$39

Mitsubishi Galant 2007 Workshop Manual – PDF DOWNLOAD

Mitsubishi Galant 2007 Workshop Manual – PDF DOWNLOAD

FILE DETAILS:

Mitsubishi Galant 2007 Workshop Manual – PDF DOWNLOAD

Language : English

Pages : 215

Downloadable : Yes

File Type : PDF

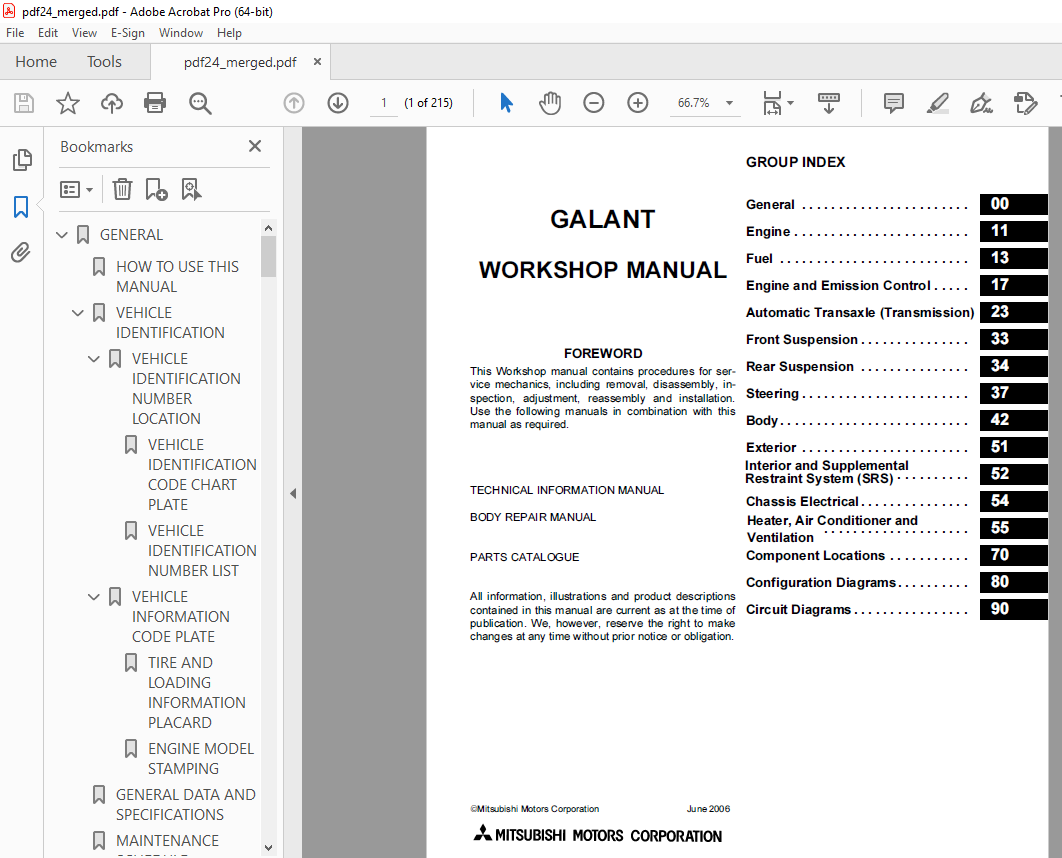

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Mitsubishi Galant 2007 Workshop Manual – PDF DOWNLOAD

GENERAL 101

HOW TO USE THIS MANUAL 4

VEHICLE IDENTIFICATION 71

VEHICLE IDENTIFICATION NUMBER LOCATION 180

VEHICLE IDENTIFICATION CODE CHART PLATE 101

VEHICLE IDENTIFICATION NUMBER LIST 4

VEHICLE INFORMATION CODE PLATE 188

TIRE AND LOADING INFORMATION PLACARD 79

ENGINE MODEL STAMPING 189

GENERAL DATA AND SPECIFICATIONS 7

MAINTENANCE SCHEDULE 21

ENGINE 187

ENGINE MECHANICAL 187

GENERAL DESCRIPTION 172

CAMSHAFT AND VALVE STEM SEAL 10

ENGINE OVERHAUL 187

GENERAL DESCRIPTION 71

ROCKER ARMS AND CAMSHAFT 172

FASTENER TIGHTENING SPECIFICATIONS 13

MULTIPORT FUEL INJECTION (MFI) 187

GENERAL DESCRIPTION 59

OUTLINE OF CHANGE 15

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS 57

PROVISIONAL DTCs [OBD-II Test Mode – Results (Mode 7)] 110

MODE 6 REFERENCE TABLE 20

SYSTEM READINESS TEST STATUS 22

ON-VEHICLE SERVICE 51

EVAPORATVE EMISSION VENTILATION SOLENOID CHECK 51

SPECIFICATION(S) 51

ENGINE AND EMISSION CONTROL 187

EMISSION CONTROL 53

OUTLINE OF CHANGE 183

POSITIVE CRANKCASE VENTILATION SYSTEM 53

POSITIVE CRANKCASE VENTILATION SYSTEM CHECK 180

POSITIVE CRANKCASE VENTILATION VALVE CHECK 61

AUTOMATIC TRANSAXLE 187

GENERAL DESCRIPTION 178

FRONT SUSPENSION 187

GENERAL INFORMATION 61

SPECIFICATIONS 61

ON-VEHICLE SERVICE 57

FRONT WHEEL ALIGNMENT CHECK AND ADJUSTMENT 188

REAR SUSPENSION 187

GENERAL DESCRIPTION 61

ON-VEHICLE SERVICE 63

REAR WHEEL ALIGNMENT CHECK AND ADJUSTMENT 59

SPECIFICATIONS 59

POWER STEERING 187

GENERAL INFORMATION 61

ON-VEHICLE SERVICE 61

STEERING ANGLE CHECK 67

SPECIFICATIONS 73

BODY 187

GENERAL DESCRIPTION 71

FENDER 63

REMOVAL SERVICE POINT 65

INSTALLATION SERVICE POINT 188

EXTERIOR 187

GENERAL 67

FRONT BUMPER ASSEMBLY 85

REAR BUMPER ASSEMBLY 180

INTERIOR 187

GENERAL DESCRIPTION 72

INSIDE REAR VIEW MIRROR DIAGNOSIS 72

SYMPTOM PROCEDURES 73

The Inside Rear View Mirror can’t be Set to Night Mode 73

DIAGNOSIS 188

STEP 1 Check inside rear view mirror assembly connector D-49 for loose, corroded or damaged terminals, or terminals pushed back in the connector 75

STEP 2 Measure the voltage at inside rear view mirror assembly connector D-49 174

STEP 3 Check the wiring harness between inside rear view mirror assembly connector D-49 (terminal 1) and the ignition switch (IG2) 76

STEP 4 Measure the resistance at inside rear view mirror assembly connector D-49 77

STEP 5 Check the wiring harness between inside rear view mirror assembly connector D-49 (terminal 2) and ground 77

STEP 6 Measure the voltage at inside rear view mirror assembly connector D-49 78

STEP 7 Check transmission range switch connector B-110 for loose, corroded or damaged terminals, or terminals pushed back in the connector 189

STEP 8 Check the transmission range switch 79

STEP 9 Check the ignition switch (IG1) circuit to the backup light switch Measure the voltage at transmission range switch connector B-110 79

STEP 10 Check the wiring harness between transmission range switch connector B-110 (terminal 8) and the ignition switch (IG1) 191

STEP 11 Check the wiring harness between inside rear view mirror assembly connector D-49 (terminal 3) and transmission range switch connector B-110 (terminal 7) 82

STEP 12 Check the inside rear view mirror assembly 83

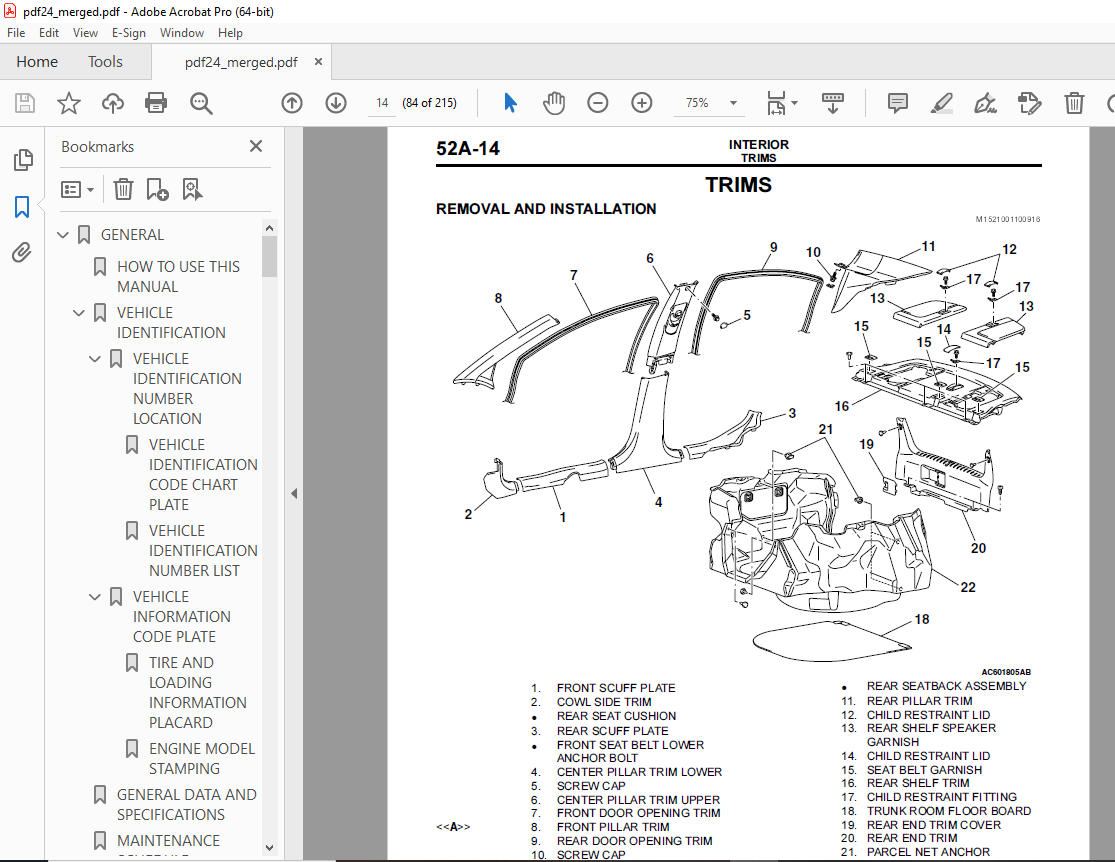

TRIMS 94

CHASSIS ELECTRICAL 101

GENERAL INFORMATION 86

IGNITION SWITCH 188

ON-VEHICLE SERVICE 87

ENCRYPTED CODE REGISTRATION PROCEDURE 87

PRECAUTIONS DURING SERVICE 87

ENCRYPTED CODE REGISTRATION USING IGNITION KEY <REGISTRATION USING SCAN TOOL MB991958 (M U T -III SUB ASSEMBLY)> 180

ENCRYPTED CODE REGISTRATION USING BARCODE NO 90

COMBINATION METER 181

ON-VEHICLE SERVICE 94

SPEEDOMETER CHECK 191

HEADLIGHT, FRONT SIDE MARKER LIGHT AND POSITION LIGHT ASSEMBLY 182

ON-VEHICLE SERVICE 95

HEADLIGHT LEVELING SWITCH CONTINUITY CHECK 96

REAR FOG LIGHT 96

REAR FOG LIGHT 97

INSPECTION 97

REAR FOG LIGHT RELAY CHECK 200

SIDE TURN-SIGNAL LIGHT 98

REMOVAL SERVICE POINT 99

INSTALLATION SERVICE POINT 100

LICENSE PLATE LIGHT 100

SIMPLIFIED WIRING SYSTEM (SWS) 101

GENERAL INFORMATION 188

OUITLINE OF CHANGE 102

SPECIAL TOOL 103

SYMPTOM CHART 180

INPUT SIGNAL CHART 106

SCAN TOOL OR VOLTMETER 106

SYMPTOM PROCEDURES 107

HEADLIGHT AND TAILLIGHT 107

INSPECTION PROCEDURE H-6: Headlight and Taillight: The taillights, the position lights or the license plate light do not illuminate 107

STEP 1 Check the operation of each light 191

STEP 2 Check joint connector C-01 and front-ECU connector A-11X for loose, corroded or damaged terminals, or terminals pushed back in the connector 109

STEP 3 Check the wiring harness between joint connector C-01 (terminal 1) and front-ECU connector A-11X (terminal 4) 110

STEP 4 Check joint connector C-01 and front-ECU connector A-11X for loose, corroded or damaged terminals, or terminals pushed back in the connector 110

STEP 5 Check the wiring harness between joint connector C-01 (terminal 18) and front-ECU connector A-11X (terminal 4) 111

STEP 6 Check joint connector C-01 for loose, corroded or damaged terminals, or terminals pushed back in the connector 191

STEP 7 Check the wiring harness between joint connector C-01 (terminal 4) and rear combination light (LH) connector F-09 (terminal 4) 182

STEP 8 Check rear combination light (LH) connector F-09 for loose, corroded or damaged terminals, or terminals pushed back in the connector 191

STEP 9 Check the tail light bulb (LH) 182

STEP 10 Check the ground circuit to the rear combination light (LH) Measure the resistance at rear combination light (LH) connector F-09 113

STEP 11 Check the wiring harness between rear combination light (LH) connector F-09 (terminal 2) and ground 114

STEP 12 Check the wiring harness between rear combination light (LH) connector F-09 (terminal 4) and intermediate connector C-25 (terminal 10) 114

STEP 13 Check rear combination light (RH) connector F- 03 for loose, corroded or damaged terminals, or terminals pushed back in the connector 115

STEP 14 Check the taillight bulb (RH) 115

STEP 15 Check the ground circuit to the rear combination light (RH) Measure the resistance at rear combination light (RH) connector F-03 115

STEP 16 Check the wiring harness between rear combination light (RH) connector F-03 (terminal 2) and ground 116

STEP 17 Check joint connector C-01 for loose, corroded or damaged terminals, or terminals pushed back in the connector 116

STEP 18 Check the wiring harness between rear combination light (RH) connector F-03 (terminal 4) and joint connector C-01 (terminal 22) 183

STEP 19 Check position light (LH) connector A-45 for loose, corroded or damaged terminals, or terminals pushed back in the connector 118

STEP 20 Check the position light bulb (LH) 118

STEP 21 Check the ground circuit to the position light (LH) Measure the resistance at position light (LH) connector A-45 118

STEP 22 Check the wiring harness between position light light (LH) connector A-45 (terminal 2) and ground 119

STEP 23 Check joint connector C-01 for loose, corroded or damaged terminals, or terminals pushed back in the connector 119

STEP 24 Check the wiring harness between position light light (LH) connector A-45 (terminal 1) and joint connector C-01 (terminal 3) 119

STEP 25 Check position light (RH) connector A-48 for loose, corroded or damaged terminals, or terminals pushed back in the connector 120

STEP 26 Check the position light bulb (RH) 120

STEP 27 Check the ground circuit to the position light (RH) Measure the resistance at position light (RH) connector A-48 120

STEP 28 Check the wiring harness between position light light (RH) connector A-48 (terminal 2) and ground 121

STEP 29 Check joint connector C-01 for loose, corroded or damaged terminals, or terminals pushed back in the connector 121

STEP 30 Check the wiring harness between position light light (RH) connector A-48 (terminal 1) and joint connector C-01 (terminal 19) 185

STEP 31 Check license plate light (LH) connector F-12 for loose, corroded or damaged terminals, or terminals pushed back in the connector 122

STEP 32 Check the wiring harness between license plate light (LH) connector F-06 (terminal 2) and ground 122

STEP 33 Check license plate light (LH) connector F-12 for loose, corroded or damaged terminals, or terminals pushed back in the connector 122

STEP 34 Check the license plate light (LH) bulb 122

STEP 35 Check the ground circuit to the license plate light (LH) Measure the resistance at license plate light (LH) connector F-12 123

STEP 36 Check the wiring harness between license plate light connector (LH) F-12 (terminal 2) and ground 123

STEP 37 Check intermediate connector C-25 for loose, corroded or damaged terminals, or terminals pushed back in the connector 185

STEP 38 Check the wiring harness between license plate light (LH) connector F-12 (terminal 1) and intermediate connector C-25 (terminal 10) 124

STEP 39 Check license plate light (RH) connector F-11 for loose, corroded or damaged terminals, or terminals pushed back in the connector 124

STEP 40 Check the license plate light (RH) bulb 124

STEP 41 Check the ground circuit to the license plate light (RH) Measure the resistance at license plate light (RH) connector F-11 125

STEP 42 Check the wiring harness between license plate light connector (RH) F-11 (terminal 2) and ground 125

STEP 43 Check intermediate connector C-25 for loose, corroded or damaged terminals, or terminals pushed back in the connector 125

STEP 44 Check the wiring harness between license plate light (RH) connector F-11 (terminal 1) and intermediate connector C-25 (terminal 10) 126

INSPECTION PROCEDURE H-7: Headlight and Taillight: One of the headlights does not illuminate 127

STEP 1 Check the headlight operation 128

STEP 2 Check headlight (LH) connector A-46 for loose, corroded or damaged terminals, or terminals pushed back in the connector 129

STEP 3 Check headlight (LH) bulb 129

STEP 4 Check the wiring harness between headlight (LH) connector A-46 (terminal 1) and ground 129

STEP 5 Check headlight (RH) connector A-47 for loose, corroded or damaged terminals, or terminals pushed back in the connector 129

STEP 6 Check the headlight (RH) bulb 130

STEP 7 Check the wiring harness between headlight (RH) connector A-47 (terminal 1) and ground 130

STEP 8 Check headlight (LH) connector A-46 and front- ECU connector A-11X for loose, corroded or damaged terminals, or terminals pushed back in the connector 130

STEP 9 Check headlight (LH) bulb 131

STEP 10 Check the wiring harness between headlight (LH) connector A-46 (terminal 2) and front-ECU connector A- 11X (terminal 6) 131

STEP 11 Check headlight (RH) connector A-47 and front- ECU connector A-11X for loose, corroded or damaged terminals, or terminals pushed back in the connector 132

STEP 12 Check the headlight (RH) bulb 132

STEP 13 Check the wiring harness between headlight (RH) connector A-47 (terminal 2) and front-ECU connector A- 11X (terminal 6) 133

STEP 14 Check headlight (LH) connector A-46 and front- ECU connector A-11X for loose, corroded or damaged terminals, or terminals pushed back in the connector 133

STEP 15 Check headlight (LH) bulb 134

STEP 16 Check the wiring harness between headlight (LH) connector A-46 (terminal 3) and front-ECU connector A- 11X (terminal 10) 134

STEP 17 Check headlight (RH) connector A-47 and front- ECU connector A-11X for loose, corroded or damaged terminals, or terminals pushed back in the connector 135

STEP 18 Check the headlight (RH) bulb 135

STEP 19 Check the wiring harness between headlight (RH) connector A-47 (terminal 3) and front-ECU connector A- 11X (terminal 10) 136

FLASHER TIMER 137

INSPECTION PROCEDURE I-3: Flasher Timer: One of the turn-signal lights does not illuminate 137

DIAGNOSIS 138

STEP 1 Check the hazard warning light 139

STEP 2 Check front turn signal light (LH) connector A-43 for loose, corroded or damaged terminals, or terminals pushed back in the connector 139

STEP 3 Check the front turn-signal light bulb (LH) 139

STEP 4 Check the ground circuit to the ETACS-ECU Measure the resistance at front turn signal light (LH) connector A-43 140

STEP 5 Check the wiring harness between front turn signal light (LH) connector A-43 (terminal 1) and ground 140

STEP 6 Check ETACS-ECU connector C-219 for loose, corroded or damaged terminals, or terminals pushed back in the connector 140

STEP 7 Check the wiring harness between front turn signal light (LH) connector A-43 (terminal 2) and ETACS- ECU connector C-219 (terminal 14) 141

STEP 8 Check front turn signal light (RH) connector A-49 for loose, corroded or damaged terminals, or terminals pushed back in the connector 142

STEP 9 Check the front turn-signal light bulb (RH) 142

STEP 10 Check the ground circuit to the front turn signal light (RH) Measure the resistance at front turn signal light (RH) connector A-49 142

STEP 11 Check the wiring harness between front turn signal light (RH) connector A-49 (terminal 1) and ground 143

STEP 12 Check ETACS-ECU connector C-219 for loose, corroded or damaged terminals, or terminals pushed back in the connector 143

STEP 13 Check the wiring harness between front turn signal light (RH) connector A-49 (terminal 2) and ETACS- ECU connector C-219 (terminal 9) 143

STEP 14 Check rear combination light (LH) connector F-09 for loose, corroded or damaged terminals, or terminals pushed back in the connector 144

STEP 15 Check the rear turn-signal light bulb (LH) 144

STEP 16 Check the ground circuit to the rear combination light (LH) Measure the resistance at rear combination light (LH) connector F-09 145

STEP 17 Check the wiring harness between rear combination light (LH) connector F-09 (terminal 2) and ground 145

STEP 18 Check ETACS-ECU connector C-219 for loose, corroded or damaged terminals, or terminals pushed back in the connector 146

STEP 19 Check the wiring harness between rear combination light (LH) connector F-09 (terminal 5) and ETACS-ECU connector C-219 (terminal 14) 146

STEP 20 Check rear combination light (RH) connector F- 03 for loose, corroded or damaged terminals, or terminals pushed back in the connector 147

STEP 21 Check the rear turn-signal light bulb (RH) 147

STEP 22 Check the ground circuit to the rear turn-signal light (RH) Measure the resistance at rear combination light (RH) connector F-03 148

STEP 23 Check the wiring harness between rear combination light (RH) connector F-03 (terminal 2) and ground 148

STEP 24 Check ETACS-ECU connector C-219 for loose, corroded or damaged terminals, or terminals pushed back in the connector 149

STEP 25 Check the wiring harness between rear combination light (RH) connector F-03 (terminal 5) and ETACS-ECU connector C-219 (terminal 9) 149

STEP 26 Check side turn signal light (LH) connector A-42 for loose, corroded or damaged terminals, or terminals pushed back in the connector 150

STEP 27 Check the side turn-signal light bulb (LH) 150

STEP 28 Check the ground circuit to the ETACS-ECU Measure the resistance at side turn signal light (LH) connector A-42 151

STEP 29 Check the wiring harness between side turn signal light (LH) connector A-42 (terminal 1) and ground 151

STEP 30 Check ETACS-ECU connector C-219 for loose, corroded or damaged terminals, or terminals pushed back in the connector 151

STEP 31 Check the wiring harness between side turn signal light (LH) connector A-42 (terminal 2) and ETACS- ECU connector C-219 (terminal 14) 152

STEP 32 Check side turn signal light (RH) connector A-51 for loose, corroded or damaged terminals, or terminals pushed back in the connector 153

STEP 33 Check the side turn-signal light bulb (RH) 153

STEP 34 Check the ground circuit to the side turn signal light (RH) Measure the resistance at side turn signal light (RH) connector A-51 153

STEP 35 Check the wiring harness between side turn signal light (RH) connector A-51 (terminal 1) and ground 154

STEP 36 Check ETACS-ECU connector C-219 for loose, corroded or damaged terminals, or terminals pushed back in the connector 154

STEP 37 Check the wiring harness between side turn signal light (RH) connector A-51 (terminal 2) and ETACS- ECU connector C-219 (terminal 9) 154

FOG LIGHT 155

ECU FUNCTIONS AND CONTROLS IN THE SWS 155

INSPECTION PROCEDURE J-5: The Rear Fog Light do not Illuminate Normally 156

DIAGNOSIS 157

STEP 1 Check the taillight operation 157

STEP 2 Use scan tool MB991958 to select “ECU COMM Check” on the SWS monitor display 158

STEP 3 ETACS switch data by using the SWS monitor 159

STEP 4 Check rear fog light relay connector A-09X for loose, corroded or damaged terminals, or terminals pushed back in the connector 159

STEP 5 Check the rear fog light relay 160

STEP 6 Check the battery power supply circuit to the rear fog light relay Measure the voltage at rear fog light relay connector A-09X 160

STEP 7 Check the wiring harness between rear fog light relay connector A-09X (terminals 1 and 2) and the battery 161

STEP 8 Check ETACS-ECU connector C-217 for loose, corroded or damaged terminals, or terminals pushed back in the connector 161

STEP 9 Check the wiring harness between rear fog light relay connector A-09X (terminal 3) and ETACS-ECU connector C-217 (terminal 40) 161

STEP 10 Check rear fog light connector F-13 for loose, corroded or damaged terminals, or terminals pushed back in the connector 162

STEP 11 Check the ground circuit to the rear fog light Measure the resistance at rear fog light connector F-13 162

STEP 12 Check the wiring harness between rear fog light connector F-13 (terminal 1) and ground 162

STEP 13 Check the wiring harness between rear fog light relay connector A-09X (terminal 4) and rear fog light connector F-13 (terminal 2) 163

INSPECTION PROCEDURE J-6: The Rear Fog Light Indicator does not Illuminate Normally 163

STEP 1 Check the rear fog light 164

STEP 2 Using scan tool MB991958, diagnose the CAN bus line 165

STEP 3 Using scan tool MB991958, read the combination meter diagnostic trouble code 165

STEP 4 Use scan tool MB991958 to select “ECU COMM Check” on the SWS monitor display 166

STEP 5 Replace the combination meter 166

INPUT SIGNAL PROCEDURES 167

INSPECTION PROCEDURE N-11: ETACS-ECU does not Receive Any Signal from the Rear Fog Light Switch 167

DIAGNOSIS 168

STEP 1 Check fog light switch connector C-128 for loose, corroded or damaged terminals, or terminals pushed back in the connector 168

STEP 2 Check the rear fog light switch 168

STEP 3 Check the ground circuit to the fog light switch Measure the resistance at fog light switch connector C- 128 169

STEP 4 Check the wiring harness between fog light switch connector C-128 (terminal 6) and ground 169

STEP 5 Check ETACS-ECU connector C-217 for loose, corroded or damaged terminals, or terminals pushed back in the connector 169

STEP 6 Check the wiring harness between fog light switch connector C-128 (terminal 1) and ETACS-ECU connector C- 217 (terminal 54) 170

AUTOMATIC AIR CONDITIONING 187

GENERAL DESCRIPTION 172

SYMPTOM PROCEDURES 172

When Sunlight Intensity Changes, Air Outlet Temperature Does Not Change 172

DIAGNOSIS 180

STEP 1 Check the defogger and outside/inside air selection damper control motor operation 173

STEP 2 Using scan tool MB991958, read diagnostic trouble code 180

STEP 3 Using scan tool MB991958, check data list item 06: Photo sensor 174

STEP 4 Check A/C-ECU connectors C-15, C-16 and photo sensor connector C-04 for loose, corroded or damaged terminals, or terminals pushed back in the connector 175

STEP 5 Check the wiring harness between photo sensor connector C-04 (terminal 1, 2) and A/C-ECU connector C-15 (terminal 19), C-16 (terminal 25) 176

STEP 6 Replace the photo sensor 180

STEP 7 Check the refrigerant level 176

COMPONENT LOCATIONS 187

RELAY 178

CONFIGURATION DIAGRAMS 187

ENGINE COMPARTMENT <VEHICLES FOR RUSSIA> 187

DASH PANEL <VEHICLES FOR RUSSIA> 181

FLOOR AND ROOF <VEHICLES FOR RUSSIA> 185

LUGGAGE COMPARTMENT <VEHICLES FOR RUSSIA> 186

CIRCUIT DIAGRAMS 187

CENTRALIZED JUNCTION <VEHICLES FOR RUSSIA> 188

FUSIBLE LINK AND FUSE 188

POWER DISTRIBUTION SYSTEM <VEHICLES FOR RUSSIA> 195

HEADLIGHT <VEHICLES FOR RUSSIA> 197

TAILLIGHT, POSITION LIGHT AND LICENSE PLATE LIGHT <VEHICLES FOR RUSSIA> 199

REAR FOG LIGHT <VEHICLES FOR RUSSIA> 201

HEADLIGHT LEVELING SYSTEM <VEHICLES FOR RUSSIA> 203

TURN-SIGNAL LIGHT AND HAZARD WARNING LIGHT <VEHICLES FOR RUSSIA> 205

CENTRAL DOOR LOCKING SYSTEM <VEHICLES FOR RUSSIA> 208

AUTOMATIC AIR CONDITIONING SYSTEM <VEHICLES FOR RUSSIA> 212

AUTOMATIC ANTI-DAZZLING MIRROR <VEHICLES FOR RUSSIA> 215