$39

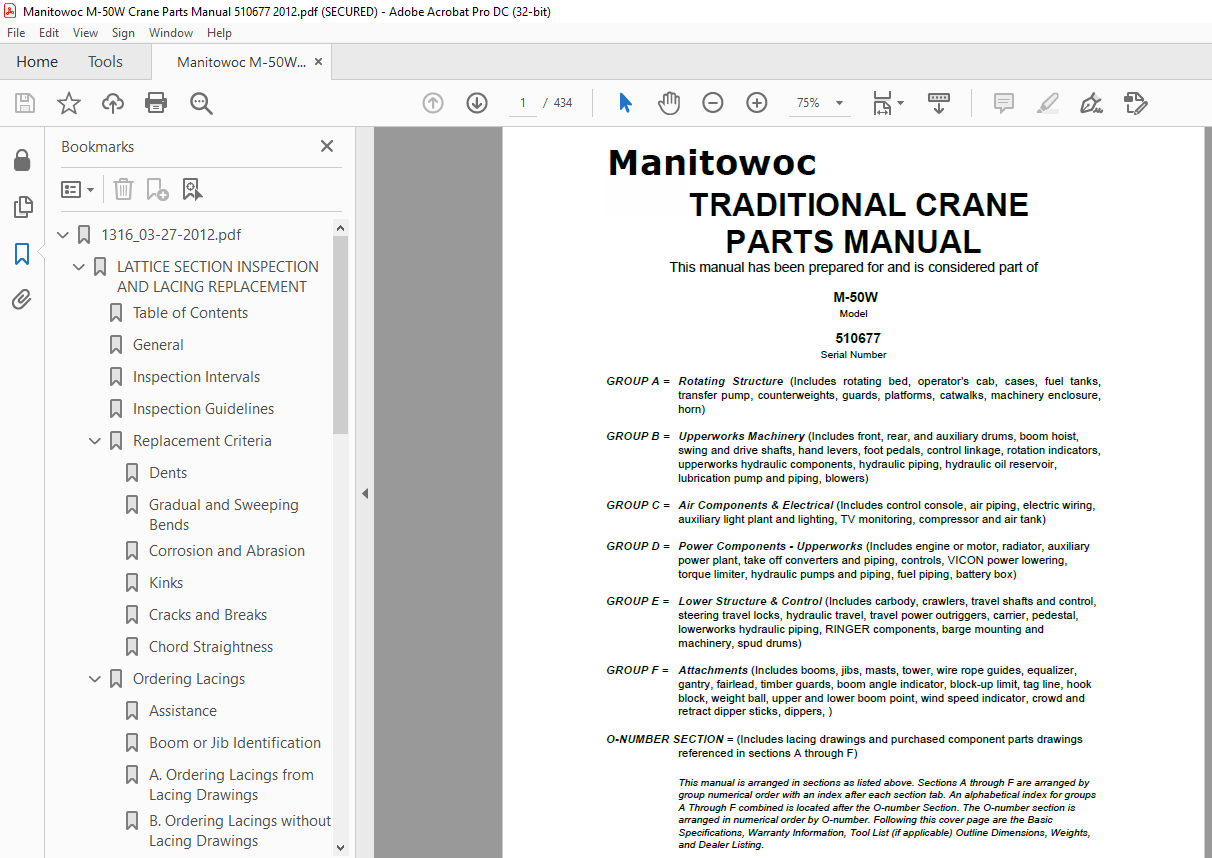

Manitowoc Traditional Crane M-50W Parts Manual SN 510677 – PDF DOWNLOAD

Manitowoc Traditional Crane M-50W Parts Manual SN 510677 – PDF DOWNLOAD

The Manitowoc Traditional Crane M-50W Parts Manual (SN 510677) in PDF format is essential for maintenance. Download for detailed insights into crane components, facilitating effective servicing and operational comprehension.

FILE DETAILS:

Manitowoc Traditional Crane M-50W Parts Manual SN 510677 – PDF DOWNLOAD

Language : English

Pages : 434

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Manitowoc Traditional Crane M-50W Parts Manual SN 510677 – PDF DOWNLOAD

1316_03-27-2012 pdf 0

LATTICE SECTION INSPECTION AND LACING REPLACEMENT 7

Table of Contents 7

General 7

Inspection Intervals 7

Inspection Guidelines 9

Replacement Criteria 9

Dents 9

Gradual and Sweeping Bends 9

Corrosion and Abrasion 11

Kinks 11

Cracks and Breaks 11

Chord Straightness 13

Ordering Lacings 13

Assistance 13

Boom or Jib Identification 13

A Ordering Lacings from Lacing Drawings 14

B Ordering Lacings without Lacing Drawings 15

Repair Procedure 16

Extent of Repair 16

Preparing for Welding 16

Repair Facility 16

Outdoor Repairs 16

General Equipment Requirements 16

Repair Procedures and Processes 17

Lacing Replacement 17

End Lacing Replacement 18

End Lacing Replacement on an Insert (Angle and Tubular Chords) 19

End Lacing Replacement on Tapered Sections (Tubular Chords) 19

Lacing Removal — Boom Section with a Bent or Bowed Chord Member 19

Determining Amount of Stick Electrode Needed 20

Inspection Checklist 25

Record Keeping 25

170177_-_10-18-1991_07-17-1996 pdf 0

17017701 pdf 59

17017702 pdf 60

170942_-_07-17-1991 pdf 0

170942_11 by 17 pdf 61

170942_02_11 by 17 pdf 62

170772_-_06-03-1991_06-14-2006 pdf 0

17077201 pdf 163

17077202 pdf 164

17077203 pdf 165

170935_-_04-19-1991_06-14-2006 pdf 0

17093501 pdf 167

17093502 pdf 168

17093503 pdf 169

171043_-_06-10-1991_05-23-1994 pdf 0

17104301 pdf 171

17104302 pdf 172

17104303 pdf 173

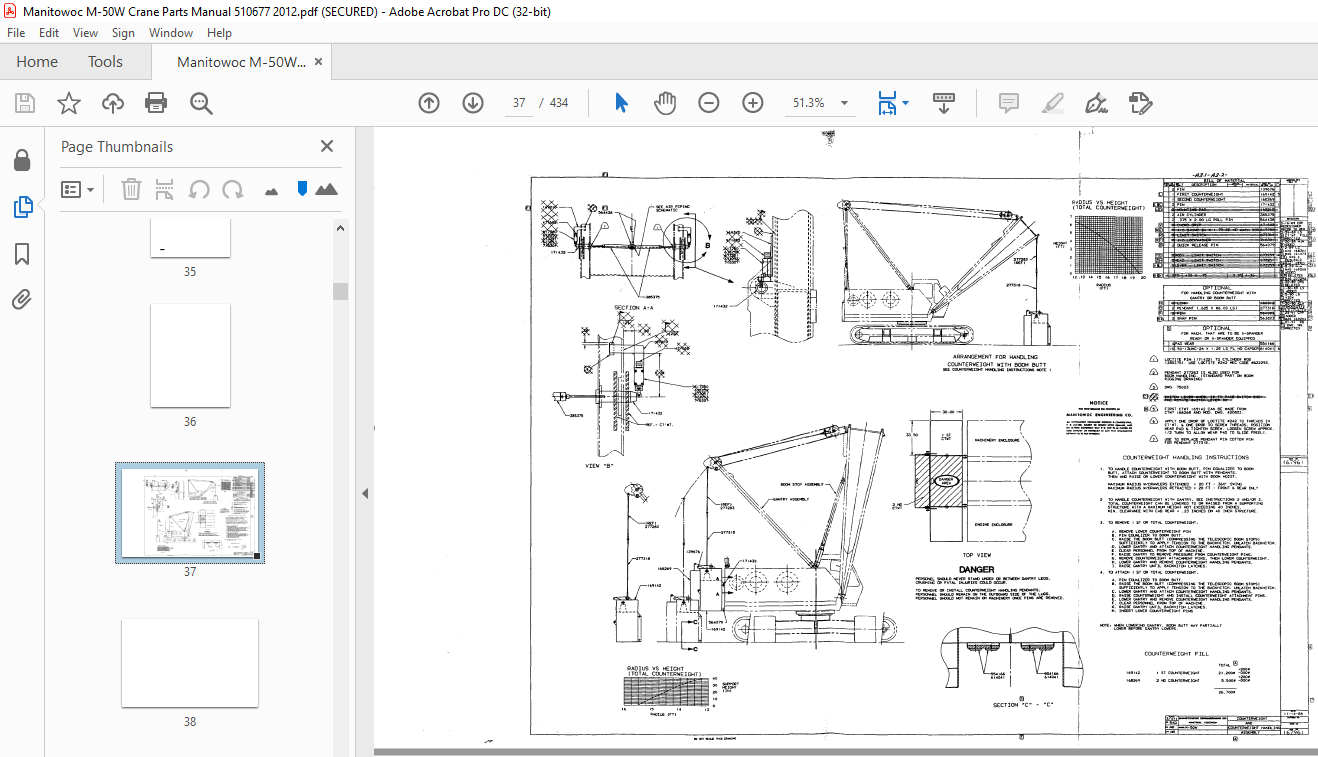

GROUP A = Rotating Structure (Includes rotating bed, operator’s cab, cases, fuel tanks,

transfer pump, counterweights, guards, platforms, catwalks, machinery enclosure,

horn)

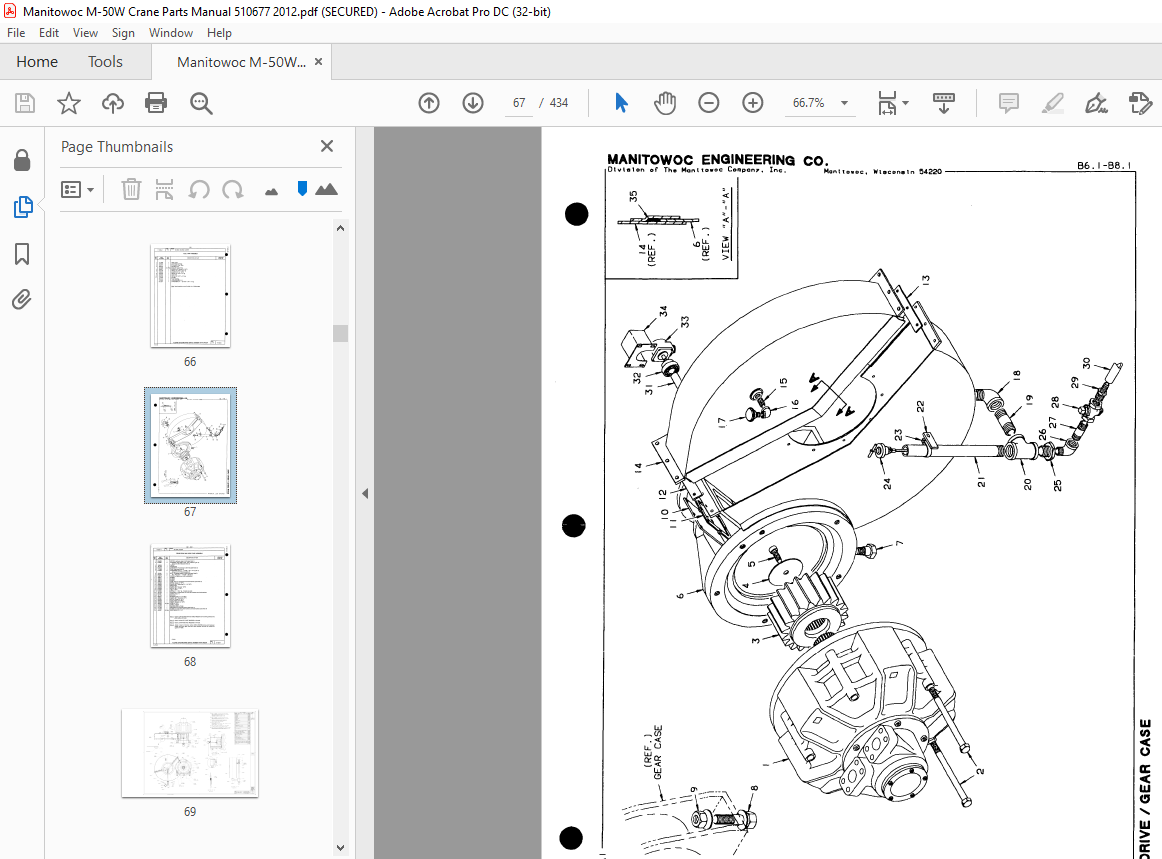

GROUP B = Upperworks Machinery (Includes front, rear, and auxiliary drums, boom hoist,

swing and drive shafts, hand levers, foot pedals, control linkage, rotation indicators,

upperworks hydraulic components, hydraulic piping, hydraulic oil reservoir,

lubrication pump and piping, blowers)

GROUP C = Air Components & Electrical (Includes control console, air piping, electric wiring,

auxiliary light plant and lighting, TV monitoring, compressor and air tank)

GROUP D = Power Components – Upperworks (Includes engine or motor, radiator, auxiliary

power plant, take off converters and piping, controls, VICON power lowering,

torque limiter, hydraulic pumps and piping, fuel piping, battery box)

GROUP E = Lower Structure & Control (Includes carbody, crawlers, travel shafts and control,

steering travel locks, hydraulic travel, travel power outriggers, carrier, pedestal,

lowerworks hydraulic piping, RINGER components, barge mounting and

machinery, spud drums)

GROUP F = Attachments (Includes booms, jibs, masts, tower, wire rope guides, equalizer,

gantry, fairlead, timber guards, boom angle indicator, block-up limit, tag line, hook

block, weight ball, upper and lower boom point, wind speed indicator, crowd and

retract dipper sticks, dippers, )

O-NUMBER SECTION = (Includes lacing drawings and purchased component parts drawings

referenced in sections A through F)