$45

New Holland Compact Tractor Workmaster 35, 40 Service Manual

New Holland Compact Tractor Workmaster 35, 40 Service Manual

FILE DETAILS:

New Holland Compact Tractor Workmaster 35, 40 Service Manual

Size: 88.3 MB

Format: PDF

Language: English

Number of Pages : 812 pages

Brand: New Holland

Type of document: Service Manual

Model: Workmaster 35, 40

Part No: 47446617

DESCRIPTION:

New Holland Compact Tractor Workmaster 35, 40 Service Manual

FOREWORD:

This repair manual provides the technical information needed to properly service the NEW HOLLAND AGRICULTURE models Boomer 30and 35 tractors. Use this manual in conjunction with the operator’s manual for complete operation, adjustment, and maintenance information On NEW HOLLAND AGRICULTURE equipment, left and right are determined by standing behind the unit, looking in the direction of travel.

Soil, air, and water are vital factors of agriculture and life in general. When legislation does not yet rule the treatment of some of the substances required by advanced technology, sound judgment should govern the use and disposal of products of a chemical and petrochemical nature.

NOTE: The following are recommendations that may be of assistance:

• Become acquainted with and ensure that you understand the relative legislation applicable to your country.

• Where no legislation exists, obtain information from suppliers of oils, filters, batteries, fuels, antifreeze, cleaning agents, etc., with regard to their effect on man and nature and how to safely store, use, and dispose of these substances.

• Agricultural consultants will, in many cases, be able to help you as well.

Helpful hints:

• Avoid filling tanks using cans or inappropriate pressurized fuel delivery systems that may cause considerable spillage.

• In general, avoid skin contact with all fuels, oils, acids, solvents, etc. Most of them contain substances that may be harmful to your health.

• Modern oils contain additives. Do not burn contaminated fuels and or waste oils in ordinary heating systems.

• Avoid spillage when draining off used engine coolant mixtures, engine, gearbox and hydraulic oils, brake fluids, etc. Do not mix drained brake fluids or fuels with lubricants. Store them safely until they can be disposed of in a proper way to comply with local legislation and available resources.

• Modern coolant mixtures, i.e. antifreeze and other additives, should be replaced every two years. They should notbe allowed to get into the soil, but should be collected and disposed of properly.

• Do not open the air-conditioning system yourself. It contains gases that should not be released into the atmosphere. Your NEW HOLLAND AGRICULTURE dealer or air conditioning specialist has a special extractor for this purpose and will have to recharge the system properly.

• Repair any leaks or defects in the engine cooling or hydraulic system immediately.

• Do not increase the pressure in a pressurized circuit as this may lead to a component failure.

• Protect hoses during welding as penetrating weld splatter may burn a hole or weaken them, allowing the loss of oils, coolant, etc.

TABLE OF CONTENTS:

New Holland Compact Tractor Workmaster 35, 40 Service Manual

INTRODUCTION

Engine 10

[10001] Engine and crankcase 101

[10304] Engine lubrication system 102

Clutch 18

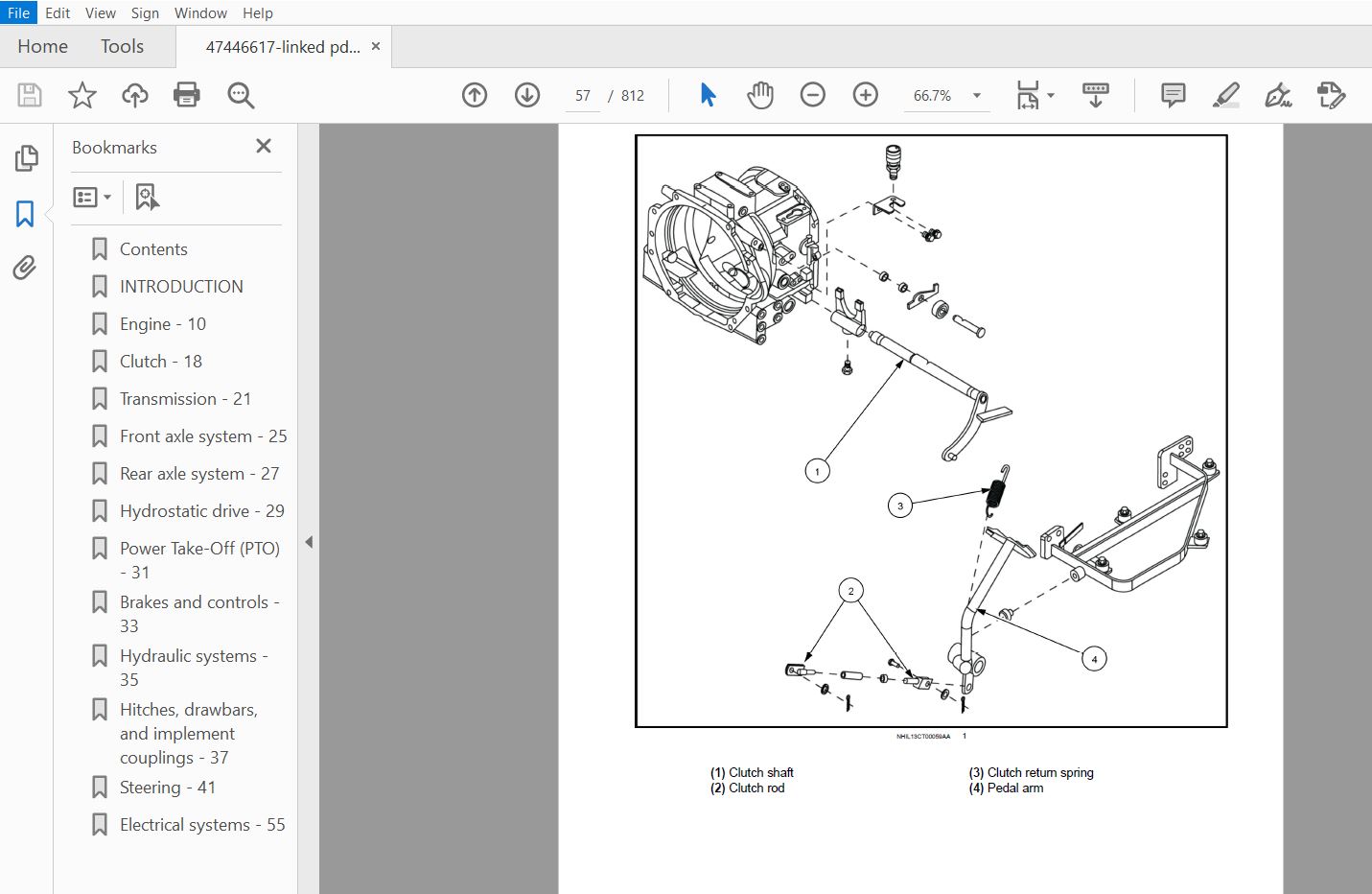

[18104] Clutch hydraulic release control 181

[18110] Clutch and components 182

Transmission 21

[21114] Mechanical transmission211

[21130] Mechanical transmission external controls 212

[21140] Mechanical transmission internal components 213

[21182] Differential 214

Front axle system 25

[25100] Powered front axle251

[25102] Front bevel gear set and differential252

[25108] Final drive hub, steering knuckles, and shafts 253

[25310] Final drives 254

Rear axle system 27

[27120] Planetary and final drives 271

Hydrostatic drive 29

[29100] Transmission and steering hydrostatic control 291

[29218] Pump and motor components292

[29202] Hydrostatic transmission293

Power Take-Off (PTO) 31

[31110] One-speed rear Power Take-Off (PTO) 311

[31101] Rear mechanical control312

[31104] Rear electro-hydraulic control 313

[31120] Central Power Take-Off (PTO)314

Brakes and controls 33

[33120] Mechanical service brakes 331

[33110] Parking brake or parking lock 332

Hydraulic systems 35

[35000] Hydraulic systems351

[35300] Reservoir, cooler, and filters 352

[35104] Fixed displacement pump 353

[35350] Safety and main relief valves 354

[35204] Remote control valves 355

[35114] Three-point hitch control valve356

[35116] Three-point hitch cylinder 357

Hitches, drawbars, and implement couplings 37

[37110] Rear three-point hitch 371

Steering 41

[41106] Tie rods 411

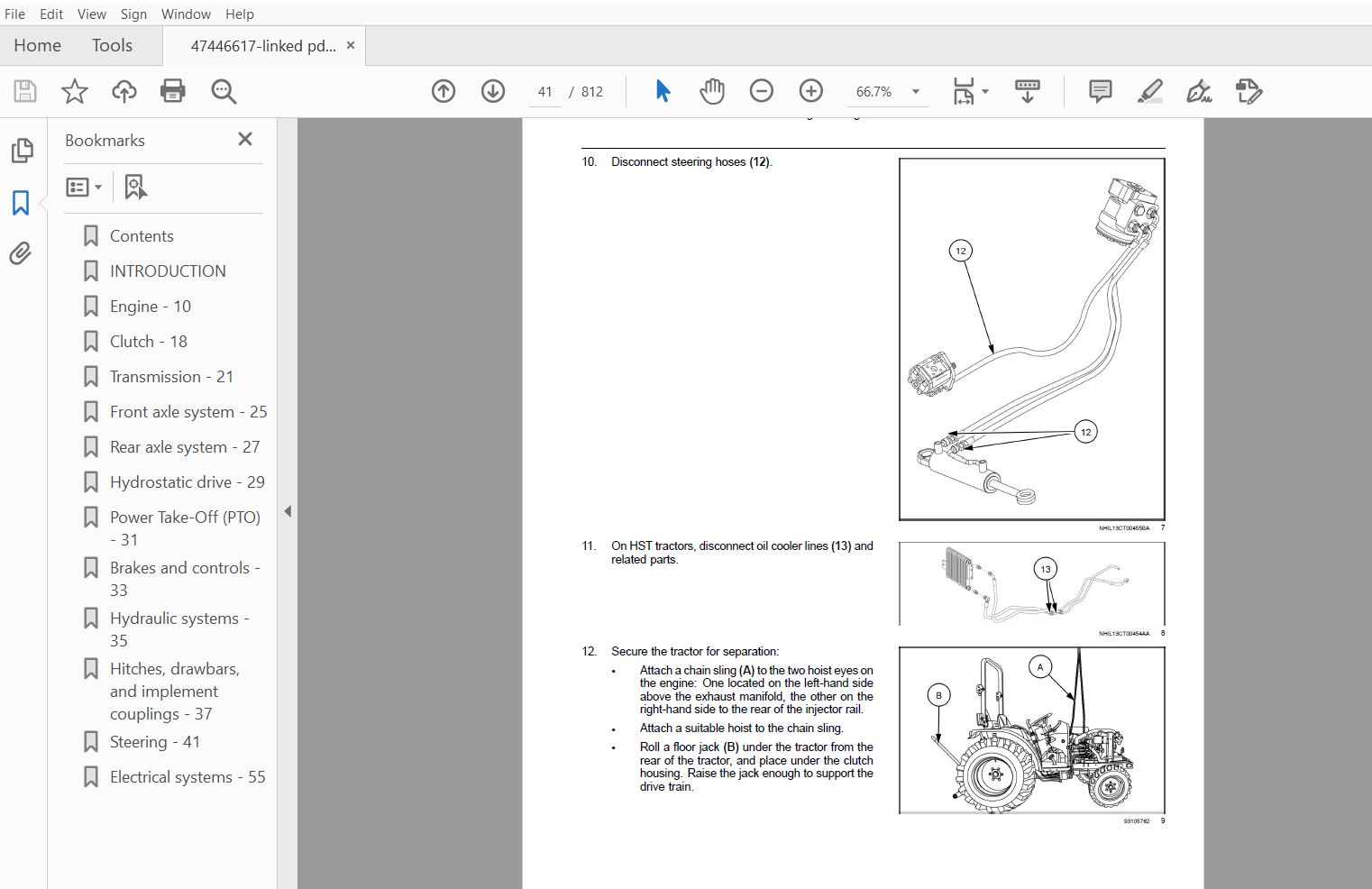

[41200] Hydraulic control components412

[41216] Cylinders 413

Electrical systems 55

[55000] Electrical system 551

[55100] Harnesses and connectors 552

[55201] Engine starting system 553

[55302] Battery554

[55202] Cold start aid555

[55011] Fuel tank system 556

[55010] Fuel injection system 557

[55012] Engine cooling system 558

47446617 23/04/2013

[55013] Engine oil system 559

[55610] Ground speed control 5510

[55048] Rear Power Take-Off (PTO) control system 5511

[55031] Parking brake electrical system 5512

[55404] External lighting 5513

[55405] External lighting switches and relays 5514

[55408] Warning indicators, alarms, and instruments 5515

[55513] Cab transmission controls 5516

IMAGES PREVIEW OF THE MANUAL: