$45

New Holland T7030 T7040 T7050 T7060 Service Manual

New Holland T7030 T7040 T7050 T7060 Service Manual

FILE DETAILS:

New Holland T7030 T7040 T7050 T7060 Service Manual

Size : 97.4 MB

Format : PDF

Language : English

Number of Pages : 3061 Pages

DESCRIPTION:

New Holland T7030 T7040 T7050 T7060 Service Manual

TO PREVENT ACCIDENTS:

Most accidents and personal injuries taking place in workshops are due from non-observance of some essential rules and safety precautions. The possibility that an accident might occur with any type of machines should not be disregarded, no matter how well the machine in question was designed and built. A wise and careful service technician is the best precautions against accidents. Careful observance of this basic precaution would be enough to avoid many severe accidents.

SAFETY RULES:

Generalities

• Carefully follow specified repair and maintenance procedures.

• Do not wear rings, wristwatches, jewels, unbuttoned or flapping clothing such as ties, torn clothes, scarves, open jackets or shirts with open zips which could get caught on moving parts. Use approved safety clothing such as anti-slipping footwear, gloves, safety goggles, helmets, etc.

• Wear safety glasses with side guards when cleaning parts using compressed air.

• Damaged or frayed wires and chains are unreliable. Do not use them for lifting or towing.

• Wear suitable protection such as approved eye protection, helmets, special clothing, gloves and footwear whenever welding. All persons standing in the vicinity of the welding process should wear approved eye protection. NEVER LOOK AT THE WELDING ARC IF YOUR EYES ARE NOT SUITABLY PROTECTED.

• Never carry out any repair on the machine if someone is sitting on the operator’s seat, except if they are qualified operators assisting in the operation to be carried out.

• Never operate the machine or use attachments from a place other than sitting at the operator’s seat or at the side of the machine when operating the fender switches.

• Never carry out any operation on the machine when the engine is running, except when specifically indicated. Stop the engine and ensure that all pressure is relieved from hydraulic circuits before removing caps, covers, valves, etc.

• All repair and maintenance operations should be carried out with the greatest care and attention.

• Disconnect the batteries and label all controls to warn that the tractor is being serviced. Block the machine and all equipment which should be raised.

• Never check or fill fuel tanks or batteries, nor use starting liquid if you are smoking or near open flames as such fluids are flammable.

• The fuel filling gun should always remain in contact with the filler neck. Maintain this contact until the fuel stops flowing into the tank to avoid possible sparks due to static electricity build-up.

• To transfer a failed tractor, use a trailer or a low loading platform trolley if available.

• To load and unload the machine from the transportation means, select a flat area providing a firm support to the trailer or truck wheels. Firmly tie the machine to the truck or trailer platform and block wheels as required by the transporter.

• Always use lifting equipment of appropriate capacity to lift or move heavy components.

• Chains should always be safely fastened. Ensure that fastening device is strong enough to hold the load foreseen. No persons should stand near the fastening point.

• The working area should be always kept CLEAN and DRY. Immediately clean any spillage of water or oil.

• Never use gasoline, diesel oil or other flammable liquids as cleaning agents. Use non-flammable non-toxic proprietary solvents.

• Do not pile up grease or oil soaked rags, as they constitute a great fire hazard. Always place them into a metal container.

TABLE OF CONTENTS:

New Holland T7030 T7040 T7050 T7060 Service Manual

INTRODUCTION

DISTRIBUTION SYSTEMS A

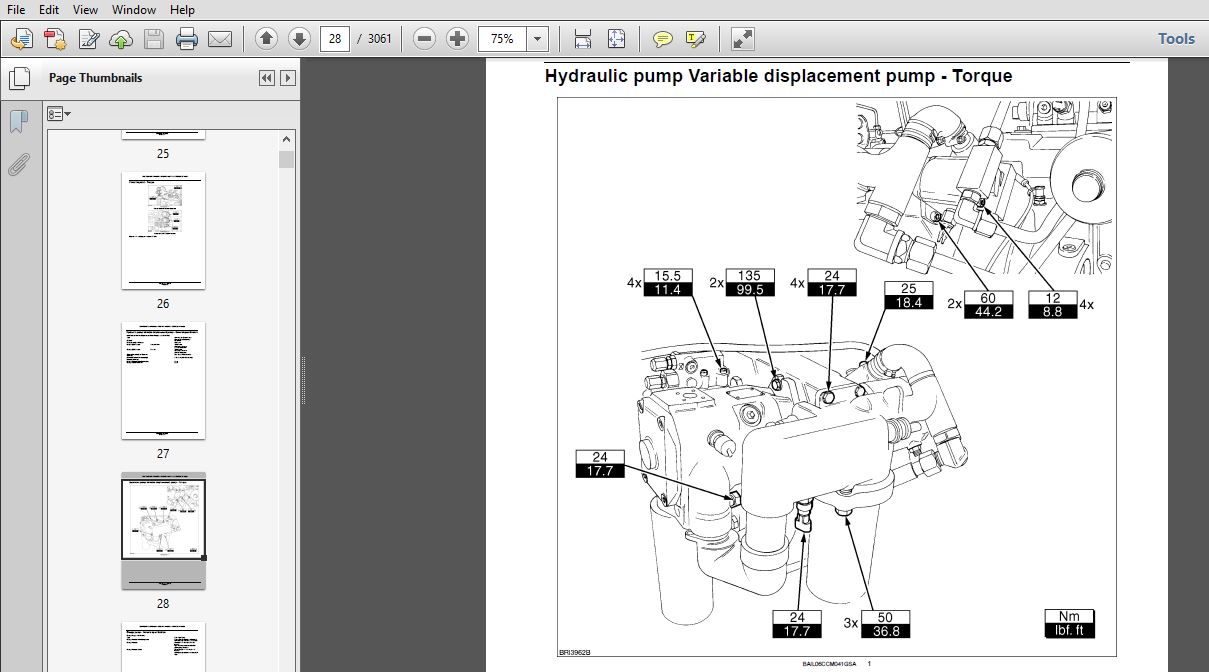

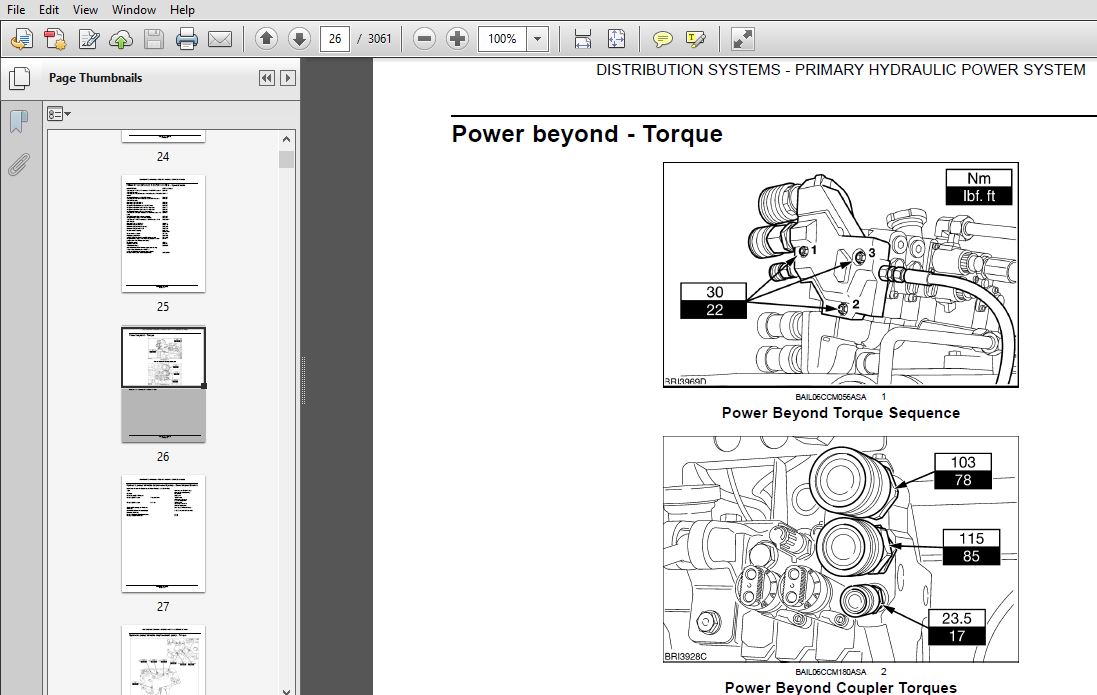

PRIMARY HYDRAULIC POWER SYSTEMA10A

PRIMARY HYDRAULIC POWER SYSTEM Closed center mechanical remote valve A10B

PRIMARY HYDRAULIC POWER SYSTEM Electro-hydraulic remote valveA10C

PRIMARY HYDRAULIC POWER SYSTEM Electro-hydraulic remote valveA10C

SECONDARY HYDRAULIC POWER SYSTEM A12A

HYDRAULIC COMMAND SYSTEM A14A

PNEUMATIC SYSTEMA20A

ELECTRICAL POWER SYSTEM A30A

ELECTRICAL POWER SYSTEM A30A

ELECTRONIC SYSTEM A50A

FAULT CODES A50A

POWER PRODUCTION B

ENGINEB10A

FUEL AND INJECTION SYSTEMB20A

AIR INTAKE SYSTEM B30A

EXHAUST SYSTEM B40A

ENGINE COOLANT SYSTEM B50A

LUBRICATION SYSTEM B60A

STARTING SYSTEM B80A

POWER TRAIN C

TRANSMISSION PowershiftC20E

ADDITIONAL REDUCERS CreeperC30C

ADDITIONAL REDUCERS Overdrive C30D

REAR PTO Mechanical C40B

REAR PTO HydraulicC40C

FRONT PTO Hydraulic C42C

TRAVELLINGD

87628084B 12/06/2009

FRONT AXLED10A

REAR AXLE D12A

2WD-4WD SYSTEM HydraulicD14C

STEERING HydraulicD20C

STEERING AutoPilot D20E

SERVICE BRAKE Mechanical D30B

SERVICE BRAKE Hydraulic D30C

SERVICE BRAKE Pneumatic D30E

PARKING BRAKE Mechanical D32B

PARKING BRAKE Electronic D32D

BRAKE CONNECTION HydraulicD34C

SUSPENSION HydraulicD40C

WHEELS AND TRACKS WheelsD50C

BODY AND STRUCTURE E

FRAME Primary frameE10B

USER PLATFORM E34A

ENVIRONMENT CONTROL Heating, ventilation and air-conditioning E40D

WORKING ARM H

HITCH Front hitch H10B

HITCH Rear hitch H10C

HITCH Electronic draft controlH10D

HITCH Electronic draft controlH10D

VIDEO PREVIEW OF THE MANUAL:

IMAGES PREVIEW OF THE MANUAL: