$36

Manitowoc Grove RT9130E-2 Operator Manual – PDF DOWNLOAD

Manitowoc Grove RT9130E-2 Operator Manual – PDF DOWNLOAD

FILE DETAILS:

Manitowoc Grove RT9130E-2 Operator Manual – PDF DOWNLOAD

Language : English

Pages : 208

Downloadable : Yes

File Type : PDF

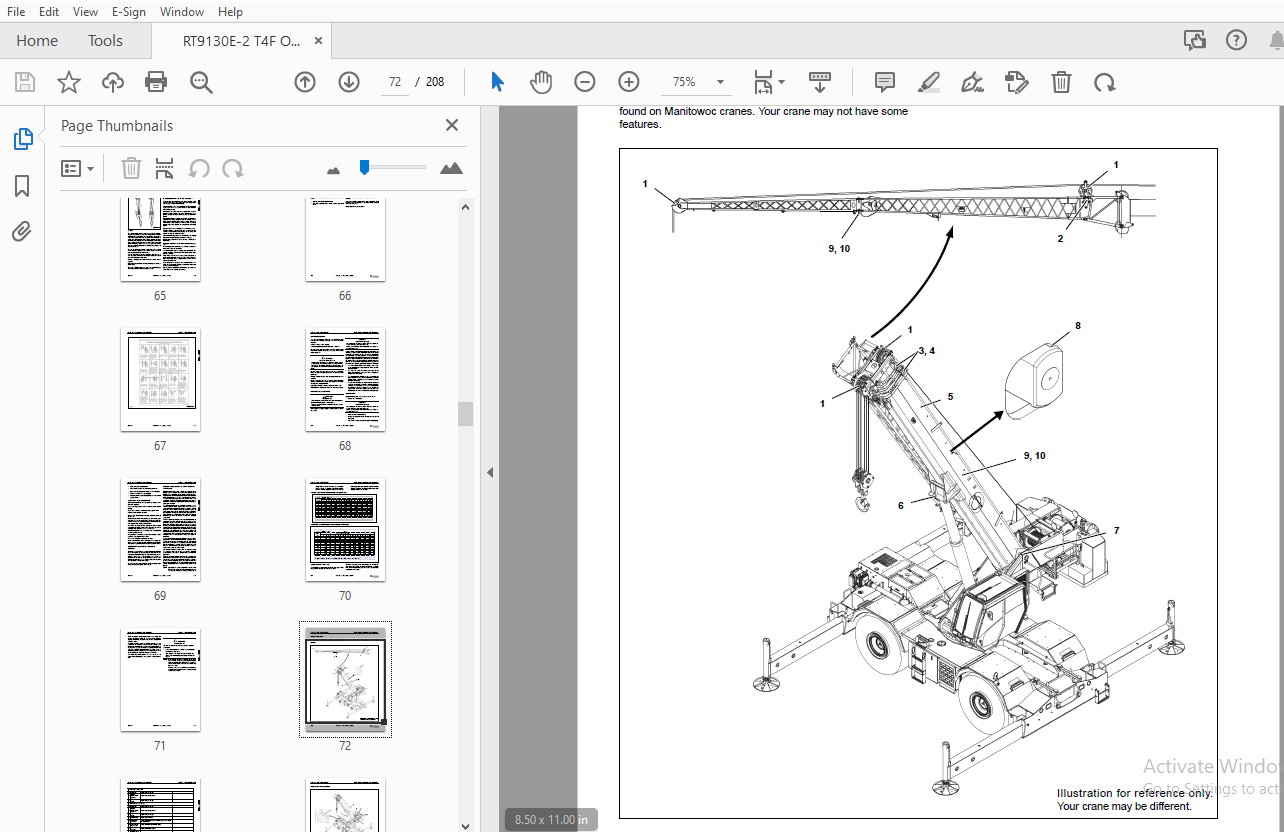

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Manitowoc Grove RT9130E-2 Operator Manual – PDF DOWNLOAD

See end of this Manual for Alphabetical Index 7

SECTION 1 15

Introduction 15

General 15

Customer Support 15

New Owners 15

Safety Information 16

Noise/Vibration Test Results 16

Noise Level Test Results 16

Vibration Level Test Results 16

Serial Number Location 17

List Of Specifications 21

General 21

Dimensions 21

Capacities 21

Torque Converter 21

Transmission 21

Engine 21

Cummins QSL or (QSC) 21

Axles 21

Brakes 21

Wheels and Tires 21

Swing Gearbox 21

Boom 21

Swivel Assembly 21

Hydraulic Pumps 22

Pump #1 22

Pump #2 22

Pump #3 22

Pump #4 22

Hoists 22

Wire Rope (Hoist Cable) 25

General 25

Environmental Conditions 25

Dynamic Shock Loads 25

Lubrication 25

Precautions and Recommendations During Inspection or Replacement 25

Wire Rope Inspection (Running Ropes and Pendant Cables) 26

Keeping Records 26

Frequent Inspection 26

Periodic Inspection 27

Wire Rope Inspection/Replacement (All Wire Rope) 27

Seizing Wire Rope 27

Method 1 27

Method 2 28

Installing 35×7 Class Wire Rope 28

SECTION 2 31

Safety Information 31

Safety Messages 31

General 31

Safety Alert Symbol 32

Signal Words 32

General 32

Safety Decals 32

Accidents 32

Operator Information 32

Operator Qualifications 33

Operational Aids 34

Rated Capacity Limiter (RCL) Systems (If Equipped) 34

Anti-Two-Blocking Device 34

Working Area Limiter (If Equipped) 35

Crane Stability/Structural Strength 36

Load Charts 36

Work Site 36

Wind Forces 37

Wind Speeds 37

Determination of 3-second wind gust speed at boom tip height: 40

Size and Shape of the load: 40

Determining Wind Drag Coefficient (Cd) 41

Maximum Permissible Wind Speed 42

Example and Sample Calculations (metric) 44

Example 1: Crane Configuration: 44

Load example 1 1: 45

Load example 1 2: 45

Load example 1 3a: 45

Load example 1 3b: 45

Example and Sample Calculations (Non-metric) 48

Example 2: 48

Load example 2 1: 49

Load example 2 2: 49

Load example 2 3a: 49

Load example 2 3b: 49

Lifting Operations 50

Counterweight 51

Outrigger Lift Off 51

Multiple Crane Lifts 51

Tilt-Up Panel Lifting 51

Pile Driving and Extracting 52

Crane Equipment 52

Crane Inspection 52

Electrocution Hazard 53

Set-Up and Operation 54

Electrocution Hazard Devices 54

Electrical Contact 55

Special Operating Conditions and Equipment 55

Grounding the Crane 55

Personnel Handling 56

Environmental Protection 57

Maintenance 57

Service and Repairs 57

Lubrication 58

Tires 59

Hoist Rope 59

Synthetic Hoist Rope 59

Wire Rope 59

Sheaves 60

Batteries 61

Super Capacitor (If Equipped) 61

General Maintenance 61

Transporting the Crane 62

Travel Operation 62

Work Practices 63

Personal Considerations 63

Crane Access 63

Job Preparation 63

Working 64

Lifting 65

Hand Signals 66

Boom Extension 68

Parking and Securing 68

Shut-Down 68

Cold Weather Operation 69

Temperature Effects on Hook Blocks 69

Temperature Effects on Hydraulic Cylinders 69

Overload Inspection 70

Boom Inspection 72

Superstructure Inspection 74

Carrier Inspection 76

SECTION 3 79

Operating Controls and Procedures 79

Steering column 83

Drive Axle Selector Switch 84

Turn Signal Lever and Windshield Wiper/ Washer/Headlight /Horn Controls 84

Steering Column Tilt/Telescope Lever 84

Park Brake Control Switch 84

Headlights Switch 84

Drive Axle Selector Switch 84

Hazard Lights Switch 85

Engine Diagnostic and Engine Speed Control Switches 85

Engine Diagnostic/Speed Control Switch 85

Increment/Decrement Switch 85

Ignition Switch 85

Transmission Shift Lever 85

Cab Overhead Controls 86

Skylight Window Latch 86

Skylight Wiper and Wiper Motor 86

Skylight Sunscreen 86

Overhead Light 86

Cab Circulating Fan 86

Right Side Window Latch 86

Overhead Control Panel 87

Heater/Air Conditioner Fan Switch 87

Heater Control Switch 87

Air Conditioner Switch 87

Skylight Wiper Switch 87

Dimmer Switch 87

Work Lights Switch 87

Boom Lights Switch (Optional) 87

Crane Function Power Switch 87

Hoist Rotation Indicator Display 88

Exhaust System Cleaning Switch (Tier 4 Engines Only) 88

Boom Tele-1 / Tele-2 Select Switch & Indicator 88

Boom Manual/Auto Switch 88

Steering Column Indicator and Gauge Display 90

Swing Brake Engaged 91

Parking Brake Engaged 91

Light Malfunction 91

Emergency Stop 91

Hydraulic Oil High Temperature 91

Transmission Warning 91

Low Steer Pressure 91

Left Turn Signal Indicator 91

Low Brake Pressure 91

Electronic Module Control 91

Electronic System Diagnostic 91

LCD Display 92

Engine Stop 92

Engine Warning 92

Exhaust System Cleaning (Tier 4 Engines Only) 92

Right Turn Signal Indicator 93

Inhibit Cleaning 93

Diesel Exhaust Fluid (Tier 4F Engines Only) 93

High Exhaust System Temperature 93

Engine Wait to Start 93

Four-Wheel Drive Engaged 93

Interaxle Locked 93

Rear Wheels Not Centered Indicator 93

Engine Coolant Temperature Gauge 93

Fuel Gauge 93

Low Fuel Level 93

Battery Charge Indicator 94

Voltmeter 94

Tachometer 94

Control Seat Assembly – Single Axis 95

Main Hoist Control (Single Axis Option) 95

Boom Lift Control (Single Axis Option) 95

Boom Lift and Main Hoist Control Lever (Dual Axis Option — Not Shown) 95

Main Hoist Speed Selector Switch 95

Auxiliary Hoist Control (Single Axis Option) 96

Swing Control (Single Axis Option) 96

Swing and Telescope or Swing and Auxiliary Hoist Control Lever (Dual Axis Option—Not Shown) 96

Auxiliary Hoist Speed Selector Switch (Optional) 96

Rear Steer Switch 96

Swing Brake Control Switch 96

Axle Differential Lock Control Switch (Optional) 96

Cab Door Release 97

Seat Back Adjustment 97

A/C Heater, Climate Control 97

Seat Slide Lever 97

Seat Frame Slide Lever 97

Armrest Adjustment 97

Hoist Rotation Indicators (HRI) 97

HRI Display 97

Cab Tilt Switch 97

Luffing Jib Raise/Lower Switch (Optional) 98

Luffing Jib On/Off Switch (Optional) 98

Two-Speed Swing Switch 98

Armrest Switch (Not Shown) 98

Seat Switch (Not Shown) 98

Side Control Panel 98

Rated Capacity Limiter (RCL) and Work Area Definition System Control Panel 99

Rated Capacity Limiter (RCL) Bypass Switch 99

Emergency Stop Switch 99

Transmission Oil Temperature Gauge 99

Turntable Pin Swing Lock Control 99

12V Receptacle 99

Diagnostic Connector 99

Bubble Level Indicator 99

Hose Reel Brake Indicator 99

Boom Not Sync Indicator 99

Hoist Minimum Wrap Indicator (Optional, Standard w/CE) 100

Cold Weather Indicator (Optional) 100

Telescope Cylinder Charge Indicator (If Equipped) 100

Ambient Temperature Indicator (Optional) 100

Outrigger Control 100

Cab Outrigger Control 100

Extend/Retract Switch 100

Outrigger Selector Switches 100

Foot Pedal Controls 101

Swing Lock Pedal 101

Swing Brake Pedal 101

Telescope Control Foot Pedal 102

Service Brake Foot Pedal 102

Foot Throttle Pedal 102

Miscellaneous Controls and Indicators 103

Fuse Panel 103

Buzzer 103

Rated Capacity Limiter (RCL) Emergency Override Switch (Non-CE Certified Cranes) 103

Rated Capacity Limiter (RCL) Emergency Override Switch and Indicator (CE Certified Cranes) 104

Rated Capacity Limiter (RCL) Internal Light Bar (Optional—Not Shown) 104

Strobe Light or Beacon (Optional—Not Shown) 104

Backup Alarm (Not Shown) 104

Emergency Exit 104

Operating Procedures 105

Pre-Starting Checks 105

Fuel Supply 105

Engine Oil 105

Engine Coolant 105

Batteries 105

Signal and Running Lights 105

Foot and Parking Brakes 105

Daily Lubrication 105

Hydraulic Reservoir and Filter 105

Tires 105

Wire Rope 105

Hook Block 105

Air Cleaner 105

Air Intake Restriction Monitoring (AIRM) Communications System – Tier 4 Only 105

Cold Weather Operation 105

Component Coolant Heater 106

Radiator Shutters 107

Auxiliary Cab Heater 107

Battery Heater 107

Air Diverter 107

Super Capacitor 107

Operation Below -40°C (-40°F) 108

Crane Warm-up Procedures 108

Engine 108

Transmission 108

Hoist 109

Swing Drive and Turntable Bearing 109

Axles 109

Hydraulic Oil System 109

Engine Operation 109

Starting Procedure 110

Use the correct grade of oil for the prevailing temperature in the crankcase to prevent hard cranking Diesel fuel should have a cloud point of 6°C (10°F) less than the lowest expected temperature In case of emergency, white kerosene may be added 110

Battery Disconnect Switch 110

Cold Engine 110

Warm Engine 111

Allow the engine to warm up at least five minutes before applying a load Do not race the engine for a faster warm up 111

Idling the Engine 111

Racing the Engine 111

Shutdown Procedure 111

Crane Travel Operation 112

Traveling — General 112

Traveling — Towing/Pulling 113

Traveling — Being Towed/Pulled 113

Travel on Slopes 114

Traveling with Elevated Boom 114

Traveling with Jib and/or Inserts Erected 115

11 m (36 ft)/18 m (59 ft) Jib 115

18 m (59 ft) Jib Plus 8 m (26 ft) / 16 m (52 ft) Insert 115

Extended Travel 116

Traveling — Forward 116

Traveling — Reverse 117

Steering 117

Front Wheel Steering 117

Rear Wheel Steering 117

Four Wheel Steering 117

Crabbing 117

Four-Wheel Drive Operation 118

Differential Lock Operation (Optional) 118

General 118

Operation 119

Axle Oscillation Lockouts Operation 119

If the axle oscillation lockout valve is functioning properly, the crane will re-level itself; if the valve is not working properly, the crane will not re-level itself If the rear axle does not lock or unlock properly, evaluate the lockout system an 119

General Crane Operation 119

Pump Drive 119

Control Lever Operation 120

Preload Check 120

Using Your Load Chart 120

Proper Leveling of the Crane 121

Bubble Level Adjustment 121

Setting the Outriggers 121

Outrigger Monitoring System (OMS) (Optional) 122

Engaging the Mid-Extend Lock Pin 123

Stowing the Outriggers 123

Stowing the Mid-Extend Lock Pin 123

Swinging the Boom 123

Elevating and Lowering the Boom 124

Elevating the Boom 124

Lowering the Boom 124

Telescoping the Boom 124

Extending the Boom 124

Retracting the Boom 124

Lowering and Raising the Hoist Cable 125

Lowering the Cable 125

Raising the Cable 125

Hoist Speed Range Selection 125

Raising and Lowering the Hydraulic Jib 125

Raising the Hydraulic Jib 125

Lowering the Hydraulic Jib 126

Operational Aids 126

Rated Capacity Limiter (RCL) System 126

Control Lever Lockout System 127

Stowing and Parking 127

Unattended Crane 128

SECTION 4 129

Set-up and Installation 129

General 129

Installing Cable on the Hoist 129

Cable Reeving 130

Boom Cable Reeving 131

Dead-End Rigging/Wedge Sockets 131

Installing Wedge and Socket 131

Anti Two Block (A2B) Switch 138

Lock 138

Unlock 138

Before Operation 138

Cranes with Main Hoist Only 138

Machines with Main and Auxiliary Hoists 139

Counterweight Removal and Installation 140

Counterweight Stand Installation 140

Standard and Heavy Counterweight and Auxiliary Hoist Structure 140

Removal 140

Installation 143

Counterweight Stand Removal 144

Outrigger Box Removal and Installation 145

Bleed Valve Operation 145

Procedure 145

Removal 145

Installation 146

Removing and Installing the Swingaway Jib 147

Removal 147

Installation 148

Connecting and Disconnecting Hydraulic Boom Extension 153

Connecting 153

Establish a Hydraulic Connection Between the Boom Extension and the Main Boom 153

Establish an Electrical Connection Between the Lattice Extension and the Main Boom 153

Establish Electrical Connection Between Boom Extension and Anti-Two Block Switch 154

Disconnecting 154

Disconnect the Electrical Connection Between the Jib and the Main Boom 154

Disconnect the Hydraulic Connection Between the Jib and the Main Boom 154

Swingaway Mounting Adjustment 154

Jib—with Inserts 154

Identification 154

Serial Numbers On the 8 m (26 ft) Inserts 155

Slinging Points 155

Assembly of Jibs 156

Installing the 26 m (85 ft)/34 m (112 ft) Jib 156

Removing the 26 m (85 ft)/34 m (112 ft) Jib 157

Installing/Removing 8 m (26 ft) Inserts 157

Installing 8 m (26 ft) Inserts 157

Removing 8 m (26 ft) Inserts 158

Hydraulic Connection on the Boom Inserts 159

Connections on the 8 m (26 ft) Sections 159

Electrical Connection on the Boom Inserts 159

Connections on the 8 m (26 ft) Sections 159

Establishing Electrical Connections 160

For the 26 m (85 ft) Jib 160

For the 34 m (112 ft) Jib 160

Folding Out/In the Deflection Sheaves on the 8 m (26 ft) Sections 160

Folding Out Deflection Sheave 160

Folding In Deflection Sheave 160

Positioning/Removing Hoist Cable 160

Positioning the Hoist Cable 160

Removing the Hoist Cable 161

Setting Folding Swingaway Extension Offset 161

SECTION 5 163

Maintenance and Lubrication 163

General 163

Environmental Protection 163

Lubricants and Lubrication Intervals 163

Standard Lubricants 165

Arctic Lubricants and Conditions 166

Temperatures Below -9°C (15°F) 166

Cold Weather Package and Lubricants 166

Surface Protection for Cylinder Rods 169

Wire Rope Lubrication 169

Lubrication Points 170

CraneLUBE 170

Cummins Oil Registration List 170

Safety 170

Steering and Suspension 171

Axles 173

Drive Train 175

Drive Train (continued) 177

Turntable 179

Cab Tilt 181

Outriggers 183

Boom 185

Boom (continued) 188

Boom (continued) 190

Hoist 192

Hydraulic 194

Diesel Exhaust Fluid (DEF) 196

Instructions for Accessing Lubrication Points on Boom 198

Carwell® Rust Inhibitor 199

Protecting Cranes From Rusting 199

Cleaning Procedures 199

Inspection and Repair 200

Application 200

Areas of Application 200