$31

Mustang Wheel Loader ML48 Service Manual (918136) – PDF DOWNLOAD

Mustang Wheel Loader ML48 Service Manual (918136) – PDF DOWNLOAD

DESCRIPTION:

Mustang Wheel Loader ML48 Service Manual (918136) – PDF DOWNLOAD

1 Overview

1.1 Important information

- This service manual contains important information on how to service your machine safely, correctly and economically. Therefore, it aims not only at new users, but also serves as a reference for experienced users. It helps to avoid hazardous situations and reduce repair costs and downtimes.

- Furthermore, the reliability and the service life of the machine will be increased by following the instructions in the Operator’s Manual. Careful and prudent work is the best way to avoid accidents! Operational safety and readiness of the machine do not only depend on your skill, but also on maintenance and service of the machine. Insist on using original Mustang spare parts when performing maintenance and repair work.

- This ensures operational safety and readiness of your machine, and maintains its value. Your Mustang dealer will be pleased to answer any further questions regarding the machine or this service manual.

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Mustang Wheel Loader ML48 Service Manual (918136) – PDF DOWNLOAD

Overview

Important information 1-1

Type decals and component numbers 1-2

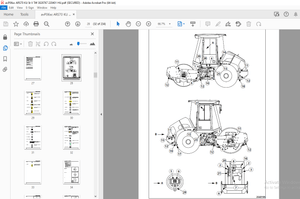

Machine overview 1-4

Cab overview 1-5

Instrument panel, multifunctional lever and drive lever: overview 1-6

Specifications

Frame 2-1

Engine 2-1

Power train 2-2

Axles 2-3

Brakes 2-3

Steering 2-4

Work hydraulics 2-4

Pilot control 2-4

Loader unit 2-5

Electrical system 2-6

Fuse box on left and right

of steering column 2-6

Main fuse box with relays 2-7

Relays 2-7

Tires 2-8

Weights 2-8

Sound levels 2-8

Vibration 2-8

Tightening torques 2-9

General tightening torques 2-9

Specific tightening torques 2-9

Dimensions 2-10

Maintenance

Fluids and lubricants 3-1

Maintenance decal 3-2

Explanation of symbols on

maintenance decal 3-2

Maintenance schedule Model ML48 (overview) 3-4

Maintenance items 3-7

Introduction 3-7

Fuel system 3-8

Specific safety instructions 3-8

Refueling 3-8

Stationary fuel pumps 3-8

Diesel fuel specification 3-8

Bleeding the fuel system 3-9

Replacing the fuel filter 3-9

Cleaning the fuel pump screen filter 3-10

Engine lubrication system 3-11

Checking and filling up the oil level 3-11

Changing engine oil 3-12

Replacing the engine oil filter cartridge 3-13

Engine and hydraulic cooling system 3-14

Specific safety instructions 3-14

Cleaning the oil cooler 3-14

Table of contents

I-2 918136/AP0505

Table of contents

Air filter 3-15

Weekly check of air filter

contamination 3-15

Weekly functional check of the dust valve 3-16

Replacing the filter cartridge 3-16

V-belt 3-17

Checking the V-belt tension 3-17

Tightening the V-belt 3-17

Gearboxes and axles 3-18

Checking the oil level on

the gearbox 3-18

Filling up the gearbox oil 3-19

Changing the gearbox oil 3-20

Checking the oil level in the rear axle differential 3-21

Filling up the oil level 3-21

Changing the oil 3-21

Checking the oil level in the front axle differential 3-22

Filling up the oil level 3-22

Changing the oil 3-22

Planetary drives: Checking and filling up the oil level 3-23

Changing the oil 3-23

Hydraulic system 3-24

Specific safety instructions 3-24

Checking the hydraulic oil level 3-25

Adding the hydraulic oil 3-25

Monitoring the hydraulic oil return filter 3-25

Important information for the use of biodegradable oil 3-26

Checking hydraulic pressure lines 3-27

Specific safety instructions 3-27

Lubrication work 3-28

Lubricating the rear axle

oscillation-type bearing 3-28

Lubricating the planetary drive bearing 3-28

Lubricating the pivots on the loader unit 3-29

Maintenance of attachments 3-29

Maintenance of the brake system 3-30

Specific safety instructions 3-30

Checking/filling up the brake fluid level 3-30

Tire maintenance 3-31

Daily checks 3-31

Weekly checks 3-31

Changing wheels 3-32

Removing the wheels 3-32

Fitting the wheels 3-32

Electrical system 3-33

Specific safety instructions 3-33

Service and maintenance work at regular intervals 3-34

Cables, bulbs and fuses 3-34

Alternator 3-34

Battery 3-34

General maintenance work 3-35

Cleaning 3-35

General instructions for all areas of the machine 3-35

Cleaning inside the cab 3-36

Cleaning outside of the machine 3-36

Cleaning the engine compartment 3-36

Screw connections 3-37

918136/AP0505 I-3

Table of contents

Pivots and hinges 3-37

Heating 3-37

Cleaning the dust filter of the heating system 3-37

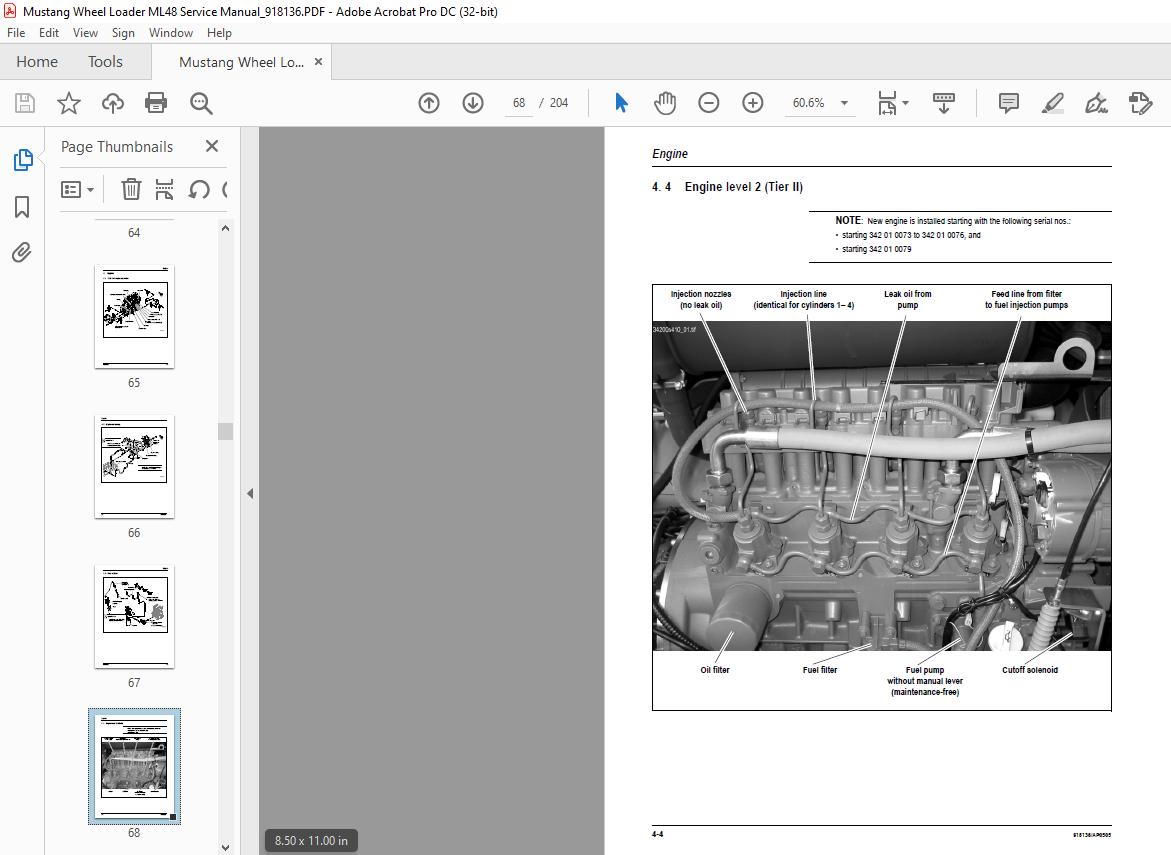

Engine

F4M 2011 engine: overview 4-1

Engine oil cooling 4-2

Fuel system 4-3

Engine level 2 (Tier II) 4-4

Checking and adjusting valve tip clearance 4-5

Replacing the fuel injection pump 4-6

Turning off minus compensation 4-11

Heating connection 4-11

Removing/mounting the cylinder head 4-12

Sealing the bleeder valve 4-15

Intake/exhaust manifold 4-15

Engine trouble 4-15

Power train

Variable displacement pump 125 mph (20 km/h) 5-1

Hydraulic motor – hydraulic connections 125 mph (20 km/h) 5-2

Hydraulic motor – control element 125 mph (20 km/h) 5-3

Power train circuit with cooling 125 mph (20 km/h) 5-4

Power train diagram 125 mph (20 km/h) 5-5

Inching valve (left-hand side access) 5-6

Inching valve (component parts) 5-7

Test report 125 mph (20 km/h) 5-8

Towing and transporting the machine 5-9

Safety instructions 5-9

Towing 5-9

Adjustment work on power train 5-10

Starting speeds 5-10

Adjust boost pressure 5-10

Adjusting pilot pressure 5-10

Hydraulic resistance

(characteristic curve) 5-11

High pressure/drive pressure 5-12

Secondary valves Fwd – Rev 5-13

Pump output/diesel output 5-13

Control initiation on hydraulic motor 5-14

Adjustment for wheel speed 125 mph (20 km/h) 5-15

ECO speed (25 mph (40 km/h) high speed) 5-16

Variable displacement pump 25 mph (40 km/h) 5-16

Variable displacement pump test ports 5-17

ECO speed hydraulic motor 5-18

Installation position: overview 5-19

ECO speed power train 25 mph (40 km/h): diagram 5-20

Test report 25 mph (40 km/h) 5-21

ECO speed settings 5-22

Control initiation M3: settings 5-22

Control initiation M4: settings 5-23

Wheel speed: settings 5-24

I-4 918136/AP0505

Table of contents

Axles

Type decal – axle 6-1

Front axle screw connections 6-2

Rear axle screw connections 6-3

Drain, fill and check plug – front axle 6-4

Drain, fill and check plug – rear axle 6-5

Tightening torques lb-ft (Nm) – front axle 6-6

Tightening torques lb-ft (Nm) – rear axle 6-7

Sealing work 6-8

Input flange – front axle: sealing work 6-8

Input flange – rear axle: sealing work 6-9

Brake cylinder – front axle 6-10

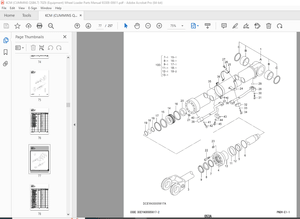

Planetary carrier – planetary drive: sealing work 6-13

Planetary carrier – axle tube: sealing work 6-16

Sealing ring in planetary carrier: sealing work 6-18

Self-locking differential 6-21

Sealing the gearbox 6-23

Brakes

Brake circuit 7-1

Brake diagram 7-2

Service brake 7-3

Important information on the

brake system 7-3

Bleeding the brake system with

bleed equipment 7-3

Parking brake: overview 7-4

Steering

125 mph (20 km/h) steering circuit 8-1

125 mph (20 km/h) steering circuit 8-2

25 mph (40 km/h) steering circuit 8-3

25 mph (40 km/h) steering circuit 8-4

Hydraulic ports on servostat 8-5

Pressure relief valve – servostat: settings 8-5

Sealing the steering cylinder 125 / 25 mph (20 km/h / 40 km/h) 8-6

Adjusting the steering sensors 25 mph (40 km/h) 8-7

Hydraulic system

Test report 9-1

Control valve: overview – connections 9-2

Work hydraulics oil supply 9-3

Priority valve for work hydraulics

and steering 9-4

Control valve (position) 9-4

Pilot control unit: design 9-5

Pilot control circuit 9-6

Work hydraulics circuit 9-7

Load stabilizer circuit with hose burst valve 9-8

Load stabilizer: circuit diagram 9-9

Load stabilizer with hose burst valve: circuit diagram 9-10

Hose burst valve with load stabilizer: connections 9-11

Solenoid valve for 3rd control circuit 9-12

Lift cylinder: sealing work 9-13

Tilt cylinder: sealing work 9-14

Control cylinder (quickhitch frame): sealing work 9-15

Work hydraulics diagram 9-16

918136/AP0505 I-5

Table of contents

Electrical system

Ohm’s Law (current, voltage, resistance); power 10-1

Measuring equipment, measuring methods 10-1

Terminal description 10-3

Cable color coding 10-6

Other color codes (identical to IEC 757, edition 1983) 10-7

Relays 10-7

Use, mode of function 10-7

Terminal description on relay 10-7

Electric units 10-8

Fuse box on left and right of steering column 10-8

Main fuse box with relays 10-9

Relays 10-9

Steering electronics 10-10

Instrument panel, fuse box, relays: overview 10-11

Legend for wiring diagram 10-14

Wiring diagram 10-15

Legend: wiring harness 208587 engine – frame 125 mph (20 km/h) 10-16

Wiring harness: 208587 engine – frame 125 mph (20 km/h) 10-17

Legend: wiring harness engine – frame 25 mph (40 km/h) 208689 10-18

Wiring harness: engine – frame 25 mph (40 km/h) 208689 10-19

Legend: wiring harness 207408 cab 10-20

Wiring harness – cab 208659 10-21

Wiring harness – high speed cab 208701 (option) 10-22

Roof wiring harness 208700 10-23

Wiring harness to control lever base 208562 (option) 10-24

Wiring harness to control lever base 207968 (standard) 10-25

Roof wiring harness 208728 (option) 10-26

Wiring harness – steering-column control lever 207810 10-27

Wiring harness: rear lights/clearance lights 207409 10-28

Wiring harness 208609 (joystick) 10-29

Electronics between joystick and wiring harness 208609 10-29

Wiring harness 208589: load stabilizer (option) 10-30

Wiring harness 208676: solenoid valve – load stabilizer (option) 10-31

Wiring harness 207410: lock for long-haul travel – control lever base 10-32

Wiring harness 207407: lock for long-haul travel – instrument panel 10-33

Wiring harness 208563: numberplate light (option) 10-34

Wiring harness 208113: air-suspension driver’s seat (option) 10-35

Wiring harness 208587: air conditioning (option) 10-36

Wiring harness 207411: 4th additional hydraulics (HighFlow option) 10-37

Console plug and socket connection 10-38

Plug and socket connection: fuse box and relay (left) 10-39

Relay assignment (center) 10-40

Plug and socket connection: fuse box and relay (right) 10-41

Plug and socket connection: cab 10-42