$40

MTU Electronics Training Documentation Electronic Engine Control Technical Documentation Manual PDF

MTU Electronics Training Documentation for Electronic Engine Control Unit ECU-7 (ADEC) Technical Documentation Manual T000001-01E PDF DOWNLOAD

FILE DETAILS:

MTU Electronics Training Documentation for Electronic Engine Control Unit ECU-7 (ADEC) Technical Documentation Manual T000001-01E PDF DOWNLOAD

Language : English

Pages : 246

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

VIDEO PREVIEW:

DESCRIPTION:

MTU Electronics Training Documentation for Electronic Engine Control Unit ECU-7 (ADEC) Technical Documentation Manual T000001-01E PDF DOWNLOAD

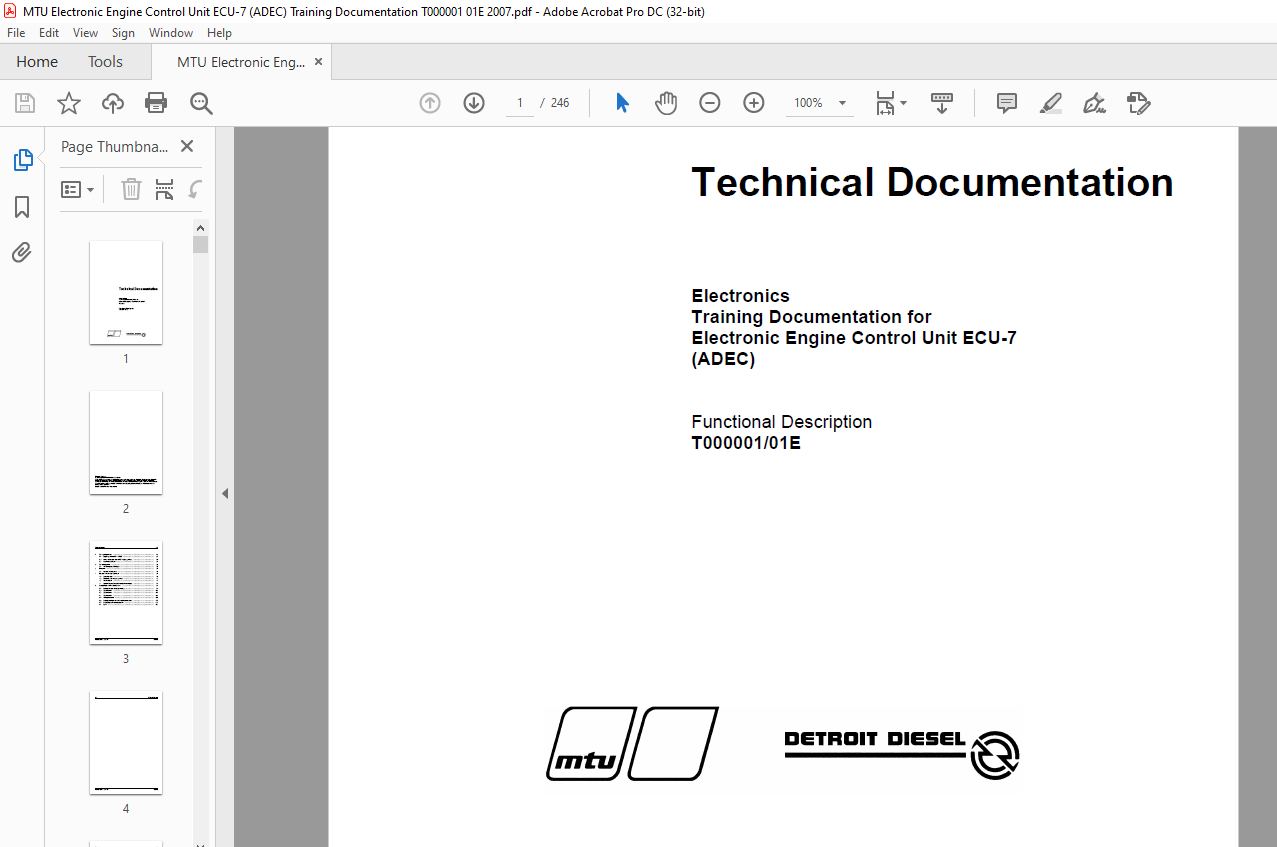

The engine governor1.1 Engine governor ECU 7 – ADEC

General information

To control and regulate a diesel engine, a large number of measurement variables and control signals have to be recorded, evaluated and processed. This information can either be generated on the engine side (e.g. operating data such as pressure and temperatures) or on the system side, i.e. by devices of a higher-order system, which determine how the diesel engine behaves.

Application

The term “application” is used to describe the environment in which the engine (and thus the governor) is used. MTU engines are designed and adapted for the following applications:• Marine These are drive motors for the ship’s main drive. The engine governor Engines for railroad vehicles are used for diesel-electric drives or diesel-hydraulic drives. Diesel-electric drives are basically engines that drive a generator to produce operating voltage. This generator package is geared to the special requirements of a locomotive drive. In the case of diesel-hydraulic drives, a hydraulic pump is driven • Genset Gensets for current generation are either stationary or mobile plants. Mobile plants are used, for example, in ships for on-board power generation (marine gensets”) or in power containers for autonomous power generation. Stationary plants are used, for example, as emergency power units or in combined heat and power plants.• C&I The term C&I covers industrial engines, which can be used in many areas, e.g. excavators or off-highway dump trucks. These engines generally drive generators or hydraulic pumps in a vehicle. These engines are normally delivered to the manufacturer of these vehicles, who then have to adapt the engine and its characteristics to their application.

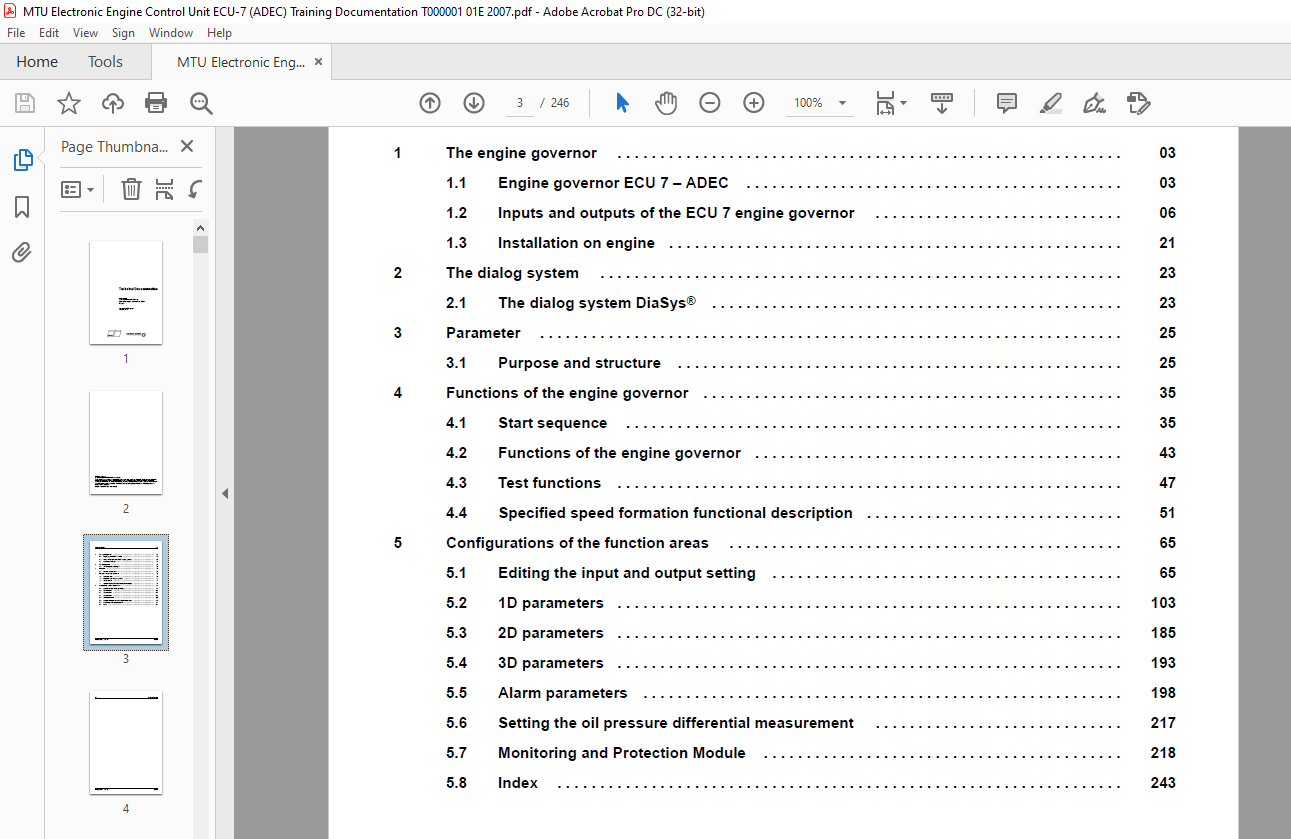

TABLE OF CONTENTS:

MTU Electronics Training Documentation for Electronic Engine Control Unit ECU-7 (ADEC) Technical Documentation Manual T000001-01E PDF DOWNLOAD

Title....................................................................... 1 Table of Contents........................................................... 3 1 The engine governor....................................................... 5 1.1 Engine governor ECU 7 – ADEC........................................ 5 General information................................................. 5 Application......................................................... 5 Engine types........................................................ 6 Series.............................................................. 6 Main features....................................................... 6 Adaptation of the engine governor................................... 6 1.2 Inputs and outputs of the ECU 7 engine governor..................... 8 Block diagram....................................................... 8 Number of inputs and outputs........................................ 10 Connector Assignment................................................ 11 Pin assignment X1................................................... 11 Pin assignment X2................................................... 14 Pin assignment X3................................................... 18 Pin assignment X4................................................... 20 1.3 Installation on engine.............................................. 23 Specifications...................................................... 23 Mechanical installation............................................. 23 2 The dialog system......................................................... 25 2.1 The dialog system DiaSys ®.......................................... 25 General information................................................. 25 Design.............................................................. 25 Connection options.................................................. 25 Software............................................................ 26 3 Parameter................................................................. 27 3.1 Purpose and structure............................................... 27 What is a parameter?................................................ 27 Dongle and access options........................................... 27 Structure of a ..................................................... 28 Number ranges....................................................... 28 4 Functions of the engine governor.......................................... 37 4.1 Start sequence...................................................... 37 Engine governor-internal starting sequence.......................... 37 General information................................................. 37 Settings............................................................ 37 Functions of the starting sequence.................................. 38 Start request (initialization from S1).............................. 39 Non-stored start.................................................... 39 Stored start........................................................ 39 Prelubrication...................................................... 39 Stop request........................................................ 39 Coolant temperature................................................. 39 Prelubrication (S2, S3)............................................. 40 Starting (S4)....................................................... 41 Starter speed (S5, S6).............................................. 41 Starter release speed (S7).......................................... 42 Idle speed (S8)..................................................... 42 Start termination (S9).............................................. 42 Manual turning...................................................... 42 Setting parameters.................................................. 42 Alarm parameters.................................................... 44 4.2 Functions of the engine governor.................................... 45 Idle-maximum-speed governor — variable-speed governor............... 45 Common Rail injection system........................................ 45 Angle measurement/determination of injection timing................. 46 Crankshaft:......................................................... 46 Camshaft:........................................................... 46 Adjustable speed droop.............................................. 46 Power limitations................................................... 47 Exhaust turbocharger................................................ 47 Cylinder cutout..................................................... 47 Overspeed........................................................... 48 4.3 Test functions...................................................... 49 Bedia level sensors................................................. 49 Binary outputs...................................................... 51 Overspeed........................................................... 51 Integrated test system – diagnosis lamp DILA........................ 52 4.4 Specified speed formation functional description.................... 53 General information................................................. 53 Selection of the speed setpoint source.............................. 53 Specified speed formation........................................... 54 Speed setpoint source............................................... 54 Selection of the input.............................................. 55 Setting the inputs for analog specified speed at the governor ...... 55 Selector switch..................................................... 56 Up/Down button...................................................... 57 Speed limits........................................................ 58 Sensor defect....................................................... 59 Default value mode.................................................. 59 Idle speed increase................................................. 59 Specified speed ramp................................................ 59 Speed droop......................................................... 62 Limitation of the effective speed setpoint.......................... 63 Speed increase (Genset application)................................. 63 Idle speed increase................................................. 64 Specified speed limitation.......................................... 64 Example............................................................. 64 5 Configurations of the function areas...................................... 67 5.1 Editing the input and output setting................................ 67 Function area in the Diasys......................................... 67 General information................................................. 67 Transistor outputs, engine.......................................... 68 Transistor outputs, plant........................................... 70 Settings............................................................ 70 Example 1........................................................... 71 Example 2........................................................... 71 Example 3........................................................... 71 Default values...................................................... 72 Analog outputs...................................................... 73 Settings............................................................ 73 Example............................................................. 73 Default values...................................................... 74 Binary outputs...................................................... 74 Channel assignment.................................................. 75 Default values...................................................... 75 ZKP numbers that can be used for the various inputs and outputs .... 76 5.2 1D parameters.......................................................105 Definition..........................................................105 Function area in the Diasys.........................................105 Sensor types........................................................109 Reference ECU input channel - channel No............................110 1D parameters.......................................................110 Details on the parameters...........................................183 ZKP No. 1.2500.001..................................................183 ZKP No. 2.0500.001..................................................183 ZKP No. 2.0500.004..................................................184 ZKP No. 2.0500.008..................................................184 ZKP No. 2.1000.007..................................................184 ZKP No. 2.1010.009..................................................186 ZKP No. 2.1050.009..................................................186 5.3 2D parameters.......................................................187 Definition..........................................................187 Function area in the Diasys.........................................187 Curves (2D parameters)..............................................189 5.4 3D parameters.......................................................195 Definition..........................................................195 Function area in the Diasys.........................................195 5.5 Alarm parameters....................................................200 Function area in the Diasys.........................................200 Setting options for each alarm measurement point....................201 Standard settings...................................................202 Marine application..................................................202 Rail application....................................................202 Genset application..................................................202 Application C&I.....................................................210 Conversion of exported values.......................................217 Values of the individual bits.......................................217 Example.............................................................218 5.6 Setting the oil pressure differential measurement...................219 Principle...........................................................219 Parameter...........................................................219 5.7 Monitoring and Protection Module....................................220 Function area in the Diasys ®.......................................220 General information.................................................224 Structure of the function element ..................................225 Difference formation................................................226 Limit value formation...............................................226 Interface for the function element .................................227 Structure of the function element ..................................227 Behavior of the Protection module...................................227 Characteristics of the Protection module............................228 Calculation of the ZKP No. for parameters...........................229 Values for calculation..............................................229 Example.............................................................230 Setting the various functions.......................................230 Relevant settings...................................................230 Warning function....................................................232 Parameter setting for a warning (the behavior of the Protection ....232 Use ................................................................233 Limitation function using the example of engine coolant temperat....234 Parameter setting for a limitation (the behavior of the Protecti....235 Use ................................................................236 Reduction function..................................................237 Parameter setting for a reduction (the behavior of the Protectio....238 Use ................................................................239 Stop function.......................................................240 Parameter setting for tripping a stop (the behavior of the Prote....241 Use ................................................................242 Limitation with delayed alarm.......................................243 5.8 Index...............................................................245