$34

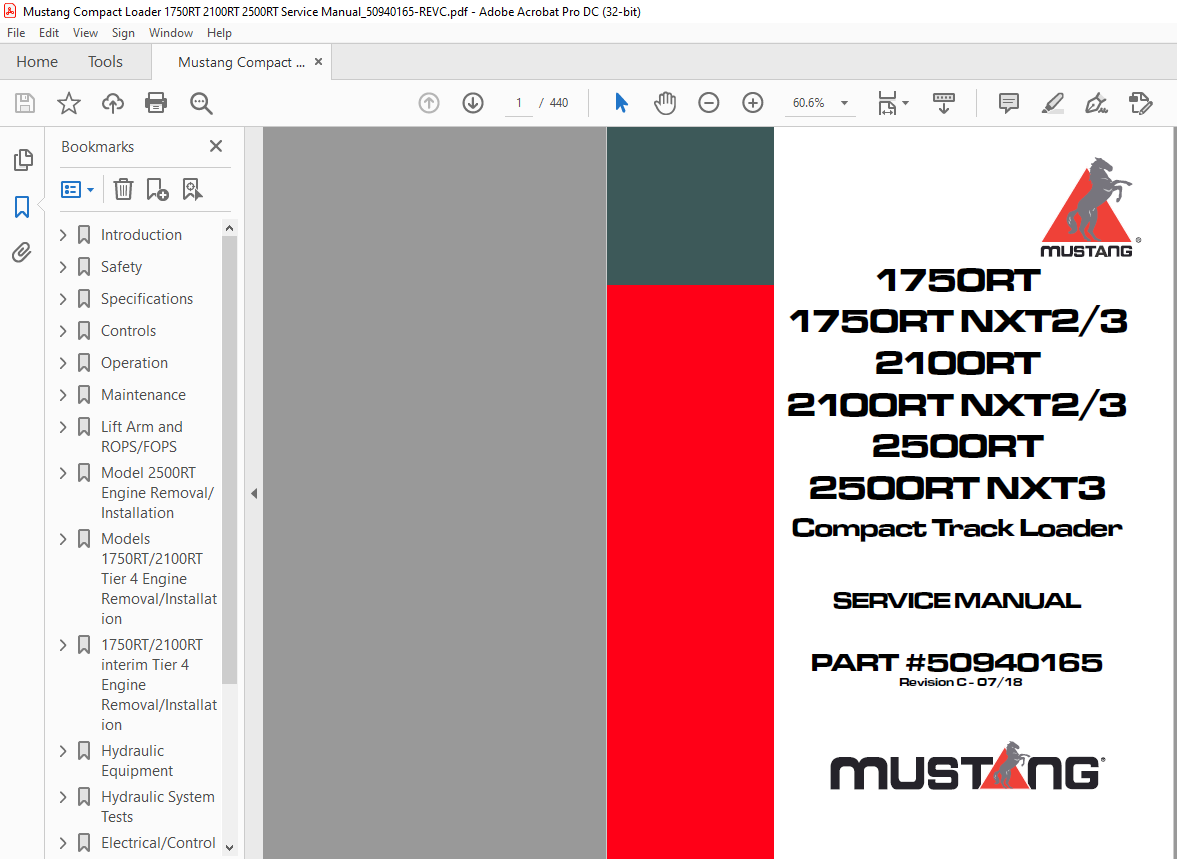

Mustang Compact Track Loader 1750RT 2100RT 2500RT Service Manual (50940165) – PDF DOWNLOAD

Mustang Compact Track Loader 1750RT 2100RT 2500RT Service Manual (50940165) – PDF DOWNLOAD

DESCRIPTION:

Mustang Compact Track Loader 1750RT 2100RT 2500RT Service Manual (50940165) – PDF DOWNLOAD

1750RT

1750RT NXT2/3

2100RT

2100RT NXT2/3

2500RT

2500RT NXT3

Safety Alert Symbol

This symbol identifies potential safety hazards, which, if not properly avoided, could result in injury. When you see this symbol in this manual or on the machine, you are reminded to BE ALERT! Your personal safety is involved

Introduction

Contents and Use of this Manual

- This manual provides information about the safe and proper operation, maintenance and service procedures for the machine. Major points of safe operation, maintenance and service are detailed in the Safety chapter of this manual. This manual also includes general troubleshooting and specification information about the machine.

- Follow the instructions in the Safety, Operation and Maintenance chapters concerning accident prevention regulations, safety and occupational regulations, and machine and traffic regulations. Manitou Americas is not liable for damage resulting from the failure to follow these regulations.

- CAUTION Improper operation, inspection, maintenance and service of the machine can cause injury or death. Become familiar with the machine before operating it. It is the owner’s or employer’s responsibility to fully instruct each operator in the proper and safe operation and maintenance of the machine.

- It is the owner’s or employer’s responsibility to fully instruct each operator in the proper and safe operation and maintenance of the machine. A storage container is provided behind the operator’s seat for storing the Operator’s Manual. After using the manual, return it to the storage container. This manual is considered a permanent part of the machine and should be with the machine at all times.

- If the machine is resold, include this operator’s manual as part of the sale. Replace this manual promptly if it becomes damaged, lost or stolen. Some illustrations in this manual may show doors, guards and shields open or removed for illustrative purposes only. BE SURE all doors, guards and shields are in their proper operating positions BEFORE starting the engine to operate the machine.

- Because of ongoing product improvements, information included in this manual may not exactly match the machine. Manitou Americas reserves the right to modify and improve products at any time without notice or obligation.

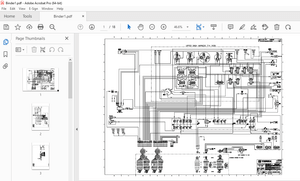

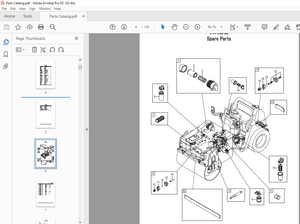

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Mustang Compact Track Loader 1750RT 2100RT 2500RT Service Manual (50940165) – PDF DOWNLOAD

Introduction11

Safety Symbol 11

Contents and Use of this Manual 11

Safety Symbol and Signal Words12

Safety Alert Symbol 12

Signal Words 12

Machine Orientation 12

Proper Machine Use12

Service and Registration 13

Machine Model and Serial Numbers 13

Component Serial Numbers 13

ROPS/FOPS Certification Label14

Component Identification15

Fields of Application 16

Using Attachments 16

Vibration Information 17

Vibration Measurement and Actions17

Vibration Levels 18

Fire Extinguisher 18

Manufacturer Information 18

Indicator and Operation Symbols19

Safety21

Safety Symbol and Signal Words21

Safety Alert Symbol 21

Signal Words 21

Mandatory Safety Shutdown Procedure22

Before Starting 22

During Operation 23

Applications with Load-Handling Devices 26

Parking the Machine27

Electrical Energy 27

Maintenance and Service Safety Practices27

Battery Hazards29

Fire Hazards30

Additional Safety Equipment 30

Crystalline Silica Exposure31

Transporting the Machine31

Lifting the Machine with a Crane 31

Loading and Transporting the Machine31

Safety Decals 32

New Decal Application32

ANSI-Style Safety Decals33

ISO-Style Safety Decals35

Specifications 37

Fluids/Lubricants Types and Capacities37

Dimensions38

Payloads/Capacities40

Weights 41

Track Drive 41

Coolant Compound Table 41

Engine 42

Table of Contents

50940165/C0718 2 Printed in USA

Hydraulic System 43

General 43

Drive Hydraulics 44

Pumps 44

Cylinders 45

Forces and Cycle Times 45

Electrical System 46

Sound Power/Pressure Levels 46

Vibration Levels 46

Features 47

Standard Features 47

Optional Features 47

Common Materials and Densities 48

Controls 49

Multi-Function Display 50

Switches/Indicators 51

Multi-Function Display Screens 52

Screen Access 52

Status, Maintenance and Error Code Screens 52

Configuration Screens 54

Audible Alerts 57

Control Joysticks 57

Joystick Tilt Function ISO/D-H Control Patterns 57

Activating D-H Control Pattern Option 57

Deactivating D-H Control Pattern Option 58

Left Joystick Functions 58

Right Joystick Functions 59

Joystick Buttons/Switch Functions 59

Joystick Control Sensitivity 60

Configuring Control Sensitivity 60

Straight Tracking Adjust 61

Parking Brake/Work Hydraulics Lock-out 63

Cab Heat and Air Conditioning (Option) 63

Operator’s Seat 64

Seat Forward and Back Horizontal Adjustment 64

Seat Height Vertical Height/Weight Suspension Adjustment 64

Air Suspension 64

Mechanical Suspension 64

Seat Belt 64

Fastening/Unfastening the Seat Belt 65

Armrest/Joystick Console Adjustment 65

Throttle Controls 66

Travel Controls 66

Travel Speed Range Selection 66

Travel Speed Limit (Option) 67

Activating Travel Speed Limit Option 67

Deactivating Travel Speed Limit Option 68

Travel Speed Limit Option Operation 68

Lift Arm Float Button 69

Hydraglide™ Button (Option) 69

Work Lights 70

Work Lights 70

Battery Disconnect Switch (Option) 70

Windshield Wipers/Washer 71

Wiper/Washer Control 71

Washer Fluid Reservoir 71

Printed in USA 3 50940165/C0718

Operation73

Operational Checks73

Pre-Start Checks 73

Checks During Operation 74

Parking Checks 74

Before Operation 75

Cab Entry and Exit75

Opening/Closing the Cab Door (Option)75

Cab Door Removal76

Seat and Armrest/Joystick Console Adjustment76

Seat Belt 77

Parking Brake 77

Disengage Parking Brake 78

Starting the Engine78

Cold-Starting79

After Starting79

Warm Up 80

Run-In Period 80

Stopping the Engine 80

Engine Stalling 81

Diesel Particulate Filter (DPF) Regeneration Procedures81

Reset Regeneration82

Stationary Regeneration82

Forcing Stationary Regeneration 83

Regeneration Inhibit 85

Cancelling Regeneration Inhibit 86

DPF Service 87

After Operation 88

Jump-Starting 88

Travel Drive Operation 90

ISO Pattern Travel Drive Controls91

D-H Pattern Travel Drive Controls (Option) 91

Straight Tracking Adjust 92

Rubber Track Use Cautions and Tips 92

Travel Drive Error Condition Operation (Limp Mode) 94

Alternate Transport Mode Activation94

Alternate Transport Mode Cancel 95

Backup Alarm 95

Lift Arm Operation 96

Attachment Transport Position 96

Joystick Control Patterns96

ISO Pattern Lift Arm Operation Controls96

D-H Pattern Lift Arm Operation Controls (Option)97

Self-Leveling98

Self-Leveling Cancel (Option)98

Lift Arm Float 99

Hydraglide™ Ride Control System (Option)100

Hydraulics Control Lock 101

Lift Arm Support 102

Engage Lift Arm Support 102

Model 1750RT (Serial Numbers 131001 and Up) Model 2100RT (Serial Numbers 241001 and

Up) Model 2500RT (All Serial Numbers)102

Model 1750RT (Serial Numbers 131001 and before) Model 2100RT (Serial Numbers 241001

and before)103

Release Lift Arm Support 104

Model 1750RT (Serial Numbers 30871 and Up) Model 2100RT (Serial Numbers 40421 and Up)

Model 2500RT (All Serial Numbers) 104

50940165/C0718 4 Printed in USA

Model 1750RT (Serial Numbers 30870 and before) / Model 2100RT (Serial Numbers 40420

and before) 104

Connecting/Disconnecting Attachments 105

Connecting Attachments 105

Disconnecting Attachments 106

Powering Attachments with Hydraulic Function 107

Connecting Hydraulic Attachments to the Auxiliary Hydraulic Circuits 107

Disconnecting Hydraulic Attachments from the Auxiliary Hydraulics Circuit 108

Auxiliary Hydraulics Operation 108

Standard-Flow Auxiliary Hydraulics Control 108

High-Flow Auxiliary Hydraulics Control (Option) 109

Optional 14-Pin Connector 109

Switch / Pin Assignments 109

Lifting the Machine using a Crane 110

Crane Lifting Preparation 110

Loading and Transporting the Machine on a Transport Vehicle 111

Loading and Securing the Machine 112

Storage Box 113

Maintenance 115

Maintenance Schedule 116

Checks, Cleaning and Inspection 116

Leakage Check 117

Lubrication and Filter Changes 117

Functional Check 117

Maintenance Interval 118

Engine Maintenance 119

Engine Access 119

Closing Engine Covers 119

Engine Oil 120

Checking Engine Oil Level 120

Changing Engine Oil and Filter 121

Engine Air Filters 123

Changing Air Filter Elements 123

Engine Cooling System 124

Checking Coolant Level 124

Cleaning Radiator Fins 125

Draining/Refilling Cooling System 125

Belt Maintenance 126

Checking and Adjusting Belt Tension 126

Air Conditioning Belt 127

DPF Service 127

Fuel System Maintenance 127

Adding Fuel 128

Water Separator Inspection/Maintenance 128

Changing Fuel Filter 130

Hydraulic System Maintenance 131

Checking Hydraulic Oil Level 131

Changing Hydraulic Oil and Filter 132

Hydraulic Hose Maintenance 134

Travel Motor Maintenance 135

Travel Motor Gearbox Oil 135

Track Maintenance 135

Track Replacement 136

General Lubrication 139

Tilting ROPS/FOPS 140

Raising ROPS/FOPS 140

Printed in USA 5 50940165/C0718

Lower ROPS/FOPS142

Electrical System143

Battery 143

Using a Booster Battery (Jump-Starting)144

Fuses and Relays145

Engine Compartment Fuses/Relays

(Model 2500RT)145

Engine Compartment Fuses/Relays 147

Engine Compartment Fuses/Relays 149

Fuses Under ROPS/FOPS150

Control Modules 151

Multi-function Control Module 151

Lift Arm and Standard Auxiliary Flow Control Module151

Engine Control Module (ECU)151

Main/Drive Control Module151

Long-Term Storage 152

Before Storage 152

After Storage 152

Air Conditioning Maintenance 153

Air Conditioning Filters 153

Cab Air Filter 153

Outside Air Intake Filter153

Windshield Washer Reservoir 154

Final Shutdown / Decommissioning 155

Before Disposal 155

Machine Disposal 155

Maintenance Log156

Lift Arm and ROPS/FOPS 159

Lift Arm Alignment Stops159

Tilt Stop Adjustment 159

Lift Arm Removal162

Lift Arm Installation165

ROPS/FOPS Service 167

ROPS/FOPS Removal 167

ROPS/FOPS Installation 173

Model 2500RT Engine Removal/Installation 181

Engine Removal – Model 2500RT 181

Engine Installation – Model 2500RT 194

Models 1750RT/2100RT Tier 4 Engine Removal/Installation 207

Tier 4 Engine Removal

Model 1750RT (S/N 131001 and Up)

Model 2100RT (S/N 241001 and Up) 207

Tier 4 Engine Installation

Model 1750RT (S/N 131001 and Up)

Model 2100RT (S/N 241001 and Up) 220

1750RT/2100RT interim Tier 4 Engine Removal/Installation 233

Interim Tier 4 Engine Removal

Model 1750RT (S/N 131000 and Before)

Model 2100RT (S/N 241000 and Before) 233

Interim Tier 4 Engine Installation

Model 1750RT (S/N 131000 and Before)

Model 2100RT (S/N 241000 and Before) 247

50940165/C0718 6 Printed in USA

Hydraulic Equipment 263

General Hydraulic Service Notes 263

Hydraulic Hoses/Piping 263

Seals 263

Hydraulic Oil Analysis 264

Hydraulic Control Valve 264

Main Control Valve Removal 265

Main Control Valve Installation 265

High-Flow Hydraulics 266

Hydraulic Pilot Valve 266

Self-Level Valve 267

Float/Hydraglide™ Valve 267

Travel Drive Motors 268

Drive Motor Idle Speed 268

Drive Motor High Speed Adjustment 268

Model 1750RT (Serial Numbers 30871 and Up), Model 2100RT (Serial Numbers 40421 and

Up), Model 2500RT (All Serial Numbers) 268

Model 1750RT (Serial Numbers 30870 and before), Model 2100RT (Serial Numbers 40420

and before) 268

Travel Motor Gearbox Oil 269

Hydrostatic Drive Pump 269

Hydrostatic Pump Swash Plates 269

Swash Plate Sensors 269

Forward and Reverse Solenoids 270

Hydrostatic Pump Removal 270

Hydrostatic Pump Installation 273

Hydrostatic Pump Drive Coupling Removal and Installation 276

Installation 277

Hydrostatic Pump Input Shaft Seal Replacement 278

Input Shaft Seal Removal 278

Input Shaft Seal Installation 279

Hydraulic Gear Pump 280

Hydraulic Cylinder Disassembly/Assembly 280

Cylinder Disassembly 281

Cylinder Assembly 282

Bleeding Air After Cylinder Installation 283

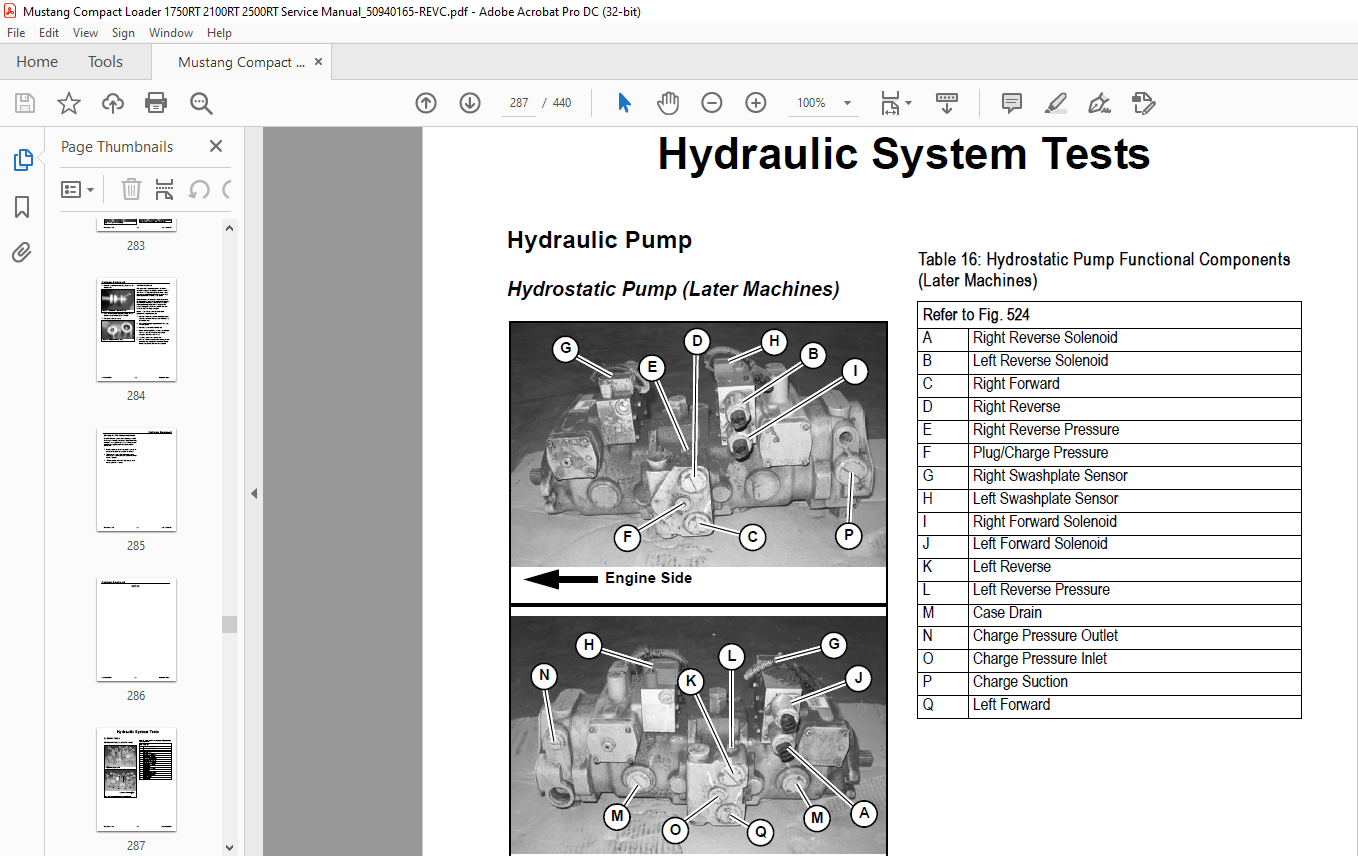

Hydraulic System Tests 285

Hydraulic Pump 285

Hydrostatic Pump (Later Machines) 285

Hydrostatic Pump (Early Machines) 286

Hydrostatic Drive System Pressures 287

Hydrostatic Charge Pressure Test and Adjustment 287

Main Relief Pressure Test 288

Main Pressure Adjustment 289

Tilt/Lift Cylinder Relief Pressure Tests 290

Inspection 290

Cylinder Rod/Base End Pressure Tests 291

Tilt Cylinder Base End Pressure Test 291

Tilt Cylinder Rod End Pressure Test 292

Lift Cylinder Base End Pressure Test 292

Lift Cylinder Rod End Pressure Test 293

Cylinder Drift Tests 294

Tilt Cylinder Drift Test 294

Lift Cylinder Drift Test 294

Cylinder Internal Leakage Tests 294

Tilt Cylinder Internal Leakage Test 294

Printed in USA 7 50940165/C0718

Lift Cylinder Internal Leakage Test295

Lift/Tilt Relief Pressure Adjustment 296

Electrical/Control Systems297

Electrical Schematics 297

Battery 297

Power Distribution 297

Power Distribution Module Fuse Socket Test297

Main Power Relay 298

Relay Testing298

Machine Test 298

Bench Test298

Electrical Control System 299

Electrical Control System General Information299

CAN System General Information 299

Control Module Locations300

Multi-function Control/Interlock Module (Controller 3)301

Engine Control Module (ECU)302

Main ECU Power Relay 2 302

Lift Arm and Standard Auxiliary Flow Control Module (Maestro Controller 1)303

Control Module (Maestro Controller 2)303

Optional High-Flow Module (Early Machines)303

Multi-Function Display304

CAN System Service/Computer Connection305

J1939 Data Connector305

Electronics Diagnostic Kit 305

CAN/Computer Connection Harnesses305

Service Adapter Harness 305

Deutz Engine CAN/Computer Connection Harness (SerDia) (Model 2500RT)306

Lighting307

Work Light Bulb Replacement 307

Tail Light Bulb Replacement308

Dome Light Bulb Replacement309

Electronics Diagnostic Kit 311

Diagnostic Kit Operation311

Displayed Telemetry Information312

Troubleshooting 313

Engine Troubleshooting 313

Indicator Lamp Troubleshooting314

Seal and Hose Troubleshooting 315

Hydraulic System Troubleshooting316

Hydrostatic Travel Drive System Troubleshooting 318

Hydrostatic Drive Motors Troubleshooting 320

Electrical Troubleshooting 321

Miscellaneous Troubleshooting321

Error Codes322

Controller Communication Error Codes322

Yanmar Engine Diagnostic Trouble Codes (DTC) – Models 1750RT/2100RT 322

Deutz Engine Error Codes – Model 2500RT330

Drive and Valve Error Codes335

50940165/C0718 8 Printed in USA

Schematics 343

Schematic Conventions 343

Model 2500RT (SN 80301 and Up) Schematics 344

2500RT Fuse/Relay Locations Index 344

2500RT Connector / Splice Locations Index 345

Engine/Starting and Charging – Model 2500RT 348

Engine Sensors – Models 2500RT 349

Engine ECU – Models 2500RT 350

Power Distribution/Fuses – Models 2500RT 351

Power Distribution/Relays – Models 2500RT 352

I/O Controller – Models 2500RT 353

Solenoid Controller A – Models 2500RT 354

Solenoid Controller B – Models 2500RT 355

Operator/Drive Controls – Models 2500RT 356

High-Flow/Self-Level/Power-A-Tach® Quick Attach System – Models 2500RT 357

HVAC – Models 2500RT 358

Track Tension/Work Lights – Models 2500RT 359

Wipers/Washer Pump – Models 2500RT 360

EU Road Lighting – Models 2500RT 361

Auxiliary Power/Dome Light/Radio – Models 2500RT 362

Operator CAN Interface – Models 2500RT 363

Grounds – Models 2500RT 364

Model 1750RT with Tier 4 Engines (Serial Numbers 131301 and Up) Model 2100RT with Tier 4

Engines (Serial Numbers 280051 and Up) 365

Models 1750RT and 2100RT with Tier 4 Engines – Fuse/Relay Locations Index 365

1750RT / 2100RT with Tier 4 Engines Connector / Splice Locations Index 366

Engine/Starting and Charging – Models 1750RT / 2100RT with Tier 4 Engines 368

Power Distribution/Fuses – Models 1750RT / 2100RT with Tier 4 Engines 369

Power Distribution/Relays – Models 1750RT / 2100RT with Tier 4 Engines 370

Engine Sensors – Models 1750RT / 2100RT with Tier 4 Engines 371

Engine ECU – Models 1750RT / 2100RT with Tier 4 Engines 372

Engine ECU (Continued) – Models 1750RT / 2100RT with Tier 4 Engines 373

I/O Controller – Models 1750RT / 2100RT with Tier 4 Engines 374

Solenoid Controller A – Models 1750RT / 2100RT with Tier 4 Engines 375

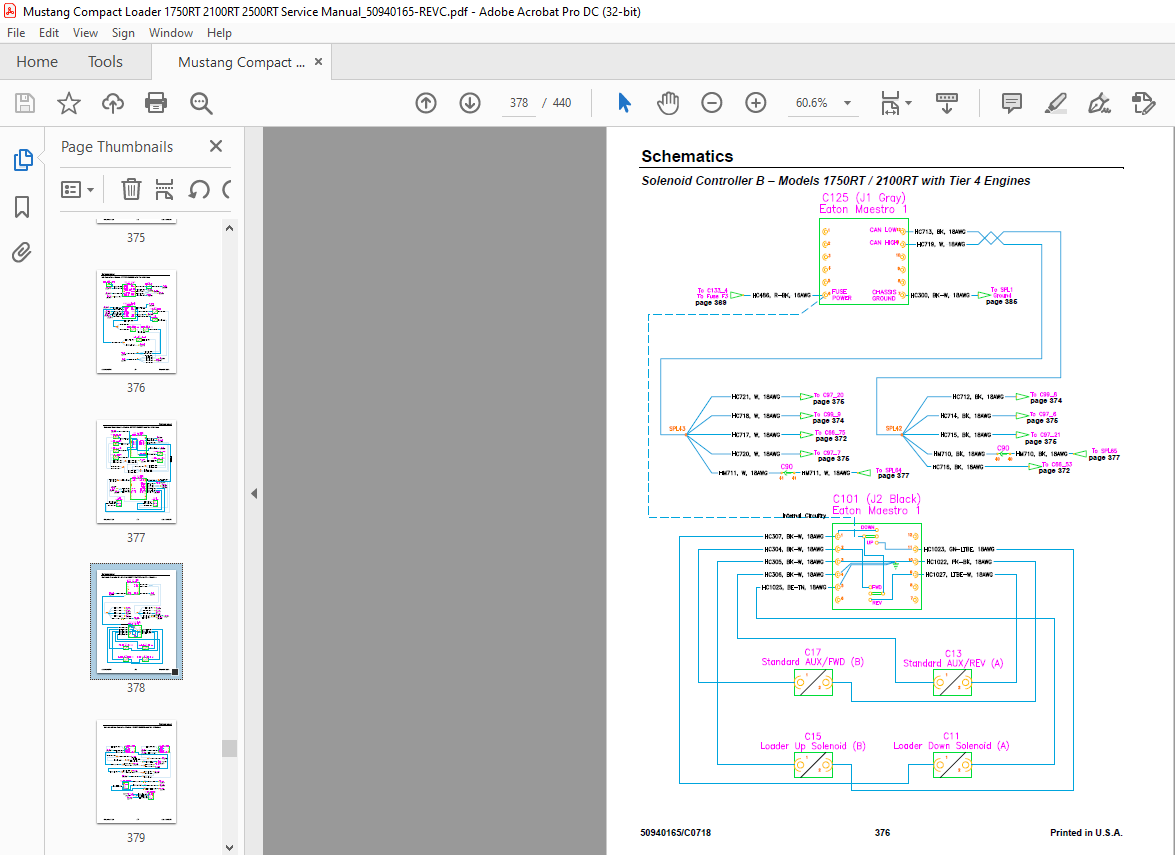

Solenoid Controller B – Models 1750RT / 2100RT with Tier 4 Engines 376

Operator/Drive Controls – Models 1750RT / 2100RT with Tier 4 Engines 377

High-Flow/Self-Level/Power-A-Tach® Quick Attach System – Models 1750RT / 2100RT with Tier 4

Engines 378

HVAC – Models 1750RT / 2100RT with Tier 4 Engines 379

Track Tension/Work Lights – Models 1750RT / 2100RT with Tier 4 Engines 380

Wipers/Washer Pumps – Models 1750RT / 2100RT with Tier 4 Engines 381

EU Road Lighting – Models 1750RT / 2100RT with Tier 4 Engines 382

Auxiliary Power/Dome Light/Radio – Models 1750RT / 2100RT with Tier 4 Engines 383

Operator CAN Interface – Models 1750RT / 2100RT with Tier 4 Engines 384

Grounds – Models 1750RT / 2100RT with Tier 4 Engines 385

Model 1750RT with Tier 4 Engine (Serial Numbers 131001 and Up)

Model 2100RT with Tier 4 Engine (Serial Numbers 241001 and Up) 386

Models 1750RT and 2100RT with Tier 4 Engines – Fuse/Relay Locations Index 386

1750RT / 2100RT with Tier 4 Engines Connector / Splice Locations Index 387

Engine/Starting and Charging – Models 1750RT / 2100RT with Tier 4 Engines 389

Power Distribution/Fuses – Models 1750RT / 2100RT with Tier 4 Engines 390

Power Distribution/Relays – Models 1750RT / 2100RT with Tier 4 Engines 391

Engine Sensors – Models 1750RT / 2100RT with Tier 4 Engines 392

Engine ECU – Models 1750RT / 2100RT with Tier 4 Engines 393

Engine ECU (Continued) – Models 1750RT / 2100RT with Tier 4 Engines 394

I/O Controller – Models 1750RT / 2100RT with Tier 4 Engines 395

Solenoid Controller A – Models 1750RT / 2100RT with Tier 4 Engines 396

Printed in USA 9 50940165/C0718

Solenoid Controller B – Models 1750RT / 2100RT with Tier 4 Engines397

Operator/Drive Controls – Models 1750RT / 2100RT with Tier 4 Engines398

High-Flow/Self-Level/Power-A-Tach® Quick Attach System – Models 1750RT / 2100RT with Tier 4

Engines399

HVAC – Models 1750RT / 2100RT with Tier 4 Engines400

Track Tension/Work Lights – Models 1750RT / 2100RT with Tier 4 Engines 401

Wipers/Washer Pumps – Models 1750RT / 2100RT with Tier 4 Engines 402

EU Road Lighting – Models 1750RT / 2100RT with Tier 4 Engines403

Auxiliary Power/Dome Light/Radio – Models 1750RT / 2100RT with Tier 4 Engines 404

Operator CAN Interface – Models 1750RT / 2100RT with Tier 4 Engines 405

Grounds – Models 1750RT / 2100RT with Tier 4 Engines 406

Model 1750RT with interim Tier 4 Engines (Serial Numbers 31051 – 131000), Model 2100RT with interim

Tier 4 Engines (Serial Numbers 40501 – 241000)407

1750RT (Serial Numbers 30981 – 131000), 2100RT (Serial Numbers 40501 – 241000) Fuse/Relay

Locations Index 407

1750RT (Serial Numbers 30981 – 131000), 2100RT (Serial Numbers 40501 – 241000) Connector /

Splice Locations Index408

Engine/Starting and Charging – Model 1750RT / 2100RT with interim Tier 4 Engines411

Engine Sensors – Model 1750RT / 2100RT with interim Tier 4 Engines 412

Engine ECU – Model 1750RT / 2100RT with interim Tier 4 Engines 413

Power Distribution – Model 1750RT / 2100RT with interim Tier 4 Engines414

Controller 3 – Model 1750RT / 2100RT with interim Tier 4 Engines 415

Controller 2 – Model 1750RT / 2100RT with interim Tier 4 Engines 416

Controller 1 – Model 1750RT / 2100RT with interim Tier 4 Engines 417

Operator/Drive Controls – Model 1750RT / 2100RT with interim Tier 4 Engines418

High-Flow/Self-Level/Power-A-Tach® Quick Attach System – Model 1750RT / 2100RT with interim

Tier 4 Engines 419

HVAC – Model 1750RT / 2100RT with interim Tier 4 Engines420

Track Tension/Lighting Control – Model 1750RT / 2100RT with interim Tier 4 Engines421

Wipers/Washer Pumps – Model 1750RT / 2100RT with interim Tier 4 Engines 422

Work Lights – Model 1750RT / 2100RT with interim Tier 4 Engines423

EU Road Lighting – Model 1750RT / 2100RT with interim Tier 4 Engines424

Operator Display/CAN Interface – Model 1750RT / 2100RT with interim Tier 4 Engines 425

Grounds – Model 1750RT / 2100RT with interim Tier 4 Engines 426

Hydraulic Schematic427

Index 429

Torque Specifications435

SAE Torque Values