$38

Manitowoc Grove RT770E Service Manual – PDF DOWNLOAD

Manitowoc Grove RT770E Service Manual – PDF DOWNLOAD

FILE DETAILS:

Manitowoc Grove RT770E Service Manual – PDF DOWNLOAD

Language : English

Pages :360

Downloadable : Yes

File Type : PDF

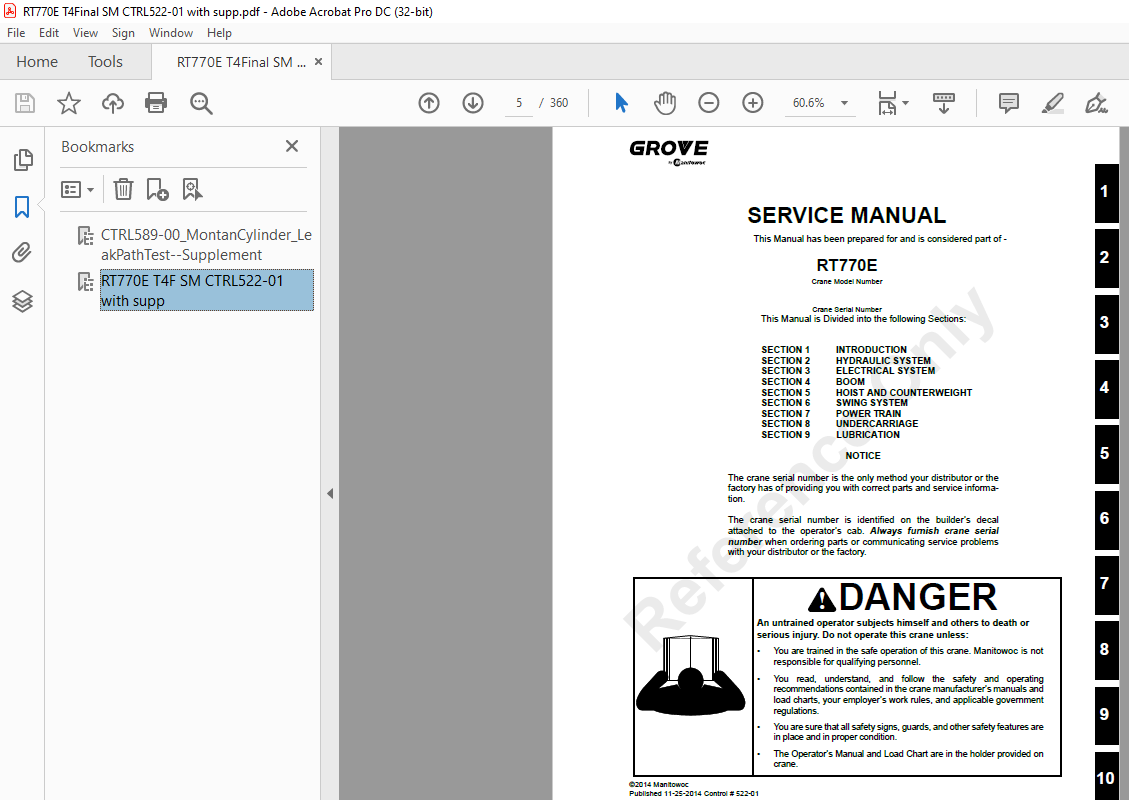

TABLE OF CONTENTS:

Manitowoc Grove RT770E Service Manual – PDF DOWNLOAD

SECTION 1 Introduction

General 1-1

Overview of Manuals 1-1

Customer Support 1-2

General Crane Design 1-2

Specific Crane Description 1-2

Lifting Capacities (Load Chart) 1-2

Basic Components 1-2

Axle Weight Distribution 1-2

Serial Number Location 1-2

Transportation and Lifting Data 1-2

List Of Specifications 1-3

General 1-3

Dimensions 1-3

Capacities 1-3

Torque Converter 1-3

Transmission 1-3

Engine 1-3

Axles 1-3

Brakes 1-3

Wheels and Tires 1-3

Swing Gearbox 1-3

Boom 1-3

Swivel Assembly 1-3

Hydraulic Pumps 1-3

Hoists 1-4

Crane Nomenclature 1-7

General Maintenance 1-9

Cleanliness 1-9

After Cleaning 1-9

Removal and Installation 1-9

Disassembly and Assembly 1-9

Pressing Parts 1-10

Locking Devices 1-10

Wires and Cables 1-10

Shims 1-10

Hoses and Tubes 1-10

Bearings 1-11

Gaskets 1-11

Batteries 1-11

Hydraulic Systems 1-12

Hydraulic Fittings 1-13

Electrical System 1-14

Fatigue of Welded Structures 1-15

Loctite® 1-15

Fasteners and Torque Values 1-16

Weld Studs 1-19

Wire Rope 1-20

General 1-20

Environmental Conditions 1-20

Dynamic Shock Loads 1-20

Lubrication 1-20

Reference Only

TABLE OF CONTENTS RT770E SERVICE MANUAL

TOC-2

Precautions and Recommendations During Inspection or Replacement 1-20

Wire Rope Inspection (Running Ropes and Pendant Cables) 1-21

Wire Rope Inspection (Boom Extension and Retraction Cables) 1-22

Wire Rope Inspection/Replacement (All Wire Rope) 1-22

Seizing Wire Rope 1-23

Installing 35×7 Class Wire Rope 1-24

Procedures for Cutting and Preparing 35×7 Class Wire Rope 1-24

SECTION 2 Hydraulic System

Description 2-2

Hydraulic Symbols 2-3

Maintenance 2-5

Preparation 2-5

Hydraulic System Maintenance Precautions 2-5

Label Parts When Disassembling 2-5

Hydraulic Oil Recommendations 2-5

Draining and Flushing 2-5

Removing Air From the Hydraulic System 2-6

Parts Replacement 2-7

Directional Control Valves 2-7

Visual Inspection of Hoses and Fittings 2-8

Supply Pressure And Return Circuit 2-9

Description 2-9

Pump Distribution 2-10

Troubleshooting 2-10

Troubleshooting Aids 2-12

Troubleshooting Procedures 2-12

Hydraulic Oil Return Filter Assembly 2-13

Fill Cap/Breather 2-13

Oil Cooler 2-15

Description 2-15

Oil Temperature Switches 2-15

Maintenance 2-15

Hydraulic Pumps 2-17

Description 2-17

Maintenance 2-17

Pump Disconnect Assembly 2-21

Disassembly 2-21

Assembly 2-21

Pressure Setting Procedures 2-23

Procedure A – Main Control Valve Reliefs 2-24

Procedure B – Main Directional Control Valve Pilot Supply Pressure 2-25

Procedure C – Swing Brake Pilot Supply Pressure 2-25

Procedure D – Brake Charge Supply Valve Relief Pressure 2-25

Procedure E – Charge Air Cooler Valve Relief Pressure 2-26

Procedure F – Brake Dual Accumulator Charge Valve Pressure Limits 2-26

Procedure G – Accumulator Pre-Charge Pressure 2-26

Procedure H – PreCharging The Accumulator 2-27

Procedure I – Swing Valve Work Port Reliefs Pressure 2-27

Procedure J – Front Steer Relief Valve Pressure 2-28

Procedure K – Outrigger/Rear Steer Valve Relief 2-28

Procedure L – Hydraulic Oil Cooler Fan Motor Control Valve 2-28

Procedure M – Counterweight Removal Valve 2-29

Valves 2-30

General 2-30

Directional Control Valves 2-33

Reference Only

TOC-3

RT770E SERVICE MANUAL TABLE OF CONTENTS

T

OC

GROVE

Description 2-33

Maintenance 2-33

Hydraulic Remote Control Valve 2-38

Description 2-38

Maintenance 2-38

Dual Accumulator Charge Valve 2-42

Description 2-42

Maintenance 2-42

Swing Brake And Armrest Lockout Valve Manifold 2-44

Description 2-44

Maintenance 2-44

Holding Valve 2-46

Description 2-46

Maintenance 2-46

Outrigger/Rear Steer Valve 2-47

Description 2-47

Maintenance 2-48

Outrigger Control Manifold 2-49

Description 2-49

Maintenance 2-50

Parking Brake/Range Shift Valve 2-51

Description 2-51

Maintenance 2-51

Axle Oscillation Lockout Valve 2-53

Description 2-53

Maintenance 2-53

High Speed Boost Selector Valve 2-54

Description 2-54

Maintenance 2-54

Telescope Stage Selector Valve Manifold 2-55

Description 2-55

Maintenance 2-55

Telescope Fill Tube Control Valve Manifold 2-56

Description 2-56

Maintenance 2-57

Hydraulic Accumulator 2-58

Description 2-58

Maintenance 2-58

Service Brake and CAC Fan Motor Priority Flow Control Valve 2-59

Description 2-59

Maintenance 2-59

Oil Cooler Fan Motor Priority Flow Control Valve 2-60

Description 2-60

Maintenance 2-60

Cylinders 2-61

General 2-61

Maintenance 2-61

Surface Protection For Cylinder Rods 2-61

Temperature Effects On Hydraulic Cylinders 2-62

Lift Cylinder 2-64

Description 2-64

Maintenance 2-64

Telescope Cylinder 2-68

Description 2-68

Maintenance 2-68

Axle Oscillation Lockout Cylinder 2-69

Description 2-69

Reference Only

TABLE OF CONTENTS RT770E SERVICE MANUAL

TOC-4

Maintenance 2-69

Steer Cylinder 2-72

Description 2-72

Maintenance 2-72

Outrigger Extension Cylinder 2-75

Description 2-75

Maintenance 2-75

Outrigger Jack Cylinder 2-78

Description 2-78

Maintenance 2-78

Counterweight Removal Cylinder 2-81

Description 2-81

Maintenance 2-81

SECTION 3 Electrical System

Description 3-1

General 3-1

Alternator 3-3

Batteries 3-3

Cab Electrical Panel 3-3

Carrier Electrical Panel 3-5

Maintenance 3-7

General 3-7

General Troubleshooting 3-8

Tools for Troubleshooting 3-8

Troubleshooting Swivel-Caused Electrical Problems 3-8

Connector Troubleshooting 3-8

Alternator/Charging System Troubleshooting 3-9

Alternator Replacement 3-11

Starter Replacement 3-11

Battery Replacement 3-12

Relay Panel Component Replacement 3-12

Gauge Cluster Replacement 3-13

Rocker Switch Replacement 3-13

Ignition Switch Replacement 3-14

Turn Signal Lever and Transmission Shift Lever Replacement 3-15

Windshield Wiper Assembly Replacement 3-16

Windshield Washer Assembly Replacement 3-18

Skylight Wiper Assembly Replacement 3-18

Tools for Troubleshooting 3-19

Optional Equipment 3-19

Beacon Light 3-19

Boom Mounted Floodlights 3-19

Rear View Mirror 3-19

Air Conditioner 3-19

SECTION 4 Boom

Description 4-1

Theory of Operation 4-2

Maintenance 4-4

Removal 4-4

Disassembly 4-13

Boom Nose Sheaves 4-21

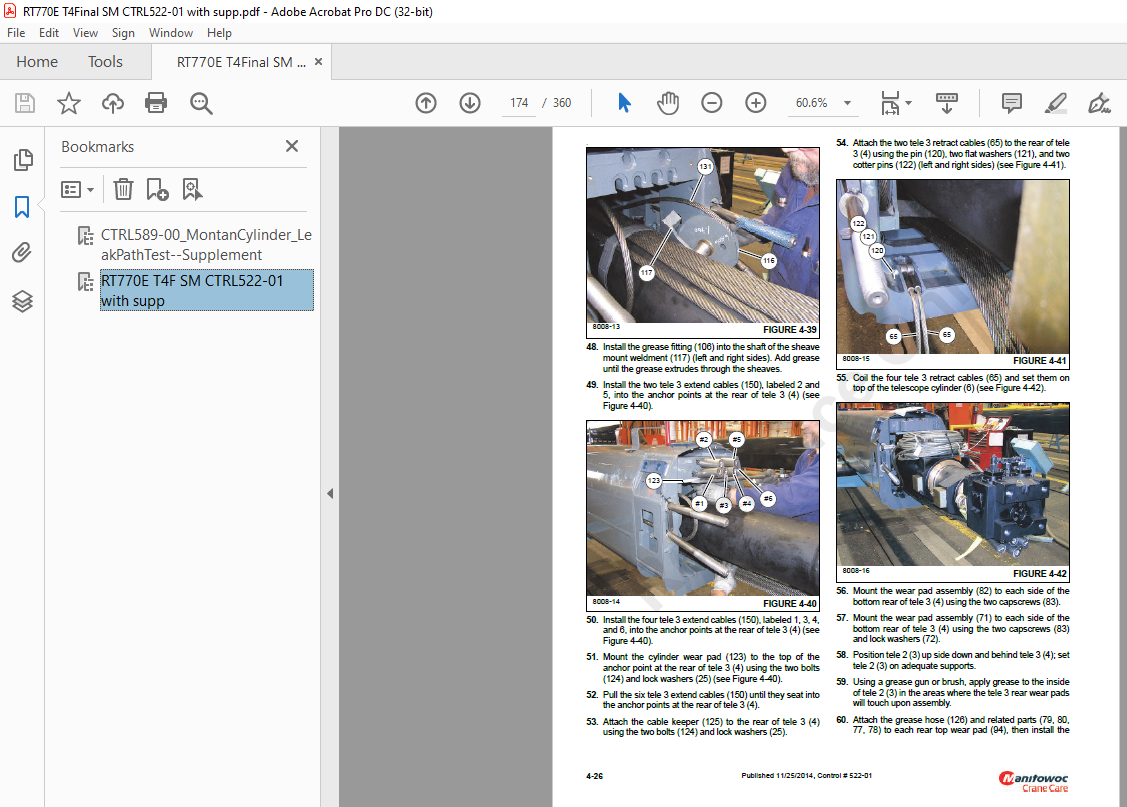

Assembly 4-21

Installation 4-32

Functional Check 4-33

Reference Only

TOC-5

RT770E SERVICE MANUAL TABLE OF CONTENTS

T

OC

GROVE

Inspection 4-33

Boom Alignment and Servicing 4-33

Boom Extension and Retraction Cables 4-33

Maintenance 4-33

Inspection 4-33

Adjustment 4-34

Telescope Circuit 4-37

Description 4-37

Theory of Operation 4-37

Maintenance 4-39

Removal And Installation 4-40

Disassembly And Assembly 4-40

Lift Circuit 4-41

Description 4-41

Theory of Operation 4-41

Maintenance 4-41

Lift Cylinder Removal 4-43

Disassembly and Assembly 4-43

Lift Cylinder Installation 4-43

Bi-Fold Boom Extension 4-45

Description 4-45

Boom Extension Rigging Mode 4-45

Erecting the Boom Extension 4-45

Stowing the Boom Extension 4-52

Setting the Folding Swingaway Offset 4-54

Boom Extension Alignment Device Adjustment 4-55

Swingaway Mounting Adjustment 4-55

Hook Block 4-56

Description 4-56

Maintenance 4-56

SECTION 5 Hoist and Counterweight

Description 5-1

Theory of Operation 5-1

Maintenance 5-2

Warm-up Procedure 5-2

Hoist Area Access 5-2

Removal 5-4

Installation 5-4

Functional Check 5-4

Fluid Level 5-4

Preventive Maintenance 5-5

Hoist To Boom Alignment 5-6

Preparation 5-6

Tools Required 5-6

Procedure 5-6

Motor And Brake 5-8

Description 5-8

Idler Drum And Cable Follower 5-9

Description 5-9

Maintenance 5-9

Third Wrap Indicator (Optional—Standard on CE) 5-12

Description 5-12

Maintenance 5-12

Hoist Drum Rotation Indicator System 5-13

Description 5-13

Reference Only

TABLE OF CONTENTS RT770E SERVICE MANUAL

TOC-6

Maintenance 5-13

Hoist Control Valves 5-15

Description 5-15

Fixed Counterweight 5-16

Description 5-16

Maintenance 5-16

Counterweight Plate 5-16

Removable Counterweight (Optional) 5-18

Removal 5-18

Installation 5-18

SECTION 6 Swing System

Description 6-1

Theory of Operation 6-1

Swing Drive 6-1

Swing Brake 6-1

Maintenance 6-3

Swing Motor 6-7

Description 6-7

Maintenance 6-7

Swing Gearbox And Brake 6-8

Description 6-8

Maintenance 6-8

Swing Bearing 6-10

Description 6-10

Maintenance 6-10

Swivels 6-15

Description 6-15

Hydraulic Swivel 6-17

Description 6-17

Theory Of Operation 6-17

Maintenance 6-17

Two Port Water Swivel 6-19

Description 6-19

Maintenance 6-19

Electrical Swivel 6-20

Description 6-20

Theory of Operation 6-20

Maintenance 6-20

Swing Lock Pin 6-22

Description 6-22

Maintenance 6-22

360° Swing Lock Control (Positive Lock Type) (Optional) 6-22

Description 6-22

Maintenance 6-22

SECTION 7 Power Train

Engine 7-1

Description 7-1

Maintenance 7-2

Electronic Control System 7-4

Description 7-4

Engine Control System Switches And Indicator Lights 7-4

Fuel System 7-7

Description 7-7

Maintenance 7-7

Reference Only

TOC-7

RT770E SERVICE MANUAL TABLE OF CONTENTS

T

OC

GROVE

Air Intake and Exhaust System 7-9

Description 7-9

Air Intake 7-9

Charge-Air Cooler System 7-13

Muffler 7-14

Water Cooling System 7-17

Description 7-17

Maintenance 7-17

Radiator Fill and Servicing 7-21

Drive Train 7-23

Description 7-23

Maintenance 7-23

Transmission/torque Converter 7-25

Description 7-25

Theory of Operation 7-25

Maintenance 7-26

Troubleshooting Procedures 7-26

Towing or Pushing 7-29

SECTION 8 Undercarriage

Axles 8-1

Description 8-1

Maintenance 8-2

Wheels And Tires 8-4

Typical Wear Patterns 8-4

Steering Systems 8-7

Description 8-7

Theory Of Operation 8-7

Maintenance 8-8

Rear Steering System 8-9

Troubleshooting 8-9

Hydraulic Pumps 8-10

Front Steering Control Valve 8-10

Integrated Outrigger/Rear Steer Control Valve 8-10

Steer Cylinders 8-10

Rear Axle Oscillation Lockout System 8-11

Description 8-11

Theory Of Operation 8-11

Axle Oscillation Lockout Cylinders 8-13

Axle Oscillation Lockout Valve 8-13

Maintenance 8-13

Brake System 8-13

Description 8-13

Theory Of Operation 8-14

Maintenance 8-15

Service Brakes 8-16

Description 8-16

Maintenance 8-16

Corrosion Protection 8-20

Parking Brake Actuator 8-22

Description 8-22

Maintenance 8-22

Parking Brake 8-23

Description 8-23

Maintenance 8-23

Park Brake Solenoid Valve 8-26

Reference Only

TABLE OF CONTENTS RT770E SERVICE MANUAL

TOC-8

Description 8-26

Maintenance 8-26

Outrigger 8-26

Outrigger Circuit 8-26

Maintenance 8-27

Outrigger Beam 8-30

Extension Cylinder 8-34

Outrigger Monitoring System (Optional—Standard in North America) 8-34

Jack Cylinder 8-35

Outrigger Control Valves 8-36

SECTION 9 Lubrication

General 9-1

Environmental Protection 9-1

Lubricants and Lubrication Intervals 9-1

Standard Lubricants 9-2

Arctic Lubricants and Conditions 9-3

Surface Protection for Cylinder Rods 9-6

Wire Rope Lubrication 9-6

lubrication Points 9-7

CraneLUBE 9-7

Safety 9-7

Steering and Suspension 9-8

Axles 9-10

Drive Train 9-12

Drive Train (continued) 9-14

Turntable 9-16

Outriggers 9-18

Boom 9-20

Hoist 9-30

Hydraulic 9-32

Carwell® Rust Inhibitor 9-35

Protecting Cranes From Rusting 9-35

Cleaning Procedures 9-35

Inspection and Repair 9-36

Application 9-36

Areas of Application 9-36

Reference Only

Published 11/25/2014, Control # 522-01 1-1

RT770E SERVICE MANUAL INTRODUCTION

1

GROVE

SECTION 1

INTRODUCTION

SECTION CONTENTS

General 1-1

Overview of Manuals 1-1

Customer Support 1-1

General Crane Design 1-2

Specific Crane Description 1-2

Lifting Capacities (Load Chart) 1-2

Basic Components 1-2

Axle Weight Distribution 1-2

Serial Number Location 1-2

Transportation and Lifting Data 1-2

List Of Specifications 1-3

General 1-3

Dimensions 1-3

Capacities 1-3

Torque Converter 1-3

Transmission 1-3

Engine 1-3

Axles 1-3

Brakes 1-3

Wheels and Tires 1-3

Swing Gearbox 1-3

Boom 1-3

Swivel Assembly 1-3

Hydraulic Pumps 1-3

Hoists 1-4

Crane Nomenclature 1-7

General Maintenance 1-9

Cleanliness 1-9

After Cleaning 1-9

Removal and Installation 1-9

Disassembly and Assembly 1-9

Pressing Parts 1-10

Locking Devices 1-10

Wires and Cables 1-10

Shims 1-10

Hoses and Tubes 1-10

Bearings 1-11

Gaskets 1-11

Batteries 1-11

Hydraulic Systems 1-12

Hydraulic Fittings 1-13

Electrical System 1-14

Fatigue of Welded Structures 1-15

Loctite® 1-15

Fasteners and Torque Values 1-16

Weld Studs 1-19

Wire Rope 1-20

General 1-20

Environmental Conditions 1-20

Dynamic Shock Loads 1-20

Lubrication 1-20

Precautions and Recommendations During

Inspection or Replacement 1-20

Wire Rope Inspection (Running Ropes and

Pendant Cables) 1-21

Wire Rope Inspection (Boom Extension and

Retraction Cables) 1-22

Wire Rope Inspection/Replacement

(All Wire Rope) 1-22

Seizing Wire Rope 1-23

Installing 35×7 Class Wire Rope 1-24

Procedures for Cutting and Preparing

35×7 Class Wire Rope 1-24

IMAGES PREVIEW OF THE MANUAL: