$45

New Holland T8.275,T8.300,T8.330,T8.360,T8.390,T8.420 (CVT) Tractor Service Repair Manual

New Holland T8.275,T8.300,T8.330,T8.360,T8.390,T8.420 (CVT) Tractor Service Repair Manual

FILE DETAILS:

New Holland T8.275,T8.300,T8.330,T8.360,T8.390,T8.420 (CVT) Tractor Service Repair Manual

Size: 369 MB

Format: PDF

Language: English

Number of Pages : 4800 pages

Brand: New Holland

Type of document: Service Manual

Model: T8.275, T8.300, T8.330, T8.360, T8.390, T8_420

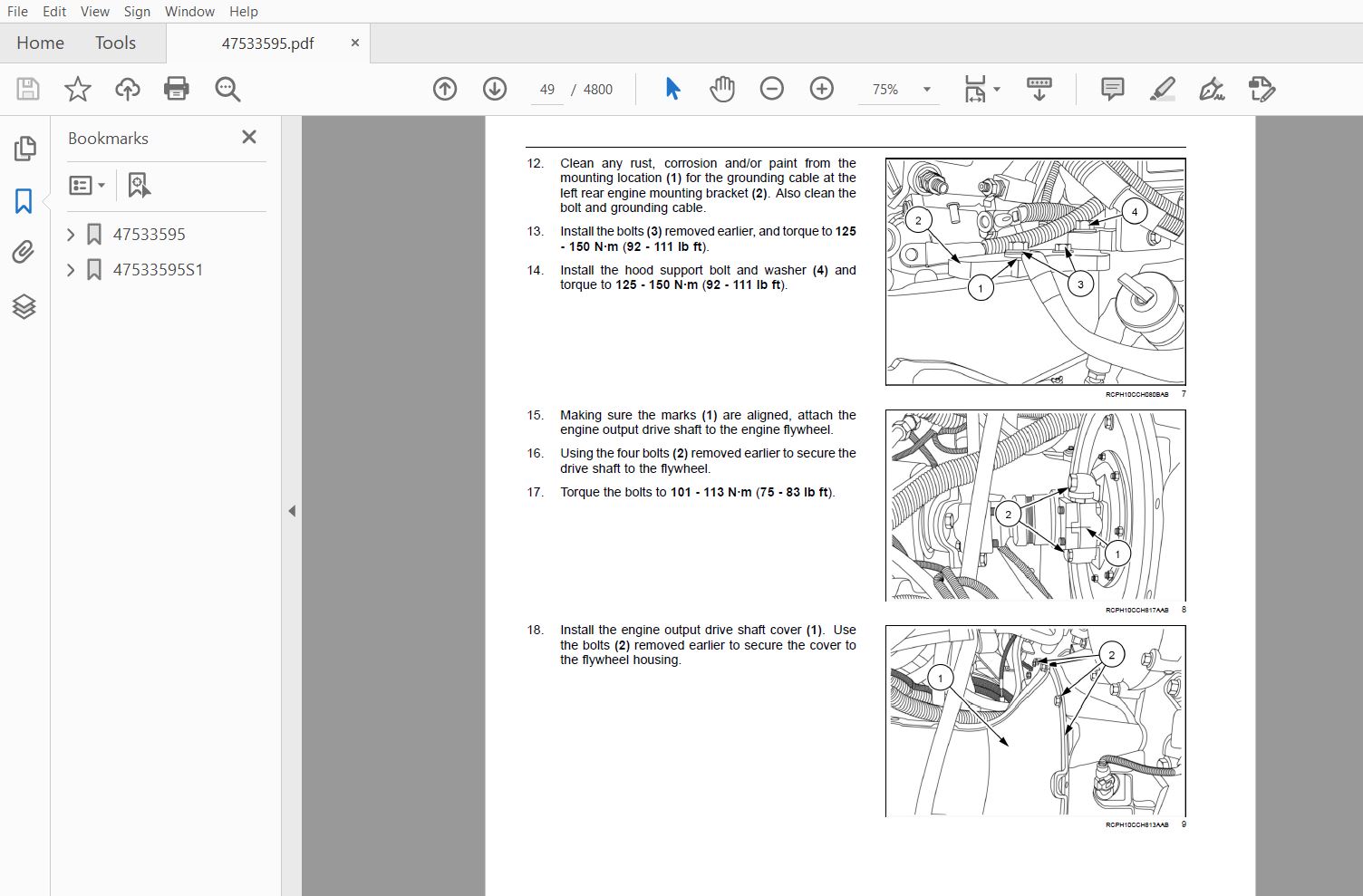

Part No: 47533595

DESCRIPTION:

New Holland T8.275,T8.300,T8.330,T8.360,T8.390,T8.420 (CVT) Tractor Service Repair Manual

Basic instructions – Important notice regarding equipment servicing:

T8.275 WE, T8.300 WE, T8.330 WE, T8.360 WE, T8.390 WE, T8.420 WE

All repair and maintenance work listed in this manual must be carried out only by qualified dealership personnel, strictly complying with the instructions given, and using, whenever possible, the special tools. Anyone who performs repair and maintenance operations without complying with the procedures provided herein shall be responsible for any subsequent damages.

- The manufacturer and all the organizations of its distribution chain, including – without limitation – national, regional, or local dealers, reject any responsibility for damages caused by parts and/or components not approved by the manufacturer, including those used for the servicing or repair of the product manufactured or marketed by the manufacturer.

- In any case, no warranty is given or attributed on the product manufactured or marketed by the manufacturer in case of damages caused by parts and/or components not approved by the manufacturer.

- The information in this manual is up-to-date at the date of the publication. It is the policy of the manufacturer for continuous improvement. Some information could not be updated due to modifications of a technical or commercial type, or changes to the laws and regulations of different countries. In case of questions, refer to your NEW HOLLAND AGRICULTURE Sales and Service Networks.

Safety rules:

T8.275 WE, T8.300 WE, T8.330 WE, T8.360 WE, T8.390 WE, T8.420 WE

Standard safety precautions

Be informed and notify personnel of the laws in force regulating safety, and provide documentation available for consultation.

• Keep working areas as clean as possible.

• Ensure that working areas are provided with emergency boxes. They must be clearly visible and always contain adequate sanitary equipment.

• Fire extinguishers must be properly identified and always be clear of obstructions. Their efficiency must be checked on a regular basis and personnel must be trained on proper interventions and priorities.

• Keep all emergency exits free of obstructions and clearly marked.

• Smoking in working areas subject to fire danger must be strictly prohibited.

Prevention of injury:

• Wear suitable work attire and safety glasses with no jewelry such as rings and chains when working close to engines and equipment in motion.

• Wear safety gloves and goggles when performing the following operations:

• Topping off or changing lubrication oils.

• Using compressed air or liquids at a pressure greater than 2 bar (29 psi).

• Wear a safety helmet when working close to hanging loads or equipment working at head level.

• Always wear safety shoes and fitting clothes.

• Use protection cream for hands.

• Change wet clothes as soon as possible.

• In the presence of voltages exceeding 48 – 60 V, verify the efficiency of the ground and mass electrical connections. Ensure that hands and feet are dry and use isolating foot boards. Workers should be properly trained to work with electricity.

• Do not smoke or start an open flame close to batteries and any fuel material.

• Place soiled rags with oil, diesel fuel or solvents in specially provided anti-fire containers.

• Do not use any tool or equipment for any use other than what it was originally intended for. Serious injury may occur.

• If running an engine indoors, make sure there is a sufficient exhaust fan in use to eliminate exhaust fumes.

During maintenance:

• Never open the filler cap of the cooling system when the engine is hot. High temperature liquid at operating pressure could result in serious danger and risk of burn. Wait until the temperature decreases under 50 °C (122 °F).

• Never add coolant to an overheated engine and use only appropriate liquids.

• Always work when the engine is turned off. Certain circumstances require maintenance on a running engine. Be aware of all the risks involved with such an operation.

• Always use adequate and safe containers for engine fluids and used oil.

• Keep engine clean of any spilled fluids such as oil, diesel fuel, and or chemical solvents.

• Use of solvents or detergents during maintenance may emit toxic vapors. Always keep working areas aerated. Wear a safety mask if necessary.

• Do not leave soiled rags that may contain any flammable substances close to the engine.

• Always use caution when starting an engine after any work has been performed. Be prepared to cut off intake air in case of engine runaway.

TABLE OF CONTENTS:

New Holland T8.275,T8.300,T8.330,T8.360,T8.390,T8.420 (CVT) Tractor Service Repair Manual

INTRODUCTION

Engine 10

[10001] Engine and crankcase 101

[10101] Cylinder heads 102

[10114] Pump drives 103

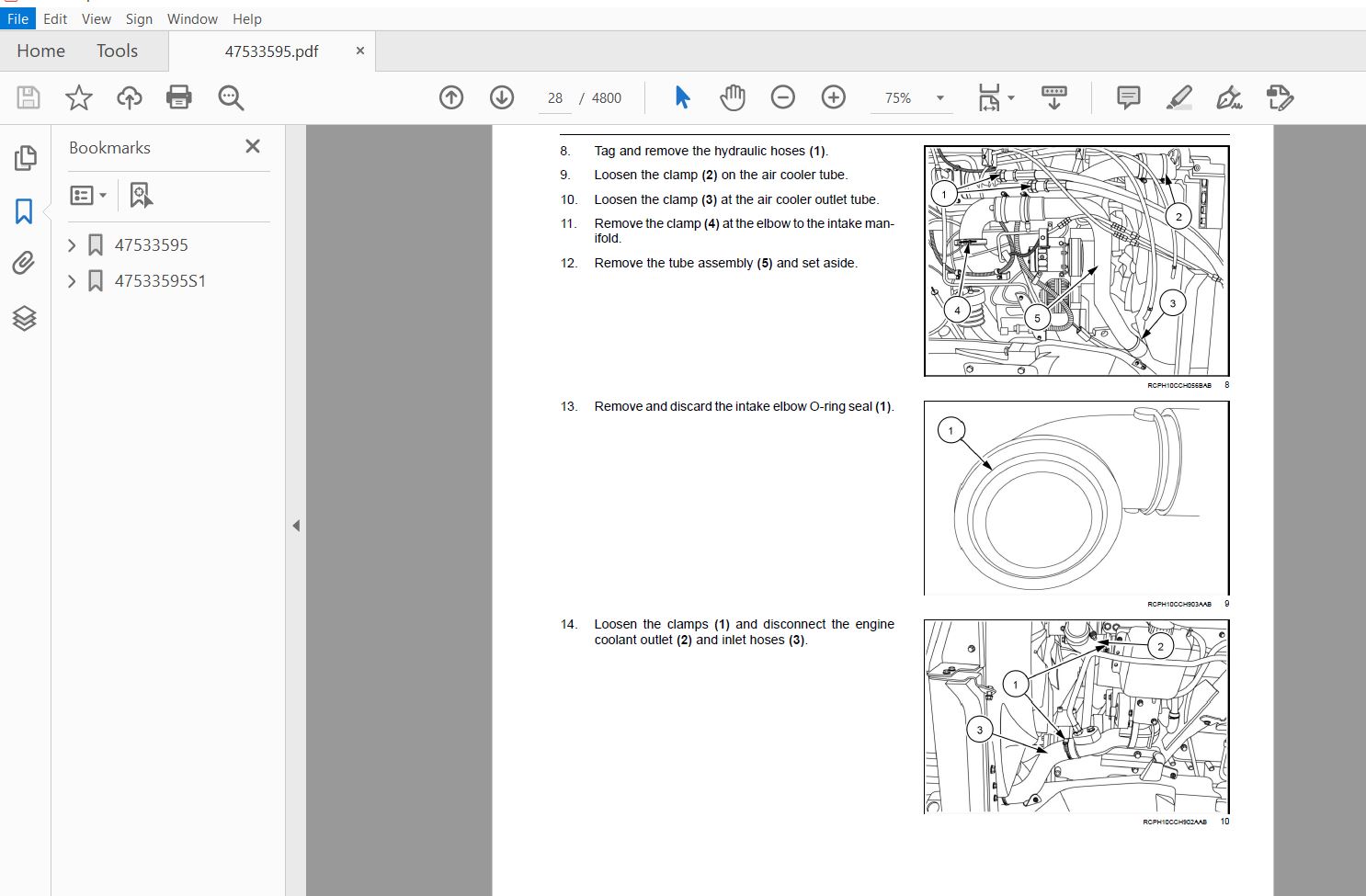

[10202] Air cleaners and lines 104

[10216] Fuel tanks 105

[10310] Aftercooler 106

[10400] Engine cooling system 107

[10414] Fan and drive 108

[10500] Selective Catalytic Reduction (SCR) exhaust treatment109

Power coupling 19

[19100] Drive shaft 191

Transmission 21

[21504] Continuously Variable Transmission (CVT) 211

[21505] Continuously Variable Transmission (CVT) external controls 212

[21507] Continuously Variable Transmission (CVT) internal components 213

[21506] Continuously Variable Transmission (CVT) lubrication system 214

Four-Wheel Drive (4WD) system 23

[23202] Electro-hydraulic control231

Front axle system 25

[25100] Powered front axle 251

[25102] Front bevel gear set and differential252

[25108] Final drive hub, steering knuckles, and shafts 253

[25122] Axle suspension control 254

Rear axle system 27

47533595 22/04/2013

[27100] Powered rear axle 271

[27106] Rear bevel gear set and differential 272

[27120] Planetary and final drives 273

Power Take-Off (PTO) 31

[31104] Rear electro-hydraulic control 311

[31110] One-speed rear Power Take-Off (PTO) 312

[31114] Two-speed rear Power Take-Off (PTO) 313

[31146] Front Power Take-Off (PTO)314

Brakes and controls 33

[33110] Parking brake or parking lock 331

[33202] Hydraulic service brakes332

[33220] Trailer brake hydraulic control 333

[33224] Trailer brake pneumatic control 334

Hydraulic systems 35

[35000] Hydraulic systems 351

[35102] Pump control valves352

[35106] Variable displacement pump353

[35114] Three-point hitch control valve 354

[35124] Three-point hitch hydraulic adjustment 355

[35204] Remote control valves 356

[35300] Reservoir, cooler, and filters357

[35304] Combination pump units358

Pneumatic system 36

[36100] Pneumatic system 361

Hitches, drawbars, and implement couplings 37

[37110] Rear three-point hitch 371

[37162] Front hitch 372

Steering 41

47533595 22/04/2013

[41101] Steering control 411

[41200] Hydraulic control components 412

[41206] Pump413

Cab climate control 50

[50100] Heating 501

[50200] Air conditioning 502

[50300] Cab pressurizing system503

Electrical systems 55

[55012] Engine cooling system 551

[55015] Engine control system 552

[55024] Transmission control system553

[55045] Front axle control system 554

[55046] Rear axle control system 555

[55050] Heating, Ventilation, and Air-Conditioning (HVAC) control system 556

[55051] Cab Heating, Ventilation, and Air-Conditioning (HVAC) controls 557

[55100] Harnesses and connectors 558

[55130] Rear three-point hitch electronic control system559

[55201] Engine starting system5510

[55301] Alternator 5511

[55302] Battery5512

[55404] External lighting 5513

[55405] External lighting switches and relays 5514

[55408] Warning indicators, alarms, and instruments 5515

[55512] Cab controls 5516

[55514] Cab lighting 5517

[55518] Wiper and washer system5518

[55640] Electronic modules5519

[55988] Selective Catalytic Reduction (SCR) electrical system 5520

[55DTC] FAULT CODES 5521

47533595 22/04/2013

Platform, cab, bodywork, and decals 90

[90100] Engine hood and panels901

[90102] Engine shields, hood latches, and trims902

[90118] Protections and footboards 903

[90124] Pneumatically-adjusted operator seat 904

[90150] Cab 905

[90151] Cab interior 906

[90160] Cab interior trim and panels907

IMAGES PREVIEW OF THE MANUAL: