Starting from:

$45

New Holland Series FH & EX Excavator Service Repair Manual

New Holland Series FH & EX Excavator Service Repair Manual

FILE DETAILS:

New Holland Series FH & EX Excavator Service Repair Manual

Item Number: 6040718901

Description: Excavators

Language: English

Type: Service Manual

DESCRIPTION:

New Holland Series FH & EX Excavator Service Repair Manual

FOREWORD:

- If construction machineries work under severe conditions for long period, welded structural components may crack. To reduce down time and to extend the life of the machine, it is imperative to check for cracks and to repair as soon as possible. Repairing cracks by appropriate welding techniques

- (crack detection, restraint, preheating, gouging, repair welding, reinforcement, and finishing) are most important and effective measures. However, if inadequate repair welding is applied, cracks will develop again in a shorter period of operation than before, making it difficult to trace the cause of the repeated crack.

- If appropriate welding techniques are not performed, this will allow cracks to develop repeatedly. This manual aims to introduce the correct method of repair welding to prevent cracks from developing repeatedly.

- This manual is intended for welders who have completed technical training of welding (American Welding Society Class 3 or up, or equivalent), FIAT KOBELCO sales support servicemen and FIAT KOBELCO Dealer servicemen who are in the position to supervise repair welding. Be sure to thoroughly read this manual for correct repair welding information and procedure. Information and specifications in this manual are for repair welding purpose only. They may be different from those of FIAT KOBELCO construction machinery factory procedures and standards. All

- Safety first.

- Allow only trained, qualified, authorized personnel to perform repair welding. (American Welding Society Class 3 or up, or equivalent) • Carefully read and follow the instructions in this manual. Also, read the safety section of the operator’s manual before performing any welding work. • Be sure to follow your local safety regulations. SAFETY PRECAUTIONS FOR REPAIR WELDING WORK • Prepare for emergencies.

- Be prepared if a fire starts or if an accident occurs. • Wear protective clothing. • Wear close fitting clothing and safety equipment appropriate for the job. • Do not wear a necktie, scarf, loose clothing, or necklace when you work near machine tools or moving parts. If these items get caught in the machine, severe injury could result. • Remove rings and other jewelry, to help avoid electric shock and entanglement in moving parts. • Be sure that clothing and gloves are dry, not damp.

- Use tools and equipments appropriate for the work to be done. • Makeshift tools, equipements and procedures can create hazards. • Be sure to ground the welding machine. Be sure that the welding machine is equipped with an elec-tric shock prevention device. • Protect against hazardous light rays and hot metal splatters.

- Hazardous light rays and hot metal splatters are produced when arc-welding. To protect your body from these hazards, wear a welding apron and shin guards. Also, be sure to use a face shield to protect your eyes and face. Protect against noise. Prolonged exposure to loud noise can cause impairment or loss of hearing.

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

New Holland Series FH & EX Excavator Service Repair Manual

Foreword

Safety rules 3

Don’t’s: fundamentals 8

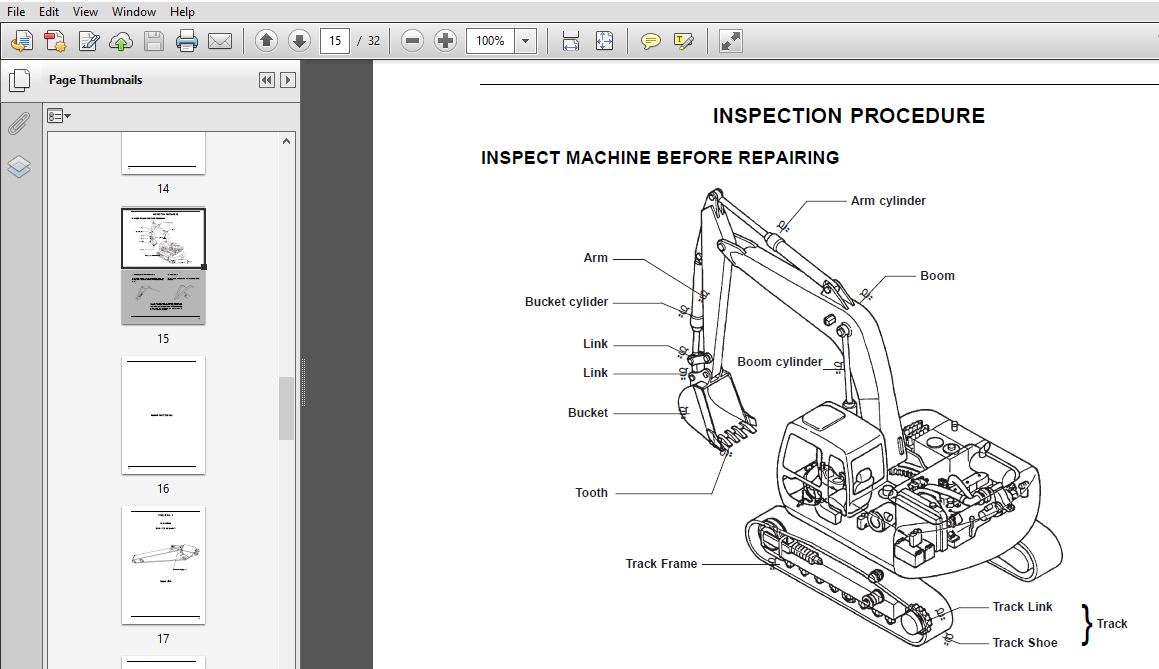

Inspection procedure 13

Repair procedures 14

Table no. 1 Dipper stick Series FH 15

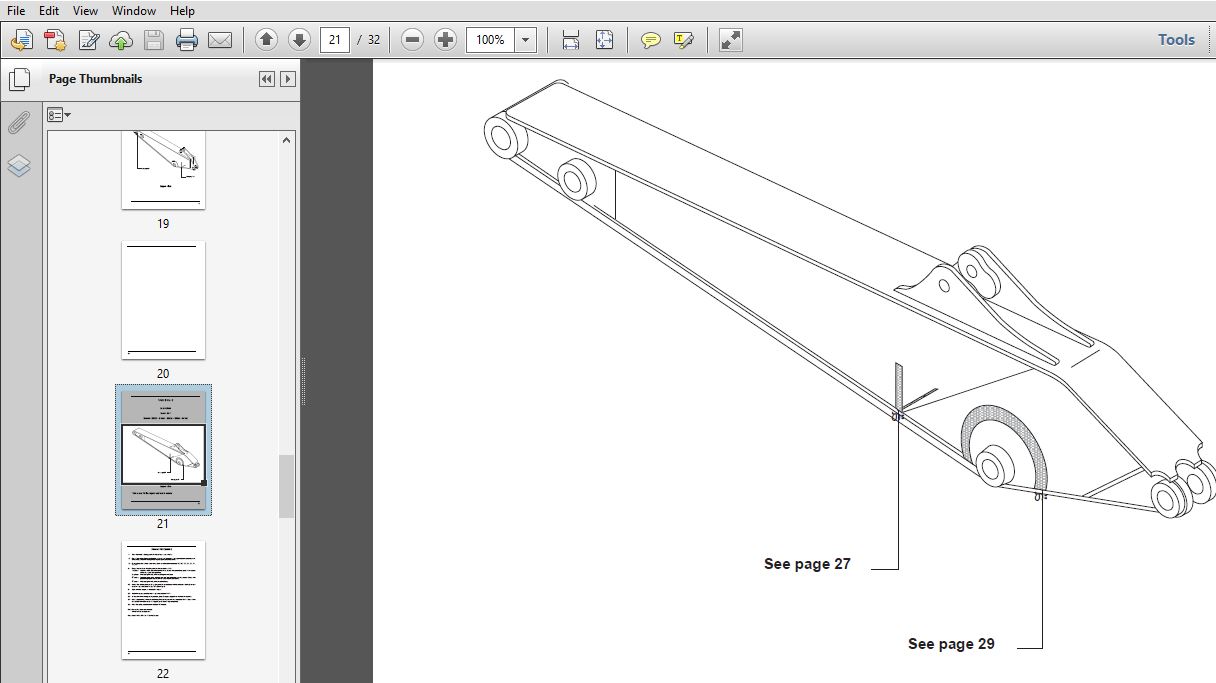

Table no. 2 Dipper stick Series EX

Models EX135 EX165 EX215 19

Table no. 3 Dipper stick Series EX

Models EX235 EX255 EX285 EX355 EX455 25

Table no. 4 Monobloc boom 31

Table no. 5 Triple articulation Arm no. 1 51

Table no. 6 Upperstructure 55

Table no. 7 Undercarriage 67

1 file (654.9KB)