooler System239

Maintenance239

Muffler240

Removal240

Installation240

Water Cooling System243

Description243

Maintenance243

General243

Effects of Cooling System Neglect243

Overheating243

Overcooling243

Antifreeze/Coolant243

Rust Prevention243

Engine Antifreeze/Coolant Fill Procedure (when level is low)243

Antifreeze/Supplemental Coolant Additives Maintenance Summary244

Cooling System Level Check Interval244

SCA Level Check Interval244

Cleaning244

Pressure Flushing244

Component Inspection245

Radiator/Surge Tank245

Engine Water Jacket245

Water Pump245

Fans and Belts245

Thermostat245

Hoses and Clamps246

Drive Train248

Description248

Maintenance248

Transmission248

Drive Shafts249

Removal249

Installation249

Lubrication249

Transmission/torque Converter250

Description250

Theory of Operation250

Maintenance251

General Information251

Troubleshooting251

Hydraulic Checks251

Troubleshooting Procedures251

Removal252

Installation252

Servicing The Crane After Transmission/torque Converter Overhaul254

Lubrication254

Type of Oil and Capacities254

Normal Drain Period254

Towing or Pushing254

SECTION 8255

Undercarriage255

Axles255

Description255

Maintenance256

Removal256

Cleaning256

Installation256

Wheel Alignment Check Procedure257

Rear Steer Indicator Adjustment Procedure257

Wheels and Tires258

Description258

Maintenance258

Mounting Wheel Assemblies258

Typical Wear Patterns258

Incorrect Tire Pressure258

Incorrect Camber259

Incorrect Toe and Axle Alignment259

Incorrect Caster and Wheel Imbalance259

Cuts in the Tire Tread260

Spot Wear260

Feathered Edges260

Cupping260

Steering Systems261

Description261

Front Steering System261

Rear Steering System261

Secondary Steering System (CE Units)261

Theory of Operation261

Front Steering System261

Rear Steering System261

Secondary Steering System (CE Units)261

Maintenance262

Front Steering System262

Troubleshooting262

Functional Check262

Secondary Steering System263

Rear Steering System263

Troubleshooting263

Hydraulic Pumps264

Description264

Front Steer264

Rear Steer264

Front Steering Control Valve264

Description264

Maintenance264

Removal264

Installation264

Integrated Outrigger/Rear Steer Control Valve264

Description264

Maintenance264

Functional Check264

Steer Cylinders264

Description264

Maintenance264

Removal265

Installation265

Rear Axle Oscillation Lockout System265

Description265

Theory of Operation265

Axle Oscillation Lockout Cylinders267

Description267

Maintenance267

Removal267

Installation267

Axle Oscillation Lockout Valve267

Description267

When the axle oscillation solenoid valves are energized and open, hydraulic oil is allowed in and out of the cylinders, allowing them to oscillate267

Maintenance267

Brake System267

Description267

Service Brakes267

Parking Brake268

Theory of Operation268

Service Brakes268

Parking Brake268

Maintenance269

Troubleshooting269

General269

Bleeding the Brake System269

Pressure Bleeding the Brake System270

Manually Bleeding the Brake System270

Service Brakes270

Description270

Maintenance270

Removal270

Linings270

Caliper271

Disassembly271

Caliper271

Inspection272

Periodic On-Vehicle272

Shoes, Linings, and End Plates272

Caliper for Leaks272

Dust Seals273

Disc273

Caliper Parts273

Cleaning274

Corrosion Protection274

Assembly274

Caliper274

Installation275

Linings275

Caliper276

Parking Brake Actuator276

Description276

Maintenance276

Removal276

Installation276

Adjustment276

Parking Brake277

Description277

Maintenance277

Removal277

Installation277

Park Brake Solenoid Valve280

Description280

Maintenance280

Removal280

Installation280

Outrigger280

Outrigger Circuit280

Description280

Theory of Operation280

Maintenance281

Troubleshooting281

Outrigger Beam284

Description284

Theory of Operation284

Maintenance284

Removal284

Inspection285

Installation285

Wear Pad Adjustment285

Extension Cylinder288

Description288

Maintenance288

Removal288

Installation288

Functional Check288

Outrigger Monitoring System (Optional— Standard in North America)288

Description288

Removal288

Installation289

Jack Cylinder289

Description289

Maintenance289

Removal289

Installation289

Functional Check290

Outrigger Control Valves290

Description290

Pilot Operated Check Valve290

Integrated Outrigger/Rear Steer Valve290

Outrigger Control Manifold290

SECTION 9291

Lubrication291

General291

Environmental Protection291

Lubricants and Lubrication Intervals291

Standard Lubricants291

Arctic Lubricants and Conditions293

Temperatures Below -9°C (15°F)293

Cold Weather Package and Lubricants293

Surface Protection for Cylinder Rods296

Wire Rope Lubrication296

lubrication Points297

CraneLUBE297

Safety297

Steering and Suspension298

Axles300

Drive Train302

Drive Train (continued)304

Turntable306

Outriggers308

Boom310

Boom (continued)312

Boom (continued)314

Hoist316

Hydraulic318

Carwell® Rust Inhibitor321

Protecting Cranes From Rusting321

Cleaning Procedures321

Inspection and Repair322

Application322

Areas of Application322

IMAGES PREVIEW OF THE MANUAL: