$40

MTU Diesel Engine 20V4000Gx2 Operating Instructions Manual M015565-03E PDF DOWNLOAD

MTU Diesel Engine 20V4000Gx2 Operating Instructions Manual M015565-03E PDF DOWNLOAD

FILE DETAILS:

MTU Diesel Engine 20V4000Gx2 Operating Instructions Manual M015565-03E PDF DOWNLOAD

Language : English

Pages : 143

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

MTU Diesel Engine 20V4000Gx2 Operating Instructions Manual M015565-03E PDF DOWNLOAD

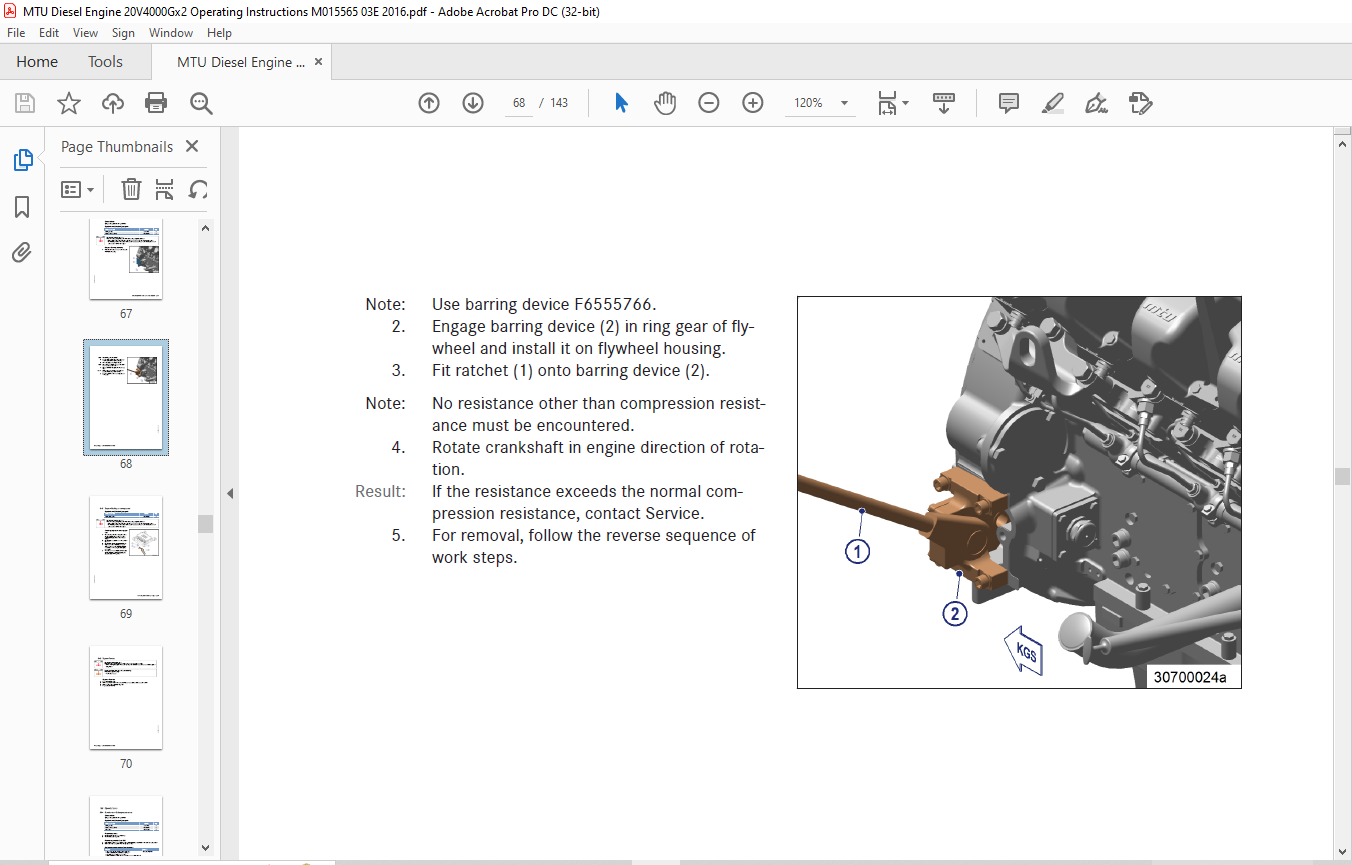

Operating Instructions 1Table of Contents 31 Safety 511 Important provisions for all products 512 Correct use for all products 613 Personnel and organizational requirements 714 Safety regulations for startup and operation 815 Safety precautions when working on the engine 1016 Fire prevention and environmental protection, fluids and lubricants, auxiliary materials 1317 Standards for safety notices in the text 152 Transport 1621 Transportation 1622 Lifting requirements 1723 Crankshaft transport locking device 183 General Information 2131 Engine side and cylinder designations 2132 Engine overview 224 Technical Data 2341 20V4000 continuous operation, unrestricted 3A, optimized fuel consumption G62, emissions-optimized (EPA) G82 2342 20V4000 continuous operation, variable 3B, optimized fuel consumption G22/G62, emissions-optimized (“TA-Luft”) G22/G62, emissions-optimized (EPA) G42/G82 2743 20V4000 continuous operation, restricted 3C, optimized fuel consumption G22/G62, emissions-optimized (“TA-Luft”) G22/G62 3244 20V4000 standby power 3D, optimized fuel consumption G22/G62, emissions-optimized (EPA) G42/G82 3645 Final compression pressure 4046 Firing order 4147 Main engine dimensions 425 Operation 4351 Putting the engine into operation after extended out-of-service periods (>3 months) 4352 Putting the engine into operation after scheduled out-of-service-period 4453 Engine – Starting in manual mode (test run) 4554 Starting the engine in emergency situations (override mode) 4655 Operational monitoring 4756 Engine – Stopping in manual mode (test run) 4857 Engine – Emergency stop 4958 After stopping the engine – Putting the engine out of operation 5059 Plant – Cleaning 516 Maintenance 5261 Maintenance task reference table [QL1] 527 Troubleshooting 5371 Troubleshooting 5372 Fault messages on engine governor 568 Task Description 6781 Engine 67811 Engine – Barring manually 67812 Engine – Cranking on starting system 69813 Engine – Test run 7082 Cylinder Liner 71821 Cylinder liner – Endoscopic examination 71822 Instructions and comments on endoscopic and visual examination of cylinder liners 7383 Crankcase Breather 75831 Crankcase breather – Oil separator element replacement 7584 Valve Drive 77841 Cylinder head cover – Removal and installation 77842 Valve gear – Lubrication 78843 Valve clearance – Check and adjustment 7985 Injection Pump / HP Pump 84851 HP fuel pump – Relief bore check 8486 Injector 85861 Injector – Replacement 85862 Injector – Removal and installation 8687 Fuel System 91871 Fuel system – Venting 9188 Fuel Filter 92881 Fuel filter – Replacement 92882 Fuel prefilter – Cleaning 93883 Fuel prefilter – Differential pressure gage check and adjustment of gage 94884 Fuel prefilter – Draining 95885 Fuel prefilter – Flushing 96886 Fuel prefilter – Filter element replacement 9889 Charge-Air Cooling100891 Intercooler – Check water drain for coolant leakage and absence of restrictions100810 Air Filter1018101 Air filter ‒ Replacement1018102 Air filter – Removal and installation102811 Air Intake1038111 Service indicator – Signal ring position check103812 Starting Equipment1048121 Air starter – Manual operation104813 Lube Oil System1058131 Engine oil – Level check1058132 Engine oil – Change106814 Oil Filtration / Cooling1088141 Engine oil filter – Replacement1088142 Centrifugal oil filter – Cleaning and filter-sleeve replacement109815 Coolant Circuit, General, High-Temperature Circuit1118151 Engine coolant – Level check1118152 Engine coolant – Change1128153 Engine coolant – Draining1138154 Engine coolant – Filling1148155 Engine coolant pump – Relief bore check116816 Low-Temperature Circuit1178161 Charge-air coolant – Level check1178162 Charge-air coolant – Change1188163 Charge-air coolant draining1198164 Charge-air coolant – Filling 1208165 Charge-air coolant pump – Relief bore check122817 Belt Drive1238171 Drive belt – Condition check123818 Battery-Charging Generator1248181 Battery-charging generator drive – Drive belt tension adjustment1248182 Battery-charging generator drive – Drive belt condition check1258183 Battery-charging generator drive – Drive belt replacement126819 Engine Mounting / Support1278191 Engine mounting – Resilient mount check127820 Cabling1288201 Engine cabling – Check128821 Accessories for (Electronic) Engine Governor / Control System 1298211 Engine Control Unit and connectors – Cleaning1298212 Engine Control Unit – Plug connection check1309 Appendix A13191 Abbreviations13192 MTU Contact/Service Partners13410 Appendix B135101 Special Tools135102 Index141

DESCRIPTION:

MTU Diesel Engine 20V4000Gx2 Operating Instructions Manual M015565-03E PDF DOWNLOAD

SAFETY INSTRUCTIONS:

Important Provisions for All Product

Nameplate

The product is identified by a nameplate, model designation, or serial number and must match the information on the title page of this manual. The nameplate, model designation, or serial number can be found on the product.

All EU-certified engines delivered by MTU come with a second nameplate. When operating the machine in the EU: The second nameplate must be affixed in a prominent position as described in the accompanying specifications.

General InformationThis product may pose a risk of injury or damage in the following cases:

- Incorrect use

- Operation, maintenance, and repair by unqualified personnel

- Modifications or conversions

- Noncompliance with the safety instructions and warning notices

Emission Regulations and Emission LabelsResponsibility for Compliance with Emission RegulationsModification or removal of any mechanical/electronic components or the installation of additional components, including the execution of calibration processes that might affect the emission characteristics of the product, are prohibited by emission regulations. Emission control units/systems may only be maintained, exchanged, or repaired if the components used for this purpose are approved by the manufacturer.Noncompliance with these regulations will invalidate the design type approval issued by the emissions regulation authorities. The manufacturer does not accept any liability for violations of the emission regulations.The maintenance schedules of the manufacturer must be observed over the entire life cycle of the product.Replacing Components with Emission LabelsOn all MTU engines fitted with emission labels, these labels must remain on the engine throughout its operational life.Engines used exclusively in land-based, military applications other than by US government agencies are excepted from this proviso.Please note the following when replacing components with emission labels:

- The relevant emission labels must be affixed to the spare part.

- Do not transfer the emission labels from the replaced part to the spare part.

- Remove the emission labels from the replaced part and destroy them.