$33

Mustang Skid Steer Loader 930 940 960 Service Manual (000-12909) – PDF DOWNLOAD

Mustang Skid Steer Loader 930 940 960 Service Manual (000-12909) – PDF DOWNLOAD

DESCRIPTION:

Mustang Skid Steer Loader 930 940 960 Service Manual (000-12909) – PDF DOWNLOAD

INTRODUCTION

- This manual was prepared to assist the experienced mechanic in troubleshooting and repair of the MUSTANG 930, 940 and 960. It contains the latest information available for proper procedures and adjustments. For information on engine repair, refer to the manufacturers service manual.

- When referred to, left and right sides of the machine are determined as if sitting in the operator’s seat facing forward. All MUSTANG products are designed with operator safety as top priority. In some cases safety equipment must be removed for access to major components.

- Be sure to replace all safety equipment and be sure of proper operation when servicing is complete. Always have the model and serial number when ordering parts or requesting service information. The serial number tag is located on the right rear upright, near the lift arm pivot pin

- (See figure 0-1) MUSTANG is continually striving to make improvements. We therefore reserve the right to make changes in product and/or specifications without notice and are under no obligation to make changes to equipment manufactured previously.

IMAGES PREVIEW OF THE MANUAL:

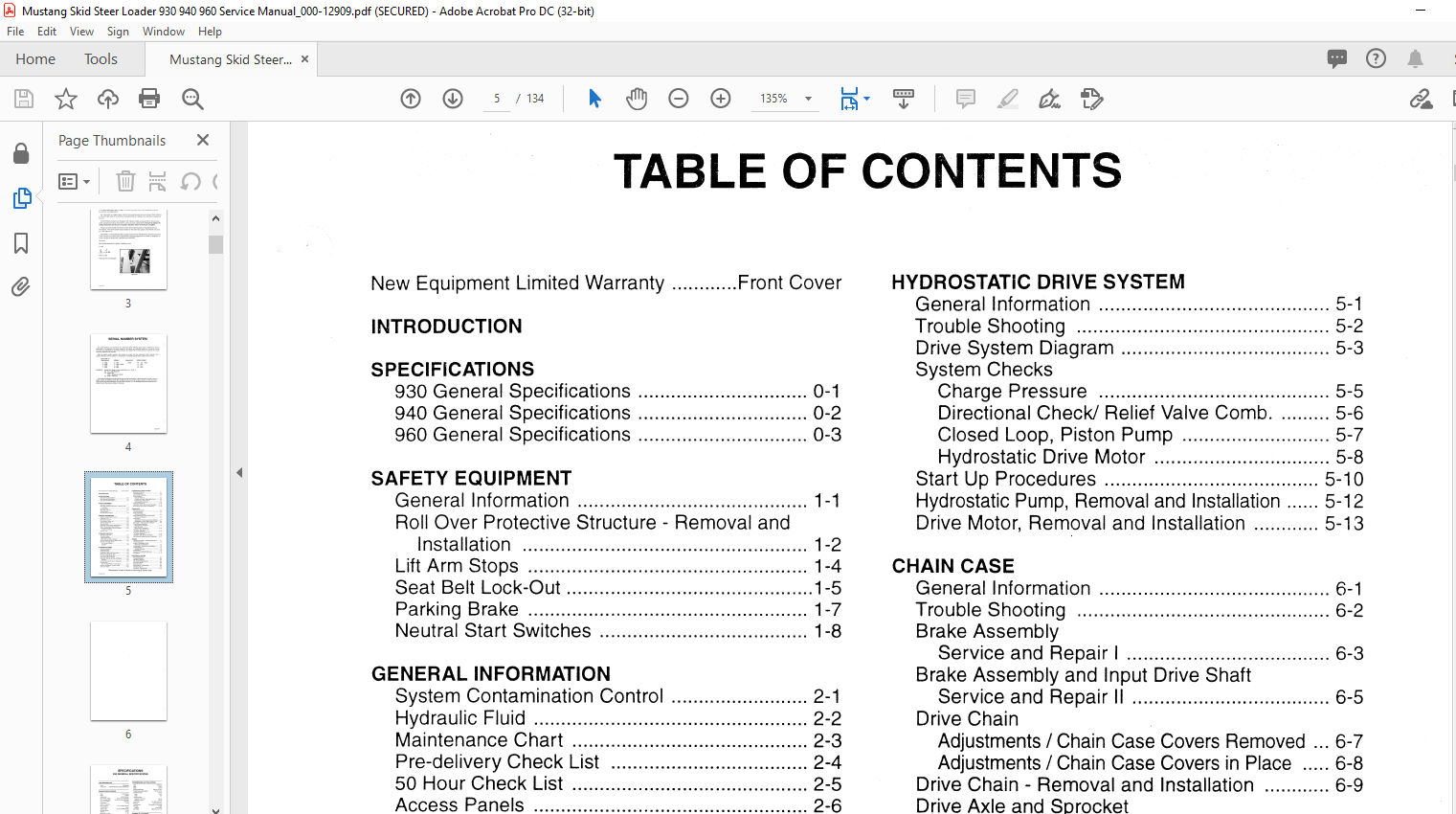

TABLE OF CONTENTS:

Mustang Skid Steer Loader 930 940 960 Service Manual (000-12909) – PDF DOWNLOAD

New Equipment Limited Warranty Front Cover

INTRODUCTION SPECIFICATIONS

930 General Specifications 0-1

940 General Specifications 0-2

960 General Specifications 0-3

SAFETY EQUIPMENT

General Information 1-1

Roll Over Protective Structure – Removal and Installation

1-2

Lift Arm Stops 1-4

Seat Belt Lock-Out 1-5

Parking Brake 1-7

Neutral Start Switches 1-8

GENERAL INFORMATION

System Contamination Control 2-1

Hydraulic Fluid 2-2

Maintenance Chart 2-3

Pre-delivery Check List 2-4

50 Hour Check List 2-5

Access Panels 2-6

Standard Torque Value Specifications 2-8

Metric Torque Value Specifications 2-9

Torque Specifications and Procedures 2-10

Hoses and Fittings

Special Tools 2-11

STEERING CONTROLS

General Information 3-1

Troubleshooting 3-2

T-Bar Adjustments 3-3

T-Bar Removal and Installation 3-4

Neutral Centering Device Adjustments 3-6

Neutral Centering Device

Service and Repair 3-7

Diagram 3-8

HYDRAULIC SYSTEM

General Information 4-1

Troubleshooting 4-2

Pressure Check 4-4

Model 960 / 940 / 930 Flow Chart 4-5

Lift Circuit Leak Down Test 4-7

Tilt Circuit Leak Down Test 4-8

Hydraulic Cylinder Testing 4-9

Hydraulic Cylinder Service and Repair 4-10

Diagram 4-13

Control Valve Removal and Installation 4-14

Control Valve

Service and Repair – Dukes Valve 4-15

Service and Repair- Gresen Valve 4-19

Self-Level Valve 4-22

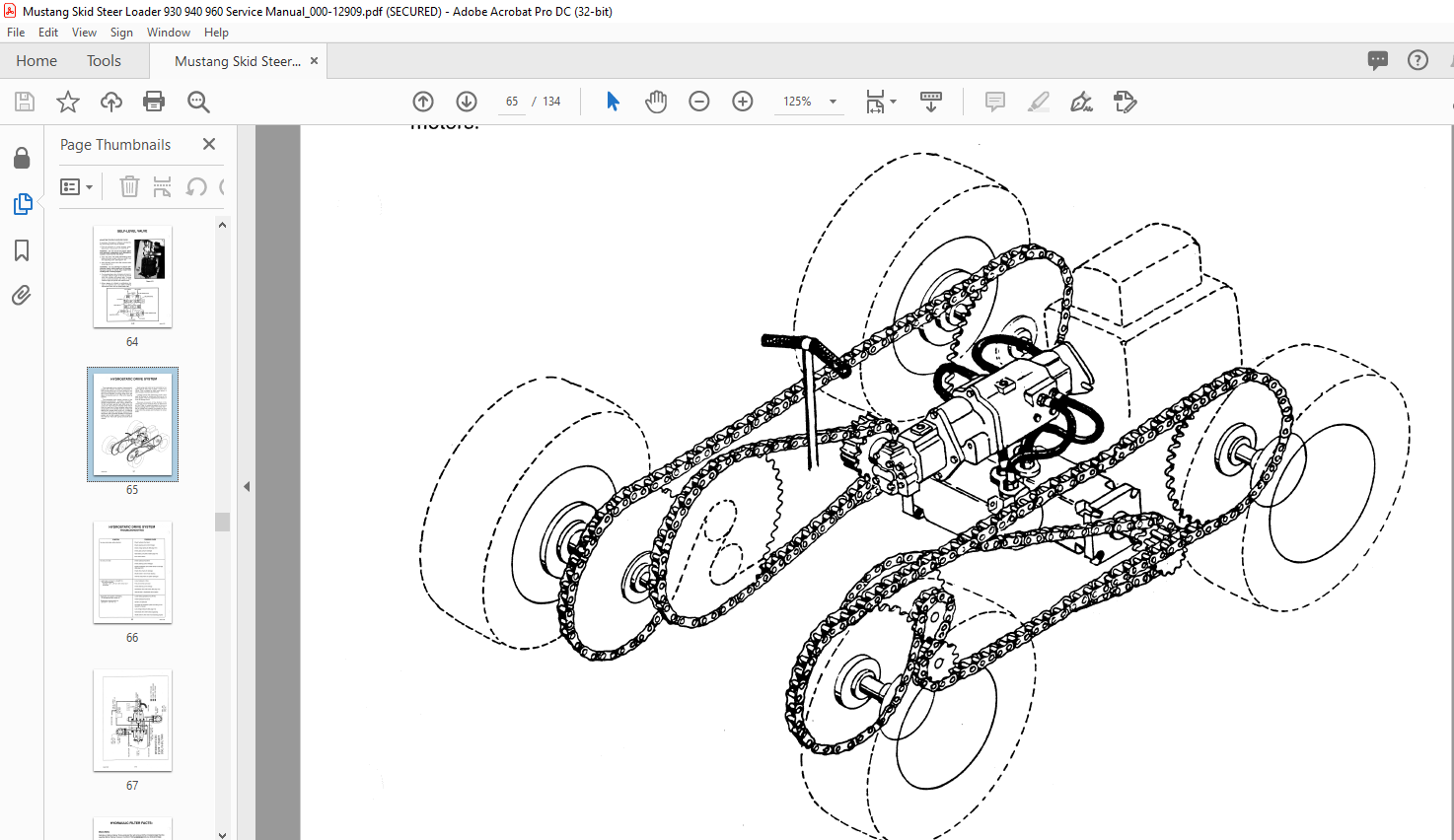

HYDROSTATIC DRIVE SYSTEM

General Information 5-1

Trouble Shooting 5-2

Drive System Diagram 5-3

System Checks

Charge Pressure 5-5

Directional Check/ Relief Valve Comb 5-6

Closed Loop, Piston Pump 5-7

Hydrostatic Drive Motor 5-8

Start Up Procedures 5-10

Hydrostatic Pump, Removal and Installation 5-12

Drive Motor, Removal and Installation 5-13

CHAIN CASE

General Information 6-1

Trouble Shooting 6-2

Brake Assembly

Service and Repair I 6-3

Brake Assembly and Input Drive Shaft

Service and Repair II 6-5

Drive Chain

Adjustments/ Chain Case Covers Removed 6-7

Adjustments/ Chain Case Covers in Place 6-8

Drive Chain – Removal and Installation 6-9

Drive Axle and Sprocket

Removal and Installation 6-10

Cluster Sprocket

Removal and Installation 6-12

Installation Dual Spacer Set

In Cluster Sprocket 6-14

Installation Single Spacer Set

In Cluster Sprocket 6-15

Installation Idler Bracket Assembly 6-16

Idler Sprocket Replacement and Adjustment 6-17

ENGINE

General Information – Model Specifications 7-1

Trouble Shooting 7-2

Engine / Hydrostatic Pump

Removal and Installation 7-3

Components – Removal and Installation 7-5

Cooling System 7-7

Trouble Shooting 7-8

Fuel System 7-9

Injection Timing Model 960 Isuzu 7-10

Air Cleaner 7-11

ELECTRICAL SYSTEM

General Information 8-1

Trouble Shooting 8-2

960 Wiring Diagram 8-4

930 & 940 Wiring Diagram 8-5

Instrument Panel 8-6

Starting Circuit 8-7

Starter Motor – Disassembly 8-8

Charging Circuit 8-9

Alternator – Disassembly 8-10